The Ultimate Guide to Stainless Steel Sheet

Stainless steel is liked by manufacturers due to unique presence of chromium in it. The metals combined as one can be unique however they all demonstrate in comparable ways. Stainless steels are metals made generally of iron and somewhere around 10. 5% Chromium makes a defensive layer on a superficial level that prevents the iron from rusting. There are various types of stainless steel. They can be arranged into three categories in view of their design, and how they are treated with heat. So, these are: martensitic, austenitic, ferritic, duplex, and precipitation-hardenable. Let’s discuss in detail about tier types, grades, finishes, and thickness, etc.

Table of Contents

ToggleTypes of Stainless Steel Sheets

Austenitic Stainless Steel:

Austenitic stainless steels are extremely normal and are utilized in various ways. They have a construction like high-temperature iron. Due to the presence of essential metals, this can be divided into two types: one with chromium and nickel (Cr-Ni) and another with chromium, manganese, and nitrogen (Cr-Mn-N). Austenitic treated steel is incorporated 16-26% chromium, a microscopic extent of carbon, up to 35% nickel, up to 15% manganese, 0. 75-3% silicon, and 0. 045-02% phosphorus. Sulfur, nitrogen, molybdenum, selenium, copper, titanium, tantalum, niobium, and cobalt are just a few of the various metals that can be found in some varieties.

The standard austenitic party contains such solidified steel: 201, 202, 205, 301, 302, 303, 304, 305, 308, 309, 310 314, 316, 317, 321, 330, 347, 348, and 384.Utilizations of this material includes: blades, screws, compartments for holding liquids under tension, compartments for blending synthetic compounds, vehicle exhaust frameworks, and parts for water-powered machines. Austenitic stainless steel is valuable in terms of strength for its adaptable properties.

Mechanical Properties

- Fantastic work hardening rate

- Great capacity to stretch and twist without breaking, and strength.

- High tensile strength

- Solid protection from bowing and sleepiness.

- High protection from rusting (up to 650 degrees Celsius)

- Can endure heat up to 650 degrees Celsius.

- Incredible capacity to weld well.

| Grades | Attributes |

| Grade 304 | One of the most widely recognized sorts of stainless steel. Its enormous measure of Chromium and Nickel pursues it a famous decision for making handling gear for the substance, food/dairy, and drink businesses. This grade has high strength for opposing erosion, and it’s additionally simple to work with. |

| Grade 316 | This stainless steel has 18% chromium, 14% nickel, and added molybdenum, which together make it more impervious to rust. In particular, the molybdenum assists with forestalling erosion assault. This grade can deal with high temperatures up to around 1600 degrees Fahrenheit. Kind 316 is utilized in taking care of synthetics, making paper, dealing with food and beverages, and in extreme circumstances. It is additionally utilized in the water business since it doesn’t rust. |

| Grade 317 | Utilized in places that have a great deal of rust since it has more molybdenum than 316. This quality necessitates having over 3% Molybdenum. Frequently utilized in scrubber frameworks of gadgets that control air contamination, they are utilized to eliminate particles as well as gases from modern exhaust. |

| Grade 321 | Contains multiple times more titanium than carbon. This expansion is utilized to lessen or kill the development of chromium carbide during welding or when presented for high temperatures. Used in the space and aeronautics industry. |

| Grade 347 | Type 347 stainless steel has somewhat better security against rust in very oxidizing conditions contrasted with type 321 stainless steel. Grade 347 is really great for things that should be warmed occasionally between 800ºF (427ºC) and 1650ºF (899ºC), or for welding in conditions that don’t consider a post-weld strengthen. |

Ferritic Stainless Steel:

Ferritic solidified stainless steel has a particular sort of sythesis called ferritic body-focused cubic. The chief part in this combination is chromium, which makes up between 10. 5% and 30%, and there isn’t more than 0. 2%. As combinations of iron and chromium (Fe-Cr), these metals are accumulated. Blends are also made with a variety of metals like molybdenum, silicon, aluminum, titanium, and niobium. Aluminum and titanium are meant to guarantee that each material will develop in a particular way. The underlying sort of hardened steel is 430, and the blend is changed to create explicit outcomes. 430 and 434 are kinds of extraordinary treated prepares, and 409 and 439 are sorts of second-age solidified prepares. 444 is an exceptionally important sort of tempered steel.

