What is Sheet Metal Bending? It’s a Complete Process, Design Tips, and Common Problems with a Solution

Sheet metal bending is used in various industries. So, it has various applications in shaping the sheet metals into a required shape. So, in this article, we will give a deep knowledge about what is sheet metal bending. Besides this, we will also discuss its purpose, multiple techniques, advantages, limitations, and applications in the diverse market.

Table of Contents

Toggle

How would you Define Sheet Metal Bending?

Sheet metal bending is commonly used to deform a metal sheet to a certain angle or a specific shape. This is usually carried out by applying external force on the sheet metal. Besides this, it has a wide scope of applications in manufacturing components or structures with specific geometric characteristics.

Purpose of Sheet Metal Bending in Manufacturing

So, sheet metal bending forges the sheet metal. So, it has found its application for converting sheet metal into specific geometry. Besides this, it is quite a suitable option for multiple processes. So, let’s discuss its main purpose here.

Component Fabrication

Sheet metal bending leads to deform the material and gives it a specific shape. So, it has a significant role in metal component manufacturing. Besides this, sheet metal bending is widely used in different component manufacturing. It may include machines, vehicles, electronics, and other products. Additionally, it is the easier and more traditional way to mold the metals into desired shapes and objects.

Structural Formation

Sheet metal bending has prominent applications in structural formations. It is widely used in making different structural elements. These may include beams, frames, and enclosures. So, it is important to understand that the bending process is an easy and simple way to turn the sheet metal into the desired structure.

Customized Metal Parts

Sheet metal bending provides flexibility in choosing material types. Besides this, it also helps in making customized metal parts based on the client’s requirements. Like other sheet metal fabrication processes, bending is also an accurate process. Additionally, it uses multiple bending techniques to reshape the material in different ways.

Cost-Effectiveness

Although, multiple metal parts manufacturing processes are now available in the market. Every process has its pros and cons. Similarly, sheet metal bending offers some pros and cons. As it is a conventional way to deform sheet metal, So, it is relatively cheaper than other technologies. Additionally, different bending techniques make it an affordable and efficient solution for metal parts manufacturing.

Different Techniques Used for Sheet Metal Bending

It is widely used in reshaping sheet metals. So, it can be carried out using different techniques, based on the client’s requirements. Each bending has its pros and cons. So, let’s discuss them in detail.

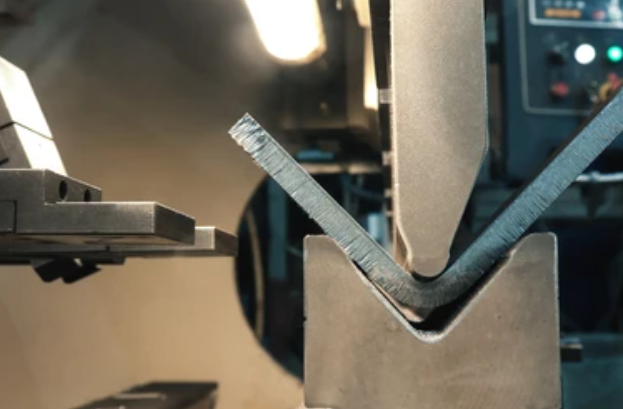

V-bending Technique

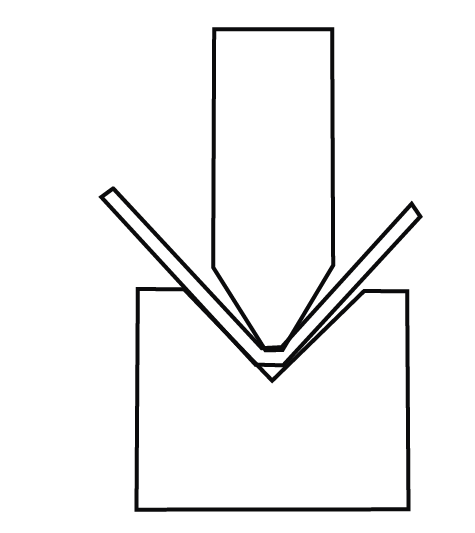

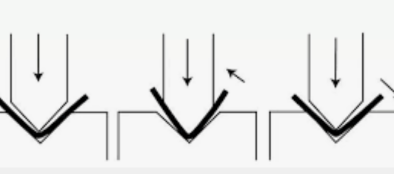

It was named because of the V-shape die and punch. So, a metal workpiece is placed between the die and punch. The punch is handed upside down. So, you need to allow it to descend and press the metal into the die cavity. This is quite a simple technique. Here, the punch uses high pressure to exert on the metal. This method is now widely used in making different shapes. These shapes are highly accurate and have precise angles. So, the metal parts produced using V-bending are widely used in many industries, i.e. electronics and automotive.

