Solution

Masion, Your Custom Metal Tubing Expert

Masion has 17+ years of experience in custom metal tube fabrication. We use advanced techniques to make your metal part highly accurate, precise, and durable. These techniques may include Cutting, bending, and assembling square, round, and profiled tubes. We’re not stopping here. We also offer;

● In-house welding fixtures and robot welding.

● Vertical integration management

● High quality, low cost, and fast delivery.

● Capable of in-house surface finish for metal tubes.

● Electronic control design and structural design.

+86-18969433502

sales@sheetmetalmasion.com

We’re your must-go-to Metal Tube Manufacturers in China

Masion is a master in manufacturing plastic injection, components, and other products associated with metal tubes in China. We expertly handle all the complex metal tube assemblies with different geometries and shapes. These shapes may include lifting tables, electric shifters, electric care beds, etc. Moreover, we hold multiple design patents. Masion has years of experience in manufacturing metal tube assemblies. So, we can assist you with the design along with the production of complex and high-quality components. Our experts always ensure precision and thorough inspection of the production process. I.e. metal tube assemblies you need.

Providing you with High-Quality Metal Tube Fabrication Services

Masion is one of the top manufacturers of metal tubes in China. We provide comprehensive metal tube services. These mainly comprise the complete process including metal tube procurement, cutting, bending, deburring, stamping, diameter reduction, drilling, tapping, riveting, and welding. Additionally, we also are a front runner in integrating all components such as plastic parts, wood, wheels, rubber parts, electronic control boards, metal plates, mechanical parts, and more. Besides this, we also have in-house secondary processing capabilities and extensive assembly experience. They both ensure that our assemblies and products are high-quality and durable. So, if you are looking for metal tube fabrication services.