At any temperature, the superferritic steel has no austenitic examples. Utilizations of this material include: making contraptions for overseeing food, pipes for conveying fluids, gear for heat trade compound cycles, making barbecues and kitchen sinks, and building frames for sun controlled chargers in warm and dry regions. The characteristics of ferritic treated steel are: Work setting happens less when how much work increments.

Mechanical Properties

- Moderate adaptability and strength.

- Solid when pulled (cold).

- Solid capacity to endure bowing and not getting drained effectively in cool circumstances.

- Moderate capacity to oppose getting harmed by rust.

- Genuinely impervious to direct temperatures

- Challenging to weld

- Generally excellent reaction to magnets.

| Grades | Attributes |

| Grade 430 | An essential trademark that isn’t as great at opposing erosion as Type 304. This kind of material can oppose harm from substances like nitric corrosive, sulfur gases, and a few sorts of food and natural acids. |

| Grade 405 | This type has less chromium and has aluminum added. This synthetic combination helps prevent from getting hard when it’s chilled off from being truly hot. Normal purposes incorporate gadgets that move heat starting with one liquid then onto the next. |

| Grade 409 | Grade 409 is a sort of stainless steel. This sort of stainless steel is less expensive because it has less chromium in it. This type ought to just be utilized for things inside or outside that will not get harmed in cruel circumstances. Fundamental applications incorporate suppressor circulation. |

| Grade 434 | Grade 434 is an excellent grade stainless steel. This sort has more Molybdenum in it, which assists it with opposing erosion better. Ordinary purposes can include vehicle designs and screws. |

| Grade 436 | This metal has columbium in it to make it impervious to rust and intensity. A ton of regular things use parts made by extending metal. |

| Grade 442 | Further developed protection from change since there’s more Chromium in it. Applications can incorporate parts for heaters and radiators. |

| Grade 446 | Besides, adding more chromium assists with making the metal more impervious to rust and scaling when presented to high temperatures. This grade is great at opposing harm from oxygen in the air with sulfur. |

Duplex Stainless Steel:

Both ferritic (body-centered cubic) and austenitic (face-centered cubic) structures make up duplex stainless steel. Each phase’s size is determined by its material and heat treatment. In comparison to austenitic stainless steel, duplex steel is stronger and more resistant to chloride-induced cracking.

Additionally, duplex steels are exceptionally resistant to pitting corrosion. It is tougher than ferritic steels, but not as tough as austenitic steels. This alloy is mostly made of nickel and chromium. Most duplex stainless steels contain between 22 and 26 percent chromium, 4 to 7 percent nickel, up to 4.5 percent molybdenum, about 0.7 percent copper and tungsten, and 0 to 035 percent nitrogen.

We deliberately keep the amount of carbon below 0.6 percent, which improves the steel’s resistance to corrosion greatly. Depending on their composition, duplex stainless steels can be divided into four groups. Additionally known as lean duplex 2304, regular duplex 2205, very strong duplex 2505, super strong duplex 2507, and super strong hyper duplex with 2707 included.

The oil and gas industry, plants that make salt water, plants that remove salt from seawater, and tanks that store wet CO2 gases are all examples of applications for this material. In terms of its strength and durability, duplex stainless steel possesses a number of characteristics.

Mechanical Properties

- The rate at which a material becomes more durable after being laboriously worked.

- Heat cannot be used to treat toughness and ductility.

- Excellent capacity to withstand pulling forces (at temperatures that are moderate).

- Strong resistance to bending and breaking (at moderate temperatures)

- Excellent resistance to rust and decay.

- Ability to withstand temperatures that are neither too hot nor too cold.

- Quite simple to weld.

