Over 400+ Employees

7+ Million Production Capacity

30,000 m3 Total Factory

+86-18969433502

sales@sheetmetalmasion.com

Masion – Your One-Stop Vertical Integration In-house sheet metal fabricator in China

Masion provides vertical in-house integration sheet metal fabrication production in Ningbo, China. All the processes are in-house. These processes include in our facilities are square tube cutting, sheet metal laser cutting, high-speed stamping, NCT CNC punching, sheet metal bending, metal tubes and pipe bending, robotic welding, riveting, plastic injection, assembly, powder coating, silk screening, polishing, and more. Hence, we cater to every process with care and expertise. Moreover, we produce metal cabinets, automatic lifting tables, automotive sheet metal parts, metal tubes, pipes, and plastic integration parts. We strictly follow ISO16949 production standards. Masion has a team of 15 R&D engineers, 20 professional mold engineers, and 7 manufacturing engineers. These engineers are masters of their domains and give high-quality products using efficient and advanced production processes.

We’re not stopping having well-experienced employees. We are also using advanced equipment for steel metal manufacturing. These include NCT turret punching machines (AMADA), YASKAWA / FANUC / PANASONIC welding robots, HSG Laser Cutting, Haitian plastic injection machines, along with professional testing equipment i.e. Hexagon GLOBAL SILVER CMM.

Aligned Supply Chain Control

Unmatched Transparency

Optimized Cost Control

Faster Delivery Rates

What We Offer

Masion provides a range of sheet metal processes. These include sheet metal manufacturing, metal pipe processing, and plastic component assembly. We use advanced methods to give customized services for any complex project.

Masion uses advanced techniques to increase efficiency and material loading. We are employing Robotic Arms, and automatic welding to reduce the costs and improve the overall precision of sheet metal components.

We are expert manufacturers of square, irregular shapes, or round tubes. Our facility is equipped with laser cutting technology and efficient bending machines,which provide accurately manufactured metal pipes based on the customer’s requirement.

We provide laser-cutting services to a wide range of materials, i.e. metal sheets or pipes. This technology helps us cut materials like Aluminium, copper, carbon steel, stainless steel, brass, and titanium alloys to suit to your any need.

If you need proper sheet metal drawings or minor design adjustments, we’re here to cater to your needs. We improve overall production efficiency along with the short delivery times at lower cost.

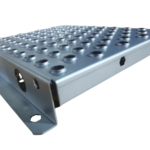

We are using advanced robotic feeding and punching technologies. Moreover, we have NCT Turret punching machines (AMADA). These help us in sheet metal blanking and punching.

We offer plastic injection services for producing components in sheet metal manufacturing assembly. It helps us to save time and costs for delivery. We also provide insert molding and over-molding

We have a team of 20 technicians to help us produce the most precise and accurate stamping molds. They are specialized in designing and manufacturing progressive dies, single dies, and compound dies.

Our facility has around 6 professional assembly production lines. These lines can assemble products including pipes, plastic components, and sheet metal parts.

We provide a variety of progressive die stamping parts processing services, with advanced presses and self-designed and manufactured Progressive Die.

We’re an Excellent Contract Manufacturer of Customized Sheet Metal Components

Masion is an exceptionally outstanding professional manufacturer of sheet metal components. We use specialized equipment for sheet metal fabrication. Additionally, we’ve extensive experience in serving major sheet metal projects. Our team is a blend of mature engineers with years of sheet metal processing expertise and technician staff. We specialize in various advanced sheet metal processing techniques such as laser cutting and sheet metal bending. We have served over 4000 clients, providing a wide range of complex sheet metal components. So, if you’re looking for a sheet metal processing factory, we’re here. We can assist you with design concepts to produce real products. We assure you receive the best possible service at every step.

Count On Us For Your All Kind Of Needs

Our products provide a convenient and smooth experience for learning and office use. They’re designed using principles, sheet metal tubing, wood board processing, 47 patents, and automatic height adjustments.

We are providing different types of kiosk exclusions. These may include wall-mounted, freestanding, desktop models and customization options for different shapes. So you can meet the diverse needs. You can get any type you want.