Air Bending Technique

Air bending works differently from normal bottoming bending. It offers flexibility in adjusting bend angles without even changing the tooling. Here, the punch starts to descend toward the die. But it leaves and small gap in between and does not touch it, So, the metal bends inside the gap. This technique provides several options for bending angles. That is why, it is widely used in the manufacturing of different metal components.

Bottoming Bending

This technique allows the punch to force the metal workpiece into the die. This process continues until the die completely comes into contact with the bottom of the die cavity. So, as a result, it precisely bends the angles. Besides this, this method gives consistent bend angles. They demand more force as compared to air bending. Additionally, it is widely used in manufacturing accurate metal parts, i.e. aerospace or architectural metalwork.

Wipe-bending

Here the wipe-bending uses a wiping die. So, it allows the metal workpiece to bend around the wiping die. Additionally, the metal undergoes formation when it moves along the wiping die surface. As a result, it gives smooth and curved bends. Moreover, this technique is widely used in creating bends having large radii. Besides this, this is also suitable for making complex shapes, i.e. furniture manufacturing or HVAC ductwork.

Roll Bending

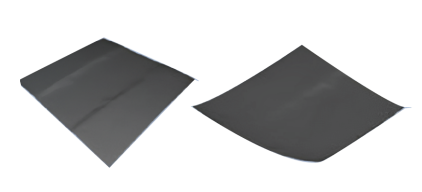

This technique contains a series of rollers in its applications. These help to gradually deform the sheet metal into the required shape and geometry. Here, the metal allows it to pass through the rollers. Then the rollers put pressure on the metal and bend it. This process is widely used in manufacturing cylindrical shapes. These may include pipes or tubes.

Rotary Draw Bending

Here the metal workpiece is allowed to clamp to a bending die. After that, it is allowed to rotate using a forming die and drawn around a bend radius. Additionally, it pulls the metal with a bend radius. Consequently, it gives precise bends and less distortion. Rotary draw bending has wide applications in creating tight-radius bends. This method is also used to make complex shapes. So, it is quite valuable in various industries, i.e. aerospace, automotive, and machinery manufacturing.

Sheet Metal Bending Complete Process

Sheet metal bending can be carried out by following these steps,

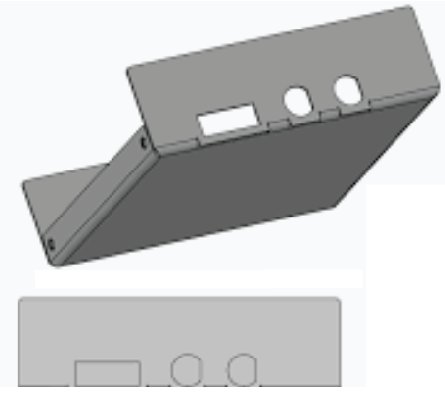

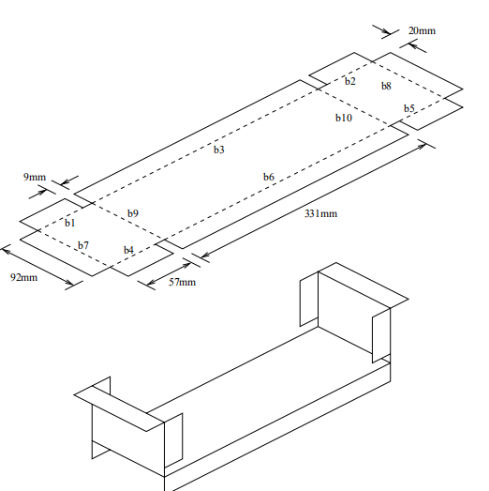

Design Making

Before starting sheet metal bending, first you need to create a design using smart tools and software, i.e. AutoCAD. Here you provide the exact geometry and precise dimensions of the metal part. This is the initial stage to carry out any sheet metal manufacturing process. It gives a 3D look to your metal part. So, make sure, your design must be neat and clean. Besides this, it must be simple. So, you can get the accurate metal part.

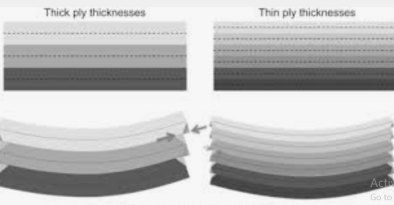

Material Preparation

After designing, the first manufacturing step is material preparation. Here you need to select the appropriate material for your metal part. This material has unique properties. This may include, material thickness, quality, flexibility, etc. Make sure that the material will fulfill your requirements and last longer. So, once the right material is selected, then cut the material into the required dimensions. Multiple processes can help you cut the sheet metal. They may include, shearing, cutting, or machining tools. So, pay careful attention to your metal part. So, you can get precise cuts to guarantee accurate bends.

