Over 400+ Employees

7+ Million Production Capacity

30,000 m3 Total Factory

+86-18969433502

sales@sheetmetalmasion.com

Masion is located in the city of Ningbo, Zhejiang Province, China. Our facility is situated just near to the Shanghai port. This smart location near the port benefits us to grow in Ningbo and stride forward in the sheet metal industry. Masion was established in 2007 and it covers an area of around 30,000 square meters. Our factory has 6 big production facilities and almost 400 employees are working on it. Masion is an expert in dealing with the original design of sheet metal products. Besides this, we cater to research and development, manufacturing, and sales services for sheet metals. We are ISO9001-2015, ISO16949, ISO4001, and FSC certified and have 47 research patents.

We have 17+ years of experience in sheet metal manufacturing. Over the years, our experts have been providing professional R&D technical design support. To this date, Masion has completed the successful delivery of over 7 million products. We have earned the trust of reputable brands all over the world. These main include Geely Auto, Tesla, LiXiang Auto, Bull, etc.

If we talk about our services. Masion is committed to producing customized sheets. Besides this, we produce Metal Enclosures, Cabinets, Mounting Brackets, Metal Nameplates, Energy Storage Enclosures, and Gun Safes. Additionally, we are experts in making Control Cabinets, Computer Cabinets, Communication Cabinets, Defibrillator Cabinets, Aid Cabinets, X-Ray Cabinets, and more. So, Masion is the one-stop sheet metal manufacturer in Ningbo, China. We provide premier sheet metal manufacturing services, i.e.DFM, rapid sheet metal manufacturing, laser cutting, and sheet metal bending, Besides this, we also provide highly accurate and precise stamping services, high-speed stamping, riveting, welding, surface treatment, assembly, plastic injection, and stamping die manufacturing services.

What We Do For You?

Masion’s sales team is an expert in communicating and swiftly handling sheet manufacturing projects. We effectively collaborate with our sheet metal manufacturing department and guarantee rapid production. We believe in providing high-quality sheet metal parts within the allocated time.