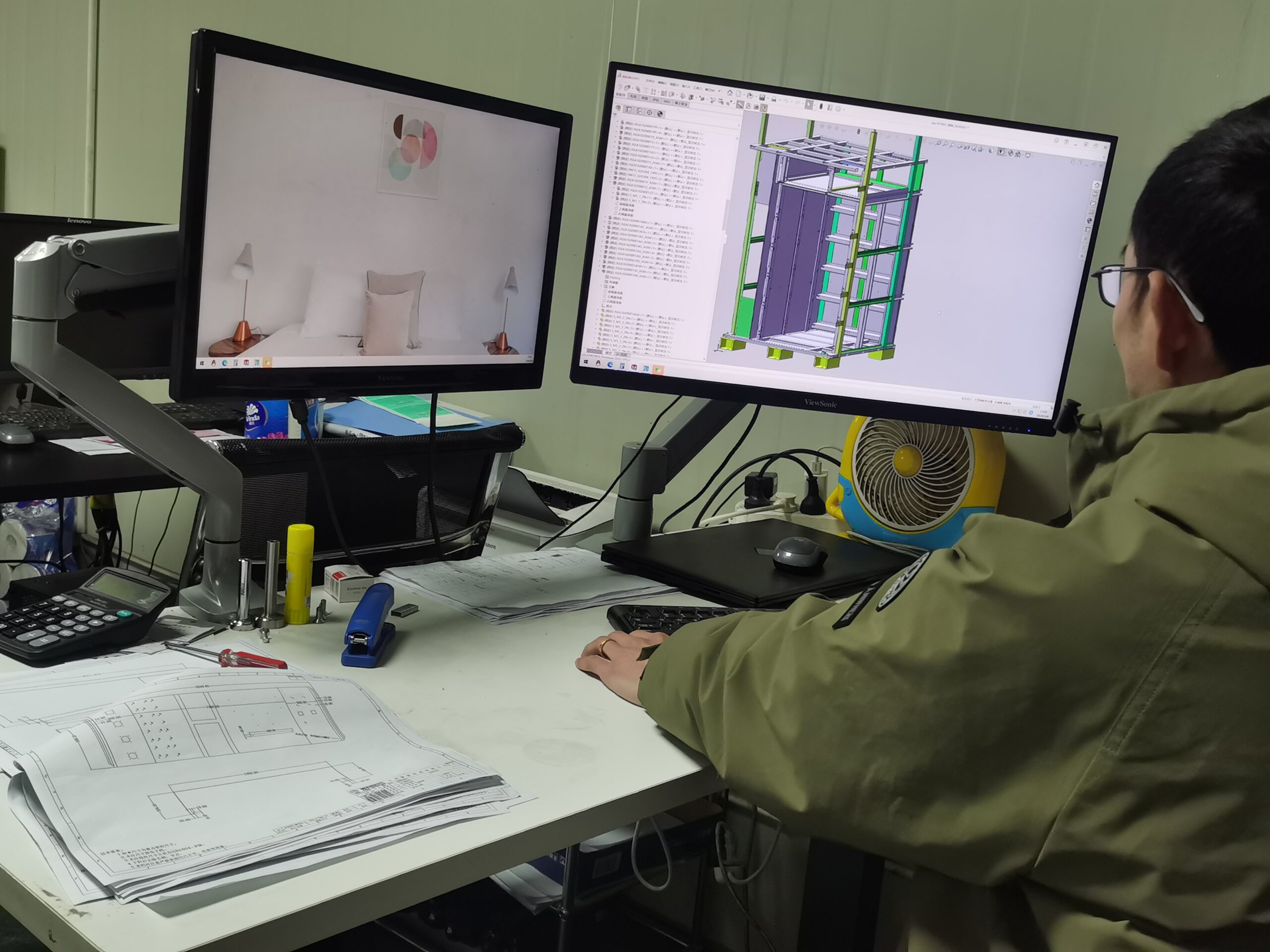

Our experts use our rich design and production experience and assist you in adjusting the metal pipes and tube components design drawing.

Masion aims to make sure that the designs are aligned with production requirements. So, we guarantee high-precision and top-quality metal pipe and tube components. Moreover, it helps reduce costs and shortens the lead time.

We are using advanced equipment to cut metal pipes in particular dimensions. These equipment include laser cutting, automatic cutting, and angle-cutting machines. Our team can efficiently and effectively complete cutting tasks with high precision and quality. They ensure an accuracy of ±0.1mm

Masion is capable of providing high-quality bending and tube forming services. So, if your project requires metal tube bending fabrication or metal tube forming. Our team will assist you to the best. Our facility is equipped with bending machines. They’re capable of adjusting angles and bending to specific angle requirements. So, we can claim, our process is convenient and efficient and give you the best results.

Our metal tube fabrication is mostly automated. It is equipped with drilling, robotic welding, laser welding, stamping, reducing diameter, riveting, tapping, and other processing equipment. It allows us to quickly and precisely complete the primary processing of metal pipes. Moreover, it helps get highly accurate and precise results.

We have six assembly lines. They support the sub-assembly of metal tubes and the assembly of finished products. Internally, we offer various surface finishes for metal tubes. This mainly includes powder coating, polishing, silk screening, and brushing. External suppliers can provide anodizing, electroplating, PVD coating, Dacromet coating, and more.

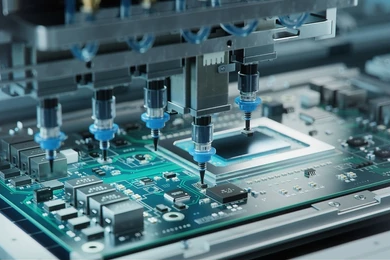

Masion also provides testing electronic components – motors. Our team of experts works to produce complex, high-precision metal tube parts and to assemble these metal tube parts with other components like nuts, plastic, and electronic parts.

We’re your One-Stop Solution to Cater to your All Metal Tubing Needs

If you are looking for custom metal tube fabrication in China. Masion is here for you. Our expertise and team of experts will never let you down. We will assist you in designing of metal part. Besides this, we will produce high-quality metal parts based on this. Masion takes pride in serving customers with ideal deals. We are capable of using multiple materials. Along with this, we can use secondary processes and refined surface finishing operations to give you high-quality results.

Materials

– Aluminum extruded tubes

(AL6061T6, AL6063T5, AL7075)

– – Carbon steel

(SPCC, CRS, SAPH440, SPCD, SPCE)

– Stainless steel tubes

(SUS201, SUS301, SUS302, SUS303, SUS304, SUS316, 2205, 904L)

– Carbon steel tubes

(20#, 45#, 16Mn, 40Cr, 45Mn2, 40MnB)

– Galvanized tubes

(Q195, Q215, Q235, Q255, Q275)

– Precision seamless steel tubes

High-pressure seamless steel tubes, hot-rolled seamless steel tubes, general seamless steel tubes, rectangular tubes, oval tubes, hexagonal tubes.