- Attraction to magnets is moderate.

| Grades | Attributes |

| Grade 2205 | The best option for locations with high pressure and extremely rough conditions is Duplex 2205. It also resists rust and wear and tear well, expands less when heated, and is better at transferring heat than austenitic. This grade ought to just be utilized at temperatures under 315 °C on the grounds that openness to higher temperatures can make the material fragile. |

| Grade 2305 | Grade 2304, also known as grade two hundred and four. The applications for Duplex 2304 are comparable to those for Alloys 304 and 316L. It is nearly twice as strong as 304 and 316, but it is resistant to rust and has almost the same or slightly better qualities. It is usable in temperatures ranging from -50 to 300 degrees Celsius. This item is extremely durable and resistant to stress and corrosion. It is simple to weld, machine, and shape. |

| Grade 2507 | Grade The stainless steel Duplex 2507 has a high degree of strength. It is used in chemical processing, oil refineries, and equipment that is used in seawater in applications that require a lot of strength and resistance to rust. This quality resists damage from chloride, cracking, and heat very well, and it also shrinks very little when it gets hot. The material is extremely resistant to wear, corrosion, and rust due to the combination of chromium, molybdenum, and nitrogen. |

Martensitic Stainless Steel:

This kind of stainless steel has high strength when it is solidified. Martensitic stainless steel is comprised of iron, chromium, and carbon organized with a specific goal in mind. How much chromium in it is between 10. 5% and 18%, and it doesn’t have more than 1. 2% carbon in it. The 403 grade is a basic sort of stainless steel. Different grades have various fixings to cause them to have various properties. The martensitic bunch comprises of the accompanying kinds of steel: 403, 410, 414, 431, 422, 420, 416, and 440. This gathering is typically utilized in things like stream motors, gas turbines, valves, blades, petrochemical gear, and clinical instruments. Martensitic stainless steel has supportive mechanical properties.

Mechanical Properties

- Moderate expansion in strength while buckling down.

- Capacity to change the properties of a material by warming it.

- Great adaptability and strength

- Solid pulling power

- Great capacity to endure bowing and not get drained without any problem.

- Reaction to magnets

| Grades | Attributes |

| Grade 410 | A basic sort of steel that has fewer metals alloys in it. The stainless steel can be warmed and utilized for different things. Frequently utilized in conditions where rust is not matter of concern, as within the sight of air, water, a few synthetic compounds, and food acids. Things for this grade should be of high strength to rust, similar to screws and fasteners. |

| Grade 410S | Type 420 has less carbon than Type 410 and is more straightforward to weld, yet it doesn’t solidify a lot. This metal is really great for rising up to rust and staying warm. It’s called chromium steel. |

| Grade 414 | Grade 414 is the level or score that somebody gets in their everyday schedule on a test. This type has more Nickel (2%) to oppose rust better. Normal purposes incorporate springs and blades. |

| Grade 416 | The Phosphorus and Sulfur in this material make it more straightforward to work with machines. Screw gear parts are in many cases utilized in average applications. |

| Grade 420 | Grade 420 is a good type of stainless steel. Expanding the carbon in this sort further develops how extreme it is. Normal purposes incorporate careful apparatuses. |

| Grade 431 | Further developed chromium in web content makes it more impervious to rust and gives high strength for its properties. The purposes of this alloy is offering high strength for products like valves and siphons. |

| Grade 440 | Expanding the degrees of Chromium and Carbon makes this type more grounded and more impervious to consumption. You can utilize it in instruments for a medical procedure. |

Precipitation Hardening Steel

PH stainless steel is another name for stainless steel that hardens by precipitation. Heat treatment has the potential to strengthen it. Unlike other materials, this one has the unique properties of being strong, heat-resistant, rust-resistant, and easy to work with. 17Cr-4Ni (17-4PH) and 15Cr-5Ni (15-5PH) are the names of these grades.

| Grades | Attributes |

| Grade 17-4 | It includes chromium, copper, and nickel makes it a strong stainless steel alloy 17-4. It is used on things that need to be really strong and have a little bit of rust resistance. It can last long and doesn’t rust effectively in warm and clammy circumstances. This kind of material can be used to build many different kinds of buildings at different temperatures. This grade of material should not be used in temperatures below freezing or above 300 degrees Celsius. |

| Grade 15-5 | A more recent variety of stainless steel can be found in this. The 15-5 alloy outperformed the 17-4 alloy in terms of strength. It is used in applications that require greater side-to-side strength and resistance to rust than other martensitic materials with similar properties. |

Common Stainless Steel Grades

200 Stainless Steel Series

201 Stainless Steel

Austenitic stainless steel with manganese, nickel, and chromium falls in 201 stainless steel. When compared to other grades of stainless steel, it is renowned for its high resistance to erosion, formability, and moderately cost-effective properties. It is frequently used in automobile trim, kitchen appliances, and cookware.

