Solution

Masion-Leading Professional sheet metal manufacturing company in China

● In-house production and rapid manufacturing

● Lower delivery times at low cost.

● 17 years of experience in sheet metal design and fabrication

● Extensive collaboration on large-scale projects.

● A 30000-square-meter sheet metal fabrication workshop,

● Serving you with CNC punching, bending, laser cutting, riveting, welding, etc.

● Assisting in designing CAD drawings, or Step drawings for sheet metal parts.

● ISO/TS 16949 certified factory.

+86-18969433502

sales@sheetmetalmasion.com

Total Serviced Clients

4000+

Total Area of Factory

30,000 m3

Part Fabricated/Month

600,000+

Satisfaction Guaranteed

100%

Masion— Your One-Stop Solution for Sheet Metal Manufacturing Needs

We’re an extraordinary sheet metal parts manufacturer in China, providing processing for metal parts with various design requirements. Our facility is equipped with comprehensive one-stop services. These include laser cutting, bending, manual and machine welding, stamping, threading, riveting, chamfering, polishing, brushing, and powder coating. So, if you’re looking for accuracy and high precision, Masion is the best fit to cater to your needs.

Offering Reliable Solutions for Precision Manufacturing

Masion provides professional solutions to produce precise sheet metal parts. We’re annually producing millions of assembled sheet metal parts. Our services provide numerous well-known enterprises. They mainly include TuoPu, Greely Auto, Tesla, Lixiang Auto, AUX, Bull, CRRC, etc. We take great pride in manufacturing highly accurate and precise metal parts for our clients. Our facility is equipped with advanced technologies, i.e. NCT turret punch presses (AMADA), laser cutting machines, bending machines, and automated welding robots. Besides this, our team consists of skilled designers, engineers, and machinists. They ensure the production of high-quality and high-precision custom sheet metal components – consistently recognized by clients. These parts meet the demands of their new business ventures and developments. Masion is confidently handling the most complex and urgent projects. We’re highly dedicated to stringent material requirements. Our experts always ensure the process refinement, and robust capabilities in assembly and design. We assure guarantee of accuracy in each part. So, you can trust our services with your projects. We’re benefiting from our strength and comprehensive service offerings.

Our Sheet Metal Capacity & Unmatched Service

Materials

● Aluminum

A1100P-O,A1050P, AL2024, A5052H32P AL5083, AL6061T6, AL6063T5, AL7075, AL1050, AL1060

● Carbon Steel

SPCC, CRS, SAPH440, SPCD, SPCE, Q195, Q215, Q235, Q255 Q275

● Stainless Steel

SUS301,SUS302,SUS303,SUS304,

SUS316,SUS420,SUS430

● Galvanized steel

St01Z, St02Z, St03Z

Thickness

0.5mm-20mm

Machines

● NCT turret punch press(AMADA)

● HSG 3000W/6000W Laser Cutting Machine

● Yawei Press Brake 110T 3+1axis/ 63T 3axis

● Drilling & Threading CNC

● Chamfering Machine

● YASKAWA /FANUC/PANASONIC Welding Robot

● 3000W Laser Welding

● Precision Grinding Machine

● Large Water Grinder

● Deburring Machine

● Mahatma Leveling Equipment

● AC/DC Inverter Welding Machine

● Argon Arc Welding Machine

● Gas Shielded Welding Machine

Secondary Processing

● Assembly Services

● TIG and MIG Welding

● Robotic Welding

● Spot Welding

● Laser Welding

● CNC Sheet Metal Bending

● Riveting

● PEM and Rivet

● Nut Insertion

● Laser Etching

Surface Finish

● Powder Coating

● Anodizing

● Electroplating

● Trivalent Zinc Plating

● Hot-Dip Galvanizing

● Metal Passivation

● QPQ (Quench-Polish-Quench)

● Dacromet Coating

● Sandblasting

● Polishing

● Silk Screening

● Phosphating

● Baking Paint

● Heat Treatment

● Electrophoretic Coating (E-Coating)

● Physical Vapor Deposition Coating (PVD Coating)

Why Choose Masion to Custom Sheet Metal Parts?