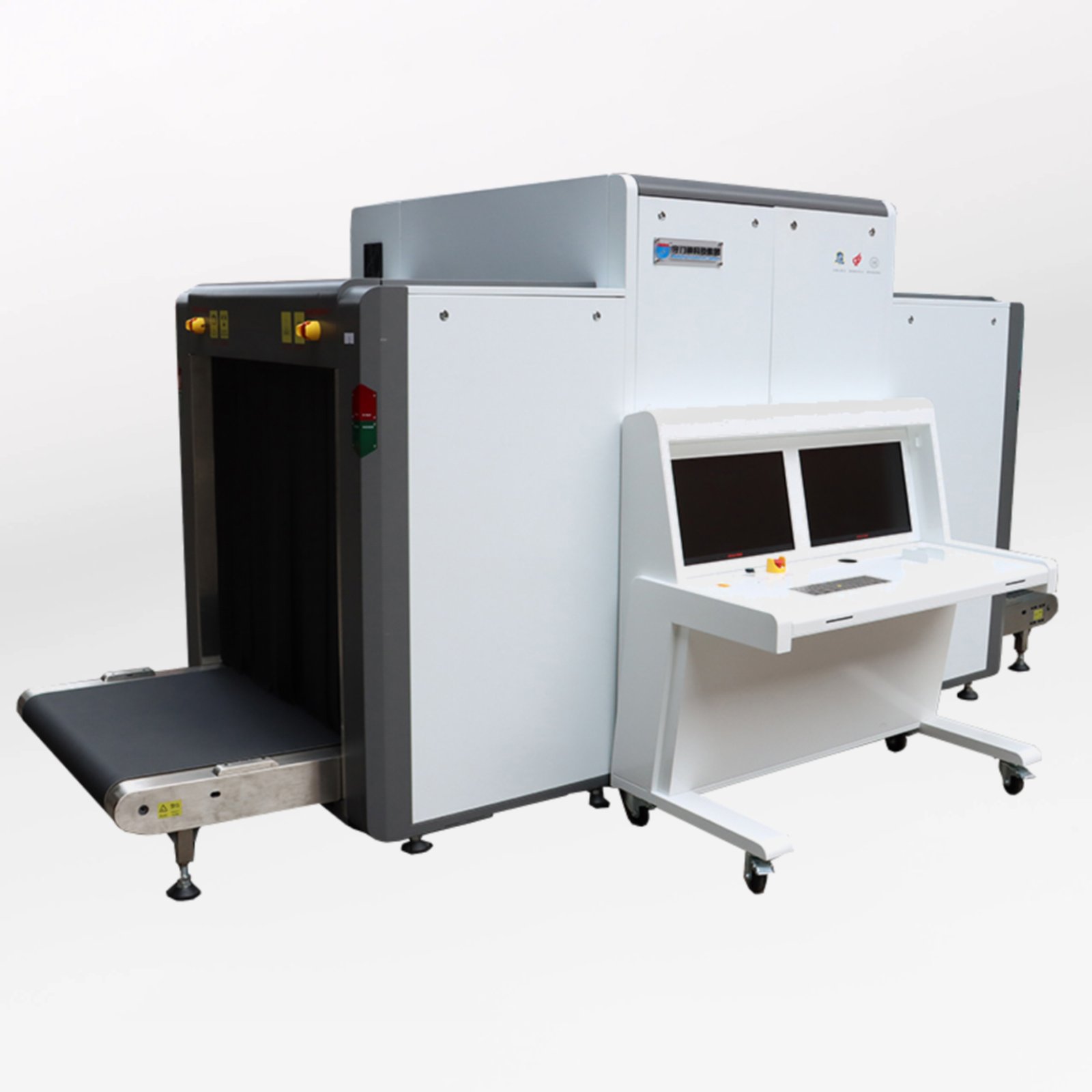

X-ray Cabinets & Enclosure

We make customized exchange enclosures with different shapes and sizes. They may feature internal powder coating, robust corrosion resistance, and rust-proof exteriors. Moreover, they could be used in train stations, airports, bus terminals, and more.

