Solution

Leading Contract Metal Fabrication Solutions in China

• Complete Vertical Sheet Metal Production Services from a Single Source

• Locating at Ningbo, Zhejiang, China with more than 400 employees.

• Covering 30,000 square meters with the help of the 6 production units and 6 assembly lines.

• A tremendous in-house ability covering stamping, laser cutting, bending, riveting, surface treatment, plastic injection, and stamping die/mold manufacturing.

• Customized for large as well as small jobs on sheet metal, ensuring the availability of sensible processing solutions.

• Reliable Contract Manufacturers for Lixiang Auto, Greely Auto, CRRC, Chisage, AUX, TUOPU, and Costco.

+86-18969433502

sales@sheetmetalmasion.com

Discover our unique offerings like original design services, fast sheet metal prototyping, PPAP documentation, and more.

How We Can Help You

Masion excels in custom fabrication of sheet metal and serves all project dimensions from big to small. With product range covering all these sectors including consumer goods, healthcare, telecommunications, electronics, defense, aerospace, automotive and new energy, we find applications in almost all the industries. Working together through metal fabrication joint ventures we provide comprehensive design and production of sheet metal components from start to finish. Being based on 17 years of experience in sheet metal processing, as well as on advanced robotic technology and a team of competent experts, our company provides comprehensive sheet metal processing services. The core of our business is the fulfillment of time-constraints and quality assurance. It accompanies each project we implement. We combine vertically integrated management practices not only for cost saving but also for enhancing the credibility of the clients’ sheet metal products in the market. What sets us apart is that we serve as a one stop solution provider for sheet metal needs. We can assemble different parts like plastic, metal, rubber, various fasteners, electronics and motors into a single unit.

Sheet Assembly

Plastic Injection

Sheet Fabrication

CNC Production

Stamping Die

DFM Support

In the world of sheet metal contract manufacturing, designers and small and medium enterprises, startups, and even well-known publicly traded companies, come to an agreement with specialized companies in metal processing or outsourcing firms, otherwise known as trading companies, to delegate sheet metal manufacturing orders. These projects consist of the following stages: design, production, assembly and packaging. This contract is an example of the shared manufacturing system, where fabricating shops or outsourcing companies perform tasks such as design drafting, laser cutting, bending, welding, riveting, and assembly in line with equitable conditions. As a third step, the fabricated sheet metal parts are supplied to the contracting authority according to the specified dimensions, thus ensuring both quality and timelines. Along this journey, the expenditure on raw materials, equipment, labor and packaging is reduced, since all are taken care of by the business factories specialized in sheetmetal, thus, costing less. Therefore, the contracting party will be able to allocate its effort in sales, marketing, and customer service activities. This collaborative model simplifies the process of getting sheet metal products to market as soon and economically as possible, an aspect that surely benefits the contracting entity.

How would you define Contract Metal Manufacturing?

Maison, on the other hand, is the leading institution in the customized sheet metal manufacturing solutions development to satisfy the specific needs of customers across various industries. Our know-how is based on a comprehensive variety of elaborate and sophisticated jobs related to sheet metals.