We are a leading custom sheet metal parts company. We’re equipped with advanced machines and expert craftsmanship. Our team of experts ensures smooth and high precision-production efficiency for your sheet metal parts.

We’ve 17 years of experience in the sheet metal industry. During this tenure, we have completed several projects of various sizes. These projects consist of complex tasks and major clients. This extensive experience makes us able to give you efficient and cost-effective custom solutions.

Years of Experience

We’re providing professional technical consultation for your project. They involve experienced engineers and designers. They ensure the smooth progress from design, sample confirmation, and mass production to delivery.

Project Professionalism

We’re experts in producing complex, high-precision sheet metal parts and assemblies. We’ve 20 skilled mold designers who tackle the challenges of stamping and assembly molds. High-precision molds ensure rapid in-house production and quality control.

In-House Mold Design and Manufacturing

Masion serves you with processes, like riveting, automatic welding, bending, powder coating, brushing, polishing, and screen printing. Moreover, we internally control quality and also manage processing costs and time.

Secondary Processing

We complete all sheet metal production processes in-house. Besides this, we maintain a sufficient stock of standard materials. We have an extensive inventory of standard screws and nuts. So, support from suppliers reduces the transit time and quickly completes sheet metal production.

Short Lead Time, High Efficiency

We adhere to ISO9001 and ISO16949 quality management standards in sheet metal production. Moreover, we deliver high-quality,high-precision sheet metal parts and assemblies.

High-Quality Control

We can produce sheet metal parts with high requirements. These may include an IP65 waterproof rating. It has wide applications like energy storage battery casings. So, it guarantees quality.

IP65 Waterproof Rating

Our stamping molds are equipped with mold monitors. They can detect product drops and protect molds from damage.

Mold Monitor

Precise Laser Cutting for Sheet Metal Manufacturing

Masion – equipped with modern laser cutting equipment for manufacturing various sheet metal cutting. We cut sheets made of different materials. These materials may include aluminum, stainless steel, copper, titanium alloy, etc. Additionally, we can cut complex shapes from various square tubes.

Laser Sheet-Cutting Machines

We’ve 4 units, with 3000 watts and 6000 watts. Each one is capable of processing sizes up to 1250 mm*2500 mm. They can deal with thickness ranges from 0.6mm to 20mm.

Laser Tube-Cutting Machines

Masion has 5 units, all 3000 watts, capable of processing square tubes from 20mm*20mm to 100mm*100mm, round tubes with diameters from 20mm to 100mm, wall thicknesses from 0.8mm to 5.0mm, and various special-shaped tubes.

Fully Automatic Tube Cutting Machines:

Our facility has 4 units. They can process square tubes from 20mm20mm to 100mm100mm, and round tubes with diameters from 20mm to 100mm.

Angle Tube Cutting Machines

2 units, capable of cutting various angles according to product requirements.

Dimensional Tolerance

It is generally ±0.1mm, but higher precision requirements can reach around ±0.01mm.

Straightness Tolerance

The straightness tolerance in the same cutting section is generally within 0.2mm. Moreover, the higher requirements are achievable within 0.05mm.

Perpendicularity Tolerance

For vertical cuts, the perpendicularity requirement reaches within ±0.05mm, or even within 0.01mm.

Tolerance Between Parts

Depending on manufacturing requirements and processing forms, the tolerance between parts is generally between 0.1~0.5mm.

Surface smoothness tolerance

The surface smoothness of laser cutting generally reaches a high Ra, which can be around 0.1μm.

High Accurate Bending Dies for Sheet Metal Manufacturing

Masion has established a long-term collaboration with a professional bending mold factory. Besides, simple V-shaped molds, we can also customize other complex non-standard dimensions for bending. That will be able to meet your various intricate bending angles.