202 Stainless Steel

Like 201 stainless steel, 202 stainless steel is an austenitic stainless steel alloy with a lower nickel content and a slightly higher chromium content. It is frequently used in utensils, kitchen sinks, and architectural applications due to its excellent resistance to erosion.

300 Stainless Steel Series

301 Stainless Steel

It is Cold-workable chromium-nickel austenitic stainless steel. It has high-quality properties and excellent resistance to erosion. Applications like springs, clasps, and fundamental components call for high quality and direct erosion resistance.

303 Stainless Steel

The austenitic stainless steel amalgam 303 may be free-machining and contain sulfur and selenium to enhance its machinability. It resists erosion very well, especially in situations that aren’t too destructive. 303 stainless steel is frequently used for machining applications like jolts, nuts, screws, gears, and shafts due to its excellent machinability. However, compared to other austenitic stainless steel grades like 304 and 316, it is less resistant to erosion.

Stainless Steel 304

304, the most common type of stainless steel, accounts for more than half of the total production of stainless steel. With 18 to 20 percent chromium and 8 to 10 percent nickel, 304 is extremely durable and resistant to erosion. It also boasts excellent formability in addition to straightforward machinability and weldability. Kitchenware, channels, chemical holders, and building boards are just a few examples of the many uses for 304 stainless steel, which is also known as UNS S30400.

Stainless Steel 309

High-temperature austenitic stainless steel with nickel and chromium known as 309 stainless steel. It is suitable for heater parts, warm exchangers, and high-temperature chemical preparing gear due to its excellent erosion resistance and high-temperature quality.

Stainless Steel 316

316 is the best choice for harsher conditions that expose it to chlorides and acids. With 16 to 18 percent chromium, 10 to 14 percent nickel, and 2 to 3 percent molybdenum, 316 resists setting and push erosion breaking. Erosion protection is enhanced by the molybdenum inclusion. Debilitate manifolds, chemical handling equipment, surgical instruments, and marine components are just a few of the applications. 316, in conjunction with UNS assignment S31600, provides widespread erosion resistance.

321 Stainless Steel

321 stainless steel may be a stabilized combination of austenitic stainless steel and titanium to prevent chromium carbide precipitation during welding and high-temperature application. It is frequently used in applications that require high temperature and erosion resistance, such as debilitate frameworks for flying machines, fly motor parts, and chemical preparing gear. It also has excellent resistance to intergranular erosion.

400 Stainless Steel Series

Stainless Steel 409

Ferritic 409 steel achieves valuable strength without nickel’s detrimental effects thanks to its 11-13 percent chromium content but lack of nickel. 409 maintains workability and machinability while maintaining a higher erosion resistance than the average austenitic steel. However, it is neither as strong nor as sparkly. Heaters and capacity tanks are among the many possible applications. Additionally, 409, or UNS S40900, is a cost-effective option for devices due to its low price point.

Stainless Steel 416

A free-machining martensitic stainless steel amalgam with sulfur could be 416 stainless steel. It is high-quality, high machinability, and resistant to erosion. 416 stainless steel is frequently used in applications where ease of machining is essential, such as jolts, nuts, screws, shafts, and pump components. However, its erosion resistance is lower than that of other stainless steel grades like 304 and 316.

Stainless Steel 420

420 stainless steel might be a martensitic-treated steel mix containing chromium. It is well-known for its high hardness, resistance to direct erosion, and ease of machining. 420 stainless steel is frequently used in surgical instruments, cutlery, and dental and surgical equipment due to its high wear resistance and tall carbon content, which can be solidified through heat treatment.

Stainless Steel 430

430, the second most widely used ferritic steel after 409, also avoids nickel for cost reasons. The 16 to 18 percent chromium content improves aesthetics and erosion resistance. However, the requirement for nickel has an effect on ductility and formability. 430, also known as S43000, is a reasonable and useful choice for the chemical industry. Common applications include car trim, kitchen appliances, and hardware like tanks.