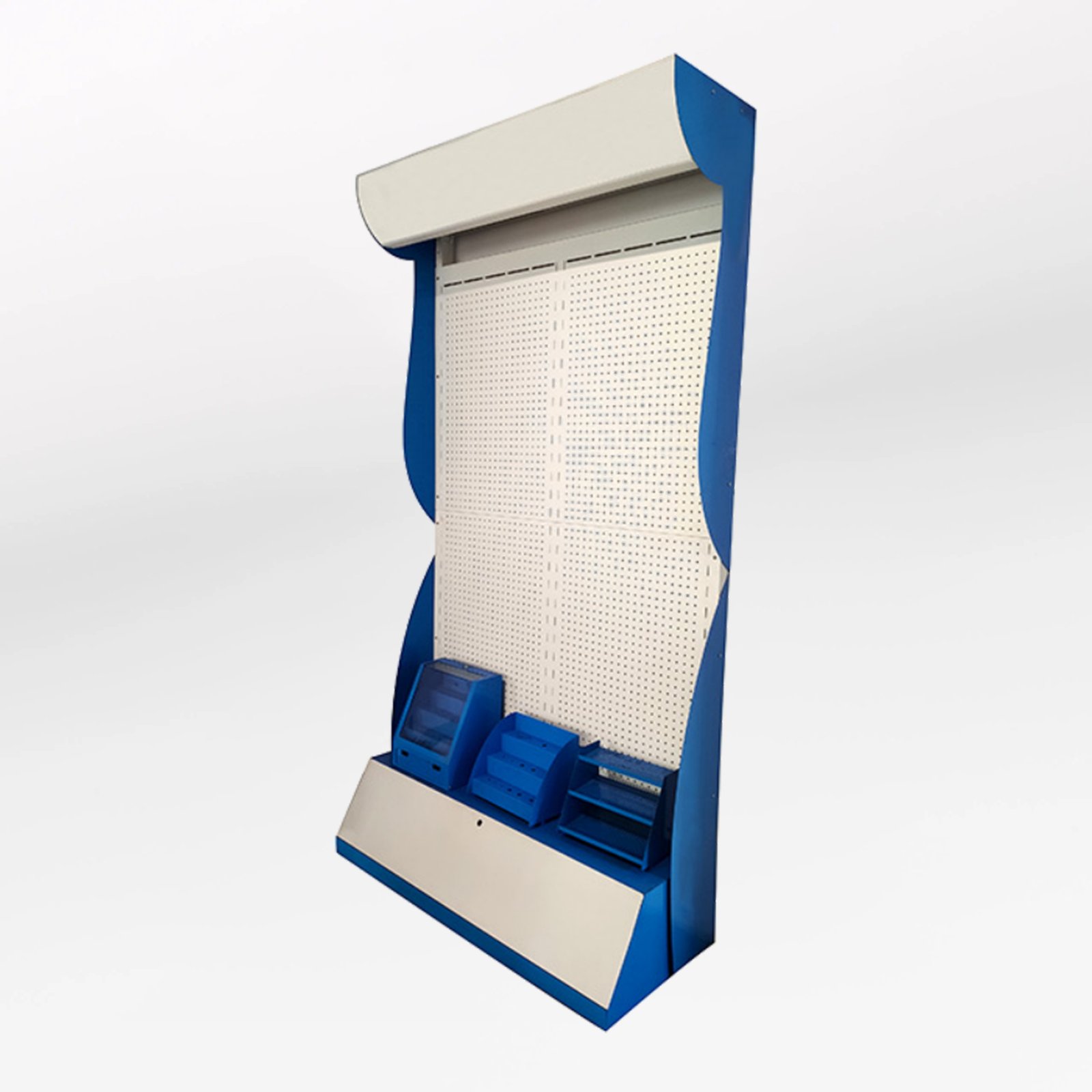

Electrical Panel Enclosure

We are providing a customized electrical panel enclosure. These panels are available in different shapes. They feature an IP68 waterproof rating, corrosion resistance, and rust-proof properties. So, it makes them suitable for outdoor use. Thier feature loaded aspect make them highly desireable.

EV Charging Station

We are providing customization of various types of charging station enclosures. This may include integrated cabinets. They are available in 7KW, 14KW and 21KW models. They are integrated with the IP56 rating. So, they are suitable for charging in different environments.

We provide customized gun safes of different shapes. They are available in military greens, navy blue, and other colour options. Moreover, we integrate smart control management systems. So, they can manage firearms, ammunition and military gear.

Masion provides customized industrial computer cabinets. They come in various sizes with the powder coating. Moreover, they have multiple functions like dustproof, corrosion resistance, Explosion-proof, Shockproof waterproof, magnetic-resistant and anti-theft capabilities.

