Solution

Precision Laser Cutting Services

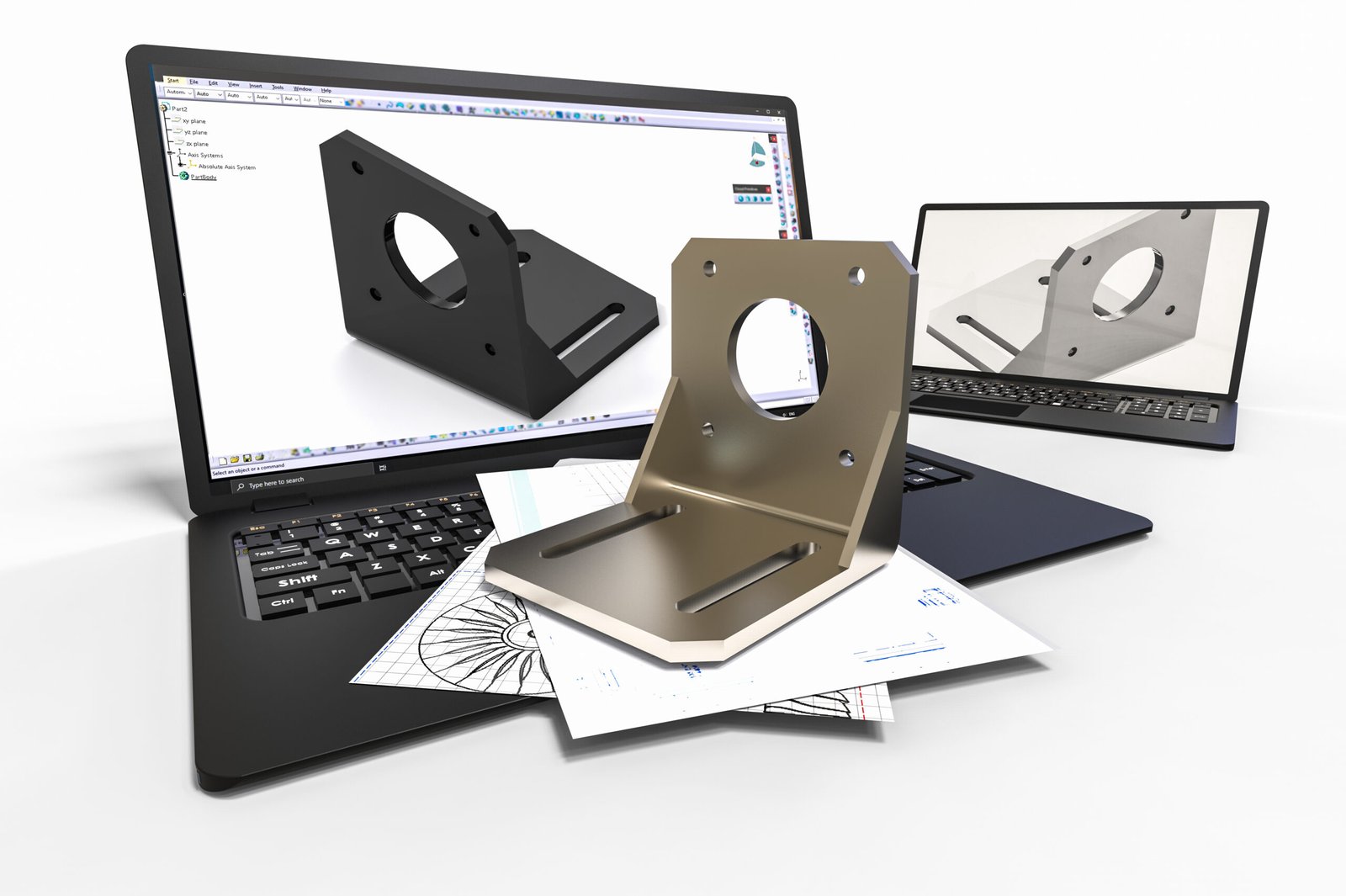

Masion – A leading company for precision laser cutting services. We are providing high-quality cutting services in China. Our facility is equipped with advanced machinery. Besides this, we have professional engineers and designers, who help you with sheet metal laser cutting services. Here we offer:

● Sheet metal laser cutting design and DFM support.