What Is a Stainless-Steel Surface Finish?

The finishing forms that are associated with stainless steel make it possible to customize its appearance:

- Mirror-Finish is a chrome-like, profoundly intelligent wrap up that is applied by rolling and cleaning. Incorporates esteemed appearance for applications like plan and excess items.

- Brushed Wrap/Finish: A matte surface with straight brushstrokes that can’t be missed across the scraped area. It demonstrates contemporary fashion and conceals fingerprints.

- Embossed Finsih: Designed impressions are rolled into the stainless surface to give it more flair. Special colored finishes are included in coatings made of titanium nitride.

- Bead Blasting—When glass or metal globules are pressed against stainless, the result is a uniform, matte surface that is ideal for concealing scratches.

- Electropolishing is used in electropolishing to remove surface roughness and smooth the metal for sterile and streamlined surfaces.

- Colored Finishes: Passivation or physical vapor statement implants made of stainless steel are covered in solid colors like dark oxide (gunmetal), rose, bronze, and others. The chosen surface finishes change the look of stainless steel from utilitarian to luxurious as needed.

Applications of Stainless Steel in Various Fields

Sinks and water heaters make up the majority of kitchen appliances, while washing machines make up the majority of household appliances. Efforts to recycle and conserve energy will require more stainless steel in the future.

Most train and automobile exhaust systems are made of stainless steel. About 20 to 30 kilograms of stainless steel are used in each vehicle’s exhaust system. The most significant application for this kind of metal is the requirement for approximately one million tons of stainless steel each year.

Recently, there has been a significant rise in demand in the construction sector. For instance, approximately 5000 tons of shiny steel were used in the protective devices in Singapore’s subway stations. Since 1980, the use of stainless steel in construction has skyrocketed in Japan. It is mostly used to make roofs, decorate buildings inside and out, and make building materials.

In the 1980s, roofs in Japan’s coastal areas were constructed from bare 304 material. But they started using painted stainless steel instead to keep it from rusting. For roofs, a robust type of rust-resistant stainless steel was produced in the 1990s. Additionally, they devised various approaches to enhance the surface’s appearance.

Stainless steel is utilized by civil engineers in Japan’s dam intake towers. Salt is spread on roads and bridges to prevent them from freezing in cold regions of Europe and the United States. They use stainless steel bars instead because this causes the metal bars inside to corrode more quickly. Around forty locations in North America have begun installing stainless steel bars on their roads in the past three years. It has been used by 200 to 1000 people in each location. It is anticipated that demand for stainless steel will rise in the future.

Protecting the environment, making stainless steel last for a long time, and making use of more technology will all contribute to its increasing use in the future. From an environmental perspective, machines used to reduce dioxin emissions will require more heat-resistant stainless steel that can withstand high temperatures.

Waste incinerators, power plants that make use of liquefied natural gas, and more energy-efficient coal-fired power plants are examples of these machines. Additionally, it is believed that stainless steel will be used to construct the battery cases in fuel cell automobiles, which are anticipated to begin use at the beginning of the 2000s.

Water treatment systems will require more rust-resistant stainless steel. In order to extend the life of bridges, highways, and tunnels, stainless steel is increasingly being used in Europe. It is also anticipated that this will occur elsewhere in the world. The majority of homes in Japan only last 20 to 30 years before they need to be thrown away, resulting in a significant waste problem.

Stainless Steel Thickness Chart

The thickness that has been measured on stainless steel (such as 1 mm, 2 mm, 3 mm, 4 mm, and so on) is referred to as the standard thickness. The measured thickness of stainless steel, which is typically accurate to two decimal places (such as 0.85 millimeters, 1.91 millimeters, 2.75 millimeters, 3.80 millimeters, and so on), is what is meant by the term “real thickness.”Let’s explain some stahinless steel thickness sheets sizes.

1MM Thickness

So, stainless steel sheets come in a variety of thicknesses that can be tailored to specific applications. A sheet with a thickness of one millimeter is ideal for specifying and enhancing boards, promoting adaptability and ease of use for fine applications.

2MM Thickness

A 2mm thick hardened steel sheet is regularly used in like decorative creation, for example, for contraption parts and vehicle parts. It gives an incredible change between versatility for molding and adequate quality for extreme use.