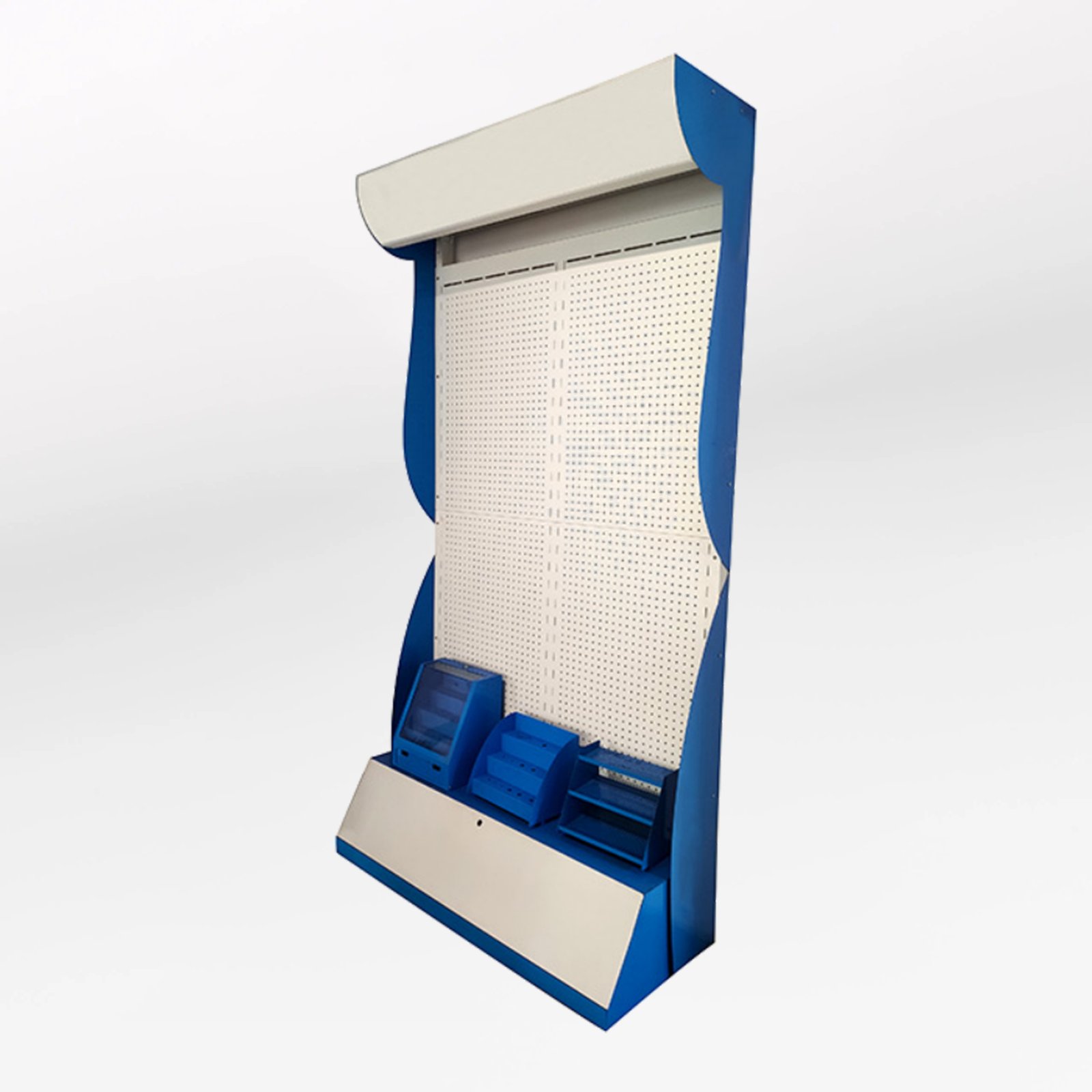

Creating a Variety of Sheet Metal Cabinets

We’re focused on manufacturing the selection of sheet metal cabinet enclosures adjusted for industries like healthcare, renewable energy, banking, automotive, telecommunications, electronics, defense, firefighting and power to ensure customer satisfaction. Being renowned not only for their superior quality, but also for their beautiful appearance, corrosion resistance, and toughness, our enclosures have become a time-honored choice of our customers.

Accurate Stainless Steel Sheet Fabrication

We can laser cut stainless steel sheets to make a variety of sizes and grades. The application of these sheets are unique in the food industry as they meet the stringent specifications while guaranteeing durability, wear resistance, visual appeal, environmental sustainability, and resistance to corrosion.

Aluminum Alloy Sheet Processing Expertise

We mainly work with aluminum alloy sheets, which may be covered with protective films to prevent them from getting oxidized. Employing the latest manufacturing techniques like NCT punching, bending, and riveting we produce aluminum sheets in different shapes. Additionally, our oxidation processes give us an array of different colours to meet the customers’ varying needs in look, size, and form.

Innovative assembly and production

Through teamwork, we design and build a variety of height-adjustable ergonomically designed tables. With motorized height adjustments and wireless charging configurations, such tables are appropriate not just for students, office personnel but also for blue-collar workers.

Sleek Computer Case Enclosures:

We create elegant and fashionable computer case enclosures using aluminum alloy as the main material. Provided in a variety of colors through a technique called anodization, the enclosure is made into different shapes by cutting and bending processes. These enclosures not only secure hard drives and memory modules but also provide portability and convenience to computer enthusiasts.

Diverse Portfolio of Custom Sheet Metal Solutions – Our Abilities.

Custom Sheet Metal Solutions for Engineering Projects

Our team provides full supporting design and assembly services for engineering projects. Our experienced engineers take control of the entire project and make it a reality by delivering excellent quality.

Quality, corrosion resistance and customer satisfaction are what we give top priority in our tailored sheet metal solutions at Masion. We always strive to improve our manufacturing processes, upgrade our equipment, and discover breakthrough techniques to remain in a leading position in the industry. If there is any question or any special requirements, you are free to contact us.