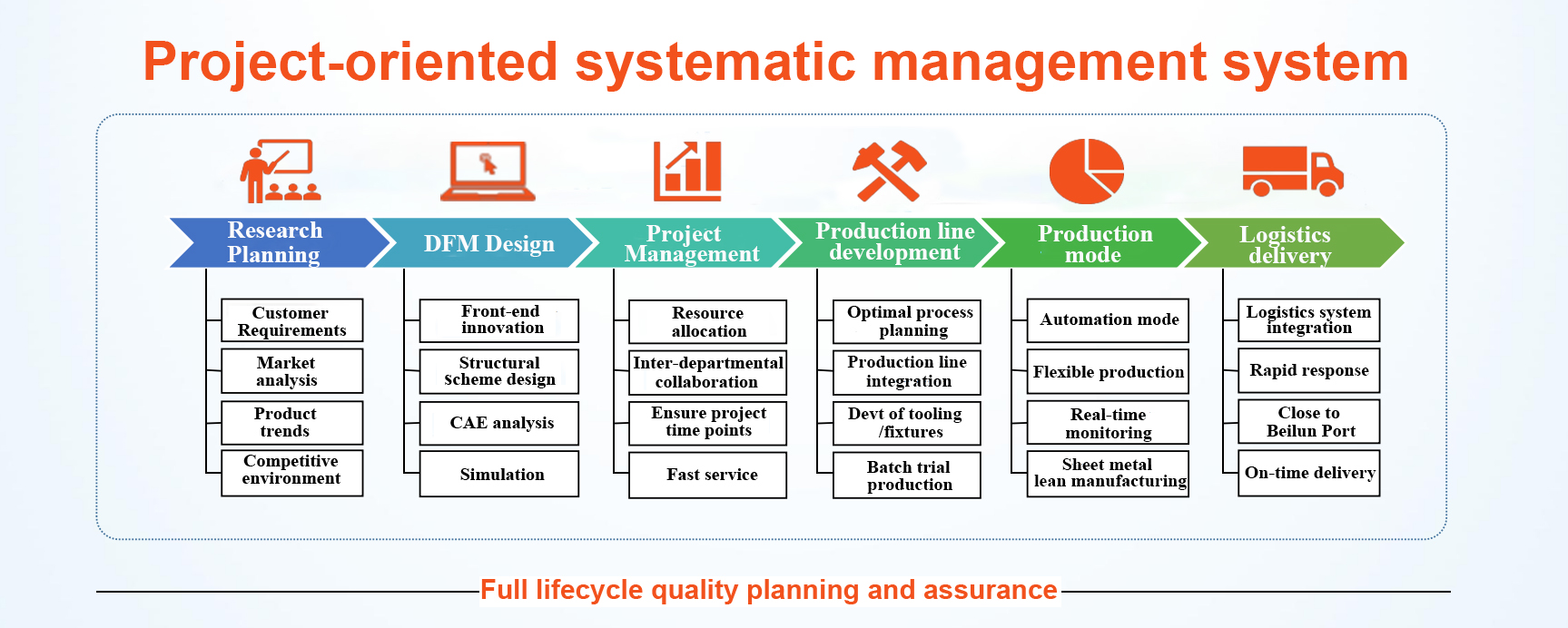

We use a strong ERP production management system that gives high-precision vertical production of sheet metal parts. Our team of experts uses both internal production capabilities and external supplier resources. So, they can carry out various sheet metal techniques in no time. Besides this, we give Design for Manufacturing (DFM) services during the production period. Our team collaborates with the client to get the detailed requirements and then manufacture the product. Besides this, our engineers and technicians optimize the production process for sheet metal parts. So, they can increase the benefits and reduce the production cost.

Masion is capable of frequently producing samples of sheet metal parts. So, our clients can promptly receive samples during the initial stage. It helps them in market validation, saving time, and also securing market shares.

Along with our premier services, we strictly believe in the continuous learning of our staff. So, we conduct technical training for sheet metal part assemblies. Besides this, our trainings also cover installation guidance for assembly sheet metal products.

Our Vision

To create market value for you with our meticulously crafted sheet metal parts.

Our Work

Masion believes in continuous research and innovations in opting for new processes for production. We aim to provide effective and high-quality sheet metal products to our clients. Keeping this aim in mind, we have invested in making 6 production facilities. These all are equipped with robotic process equipment.

Besides this, we all can serve customers in several industries. These industries are generally automotive, consumer goods, medical equipment, telecommunications, and power generation industry. Moreover, we give comprehensive sheet metal processing solutions to meet your requirements.

Masion is committed to quality and professional communication. Besides this, we strictly believe in opting time-saving process and delivering the project timely. We’re here to serve you with;

- Technical support & Professional sheet metal sales services with 24H/7 availability.

- Design for Manufacturability Services (DFM).

- Choose suitable sheet metal materials.

- Guarantee research & development of new processes and products.

- Aim to give the most cost-effective services at low prices.

- Advanced and fully-equipped sheet metal processing manufacturing solutions.

- Provides PPAP (Production Part Approval Process) reports, i.e. sheet metal production control plans, sample production approvals, and production scheduling.

- Provide After-sales sheet metal assembly training.

- Have internal manufacturing capabilities to increase the production of sheet metal projects.

So, all of our services give high-quality steel metal parts. They guarantee high accuracy and precision with smooth communication with our sales team.

Our Goals

Our goal is to give you OEM custom sheet metal services. We provide a comprehensive solution to your manufacturing needs. It includes initial design, sample confirmation, and batch production. These services guarantee timely and quality delivery of large orders.

To fulfill these goals, we invest in new equipment and also develop new processes. Besides this, continuously strive to search for innovative solutions to make your sheet metal parts. So, we’re here to serve you with all sheet metal manufacturing services. There are mainly stamping die design and manufacturing and complete sheet metal assembly. Additionally, I may also include surface treatment and refined finishing.

Our Culture

Learning Culture

Enhancing Innovation through Learning Power We place great emphasis on the coordinated development of our company and employees. We organize multiple specialized training sessions for employees on sheet metal making skills and management capabilities each year, fostering systematic thinking skills. We encourage and support employees in their personal learning and self-improvement endeavors. The exisiting libraries and training rooms offer excellent learning opportunities. We invite professional instructors to teach, helping employees broaden their horizons, enhance their comprehensive abilities, and strengthen both the company’s and employees’ competitiveness.