● Vertical integration for low cost and short delivery times.

● Both large and small orders with a minimum order quantity of 1 piece.

● Having ISO16949 Certifications

● Providing excellent quality assurance for your products.

+86-18969433502

sales@sheetmetalmasion.com

Masion - Your Most Trusted Partner for Laser Cutting Services in China

Masion provides you with high-quality laser-cutting services in China. We are using advanced technology and machinery to carry out our cutting operations. These cutting machines may include laser cutting machines, chamfering machines, tapping machines, and drilling machines. Besides this, we have skilled technicians to deal with these machines. Moreover, we have 24/7 online technical support. So, if you are looking for the best laser-cutting technologies in China. Connect with Masion. We will help you with both simpler and more complex designs. We also provide reliable custom solutions at competitive pricing. Our team of experts guarantees a fast production turnaround.

Providing you with the Best Quality Laser Cutting Solutions

Masion offers the production of a variety of complex laser-cut parts every day. Our customers put their trust in us and we constantly get a better experience of dealing with laser-cutting. We’ve years of experience in laser-cutting. So, we can manufacture various complex and unique laser-cutting products. We’re equipped with the most advanced technology. So, they can efficiently cut the the parts and assemblies. So, Masion can tackle different materials based on our customer’s needs. We complete your task within time and give you the most satisfactory results.

Materials

● Aluminum

(A1100P-O,A1050P,AL2024, A5052H32P,AL5083, AL6061T6 AL6063T5, AL7075, AL1050, AL1060)

● Carbon Steel

(SPCC, CRS, SAPH440, SPCD, SPCE)

● Stainless Steel

(SUS301, SUS302, SUS303, SUS304, SUS316, SUS420, SUS430)

● Cold galvanized steel

Q19, Q215, Q235, Q255, Q275

● Brass

C28000, C2740, C27000, C26800

● Copper

C1100, C1020, C1221

● Titanium

TC4, TA1, TA2

Thickness

Ranges between 0.5mm-20mm

● Stainless Steel: 0.5mm-12.0mm

● Steel: 0.5mm – 20.0mm

● Aluminum: 0.5mm – 8.0mm

Machines

● HSG 3000-watt Laser Cutting Machine

● HSG 6000-watt Laser Cutting Machine

● Yawei CNC Sheet Bending 110T 3+1axis

● Yawei CNC Sheet Bending 63T 3axis

● Sheet Metal Drilling & Threading CNC

● Chamfering Machine

Surface Finish

● Powder Coating

● Anodizing

● Electroplating

● Trivalent Zinc Plating

● Hot Dip Galvanizing

● Passivation

● •QPQ – Quench Polish Quench

● Dacromet coating

● Sandblasting

● Polishing

● Silk Screening

● Phosphating

● Baking Paint

● Heat Treatment

● Electrophoresis

● PVD coating

Why choose us for your custom precision laser-cutting parts?

We have years of experience in sheet metal laser cutting. We provide high-quality, precision laser-cutting parts. Besides this, we collaborate with various clients. They mostly include Bull, AUX, Costco, and others. Clients choose us for our high-precision laser-cut parts. They put their trust in us for their customized and on-demand solutions for them. So, we understand our clients’ needs. Then address their main points with precise and personalized services. Additionally, we have experience in dealing with multiple industries. It makes us capable of producing laser-cut parts that meet the highest quality standards.

● Masion undergoes a strict control process. We deal with the initial design stage of FMEA through multiple APQP product validations. Besides this, we assure the final PPAP approval.

● We have vertical integration. So, we quickly complete all the orders for laser-cut parts in a short time. So, it reduces our delivery time as well.

● We are equipped with advanced laser-cutting equipment. These all consist of a 1.5m x 2.5m working table. So, they all can meet your needs for different materials. Besides this, our technology is suitable for various material thicknesses. Additionally, we can provide efficient production services within the range of 0.5mm to 20mm thickness,

● We also offer one-stop services. These usually include deburring, tapping, riveting, welding, chamfering, and surface treatment. So, we are saving you from any worries.