1. Bending Die Types

The bending Mold operates in two parts, i.e. the upper die, used to apply pressure, and the lower die which is fixed for shaping. The upper die includes;

– Large R Die

– Segmented Die

– Flattening Die

– 88° Small Bending Die

– Scoring Die

– 88° Goose Neck Die

– 88° Straight Bending Die

– 30° Pointed Die

– 88° Straight Die, etc.

Lower molds include;

– Single V 85°

– Single V 90°

– Double V 90°

– Double V 88°

– Flattening Die, etc.

2. Material Selection & Wear Resistance

Our bending molds are processed using 42CR material. 42CrMo is a high-strength, tough, and specially alloyed steel. It has a wide scope of application in temperatures below 500°C. So, if you have special requirements, we can also use Cr12MoV material for bending molds.

3. Service Life

Generally, our upper and lower molds can be used for 4-5 years and can bend millions of times.

4. Customization and Flexibility

In addition to the conventional bending mold angles, we can customize non-standard dimensions of bending molds. Therefore, you can send us drawings with special bending angles. Moreover, we can customize complex dimensions according to your requirements.

5. Bending Safety

Our bending equipment features an induction stop system. So, if the operator places their hand on the device & presses the switch during operation. Bending equipment will sense the presence of a human hand and stop. It will confirm the safety of our operators.

6. Professional Operators

Our technicians, who operate the bending equipment have many years of experience. They are and are mature professionals. They usually undergo training and assessment before taking up their positions.

7. Accuracy and Quality

We’ve years of professional mold experience and ISO9001 quality certification. So, our bending molds undergo testing according to standards. So, they can ensure precision.

8. Quick Turnaround

Our bending equipment has a quick-change function. So, it reduces the time wasted on changing bending molds. Moreover, it shortens the production time.