• Innovative DFM Design: We initiate your projects with highly developed design for manufacturability principles which help in reducing the sheet metal product design and production processes. This ensures continuous integration of your product with our production capabilities. Via our vertically integrated model, we will be able to lower costs, shorten lead times, increase production efficiency, speed up time to market and also strengthen customer satisfaction.

• Expert Team: Our powerhouse team is a group of experienced professionals covering all R & D, manufacturing, mold engineering, quality assurance, and assembly. Having years’ experience in the industry, they like to lead your sheet metal projects from conception to completion with speed and accuracy. Be prepared to witness something exceptional that runs from project development through mass production.

• State-of-the-Art Equipment and Technology: Our mission is to be on top of sheet metal technology, advancing our machining processes and tools. Through incorporating the newest innovations and adopting automation, we are able to trickle down the production process to produce sheet metal parts that surpass your standards.

• Rigorous Quality Control: Being certified by ISO9001-2005, ISO16949 and other quality management standards, we are reliable to provide our customers with supreme quality at every phase of the fabrication process. Your contentment is our highest commitment.

• Customization Expertise: Being aware of the various needs of the projects, we specialize in designing customized sheet metal solutions in line with your specified requirements. From custom parts to complete assembly systems, we have got all your needs covered.

• Cost-Efficiency: Equipped with a good background in the management of sheet metal work of large scale, we make a difference in the cost optimization. Lean on us for procurement, production and beyond as we deliver cost-effective solutions that would not compromise on quality.

• Versatility and Variety: Utilizing a wide variety of sheet metal materials and products such as carbon steel, aluminum, stainless steel, and several others, we are able to cover all customer needs. Be it cabinets, pipe assemblies, or precision-cut pieces, we have the expertise to get the job done.

• Timely Delivery: Using the internal vertical management system and the state-of-the-art ERP software we always keep schedules under tight control. We ensure that the sheet metal parts will be delivered on time with each shipment.

Our contract manufacturing capabilities demonstrate a high level of flexibility and technology, thus ensuring reliability, precision and best-in-class sheet metal products. We are at your disposal for additional details. Feel free to reach us now!

Why Select Our Contract Metal Fabricating Services?

Design Support:

Comprehensive R&D design help includes radical solutions specific to your business. Our team of experienced R&D design engineers, who are proficient in sheet metal designs, help to ensure an optimal end result.

Precision Cutting:

Employing the most recent laser technologies, we specialize in the complicated cutting of metal sheets with different shapes and engravings. From intricate geometries with special configurations, we deal with materials such as aluminum, carbon steel, copper, and many others under +-0.1mm precision. Also, NCT stamping is used for variety options in size and shape.

Expert Bending:

In addition, we specialize in sheet metal bending, an important step in the fabrication process. Our machines together with skillful mechanics enable us to tailor sheet metal according to specified requirements by providing both function and beauty.

Advanced Assembly Techniques:

From manual MIG-MAG and TIG welding to robotic and laser welding, we apply various technologies to fit specific projects according to size and demands. Our high yield riveting techniques including pulling and pressing riveting achieve the goal of perfect assembly of sheet metal components.

Surface Enhancement:

We provide various surface treatment options like electrostatic powder spraying, anodizing and electroplating that increase the durability, corrosion resistance, and attractiveness of the sheet metal parts, hence prolonging their life and enhancing the look.

Efficient Assembly:

The final stage of the manufacturing process is sheet metal assembly, in which all components are fitted together using state-of-the-art machinery and equipment. Whether it’s cabinet doors, accessories, or the cabinet body, our assemblage results in a perfect completion of the product.

Secure Packaging and Delivery:

Lastly, we pack all the large cabinets with pallets or wooden boxes, secure them during transit, and provide convenience in handling. We will safely and on time deliver your cabinets to you.

Sheet metal manufacture process overview.

Certificate of Contract Metal Manufacturing Excellence

It is very important for Contract Metal Fabricator to verify that the supplier has a quality management certificate. These certifications are a foundation of quality control of contract metal manufacturing and a prerequisite to sustain collaboration that involves trust in relationships.

• ISO9001-2005: Quality Management System

• ISO14001: Environmental Management System Certification

• TS16949: Automotive Industry Quality Management System

• FSC: Forest Stewardship Council

• Patent Portfolio: 47 patents of invention

• CE Marking (CONFORMITE EUROPEENNE): On request.

• RoHS Compliance (Restriction of Hazardous Substances): Upon request.

Metal Point-of-Purchase (POP) Displays

Inside each and every consumer goods company is a need to have metal display racks. These racks are placed at the checkout areas to attract consumer attention towards high-demand items. So, sheet metal processing companies with design skills enter into contracts for manufacturing of customized POP displays embossed with brand logos.