Rapid Quotation and DFM (Design for Manufacturing) Capabilities

Masion is here to provide you with 24/7 technical support and quotation services. We are not afraid of the complexity of the parts. So, no matter how complex your laser-cutting parts project is. We will deal with it efficiently. Besides this, we will provide a quotation and arrange sample confirmation. So, it will ultimately save you time on your project.

● We’re here with 24/7 technical support and quotation services

● We concise the communication times, and increase the effective progression of projects.

● We’ve professional designers and engineers to analyze the laser cutting drawings. They provide expert advice.

● You can get efficient, accurate, and reliable management of laser-cutting parts via an ERP system.

● We’ve in-house production. it integrates all laser-cutting processes to reduce the delivery times

● We use error prevention management. It helps us reduce the potential issues in advance.

Top Quality Laser-Cutting for Sheet Metal Manufacturing

Masion uses modern laser-cutting equipment for different sheet metal cutting. We’re capable of handling various materials. They may include aluminum, stainless steel, copper, titanium alloy, etc. Additionally, we can cut a variety of complex shapes from various square tubes as well.

1. Laser sheet-cutting machines

We’ve 4 units. They’re 3000 watts and 6000 watts each for one. They are capable of processing sizes up to 1250 mm*2500 mm. Their parts thickness ranges from 0.6mm to 20mm.

2. Laser tube-cutting machines

Masion has 5 units with about 3000 watts. Each is capable of processing;

● Square tubes from 20mm*20mm to 100mm*100mm

● Round tubes with diameters from 20mm to 100mm,

● Wall thicknesses from 0.8mm to 5.0mm

3. Fully automatic tube-cutting machines

We’ve its 4 units. They all are capable of processing;

● Square tubes from 20mm20mm to 100mm100mm

● Round tubes with diameters from 20mm to 100mm.

4. Angle tube cutting machines:

Masion has its 2 units. They both are capable of cutting various angles according to product requirements.

Dimensional tolerance: We usually provide ±0.1mm dimensional tolerance. The higher precision requirements can reach around ±0.01mm.

Straightness tolerance:

The straightness tolerance within the same cutting section is generally within 0.2mm. It can be within 0.05mm at higher requirements.

Perpendicularity tolerance: Our perpendicularity requirement reaches within ±0.05mm- 0.01mm for vertical cuts.

Tolerance between parts: The tolerance between parts is commonly lies between 0.1~0.5mm. Its variation depends on manufacturing requirements and processing forms.

Surface smoothness tolerance: It generally reaches a high Ra, i.e. around 0.1μm.

Certificate of Laser-Cutting Service

● ISO9001 Quality Management System

● ISO14001 Environment Management System Certification.

● TS16949 Automotive Industry Quality Management System

● FSC Forest Stewardship Council

● Patent: 47 patents of invention

● CE CONFORMITE EUROPEENNE(As you need we could apply)

● •RoHs Restriction of Hazardous Substances(As you need we could apply)

Explore our Laser Cutting Parts Gallery

Serving Multiple Industries with Laser-Cutting Services

Laser-cutting has a wide scope of applications in many industries. They are especially used in high-end sectors like automotive, aerospace, military, and maritime industries. Besides this, they are also used in local sectors, which we see in our daily lives They may include. telecommunications, robotics, fitness equipment, construction industries, equipment, and consumer goods, etc. So, here are some commonly used laser-cut parts in these industries.

● Steel plates and sheet metal

● Decorative metal panels

● Railings and handrails

● Metal partitions

● Door and window frames

● Stair treads

● Ceilings and suspended ceilings

● Steel beams and columns

Construction Industry

● Metal screens or partitions

● Wall decorations, sculptures, or hangings

● Metal tables, chairs, bookshelves, etc.

● Metal lampshades, lamp bases, or chandeliers

● Wall Decor

● Metal mirror frames

● Vases or flower containers

● Metal cutlery or kitchen accessories

● Metal decorative wall panels

Home Decoration Industry

● Electronic enclosures and panels

● Metal heat sinks and radiators

● Connectors and sockets

● Metal supports for electronic components

● Printed Circuit Boards (PCBs)

● Metal antennas and frequency devices

● Metal supports and support structures for electronic devices

● Battery fixtures and brackets

Electronics Industry

- Tillage tools and plowshares

- Seedboxes, seed dispensers

- Blades for harvesters

- Connectors and brackets, irrigation system pipes

- Frames, engine covers, and seat supports

- Body structures, chassis components

- Feed boxes, drinkers

Lawnmower blades, trimming tools

Agricultural Industry

Other Sheet Metal Solutions

Sheet Metal Processing

Pipe Processing

Laser Cutting

Masion uses various techniques to shape and convert metal sheets into desired forms. It has a wide scope of applications in industries, i.e. automotive and construction.