Computer Charging Cabinet

We’re experts in customized computer charging cabinets. They come in various shapes, sizes and colours. Our cabinets are designed to charge devices like tablets, and smartphones. So, it makes them suitable for use in schools, hospitals, libraries and other settings.

Computer Case

We provide customized computer cases of various shapes. So, they can meet the demands of enthusiasts. They have a cool appearance, lightweight aluminium, and various colour anodizing options. Apart from this these cases withstand rough and tough usage.

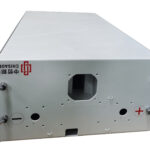

Energy Storage Cabinet

We are providing energy storage cabinets. They come up with an IP68 waterproof rating. Moreover, they feature a highly corrosion-resistant surface treatment. `They also withstand over 1000 hours of Salt spray test. So, they are suitable for outdoors.

Power Cabinet

Masion provides customized types of power cabinet enclosures. They are sturdy casing and have better surface treatment. Moreover, they’ve multiple features like corrosion resistance, rust prevention and waterproofing.

Server Cabinet Enclosure

We are providing customized server cabinets. They come in various sizes and colours. Their surfaces are powder-coated and they feature silk-screened logos. So, it ensures that they are excellent corrosion resistant and have an attractive appearance.

We are providing customization of AED standing cabinets and AED wall cabinets. They are available in different sizes, shapes and appearances. Moreover, they are of high quality with excellent waterproof and corrosion-resistant performance.

We are providing customized first aid cabinets. They come in various metals and are available in different shapes, such as portable freestanding and wall-mounted. Moreover, they’re good for schools, hospitals, homes and other environments.

We are providing customized metal mailboxes and parcels. They’re available in different shapes and sizes with different capacities. Moreover, they are powder-coated surface treatments. It boosts an attractive appearance and suitable for outdoor.

Machine Enclosure

We’re experts in customized enclosures for various equipment. They may include CNC machines, refrigeration units, etc. These machines are powder-coated. Additionally, they are available in a variety of colours with high corrosion and rust resistance.

Fire Cabinet

We are providing customized fire cabinets. They also come in different shapes, materials and colours. These are more suitable for indoor and outdoor applications. Moreover, our products are highly aesthetics and surface treated.

Metal POP Display

Masion is also providing customized types of metal pop displays. They come in different styles. It may include, Mobile freestanding wall-mounted, tabletop designs, and more. They are powder-coated and corrosion-resistant.

Tool Cabinet

Our tool cabinets are customized. They can be available in different styles like wall-mounted, upright, and portable options. Moreover, they provide a storage solution for your tools. So, they are available in various vibrant colours. They have high-quality powder-coated surfaces. So, our Cabinets are designed for long-term use without rusting.

Medical Enclosure

We are also providing customized high-quality medical equipment enclosures. They assist the clients in the design and development of corrosion-resistant surface treatments. Moreover, they are available in a range of colour coatings. So, we make sure you receive top-quality medical equipment enclosures.

Metal Storage Cabinets

We are providing customized types of metal storage cabinets. They may include filing cabinets, lockers, safety cabinets, archive cabinets, key cabinets, etc. Moreover, we also provide customized solutions in various colours and shapes. They are complete with all the necessary accessories. So, you just need to receive the finished product and use it directly.

We’re Leading the way in Sheet Metal Fabrication in China Please share your idea with us.

Why Choose Us?

Advanced Robot Technology

We are using robotic welding and automotive feeding. These technologies are used to increase the efficiency of sheet metal processing. Moreover, it improves the precision of sheet metal components. It concurrently reduces production costs.

24/7 Technical Support

Masion’s team guarantees prompt responses to all your demands. Our professional technical support team assists you 24/7 with any inquiry or challenges you may encounter with your sheet metal project.

Vertical Integration Production

We are using vertical integration to manage our production processes. It ensures that all sheet metal manufacturing processes are carried out internally. So, this reduces transfer time between production stages. It shortens production cycles. Moreover, it minimizes the risk of product damage during transfer processes.

DFM Design Service

We provide designs for manufacturing to assist you in sheet metal production. Moreover, we facilitate your production processes. It reduces your production time and lowers the manufacturing cost.

ISO9001 and ISO16949 Certified Factory

We strictly follow quality management systems. So, we can control the quality of sheet metal components. It helps us to deliver high-quality and high-efficiency sheet metal components.