Electronic Stamped Components

Contracts for circuit design usually involve the manufacture of small-scale products such as plugs, contact springs for PCB boards, and contact pins for electronic plugs and sockets. These complex parts generally undertake high-speed punching by using state-of-the-art punching presses, which demand proficiency in high-speed punching and progressive dies. Our company specializes in manufacturing such items.

Automotive Sheet Metal Components

In the automotive industry, sheet metal contract manufacturing is mainly used to satisfy high demands for automotive sheet metal components. Manufacturing facility helps provide a number of services such as precision manufacturing and assembly for auto-manufacturers. Elements such as dust covers and oil seals are routine as they need ISO/TS 16949 certification for guaranteeing good quality and fast delivery. Our company possesses the ISO/TS 16949 certification and leads in the automotive sector in meeting sheet metal processing requirements.

Defense Sector

The defense industry must establish a strict quality control standard for sheet metal parts. For example, gun safes and military communication casings are influenced by attributes such as corrosion resistance, high-temperature resistance, and waterproofing. Hence, it is hard to find trustworthy sheet metal contract manufacturers who are able to meet these requirements. Having a long experience in gun safe sheet metal parts production and with our strict quality control, our company is a reliable partner for your needs.

Medical Equipment

The medical industry needs the equipment as well as carts and medical beds for precise, reliable, and durable operation. Due to strict quality standards, it is very important to choose contract manufacturers that provide wide array of services ranging from production to surface treatment and assembly.

Gaming Cabinet Enclosures

Gaming is one of the most popular entertainment activities in the United States, involving lottery machines, slot machines, and arcade cabinets, which are all manufactured from sheet metal enclosures. Through cooperation with sheet metal contract manufacturers one can make custom enclosures of different sizes and surface treatments for intensifying the gaming experience.

Communication Equipment

Communication devices are the centre of our day-to-day activities, especially in areas like telemedicine and education. Consequently, manufacturers of communication equipment carry a high demand for sheet metal products such as cabinets and boxes. Consistent sheet metal contract manufacturers are paramount to meet the demands of communication equipment while ensuring their quality and reliability.

New Energy Sector

The new power sector demands very strict specifications from sheet metal parts such as waterproofing, corrosion resistance, rust prevention, and high-temperature resistance. Distribution boxes and energy storage boxes are constantly exposed to outdoor elements, therefore the sheet metal industry is expected to provide top quality and surface treatment in accordance to industry requirements.

Industries Related to Contract Manufacturing Companies

Contract Metal Fabrication Product Gallery

Talking About our Complete Sheet Metal Manufacturing Solution

We offer a comprehensive approach to sheet metal contract manufacturing by our highly competent R&D design engineers, proficient die makers, experienced machinists, fastidious inspectors, and modern robotic equipment and technologies. Thus, we are capable of taking on different kinds of problems with no difficulty at all and only getting quality results.

Sheet Metal Assembly

Metal Tube Fabrication

Laser Cutting

Metal Pipe tube Finished Products, Sheet Metal Parts Assembly Solutions

Supporting Tube Pipe Cutting, fabrication Solutions

Supporting laser cutting precision bending solutions

Plastic Injection

Stamping

Sheet Metal Fabrication

Supporting Plastic Injection Manufacturing Solutions

Precision Stamping, Progressive Die Design and Manufacturing Solutions

Mass Precision Sheet Metal Manufacturing Solutions

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

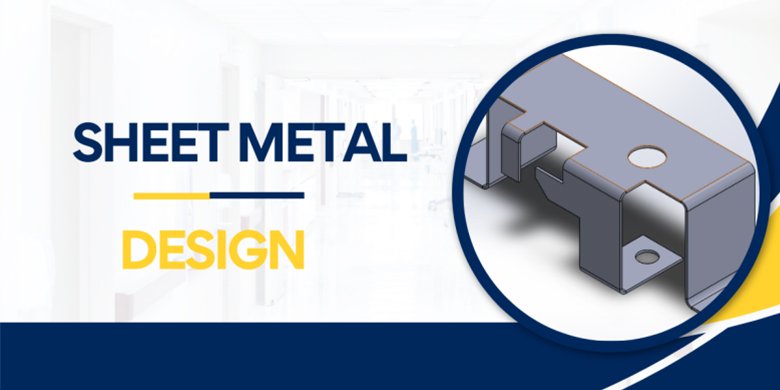

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

Frequently Asked Question

Metal fabrication on a contractual basis provides a complete solution for the production of metal components and is usually hired by startups, designers, or firms to manufacturing companies specializing in metal fabrication. This covers end-to-end metal fabrication processes like Design for Manufacturability (DFM) support, cutting, bending, stamping, welding, riveting, surface treatment, assembly, and packaging. Having extensive production experience, advanced technologies, and using professional equipment, metal fabricators are able to reduce manufacturing costs, to have the guaranteed quality and to deliver the product on time.