Machines

● 3 sets of HS-TS65 Laser Tube Cutting Machines, 3000W

● 4 sets of Fully Automatic Tube Cutting Machines

● 2 sets of Angle Tube Cutting Machines

● Deburring Machine

● Tube Bending Machine

● Punch Press

● Pipe shrinkage machine

● Riveting Press

● Radial Drilling Machine

● Standalone 4E Riveting Machine

Thickness

● Maximum thickness: 8mm

● Maximum outer diameter: 150mm

● Customizable thickness or outer diameter

Secondary Processing

● Assembly Services

● Robotic Welding

● Manual Spot Welding

● TIG and MIG Welding

● Tapping

● Drilling

● Tube Stamping

● Tube Reduction/Swaging

● Riveting

Surface Finish

● Powder Coating

● Anodizing

● Electroplating

● Trivalent Galvanizing

● Hot Dip Galvanizing

● Passivation

● QPQ (Quench-Polish-Quench)

● Dacromet Coating

● Sandblasting

● Polishing

● Silk Screening

● Phosphating

● Baking Paint

● Heat Treatment

● Electrophoresis

● PVD (Physical Vapor Deposition) Coating

Why Choose Our Custom Metal Tube Manufacturing and Assembly?

Masion possesses several compelling reasons to make it the one-go-to-place for manufacturing metal tubes and assembling products. Here are some fundamental factors that make us able to withstand diverse markets for the production of your metal tube components:

Mature Production Experience:

We have provided metal pipes and tubes and assembling products manufacturing services for many years. Our expertise may include designing metal pipe and tube products that strictly comply with standard principles. They guarantee optimal functionality.

Advanced Equipment and Technology:

Our facility is equipped with cutting-edge automated machinery, i.e. laser pipe-cutting machines, angle-cutting machines, and bending machines. This guarantees high-quality, efficient, and precise production of metal pipes and bent components. Moreover, it helps reduce the overall labor costs.

DFM Services:

We provide Design for Manufacturability (DFM) services. So, we can adjust your design with more technical support. It will help you align with optimized production processes. Additionally, Masion is working on cost reduction, efficient and high-quality processing, and time-saving methods. So, it will guarantee your project is delivered efficiently.

Variety of Pipe and tube diameters and Material Options:

We offer a wide range of metal pipe manufacturing options. They include welded pipes and circular, square, and custom-shaped pipes. So, if you require the use of different materials like stainless steel, iron, aluminum pipes, or customized non-standard dimensions and specific materials. We will use the material to meet your needs. Our offers provide a maximum pipe thickness of 8mm and a maximum outer diameter of 150mm.

In-house and Out-Sourcing Surface Finish:

Internally, we provide surface treatments, i.e. spray coating, brushing, polishing, and silk screening. Externally, our supply chain offers high-quality corrosion-resistant surface treatments. They include anodizing, electroplating, and Dacromet, ensuring your project meets varied aesthetic and corrosion-resistant requirements.

Best Assembly Capability Support:

Masion has six assembly production lines and a team of over 100 assemblers. So, we can efficiently handle the assembly of metal pipe components along with other associated products. This capability helps us achieve quality, delivery time, and cost-effectiveness.

Quick Quoting and DFM Capabilities

Masion provides 24/7 technical support and quoting services for metal tube materials. Regardless, of the size and complexity of your project. We will quickly engage in technical communication with you to provide quotes. Our team will arrange for sample confirmation to save your project timeline.

– 24/7 technical support and quoting services

– Metal tubes and assembly parts involve multiple supply chain management. We possess a strong management system for the supply chain. It gives quick access to prices and technical support.

– Reducing communication time to increase the effective progress of projects.

– Confirm professional designers and engineers to analyze project drawings for metal tube parts. So, they can give professional advice

on system backend management of orders. They help ensure efficiency, precision, and reliability.

– Internal production integrates all metal tube processing techniques. They help us shorten lead times.

– Error prevention management, anticipating and addressing issues in advance.

Certificate of Tube Fabrication Service

1. ISO9001 Quality Management System

2. ISO14001 Environment Management System Certification.

● TS16949 Automotive Industry Quality Management System

● FSC Forest Stewardship Council

● Patent: 47 patents of invention

● CE CONFORMITY EUROPEENNE(As you need we could apply)

3. RoHS Restriction of Hazardous Substances(As you need we could apply)

Advanced Fabrication Machine

Laser Tube Cutting Machine

Applicable materials: It may include cutting of different shapes.

– round tubes Φ20-Φ210mm

– square tubes 2020 – 150150mm, rectangular tubes 20-150mm;

– 0.5~5mm stainless steel tubes, galvanized tubes

– electrolytic plate tubes

– silicon steel

– other thin metal tubes.