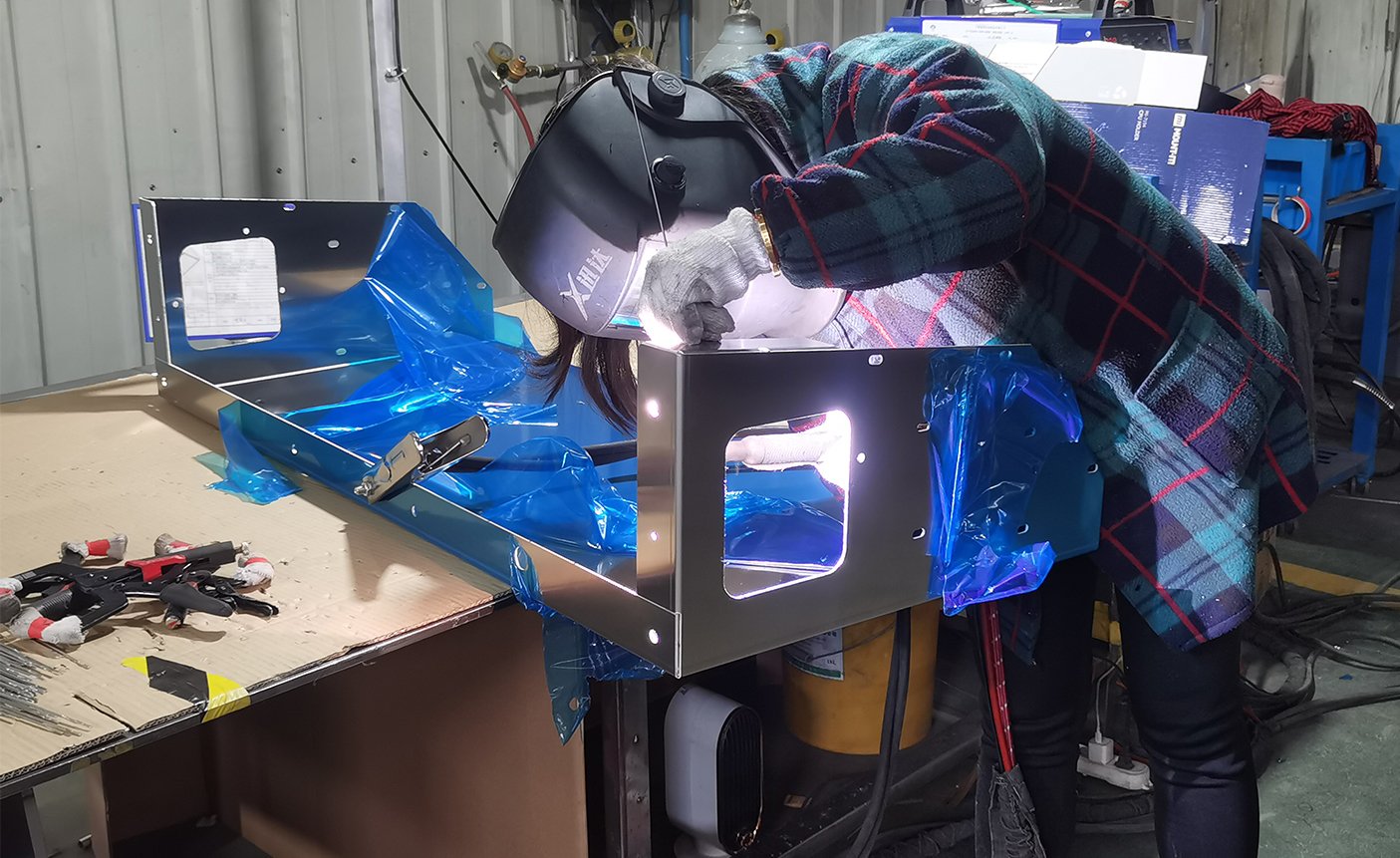

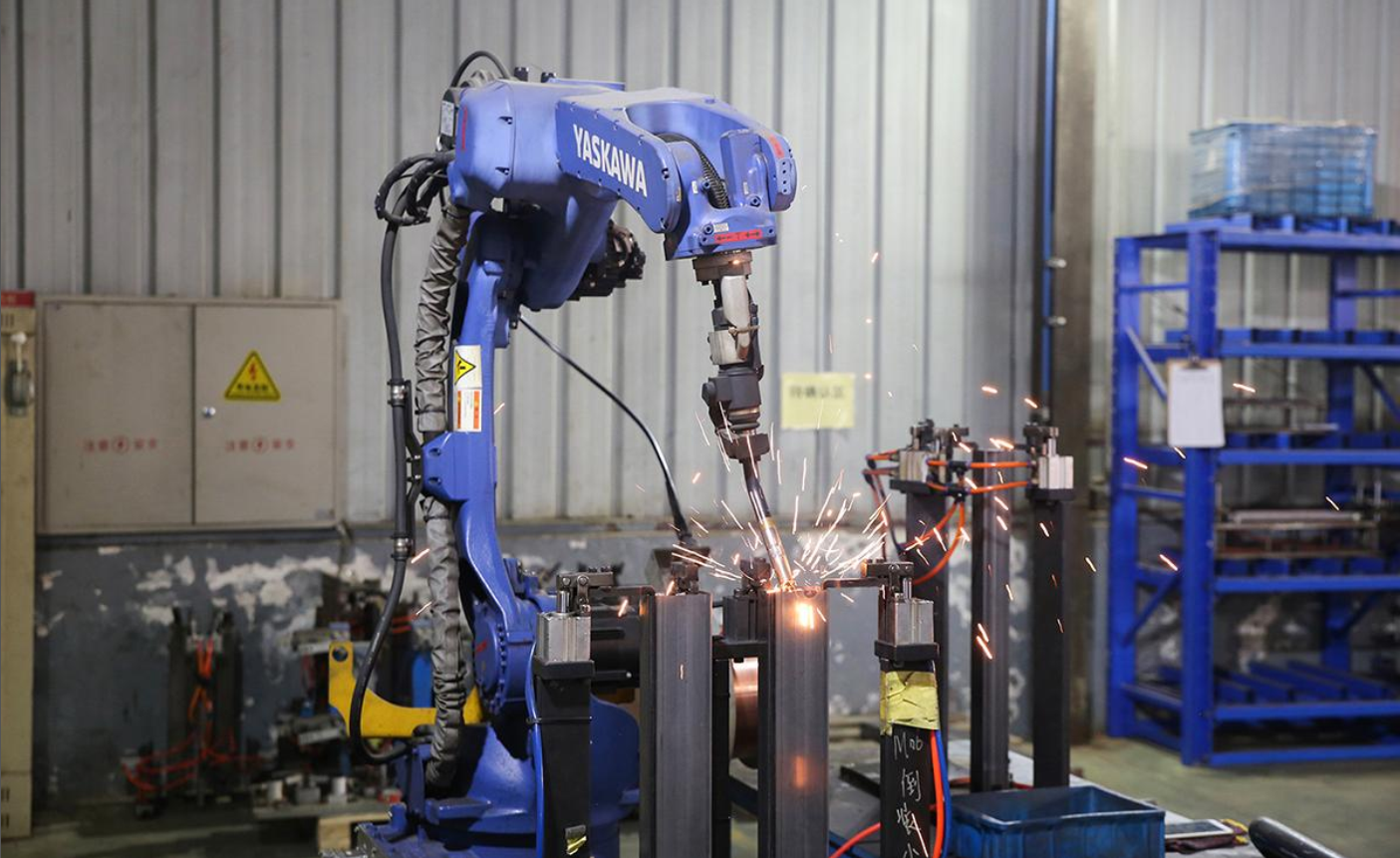

Manual, Laser, and Robotic Welding of Sheet Metal Parts

Masion uses laser equipment and robotics for welding. These options allow us to handle complex projects with different quantities and specs. We use manual welding for small processes. On the other hand, laser or robotic welding is frequently used in large quantities. Our every process complies with quality standards. We can deal with various types of metals. These may include stainless steel, aluminum alloys, brass, zinc alloy sheets, copper, carbon steel, and more.

We’re using conventional welding processes, i.e. TIG, MIG, etc. Generally, we conduct visual inspections and use special solutions to check for quality issues in welding. These may include incomplete welding or welding leaks. Additionally, we can perform stretch tests, X-ray examinations, ultrasonic testing, and other inspections based on customer requirements. It allows us to deliver high-quality and high-standard sheet metal parts to your hands.

We’ve 20 robotic welding machines and 3 laser welding devices. These all can meet the requirements for large-scale production of sheet metal parts. Moreover, they guarantee the precision and efficiency that manual welding cannot replace. Robotic welding application is typically reserved for significant projects and large quantities of sheet metal components. While they increase production efficiency. Robotics welding can handle the welding of complex-shaped sheet metal parts and operate continuously for 24 hours. Therefore, it is specifically suited for large quantities and similar types of sheet metal components.

Precise Surface finish of sheet metal parts

In-house Surface Treatment of Sheet Metal Parts for Cost Reduction and Shortened Lead Times, including in-house Surface Finish of sheet metal parts

● Electrostatic Powder Coating

● Brushed Finish

● Polishing

● Silk Screening

● Sandblasting

Outsourcing Surface Finish of Sheet Metal Parts Including

● Anodizing

● PVD Coating (Physical Vapor Deposition)

● Dacromet Coating

● Electroplating

● Baking Paint

Certificate of Sheet Metal Parts

We’ve 17 years of experience in sheet metal manufacturing. Since then, we are complied with quality standards. Here are our certifications.