3MM Thickness

A sheet with a thickness of 3 millimeters is preferred for basic applications that demand higher quality. It is used to construct brackets, bolster outlines, and other components where rigidity and resistance to misalignment are essential.

4MM Thickness

The 4mm thick tempered steel sheet is appropriate for rock solid applications where high quality and unimportant flexibility are indispensable. This thickness is oftentimes picked for building designs and parts in brutal marine circumstances. Taking advantage of stainless steel’s remarkable strength and resistance to erosion, each thickness option is determined by the specific requirements of the application.

0.85MM Thickness

A 0.85mm thick stainless steel sheet is incredibly versatile, making it fitting for applications that require confounded bowing and cutting, for example, in equipment separated regions and quick and dirty upgrading work.

1.91MM Thickness

When compared to standard 1mm sheets, a 1.91 mm thick sheet offers a little more rigidity without sacrificing much adaptability. It is ideal for slightly more demanding production requirements, such as lightweight boards and complex apparatus component groups.

2.75MM Thickness

The 2.75mm thickness is solid, giving additional quality and decreased flexibility, going with it an incredible decision for additional critical helper parts that actually require a couple of level of molding, similar to medium-obligation sections and frames.

3MM Thickness

Sheet of stainless steel measuring 3 millimeters with a plastic coating applied to safeguard the surface during material handling and transportation. Our fully certified 3mm stainless steel sheet is made with stainless steel that comes from reputable mills. Certification in mechanical and chemical aspects is available upon request.

3.80MM Thickness

Finally, last but not least, a 3.80mm thick sheet is almost lining the qualities of plate steel, promoting high quality and unimportant bending underneath stretch. It is ideal for use in applications requiring significant affect resistance, security boundaries, and overwhelming auxiliary components.

How to Choose Thickness for Stainless Steel Sheet

For various applications, stainless steel sheets are available in various thicknesses. It is very important to choose the right thickness for your project if you want it to work well and last a long time. Let’s take a look at the various thickness options available for stainless steel sheets.

| THICKNESS RANGE | COMMON APPLICATIONS |

| Thin (30-15 gauge) | It is highly used in automotive parts, kitchen backsplashes, decorative purposes |

| Medium (14-8 gauge) | You can use it in countertops, food processing types equipment, medical instruments, and construction |

| Thick (7 gauge and thicker) | So as in Industrial equipment, heavy-duty machinery, and structural applications |

Thin Stainless Steel Sheeting (30-15 gauge)

Thin stainless steel sheets are designated “sheet metal” and can go in thickness from 0. 012 crawls to 0. 065 inches It can be used for decorations, kitchen walls, bent-and-light objects like car parts, etc. There are many advantages to thin stainless steel sheets, such as:

- Easy to work with: Thin sheets are simple to cut and bend into any shape you want.

- Lightweight: Thin sheeting is lighter than thicker options, making it easier to transport and move around.

- Cost-effective: If you’re on a tight budget, thin sheets are a good option because they typically cost less than thicker ones.

Medium Thickness Stainless Steel Sheeting (14-8 gauge)

Due to their strength but still flexibility, medium-thick stainless steel sheets are frequently utilized. Steel can be as thin as 14 gauge (0.075″), or as thick as 8 gauge (0. 165 It’s used for countertops, food equipment, medical instruments, and buildings, among other things. Stainless steel sheeting with a medium thickness has numerous advantages.

- Durability and strength: Medium sheeting is more durable and strong than thin alternatives.

- Flexibility: You can still cut and bend medium sheeting into the shape you want.

- Corrosion resistance: Because medium sheeting does not rust, it can be used in environments that are extremely demanding on materials.

Thick Stainless Steel Sheeting (7 gauge and thicker)

For applications requiring the highest quality and durability, thick stainless steel sheeting is ideal. It is used in mechanical gear, heavy-duty equipment, and basic applications. It is thicker than 7 gage (0.1875 inches) and is used in these applications. There are a few interesting things about thick stainless steel sheeting:

- Quality: Overwhelming forces and high temperatures can be withstand by thick sheeting.