Rapid Turnaround Time

We can optimize your sheet metal design drawings and arrange sample productions. So, it shortens the validation cycle of your project and prepares it adequately for market development.

Robust ERP Management System

We are using powerful ERP management systems internally. It helps us control supply chain management and internal production processes. Moreover, the system effectively tracks the sheet metal production order plans. It ensures the timely completion of your project’s batch production.

Competitive Cost

We’re good at our jobs. So, we understand how to avoid material waste and reduce production processes. We are using vertical integration production. As a result, we can provide you with the highest-cost performance sheet metal components.

Advanced Sheet Metal Processing Equipment

Our facility is equipped with advanced sheet metal processing equipment. They may include Japanese-imported NCT turret punches (AMADA), High-speed punch presses, laser cutting machines, bending machines, and metal pipe bending machines. These machines help us to meet various project requirements for sheet metal processing.

On-Time Delivery

We have years of experience at advantages in sheet metal production. So, it makes us schedule sheet metal production promptly. We can deliver goods on time. So, your project remains unaffected.

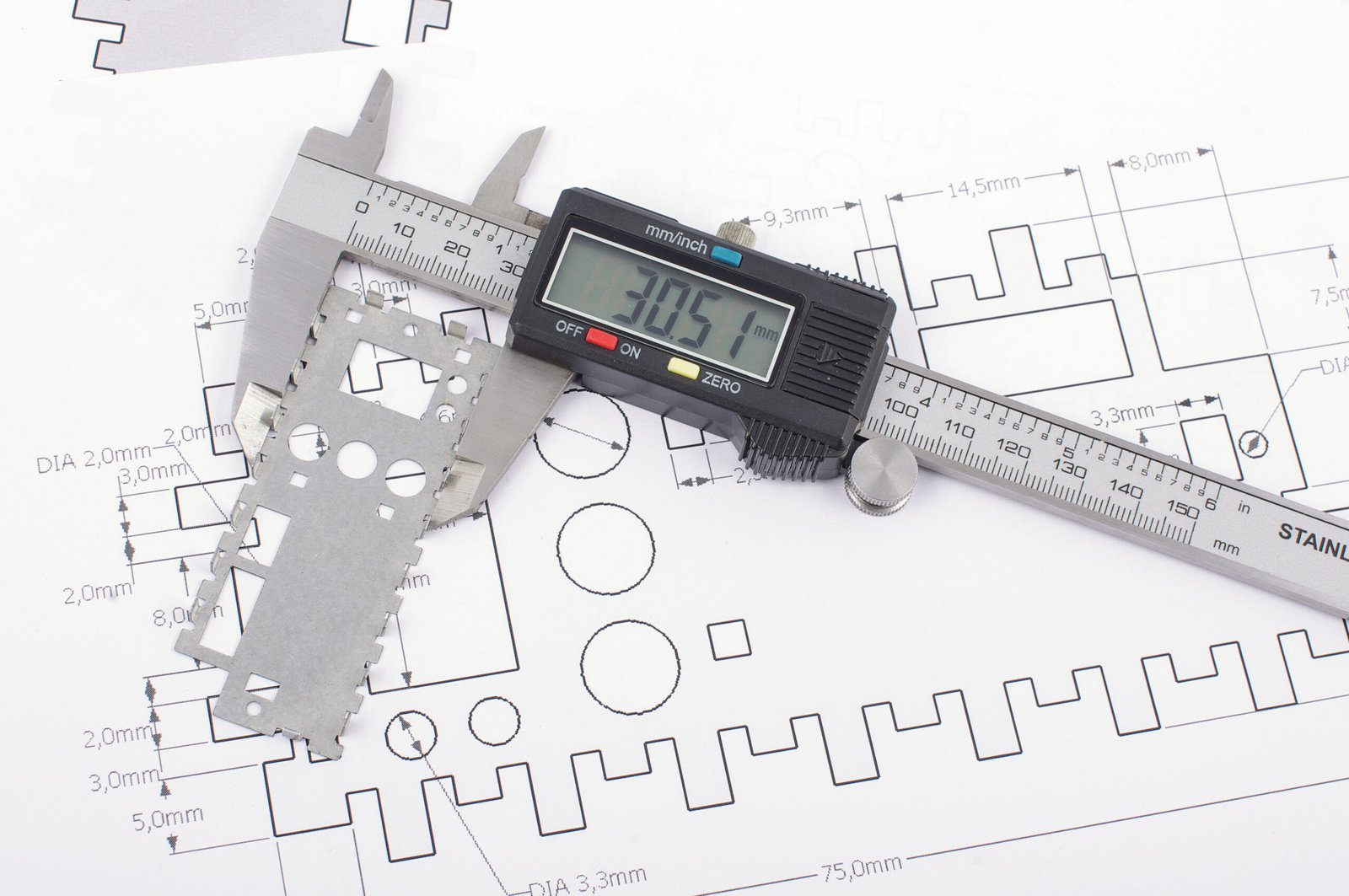

We are experts in custom sheet metal fabrication. We offer professional DFM (design for Manufacturing) services. Moreover, if you are unfamiliar with sheet metal designs, we can provide the initial sheet metal designs. It will assure the smooth progression of you.

Sheet Metal Design

We have proficient design and development engineers. They help with designing using advanced software like Autocad, UG, Solidworks, and more. So, if you have an idea, you can simply communicate with us. We will create the design drawings for you.

Design Evaluation

If in case you have a design drawing. But you don’t know, whether it is right or not. You can send them to us for evaluation. Our team will assess your design and provide recommendations.

Correct Material Selection

Our team will help you with material selection. Sometimes, few materials are not available in China. In this case, we will recommend an alternative. We make sure the selected material has similar mechanical and processing properties. Additionally, if you have material, we can assist you in choosing whether it’s right or not.

Sheet Metal Cost Analysis

We have years of experience in sheet metal fabrication. So, we will help you analyse the cost of sheet metal processing. It will be based on the design and provide cost-effective processing solutions. So, this will assure you that your sheet metal costs are more competitive in the market.

Stamping Die Design