It includes the fabrication of pipes using different techniques. These techniques may include cutting, bending, and welding. These all ways help us meet specific dimensional and structural requirements across industries.

Laser Cutting: This technique is used in high-powered lasers. It helps us precisely cut through materials such as metal, plastic, and wood. So, this method easily deals with complex designs and efficient production in industries.

Plastic Injection

Mold Processing

Stamping

Masion uses molten material and then injects them into a mold cavity. This technique is used to produce complex and precise parts in high volumes. It has wide applications in industries like automotive, consumer goods, and medical devices.

It includes the fabrication of molds. These molds are generally used in manufacturing processes, i.e. injection molding, casting, and thermoforming. Moreover, we use this process for batch production of the same designs.

We use different dies and presses to shape the metal sheet in the desired geometry. This process has a wide scope of applications in different industries. These mainly include automotive, electronics, and appliance manufacturing.

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

Frequently Asked Question

Q: Do you have ISO9001 certification?

A: We are an ISO9001-certified factory, and we undergo an ISO9001 certification audit annually. If you need a certificate, please contact us.

Q: What materials can your laser cutting process handle?

Our laser cutting machines can process materials like aluminum alloy, stainless steel, carbon steel, galvanized sheet, copper, etc. If you have special materials, please communicate with us and we will assist you in completing the task. Please contact us.

Q: What is the precision of your laser cutting?

Our laser cutting precision is generally around ±0.1mm (±0.004 inches). If you require higher precision, we can perform secondary processing, such as using surface grinding or CNC machining to ensure higher precision.

Q: How thick can your laser cutting machines cut sheet or tube material?

Our laser cutting machines can cut sheet material with thicknesses from 0 to 20mm. If you need thicker material cut, you can contact us, and we have other methods to cut thick plates, such as plasma cutting, flame cutting, etc. Our laser tube-cutting machines can cut tube materials up to 8mm thick and can cut various shapes and angles. If you need this, please contact us.

Q: Besides laser cutting services, do you offer other processing services?

Certainly, in addition to laser cutting, we also offer bending, stamping, welding, riveting, assembly, surface treatment, CNC machining, and stamping die manufacturing among other processing services. There is always a service that suits you.

Q: Can your laser-cut parts undergo surface treatment?

Yes, we conduct internal polishing, silk-screening, plastic spraying, and other surface treatments. We have cooperative surface treatment factories.

for other treatments such as oxidation, electroplating, and sandblasting.

Q: I cannot design; do you provide design services for precision laser cutting?

Our company has professional designers and engineers who can assist you in completing the design of precision laser cut parts, perfecting design dimensions, improving process efficiency, reducing processing costs, and shortening lead times.

Q: For precision laser cut parts, do you provide raw material procurement services, or do clients need to supply their materials?

Generally, we supply materials for precision laser cut parts, such as aluminum, stainless steel, zinc alloy plates, etc., and we have a stock of standard-thickness materials to save on raw material procurement time. Our materials come with material certification reports, and we test each batch to ensure they meet the mechanical properties, chemical composition, weldability, dimensional stability, corrosion resistance, and thermal performance required for precision laser cutting parts. If you prefer to supply your materials, as long as they meet our quality requirements, you can send them to us.

Q: Can you cut brass, copper, titanium alloys, and other materials for precision laser cutting parts?

Generally, our laser cutting machines can only cut stainless steel, aluminum alloy, zinc alloy plates, etc. If you need to cut precision materials like brass, copper, and titanium alloys, a specific laser cutting machine (fiber laser cutter) is needed, and we can also help you cut these materials. You can send us your drawings. Contact us.

Q: How do you ensure the precision and quality control of laser-cut parts?

A: We ensure it by following the below strategy;

- Incoming Quality Control: We ensure that each batch of materials is monitored and tested to match the batch number, model, and material performance to the design requirements, and each batch of materials has a traceability code to monitor the use of each batch without mixing.