Capable of cutting various special-shaped tubes, including round, square, oval, hexagonal, etc.

● Processable square tubes from 20mm20mm to 100mm100mm, round tubes diameter from 20mm to 100mm, wall thickness from 0.8mm to 5.0mm, and various special-shaped tubes.

● Oscillation mode: Continuous

● Control method: CNC (Computer Numerical Control)

● Power: 3000W

Tube Bending Machine:

● Maximum bending tube diameter: 50.8mm

● Maximum tube wall thickness: 2.0mm

● Maximum bending angle: 190°

● Feeding accuracy (mm): ±0.05mm

● Rotation accuracy (°): ±0.05mm

● Bending accuracy (°): ±0.05mm

Metal Tube Fabrication Assembly

Metal Tube Fabrication Industries We Serve

Metal tubes have a wide scope of applications in various industries. They may include well-known sectors like the medical industry, manufacturing, electronics, and agriculture, as well as areas we frequently encounter in daily life like the telecommunications industry, fitness equipment, construction, machinery, consumer goods, and more. Here are some common applications of metal tubes in these industries.

● Stretchers and lift beds

● Medical beds

● Electric transfer machines

● Metal walkers or crutches

● Metal IV stands

● Chairs or wheelchairs

● Support structures for medical equipment

● Leg lifters, knee benders

● Parallel bars, equipment racks for rehabilitation and physical therapy

Medical Industry

● Production line workbenches

● Mechanical supports and frames

● Goods shelf

● Machine guardrails

● Welding and assembly workbenches

● Assembly line workbenches

● Mechanical supports and frames

● Assembly line and production equipment supports and frames

Manufacturing Industry

● Display screen stands

● Power module brackets

● Electronic device casing supports.

● Metal antennas and frequency devices

● Metal supports and support structures for electronic devices.

● Battery fixtures and brackets

● Radiator brackets

● Sensor mounts

Electronics Industry

● Connectors and brackets, pipelines for irrigation systems

● Frames, and seat brackets

● Body structures, chassis components

● Feed bins, drinker brackets

● Orchard sprinkler system supports

● Irrigation system brackets

● Agricultural drainage systems

● Agricultural shade net supports

● Water reservoir supports

Agricultural Industry

Our Other Solutions

Metal tube fabrication is not our limit. We are also providing modern techniques and ways to make metal parts. We’re are equipped with multiple machinery. It helps us carry out all the processes efficiently. So, here are other ways we are using based on customers’ requirements.

Sheet Metal Processing

Stamping

Laser Cutting

Masion uses various techniques to shape and convert metal sheets into desired forms. It has a wide scope of applications in industries, i.e. automotive and construction.

We use different dies and presses to shape the metal sheet in the desired geometry. This process has a wide scope of applications in different industries. These mainly include automotive, electronics, and appliance manufacturing.

Laser Cutting: This technique is used in high-powered lasers. It helps us precisely cut through materials such as metal, plastic, and wood. So, this method easily deals with complex designs and efficient production in industries.

Plastic Injection

Sheet Metal Assembly

Progressive Stamping Die

Masion uses molten material and then injects them into a mold cavity. This technique is used to produce complex and precise parts in high volumes. It has wide applications in industries like automotive, consumer goods, and medical devices.

We provide sheet metal parts assembly services, suitable for large, small, various projects complex sheet metal parts assembly.

It includes the fabrication of stamping die . These dies are generally used in stamping. Moreover, we use this process for batch stamping production of the same designs.

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

Frequently Asked Question

Metal tube fabrication is a technique that is used to create different tube shapes. These shapes may include square, round, or profiled shape tubes. This process uses several techniques, such as cutting, bending, welding, riveting, surface treatment, etc. Additionally, we can use a range of materials, i.e. aluminum tubes, stainless steel tubes, carbon steel tubes, etc. So, these tubes are integrated with plastic or wooden accessories, nuts, screws, and metal fittings.

Masion uses various advanced equipment for metal tube manufacturing. They mainly include laser tube-cutting machines, fully automatic tube-cutting machines, angle-cutting machines, tube bending machines, diameter reduction equipment, welding robots, riveting machines, punch presses, spray painting lines, etc. This equipment can process different metal sheets to make metal tube products. These processes are usually, stamping, bending, cutting, welding, riveting, surface treatment, assembly, etc.,

So, the size and accuracy we offer with our laser pipe-cutting machine is.