Your product needs high-speed or standard punch presses sheet metal components. So, our experts will help you design suitable punching dies based on your design needs. Moreover, we can design and produce multiple dies.

Rapid Prototype Manufacturing

Firstly, our team completes the design drawings, production processes and price factors. After that, we swiftly proceed to manufacture prototypes of sheet metal components. Then we will send these prototypes to you. So, you can validate the design and quality of the product.

Testing and Validation

Once our design simulation passes, we conduct sample testing and validation to ensure that the product meets the design requirements and manufacturing standards. If any issues are identified, we can promptly address and correct them.

Wide Range of Materials Used

Besides quality, we never compromise on material quality. Each material can be detected via a QR code. This traceability may include details from the supply chain, batch number material type, and more. Moreover, our all materials come with material inspection reports. It identifies the material grades, chemical properties, and mechanical properties. Additionally, If you want to check any material, you can confidently inform us about the material needed for your project. We can resolve your material-related issues.

Our Surface Finish Capabilities

We have 17 years of experience in sheet metal manufacturing in China. We take great pride in our ISO9001 and ISO/Ts 16949 certifications. We strictly follow the requirements and management for quality. Besides this, we meet international quality standards. We also strived to exceed the customer’s expectations. Our goal is to produce high-quality sheet metal productions. We are working on the precise control and inspection of every step in the sheet metal production process. Moreover, we guarantee the consistency and reliability of the sheet metal products. This commitment to quality is our standard. We pay close attention to product details. Moreover, we use advanced production techniques. So, we can produce or cover all the projects with high-end quality.

In-house Surface Finishing Includes

• Powder Coating

• Brushing

• Polishing

• Silk Screening

Anodizing

Electroplating

Dacromat Coating

Outsourced Surface Finishing Includes

• Anodizing

• PVD Coating

• Dacromet Coating

• Electroplating

• Baking Paint

• Trivalent Zinc Plating

• Hot-dip Galvanizing

• Sandblasting

• Laser Marking

• Laser Engraving

• Dacromet Coating

Galvanized

Powder Coating

Silk Screening

Mirror Polishing

Paint Spraying

Satin

Masion always manufactures high-presision metal components using advanced equipment and mature processes. We make sure to address your production concerns for your project. Moreover, we continuously update our equipment for different new projects. We replace our old equipment to adapt to new projects. It gives you the advantages of low cost and high efficiency.