- Production Design Optimization: By optimizing design, we ensure smooth production processes and avoid using complex processes that could reduce product precision.

- First Article Inspection: Before proceeding with the production of the entire batch of cut parts, we first perform cutting and inspection of the first article to ensure all dimensions meet the design requirements.

- Production Process Inspection: During the production process, we inspect the laser-cut parts, and our quality inspectors regularly perform inspections to ensure there are no dimensional issues or errors in the manufacturing process.

- CMM Inspection: We conduct CMM inspections of some critical dimensions of laser-cut parts to ensure that the product dimensions meet quality standards.

- Advanced Equipment: We use advanced laser cutting equipment to ensure the laser cutting performance meets the quality required by the design.

- Training Operators: Our laser cutting operators have years of rich operating experience and problem-solving skills, and we regularly train them in quality and equipment operation to ensure they can operate the equipment more proficiently and check the quality of cut parts.

- Eliminating Factors Affecting Laser Cutting Quality: We eliminate factors that affect laser cutting quality, such as focal position, beam, cutting speed, laser power, and assist gas, to ensure these factors do not affect the quality of laser cutting.

Q: How do you laser-cut auto parts or medical products?

We are certified under the ISO16949 quality control system. So, we can cut the auto parts and medical components with laser cutting. So, if you need ISO13485 quality management certification, you can also discuss this with us.

Q: Can your laser-cutting machines cut plastic?

Absolutely yes, our laser tube cutting machines generally cut metal parts. So, if you have plastic material to cut. You can simply reach out to us. We will help you solve this problem.

Q: Does your laser cutting service cover multiple industries, and do you have successful case studies in related industries to share?

Our laser cutting covers multiple industries, such as the consumer goods industry, telecommunications industry, new energy industry, agriculture, industry, etc., and our clients include Geely Automobile, Ideal Automobile, Tesla, Bull, CRRC, etc. If you are interested in our services, please contact us.

Q: In the laser cutting parts production process, do you conduct comprehensive quality testing to ensure that each product meets specifications and standards?

A: Yes, we do conduct comprehensive quality testing. It may include

- Raw Material Inspection: We test raw materials to ensure batch numbers, material grades, and dimensions are accurate, and we label materials with traceability codes to prevent mixing and trace back to the supplier in case of issues. For aluminum alloy laser cutting, we generally purchase mirror-finished aluminum plates with protective film, even after laser cutting, to ensure the product’s surface is not scratched.

- Eliminating Factors in the Cutting Process: During the laser cutting production process, we monitor the accuracy of equipment adjustments and operations to ensure every parameter (laser power, focus, laser speed, laser beam, assist gas) is correct.

- Dimension and Shape Inspection: Before cutting, we inspect the first sample to ensure dimensions and shapes meet the design requirements of the drawings. After cutting, we use calipers, micrometers, CMM, or gauges to check dimensions to ensure dimensional accuracy meets design requirements.

- Appearance and Surface Quality Inspection: For laser-cut parts that do not require surface treatment, we check the surface appearance and edges for scratches or burns. For laser-cut parts that require surface treatment, we check whether the thickness of the surface film meets the requirements.

- Functional Testing: For some auto laser-cut parts that require functional testing, we conduct tests such as tensile tests, salt spray tests, hardness tests, fatigue tests, durability tests, assembly tests, etc.

- Final Inspection and Review: Before packing laser-cut parts, we conduct a final inspection to ensure that every product meets quality requirements.

- Records and Feedback: We keep inspection records and reports for each inspection phase, and we retain these for future reference and to improve the next production process and quality.

Q: What quality standards do you have for your laser-cut parts?

For ordinary laser-cut parts, we generally use the ISO9001-2015 quality control standard. For auto parts, we use the ISO16949 quality control system. For medical products, we can also apply for the ISO13485 quality control standard if you need it. Please contact us.

Q: What is the MOQ for your laser-cut parts?

For initial designs, we can quickly produce samples for you to test in the market, so our MOQ is generally 1 piece, mainly to facilitate you to quickly market your product and rapidly capture market feedback.

If you need any specific part to cut or have any more questions, feel free to ask!