● ISO9001 Quality Management System

● ISO14001 Environment Management System Certification

● TS16949 Automotive Industry Quality Management System

● FSC Forest Stewardship Council

● Patent 47 patents of invention

● CE CONFORMITY EUROPEENNE(As you need we could apply)

● RoHs Restriction of Hazardous Substances(As you need we could apply)

● SGS (As you need we could apply)

● TUV(As you need we could apply)

Diversity of Our Sheet Metal Parts

Masion can deal with small to large-size product manufacturing. We can deal with all the complex and simple designs quickly

Explore the Diverse Sheet Metal Industries

Sheet metal components have a wide scope of applications in various industries. They’re usually encountered in our daily routines. They are used in the manufacturing of electric vehicle charging station housings, within the banking and automatic teller machine (ATM) industry, and in the new energy sector as well. Moreover, sheet metal components are also used in industries such as robotics, fitness equipment, construction, machinery, consumer goods, etc. So, here are some commonly used sheet metal component applications in various industries:

● X-ray Machine, CT Scanner, Ultrasonic Instrument

● Housings Medical File Cabinets, Wardrobes, and Drawer Monitor

● Stand for Patient Monitors and Ventilators

● Operation Panels and Display Screen Mounts for Medical Instruments

● Medical Lights and Mounts in Operating Rooms and Examination Rooms

● Metal Medication Boxes, AED Metal Casings

● Protective Covers for Medical Instruments

● Metal Trays for Surgical Instruments

● Electric Hospital Beds

● Electric Transfer Lifts

Medical Industry

● Enclosures for Base Stations, Communication Terminals, and Routers

● Cabinets and Chassis for Communication Equipment

● Brackets for Antennas

● Connection Boxes

● Power Boxes

● Heatsinks and Heat Plates

● Display Screen Mounts

● Fiber Distribution Boxes

● Wall Mount Brackets, Sensor Housings

Communication Industry

● Transformer, Cable Junction Box, Power Capacitor Housings

● Cable Trays and Supports

● Battery Boxes and Supports in Power Equipment

● Control Cabinets and Instrument Panels for Power Equipment

● Heatsinks and Heat Plates for Power Equipment

● Cable Connection Boxes

● Insulation Covers and Insulation Boards for Power Equipment

● Switch Boxes and Circuit Breaker Housings

● Supports and Bases for Power Equipment

Electrical Power and Equipment Industry

● Solar Panel Mounting Bracket

● Wind Turbine Generator Housing

● Battery Energy Storage System Housing

● Battery Pack Mount

● Charging Station Housing

● New Energy Vehicle Housing

● Solar Water Heater Housing

● Photovoltaic Inverter Housing

● Solar Photovoltaic Mounting Bracket

● New Energy Equipment Heatsink

● Home Energy Storage Battery Housing

New Energy Industry

Other Manufacturing Solutions

Masion is not limited to Sheet Metal Manufacturing. We’re offering other techniques to cater to your needs.

Sheet Metal Assembly

Metal Tube Fabrication

Laser Cutting

We provide sheet metal parts assembly services, suitable for large, small, various projects complex sheet metal parts assembly.

We’re offering custom processing service solutions for various circular, square, and special-shaped metal pipes

Our services cater to all custom solutions for precision laser cutting services for various materials and complex shapes.

Plastic Injection

Stamping

Contract Manufacturing

Masion provides manufacturing solutions for assembly injection molding parts and supporting processing services.

We’re providing manufacturing solutions for progressive and compound molds, providing precision stamping parts production services

Masion provides vertical production and assembly solutions for sheet metal parts services

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

Frequently Asked Questions

A: In the fabrication of sheet metal cabinets, we mainly process aluminum, carbon steel, stainless steel, and galvanized steel. For other sheet metal stamping or laser cutting, we can also process titanium alloy, brass, copper, and other materials.

A: The thickness of materials we commonly process for sheet metal cabinets is generally below 6mm, often dealing with sheet metal thicknesses of 1-4mm. For other sheet metal parts, we can process thicknesses below 20mm. If you have particularly thick materials, we can also discuss this as we use other processes such as plasma cutting and flame cutting to process thicknesses up to 300mm.

A: We generally have technologies such as robotic feeding, and robotic welding, and also imported NCT Amada stamping equipment, bending machines, HSG laser cutting, etc. As a vertically integrated sheet metal manufacturer, we internally handle stamping, cutting, bending, welding, riveting, surface coating, assembly, packaging, and all other sheet metal processing technologies, capable of handling all your sheet metal processing needs. Please contact us.