List of Equipment of Our Facility

- Robot Welding Machine

- Robot Feeding Machine

- NCT CNC Punching Machine

- High-Speed Punching Machine

- Laser Pipe Cutting Machine

- Laser Sheet Cutting Machine

- Shearing Machine

- Sheet Metal Bending Machine

- Pipe Bending Machine

- Riveting Machine

- Plastic Injection Machine

- CNC Machining Center

- Prototype Technology

- Coordinate Measuring Machine (CMM)

- Salt Spray Test Machine

Our Patents

We have been deeply rooted in the sheet metal manufacturing industry for 17 years. We have gained 47 invention patents. Our R&D team consists of over 30 engineers. They are very dedicated to developing new processes and techniques for sheet metal manufacturing. Moreover, we develop new products every year. Our team is committed to sustainable business practices and continuous innovations. We collaborate with customers across various industries. They provide new sheet metal manufacturing solutions.

• A large pipe long bracket welding fixture

• A wire tensioning pipe welding fixture

• A telescopic bracket welding assembly fixture

• A one-step punching and forming die for outer aluminium pipes

• Lifting platform

• A retractable table frame used for lifting tables

• A multi-functional lifting trolley

• A rotating backrest cushion used for lifting seats

etc

Our Certificate

As a factory with 17 years of experience in sheet metal manufacturing in China, we take great pride in our ISO9001 and ISO/TS 16949 certifications. We uphold exceptionally stringent requirements and management for quality. Not only do we meet international quality standards, but we also strive to exceed customer expectations. Our goal is to produce high-quality sheet metal products. Through our quality management system, we ensure precise control and inspection of every step in the sheet metal production process, guaranteeing the consistency and reliability of our sheet metal products. This commitment to quality is our standard. We pay close attention to product details and utilize advanced sheet metal production techniques to ensure that all projects meet the highest quality standards.

• ISO9001 Quality Management System

• ISO14001 Environment Management System Certification.

• TS16949 Automotive Industry Quality Management System

• FSC Forest Stewardship Council

• CE CONFORMITY EUROPEENNE(As you need we could apply)

• RoHs Restriction of Hazardous Substances(As you need we could apply)

• SGS (As you need we could apply)

• TUV(As you need we could apply)

At Masion, our professional sheet metal quality control team consists of 14 members. They include 1 Quality Manager, 2 Quality Engineers, and 11 Inspectors. We strictly adhere to ISO9001 and ISO16949 quality control technical standards. Our processes include processing, inspection, material checks, defective and handling, shipment, and packaging, all are documented for traceability. These documents may include material incoming inspection, sheet processing inspection, process audits, equipment checks, final inspection ports, etc.

● Material Inspection Qualification Report

● First Sample Inspection Report

● First Sample Confirmation Label

● Process Inspection Inspection Report

● Non-Conforming Product Handling Report

● Process Capability Analysis Report

● Measurement Equipment Calibration Records

● Sample Retention Records

● Statistical Analysis Report

● Error Prevention Report

Quality Control Documents

Trusted By Our Clients

Masion serves over 4000 customers in more than 30 countries worldwide. So, no matter if you have a large or a small sheet metal project. No matter, what’s your company size. You can contact us. We will provide the same level of services to all our customers for Sheet Metal fabrication.

Custom Sheet Metal Fabrications Industries

With 17 years of experience in sheet metal manufacturing and vertical management, Masion can provide a one-stop solution for sheet manufacturing. These may include metal tubes, pipe processing and assembly, plastic injection, high-speed stamping, and surface treatment for all clients across various industries globally. Moreover, we offer professional designs for manufacturability DMF, rapid sheet metal processing and large-scale production capabilities.

- Aerospace and Defense Industry

- Optical Communication Industry

- Industrial Automation

- Electronics Industry

- Automotive Industry

- Medical Industry

- New Energy Industry

- Power Industry

- Robotics Industry

- Construction Industry

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

FAQs

Are you a manufacturer or a trading company?

We are specifically a professional sheet metal manufacturing factory. It is in Ningbo Zhejiang, China. We are experts in custom designs, prototypes, manufacturing, and sheet metal processing. Moreover, we are certified with etc. and we are a genuine one-stop service provider and technical support for sheet metal production.

Our factory has vertical. management system. So, all the processes are carried out internally.

How masion issues confidentiality for a new project? What confidentially measures do you have?