Speed Culture

In 2021, we entered into a strategic digitalization partnership with Dingjie, implementing their ERP Intelligent Management System to revolutionize our enterprise management and sheet metal production processes. By leveraging advanced digital tools, we aim to optimize operations, reduce costs, enhance efficiency, and improve product quality. This collaboration enables us to fully harness knowledge and intelligent efficiency, resulting in comprehensive sheet metal quality management. Our efforts focus on shortening production cycles, minimizing waste, and ensuring superior output, ultimately positioning our company as a leader in innovation and excellence within the industry.

Gratitude Culture

We cultivate an environment of mutual understanding and collaborative success among employees, encouraging robust support for each other’s work and expressing gratitude for colleagues’ contributions. We are committed to continuously enhancing our welfare and reward systems, ensuring that all employees benefit from the company’s growth and success. Beyond the workplace, we embrace our social responsibilities, actively contributing to societal well-being through various charitable endeavors and public welfare initiatives. Our enthusiastic participation in these activities underscores our dedication to giving back to the community and making a positive impact on society.

Our Management Idea

Fast

Fast Processing, Fast Response, Fast Decision-making, Fast Implementation

United

Wholehearted Dedication, United in desire, Working Together with all one’s strength, Unified Solidarity.

Meticulous

Meticulous craftsmanship, in-depth and detailed, perseverance, co-create value.

Efficient

Dare to strive, maintain focus, act with swift decisiveness, achieve outstanding results.

Innovative

Pioneering innovation, keeping pace with the times, changing mindset, and relentless striving

Department Morning Meetings, Evening Meetings, and Weekly all-staff Meetings:

- Each department holds morning and evening meetings to summarize the day’s work.

- Every Tuesday, all members attend the morning meeting together.

Our System Management

Ding Jie Sales Management System

Ding Jie Inventory Management System

Ding Jie MRP System

Cost Management System

PLM System

Procurement Management System

Dingjie Intelligent Logistics System

OA Office System

Our Solution

Sheet Metal Processing

Metal Tube Fabrication

Laser Cutting

We offer small, medium, and large batch custom sheet metal fabrication services.

We provide metal pipe material processing services for both small and large batches.

Custom precision laser cutting services.

Plastic Injection

Stamping

Sheet Metal Assembly

Injection molding services for various plastic parts.

Conventional stamping and progressive die stamping solutions.

Metal pipe and sheet metal assembly solutions.

Our Products Gallery

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

RFQ

We are a leading professional manufacturer of sheet metal products, so we attach great importance to the quality of sheet metal parts. We are certified with ISO9001-2015, ISO16949, ISO14001, FSC, and other certifications. You can rest assured to entrust your sheet metal projects to us.

Our sheet metal products generally do not require UL, CE, or RoHS certification from customers. However, we can obtain quality certifications such as SGS and TUV. We can negotiate to obtain these certifications if you require UL, CE, or RoHS certification.

We have many cooperative customers, whether they are large projects or small projects, customer trust has enabled us to continue to grow. We have cooperated with well-known brands such as Geely Automobile, Tesla, Aux Group, Bull, LiXiang Automotive, CRRC, and others. You can trust our strength in sheet metal manufacturing, manufacturing processes, and the quality of sheet metal parts.

Generally, the cost of sheet metal samples is determined based on the production time, processes, and complexity of the sheet metal parts. For new customers and projects, we will assess the sample fee based on the size of the project and may charge a nominal fee. If the project is successful and you place an order, we will determine the sample fee based on the size of the order. For existing customers developing new projects, we typically do not charge for samples.

If you only need progressive dies, we can discuss whether it is advantageous for us to produce them, such as offering higher cost-effectiveness and shorter production times. We are a highly specialized sheet metal stamping manufacturer, and professional matters should be handled by professionals. If we agree on terms but you are still unsatisfied, and you only require separate progressive dies, we can assist you with designing and manufacturing them. Simply provide us with the sheet metal stamping drawings, and we will address your needs.

In addition to custom processing sheet metal parts, we also manufacture high-speed stamped products, automotive stamped products, stamping dies,Plastic injection parts, and provide assembly services for other products. We can discuss the development and manufacturing of new projects together. Please contact us for more information on your products.

Our clients do not require ISO13485 certification for the medical sheet metal parts . Therefore, we can produce medical sheet metal products without ISO13485, So we have not applied for ISO13485 certification at the moment. If your project indeed requires ISO13485 certification, we can discuss obtaining it.Our quality system is comprehensive, so we can easily apply for ISO 13485 certification.