- Solidity: The most long-lasting option is thick sheeting, which also has a long lifespan.

- Stability: The thick sheeting provides excellent back and stability. Once you understand the various thickness options for stainless steel sheeting and their applications, you can make an informed decision based on your specific requirements.

Factors to Consider When Choosing Stainless Steel Sheet Thickness

There are a few factors to consider when selecting the thickness for your stainless steel sheeting.You will actually want to pursue an educated decision and select the suitable thickness that accommodates your specific necessities assuming you know about these variables. Consider the following fundamental factors:

Intended Use

The required thickness is determined by the planning application of your stainless steel sheeting. A thinner sheet might be sufficient if you intend to use it for improvement purposes. However, if it is intended for heavy-duty applications, a sheet with a greater thickness would be preferable.

Strength Requirements

When choosing the thickness, another important consideration should be the quality of your application. A sheet that has a greater thickness is required if the sheeting is going to be subjected to extreme loads or tall forces. In essence, a thinner sheeting would be reasonable if the sheeting needed to be more adaptable or bendable.

Visual Aesthetic

Another important factor to take into account is your budget. Typically, thicker stainless steel sheeting is more expensive than thinner sheets. If money is a constraint, going with a more compact sheet can help you reach your goals without breaking the bank.

Budget

A fundamental point of view is aesthetic taste, particularly if the sheeting will be used in a distinct range. The more streamlined appearance of thinner sheets makes them ideal for use in enhancement projects. The appearance of thicker sheets, which are more durable, makes them ideal for mechanical applications.

Environmental Factors

Factors from the outside Last but not least, think about the natural elements to which your stainless steel sheeting will be exposed. For example, if the sheeting is going to be exposed to harmful chemicals or high temperatures, it will need to be thicker to withstand these harsh conditions.

Conclusion

In this article, the various grades and sheet sorts of stainless steel were shown, discussed, and got a handle on comprehensively. Reach out to Us if you want more information about solidified steel sheets. To meet all of your prototyping and production requirements, we offer a wide range of fabricating capabilities in addition to additional services with added value. For additional information or to request a free, quote, visit our site.

FAQs

What is the difference between stainless steel sheeting and stainless steel plate?

The thickness and intended uses of stainless steel sheeting and plate are the primary distinctions between the two. The term “stainless steel sheeting” typically refers to thinner sheets of stainless steel with an average thickness of less than 6 millimeters (0.25 inches).

These sheets are often used for cladding, lightweight applications, and decorative purposes where flexibility and ease of handling are important. In contrast, sheets of stainless steel that are at least 6 millimeters (0.25 inches) thick are referred to as stainless steel plate. When strength, durability, and load-bearing capacity are crucial, industrial equipment, heavy-duty machinery components, and structural applications all make use of plates.

Is stainless steel magnetic?

Regarding the magnetic properties of stainless steel, it depends on the specific alloy composition. Most stainless steel alloys are non-magnetic, particularly those in the austenitic (e.g., 304, 316) and duplex (e.g., 2205) families. These alloys contain nickel and chromium, which contribute to their non-magnetic behavior. However, some stainless steel grades, such as ferritic (e.g., 430) and martensitic (e.g., 410), can be magnetic due to their higher iron content and different microstructures. Therefore, the magnetic properties of stainless steel vary depending on the alloy composition and processing methods.