We are a trustworthy sheet metal processing factory. First of all, at the beginning of cooperating on our new project, we sign a confidentiality agreement with the customer. In this case, we encrypt all the data. It includes emails or personal info, within our company. No engineer can copy sheet metal data and email drawings, or any information. We have specialized access control and non-technical personnel cannot access the sheet data. We regularly back up the sheet data and upload it to the cloud database. It helps us prevent data loss due to computer damage. For our self-developed sheet metal products, we show protect intellectual property rights and apply for patents. Over 47 patents are the best proof of it.

I haven a creative idea, but I cannot design. How can you assist me in designing and customizing sheet metal parts?

If you have a good creative idea, you can tell us directly. We will help you with sheet metal design. Our design development department is proficient in mainstream software such as Autocad, UG, Solidworks, 3D Max, Catia, PTC, Creo (ProE), etc. These can quickly help us design our creativity and reduce production times. Moreover, we will provide you with product optimization solutions.

What measures do you take to ensure the quality of sheet metal parts?

We are taking multiple measures to ensure the quality of sheet metal parts. These may include;

- Materials: The materials we are using generally have a traceability record. It has a specific QR code. It helps us to get the correct material specifications, dimensions and model numbers. So, if any issues are formed, they can be traced and terminated through a QR code.

- Equipment: We are using advanced equipment. They help us with high precision and efficiency of sheet metal production.

- Inspection: We thoroughly inspect our processes. This may include materials inspection, first article inspection, process mechanical inspection, process quality inspector patrol inspection, assembly inspection, surface inspection, packaging Inspection, etc.

- Employee Training: We believe in continuous learning. So, our operators undergo training before operating equipment. Many key positions of operation mechanics have long-term experience in sheet metal processing. So, we can say that high-quality sheet metal parts are delivered to you.

- ISO16949, ISO9001 Quality Management Standards: We have displayed our workstation process cards and pictures of defective products. Moreover, every sheet metal processing process strictly follows quality management systems. So, you can say, we are providing high-quality products.

What are your payment terms for manufacturing sheet metal parts?

We are using different payment terms, i.e. T/T, PayPal, and other payment methods specified by the customers. However, we can estimate the mutually acceptable payment terms via negotiation.

If it is automotive sheet metal parts, do you provide PPAP documents?

Absolutely yes, we provide all the relevant documentation. Masion is an ISO16949 certified company. We provide a complete set of PPAP documentation for all types of automotive metal parts. These parts can be stamping, high-speed stamping, or laser cutting. Moreover, if you are not in the metal part industry, but you need PPAP-related documents, we will still provide you with them. These documents will include drawings, production processes, and inspection records.

Are you offering Price Advantages or Discounts over Metal Parts?

Masion is fully incorporated with vertical integration management. We are using advanced technology, i.e. laser cutting, stamping, bending, high-speed stamping, riveting, welding, surface treatment, assembly, etc. We always perform our all processes inside the factory. So, if you compare our features and pricing with other industries. We are quite cost-effective for your metal parts needs. Maybe a few industries give you discounts. But they often cut corners on quality, or their product may lack after sale. Masion does not compromise on quality. We focus on process optimization. So, we cannot do that. However, if you have price inquiries, you can reach out. Our team will tell you the expected prices.

What sets you apart from other Manufacturers?

Masion is known for its quality and commitment. We believe in advanced equipment and modern facilities. So, our company serves you with both. We are using fast and accurate robotics technology. Moreover, we have well-experienced sheet metal processing mechanics and masters of stamping die. We are strictly following the ISO16949 quality management system. These all features make us different and help us to stand in the market.

What is the minimum order quantity for your sheet metal parts?

We take a minimum order of 1 piece. But it’s just a minimum value. You can choose to place multiple orders. If you need to validate the quality of the product, you can start with a one-piece order. Then go with the maximum orders you want. Masion will help you grow in the market. Moreover, weather your parts are small, large, single or in bulk quantity, we value your every requirement and deal with the project fairly.

How do you Guarantee on-time delivery of sheet metal parts?

We strictly follow ISO16949 quality standards. So, we initially design a plan, arrange the required materials in advance, and schedule our production. Moreover, we use a powerful and fully integrated ERP management system. It helps us track all the projects and productions. We record each process point time. This is the reason we always deliver projects on time and guarantee it for the future.

What additional services do you offer besides sheet metal processing?

We are a professional sheet metal manufacturer. We have years of experience in sheet metal processing. Besides this, we are experts in CNC machining, aluminium extrusion processing, plastic injection, stamping dies manufacturing, sheet metal assembly, and other processing services.