A: Feasibility Study Report: We perform computer simulations on sheet metal drawings to ensure the accuracy of the drawings and production. If any unreasonable aspects are found, we will assist you in making adjustments and modifications.

1. Material Inspection: We first trace the materials using a QR code and check the material report to ensure the accuracy and consistency of the material grade and batch number.

2. Production Process Error Prevention: Using color codes or markings to identify the production of different parts, such as automotive sheet metal left and right parts, to prevent confusion.

3. Jigs and Fixtures, Mould Error Prevention: Error prevention designs are applied to jigs, fixtures, or molds to avoid processing mistakes or incorrect orientation. Processing can only proceed if the material is placed correctly.

4. Automatic Monitoring: Our progressive die stamping uses monitoring systems to watch over the molds. If a problem occurs, it will automatically alarm and stop the machine.

5. Quality Inspection: First Sample Inspection: Before the production of sheet metal parts, we confirm that the dimensions of the first piece meet the drawing requirements, then use a first sample inspection tag for comparison with later parts.

6. Process Inspection: Our quality department personnel regularly inspect production process dimensions and keep records to ensure consistency and accuracy in manufacturing. Final Inspection: After sheet metal parts are processed, we measure every dimension, visually inspect the appearance, and also perform other functional tests, such as pressure resistance testing, gravity testing, waterproof testing, etc.

7. Quality Inspection Report: We have inspection reports for all inspections, which are kept for traceability. If there’s an issue with sheet metal parts, we can ultimately trace back to which step the problem occurred.

8. Employee Training: We provide training on equipment operation for our employees and regularly train them in quality management to ensure they are aware of quality issues and can respond promptly when issues arise.

A: So, here are some facts that will help you trust us.

1. First, our factory has 30,000 square meters of space and 6 production plants. We are a genuine sheet metal factory with rich technical experience.

2. Our clients include Greely Auto, Tesla, Ideal Auto, CRRC, Chisagess New Energy, Bull, Aux, and other brands. Therefore, you can trust our strength.

3. We have passed ISO9001-2015, ISO16949, ISO14001 certifications. If you need other certifications, you can contact us.

4. Our strong team can facilitate communication on technical and product issues, and professionalism can get your project into production and market quickly.

5. We have robotic feeding, welding equipment, and other advanced bending machines, stamping machines, riveting machines, etc. Therefore, you can trust us to handle your projects properly.

A: Several factors contribute to our distinct services;

1. DFM Design Support: Our design and development team can provide early-stage design support for sheet metal projects, optimizing design and production processes.

2. More Cost-Effective: Being a vertically integrated factory, we manufacture in-house sheet metal processes including stamping, laser cutting, welding, riveting, surface treatment assembly, etc., reducing turnaround costs and quality issues while also lowering production costs.

3. Faster Delivery: Our robust ERP production management system monitors every production process stage, making sheet metal manufacturing smoother and more efficient, shortening the entire production time.

4. Higher Quality Assurance: We produce sheet metal parts strictly according to the ISO16949 quality management system, with testing and traceability at every step, ensuring consistency and precision in production.

5. NPI Support: We have an experienced R&D design team and periodically update our products. With up to 47 patents, you can collaborate with us on designing and developing new products.

A: We have passed the ISO9001-2015 quality management certification, ISO16949 automotive quality management certification, and ISO14001 environmental protection certification. If you need ISO13485 certification, you can discuss it with us.

If you collaborate with us for sheet metal manufacturing, our payment methods are generally TT, PayPal, or any other method you accept. The lead time depends on the project size. Here small projects take 7-10 days, and large projects take 25-30 days. For more detailed lead times, please contact us.

If sheet metal parts require installation, we can provide installation instructions. If there are, we offer technical support and assistance. All to serve our esteemed customers.

A: In addition to sheet metal processing services, we can also engage in stamping mold design, development, and manufacturing. Moreover, if you need CNC machining, we can also assist with that because we have CNC machining centers.