This is why hiring an experienced steel fabricator is to your advantage.

Cost reduction in production.

A possibility to use the state of art production technologies and professional tools.

Flexibility in order sizes.

Reduced time-to-market for metal products.

Guaranteed quality and delivery deadlines.

Enables targeted efforts aimed at customer development.

If you are considering going into the process of choosing a contract metal fabricator, we answer all your concerns with the following advantages.

Extensive expertise and experience.

With the experience of 17 years in contract metal fabrication, our multifunctional research and development team, the production experts, and the skilled technical personnel will ensure a professional manufacture of diverse metal components.

DFM design assistance.

In your product development process, we offer design support from the very beginning ensuring that the design aligns with production requirements to keep the production process as optimum as possible and minimize the costs.

Vertical integration in-house production.

Our services will cover all fabrication processes such as cutting, bending, welding, stamping, riveting and surface finishing through internal work. It helps to prevent turnover risks, shortens production time, saves money, and keeps the standard of quality.

Collaboration with renowned clients.

Collaborating with reputable firms like Greely Auto, LiXiang Auto, CRRC, Tesla, etc., we ensure quality and meet deadlines for projects.

Flexible production capacity.

No matter the size of the project, we adjust with flexibility, providing consistent high quality. The Minimum Order Quantity (MOQ) could be as low as one piece, that is, for small projects.

Robotic Technology Integration.

We are using robotic welding and loading technologies, which enhance efficiency and stability in quality control.

ISO16949 Certification.

Aside from being ISO9001-2005 certified, we also apply the more stringent ISO16949 automotive quality management system which translates to optimum customer satisfaction.

NPI (New Product Introduction) Capability.

Innovation is the basis of our R&D department, and this is evident in our 39 patents, which demonstrates our ability of introducing new products.

Advanced Manufacturing Equipment.

We use the modern metal processing equipment that guarantees accuracy and quality of our fabricated products.

DFM (Design for Manufacturing) Skills.

Our team of designers is in charge of design and optimization for manufacturability.

Surface Treatment Proficiency.

Indoor surface treatment processes like powder coating and polishing are used to improve product quality and shorten their turnaround time.

Personnel strength, technological prowess, quality control measures, design services, customer communication, cost management, and delivery efficiency are the parts that should be evaluated when you are looking for the contract metal fabricators.Here’s where we excel:

Personnel Strength:

Our company employs more than 400 people and our facility, which is about 30,000 square meters large, means a significant production capacity.

Technological Prowess:

We employ robotic technology, in addition to advanced equipment such as Amada NCT turret punches and HSG laser cutting machines, for the purpose of speedy fabrication.

Quality Control:

As far as ISO16949 goes, the whole production process goes thorough repeated inspection which eventually guarantees high quality.

Design Services:

We help with improving designs for cost effective manufacturing and provide after sale technical support.

Customer Communication:

Our professionals translate design drawings to production documents in a very rapid way.

Cost Management:

Production processes being integrated and automated are factors that contribute to lowering of production costs.

Delivery Efficiency:

Our robust ERP system actually takes care of production and delivery tracking just in time.

We are certified with ISO9001-2015, ISO16949, ISO14001 and many others. To get this ISO 13485 cert or others, please contact us.

We offer a variety of services including packaging, laser cutting, welding, bending, riveting, stamping, powder coating, and assembly. For more information, please contact us.

Using the production management system of ERP, we monitor the entire production, always keeping the delivery time, without compromising the quality.

Our R&D and engineering team of 22 members provides design, engineering, technical, and manufacturing services.Contact us for assistance.

In compliance with ISO16949, we control all production phases at the topmost level to meet the highest quality standards.

Production planning.

Raw material inspection.

Error prevention control.

First Product Inspection.

Process quality control.

Final product inspection.

Pre-shipment inspection.

Customer feedback and quality improvement.

Fast Reaction to quality issues.

Continuous improvement.

We maintain technical support, assembly assistance, and quick resolutions to any quality issues. Moreover, we aid in the procurement of after-sales parts as well.

We provide the fast sample production to the market testing process. Get in touch with us for additional information, including prices.

Our client portfolio is Aux, Geely Auto, LiXiang Automobile, CRRC, Tesla, Bull, etc, testifying to our authority in contract metal fabrication.