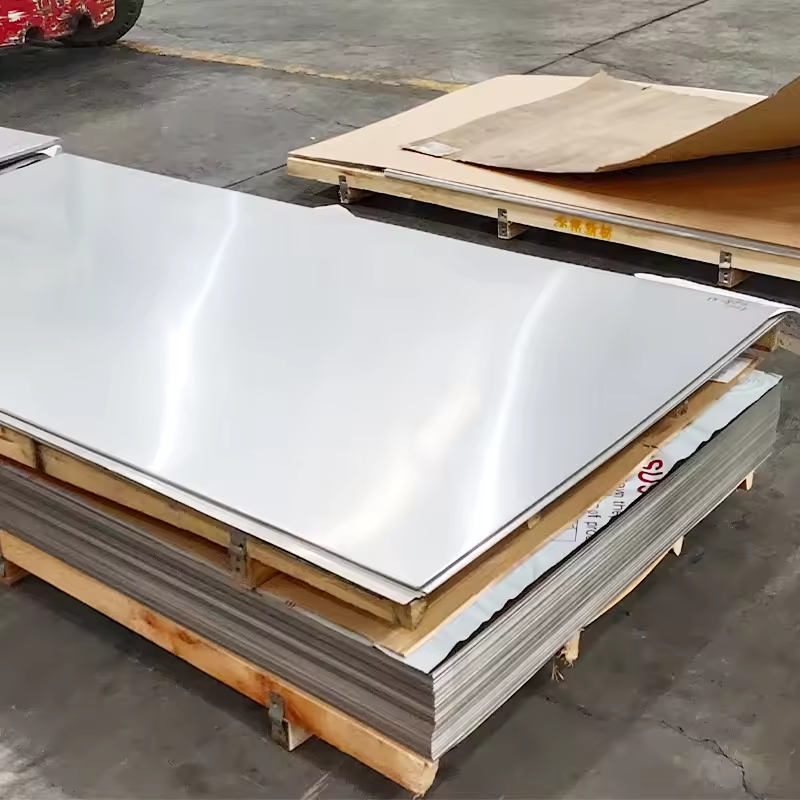

What is stainless steel sheet?

A flat-rolled metal sheet made of stainless steel, a corrosion-resistant alloy with at least 10.5% chromium, is known as stainless steel sheet. Due to its strength, resistance to erosion, and elegant appearance, it is utilized frequently in various businesses.

What are the different grades of stainless steel sheet?

Stainless steel sheets come in a variety of grades, each with distinctive properties that make them suitable for a variety of applications. The most widely recognized grades are 304, 316, 430, and 410. Grade 304 is the most generally utilized for ordinary undertakings, though 316 is known for its superior protection from disintegration.

What are the common finishes available for stainless steel sheets?

There are a few different finishes available for stainless steel sheets, including brushed, mirrored, matte, and finished finishes. The required taste, application requirements, and manufacturing forms all influence the choice of wrap.

What are the standard sizes and thicknesses of stainless steel sheets?

Stainless steel sheets come in a variety of standard sizes and thicknesses, from thin sheets used for improving purposes to thicker sheets used for other purposes. The most common thicknesses range from 0.4 to 6.0 millimeters, and the most common sheet sizes are 4 feet by 8 feet or 4 feet by 10 feet.

What are the applications of stainless steel sheets?

Sheets made of steel are utilized in many ventures, including car, flying, food arrangement, drugs, and chemical preparations, among others. For machines, kitchen equipment, designing parts, vehicle trim, and different applications makers utilize these sheets.

How do you cut stainless steel sheets?

Shearing, laser cutting, plasma cutting, waterjet cutting, and grating cutting are all methods of cutting stainless steel sheets. The strategy chosen is determined by factors like budget, craved exactness, and sheet thickness.

How do you weld stainless steel sheets?

Due to the unique properties of stainless steel sheets, welding them requires specialized techniques. TIG (tungsten inactive gas), MIG (metal inactive gas), and resistance welding are all common methods of welding. For strong and corrosion-resistant welds, proper arrangement, filler fabric selection, and protecting gas are essential.

What are the advantages of using stainless steel sheets over other materials?

Stainless steel sheets outperform other materials in a few ways, including their superior resistance to erosion, durability, adaptability, and fashion appeal. They are biologically engaging on the grounds that they are too simple to even consider cleaning, keep up with, and reuse.

How do you clean and maintain stainless steel sheets?

Stainless steel sheets require routine cleaning to maintain their appearance and prevent erosion, but they are moderately maintenance-free. A delicate cloth or wipe, a mild cleanser, and water are all necessary for cleaning. Steel fleece and rough cleaners can scratch the surface and accelerate erosion, so keep a safe distance from them.

What are the limitations of stainless steel sheets?

While stainless steel sheets offer a number of advantages, they also come with some drawbacks, such as the fact that they are relatively costly in comparison to some other materials, resistant to scratching and recoloring in certain circumstances, and necessitating legitimate manufacturing and welding techniques due to their unique properties.

Send Your Inquiry Today

+86-18969433502

sales@sheetmetalmasion.com