- Round tubes: Φ20-Φ210mm.

- Square tubes: 20*20 – 150*150mm, rectangular tubes: 20-150mm.

- 0.5~5mm stainless steel tubes.

- Accuracy:+-0.1mm

Generally, we use production processes according to different metal tubes. The conventional processes we’re using commonly may include material selection, material testing, laser cutting, automatic cutting, tube bending, tube diameter reduction, tube welding, tube riveting, tube spraying, electronic testing, wood processing, wood edging, and component assembly. For more details, please contact us.

We are capable of manufacturing different metal tube products. These may include medical beds, electric transfer carts, hand-cranked lifting tables, electric lifting tables, pipe carts, dining tables, etc. Additionally, you can also send us your pipe product requirements. Then we can provide production plans for your consideration.

Absolutely yes. We have six assembly production lines. They are capable of assembling different parts, i.e. plastic accessories, fasteners (nuts, screws), metal tube components, power motors, handles, wooden products, power lines, and other various components. This helps us to produce the finished product you need.

In addition to providing metal tubing processing techniques, we offer CNC machining, stamping mold design and manufacturing, plastic injection, and other machining services.

We have a team of 22 R&D designers and hold 47 independent design patents. This helps us to provide you with high-quality metal tube design services. Even if you only have a design concept, we can assist you in turning it into a product. Feel free to inquire.

- DFM Design: We have a professional and experienced design and R&D team. They help us develop your metal tube products based on your requirements.

- Vertical Integration Production Management: We vertically integrate the production of the entire product. It helps us shorten the production cycle. Additionally, it also reduces the production costs.

- ISO16949 Quality Management Certification: Based on ISO16949 quality management certification, we strictly control the quality of metal tube components. It helps us reduce defect rates and increase customer recognition.

- Advanced Equipment: We are equipped with an automated assembly production line. Moreover, we’ve robot welding, robot feeding, and other equipment. They help us efficiently produce metal tube components. Besides this, it also reduces production accidents, production quality, and labor costs.

We have ISO9001-2015 and ISO16949 quality management certifications. If you require ISO13485 quality management certification, we can discuss it with you.

Masion has reliable and efficient ways to meet all the client requirements. So, our measures may include,

- Material Selection and Inspection: Masion has an efficient and dedicated material QR code tracking system. It tracks and traces the quality, grade, and batch of materials. So, here the materials undergo inspections. So, we can ensure they meet drawing requirements and standards.

- Production Process Control: We guarantee to optimize the production process in advance. So, it ensures that each process has an independent process card. While our advanced equipment controls quality during production.

- Quality Inspection: Our experts inspect metal tube components through every stage. These may include initial sample inspection, production process inspection, process patrol inspection, final inspection, surface inspection, welding inspection, etc. So, our every inspection is strictly controlled to provide the quality of metal tube components.

- Strict Quality Control via ISO16949: Masion strictly adheres to the ISO16949 quality control system. So, consequently, it controls the quality of metal tube components.

- Error Prevention Management: We design molds and fixtures. They help us prevent errors during the production of metal tube components.

- Employee Training: We believe in constant learning. So, our team of experts provides regular quality management training to employees. It helps increase their quality awareness and guarantees strict adherence to equipment operation procedures during the production of metal tubes.

We believe in punctuality and customer satisfaction. So, we assure it by following ways;

- Production Planning: We manage production plans based on your project. Then we track and monitor each production process through an efficient ERP production management system. This system ultimately helps us control each production link and guarantees smooth production.

- Supply Chain Management: Masion is capable of managing the supply chain through a strong ERP system. We strictly control the procurement and delivery time of raw materials. Moreover, if there are delays in raw materials, we will work overtime. So, we can identify any production link issues and then address them properly. We closely cooperate with suppliers as well. It helps us provide timely delivery of their goods to us.

- Inventory Management: We maintain a safe stock of commonly used materials. This strategy helps us in the smooth delivery of the next batch of orders.

- Production Optimization and Control: Masion optimizes production process design. It streamlines production processes and shortens production cycles. Moreover, we use advanced production equipment, i.e. robotics to improve production efficiency and capacity. It ultimately shortens the delivery times.

- Communication and Coordination: Masion prioritizes transparency and cooperation between each department. So, before the project production process, relevant production processes are arranged. Then each department is responsible for completing each process before the project deadline and signing off on it

- Regular Employee Training: We provide regular professional knowledge and skills training to employees. It helps us polish their skills and they learn new ways to make metal tubing parts.