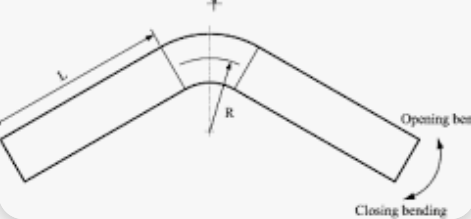

Tool Selection

Tool selection is also a very critical step in sheet metal bending. It decides the accuracy and consistency of any bend. It may include selecting the appropriate die and punch for the specific bending operation. Additionally, you must follow certain factors while choosing the right tool. They are mainly material type, thickness, bend angle, and bend radius. Besides this. It must handle the size and weight of sheet metal.

Setup

It includes the positioning of the sheet metal workpiece between the die and punch on the bending machine. Besides this, the workpiece should be aligned according to the required bend angle and location. This is usually done by using alignment marks or fixtures. Moreover, proper setup keeps the bending operation smooth. It makes bends at the right locations and angles

Clamping

After setup of the workpiece at the right location. Now securely clamp the workpiece in place. It will eventually prevent movement during the bending process. Moreover, the right clamping will keep the workpiece stable and stationary. It will then give precise and consistent bends on the workpiece. Moreover, the clamping mechanisms are also of different types. So, choose what suits your needs.

Bending

The bending starts with activating the bending machine. Here the punch allows to descend. Then it presses the sheet metal workpiece into the die cavity. Resultantly, it deforms and bends the workpiece to the required angle. This process may use different kinds of bending techniques. They usually include V-bending, air bending, or bottoming. They depend on the requirements of the application. Moreover, the operators monitor the bending process. It gives accurate bend angles and dimensions.

Bend Adjustment

If the bend adjustments are required. You can make them during the bending process. Moreover, these adjustments give the required angles and radius. The main adjustments may include adjusting the depth of the punch’s descent and the position of the workpiece on the bending machine. Besides this, it also includes the pressure applied during the bending operation. These adjustments refine the quality and give the final bends with precision and high accuracy.

Quality Inspection

So, once the bending operation is completed. The bent part undergoes a thorough inspection. It helps increase its accuracy and quality. This inspection may include measuring the bend angle and dimensions using precision tools. These tools may include calipers, protractors, or angle gauges. Moreover, you can also perform visual inspection. It will help check the defects or imperfections in the bends. Besides this, this inspection identifies any deviations from the specified tolerances.

Effective Design Tips for Sheet Metal Bending

Here are certain effective design tips for sheet metal bending. These will help you increase the overall efficiency of the bending operation.

| Considerations | Design Tips | Simplified Drawings |

| Bending Gap | – Optimize gap size to prevent material interference and enhance efficiency. |  |

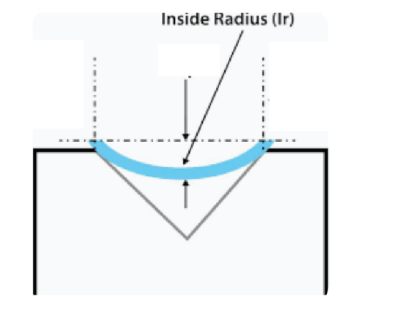

| Bending radius | – Ensure proper angles and radii for strength and ease of fabrication.The bending radius should be greater than the minimum bending radius of the material. |  |

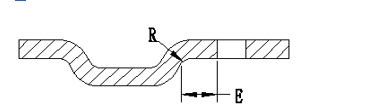

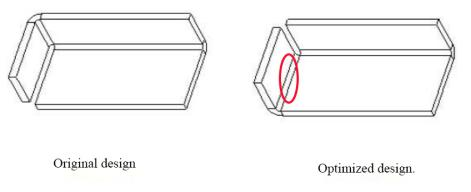

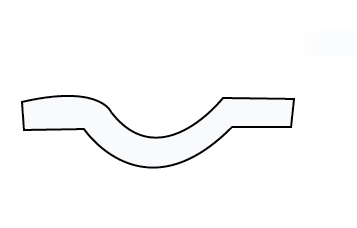

| Convex Hull | – Optimize depth and slope for efficient forming and structural integrity. |  |

| Crack Relief Groove | – Strategically design grooves to prevent material tears and ensure safety. |  |

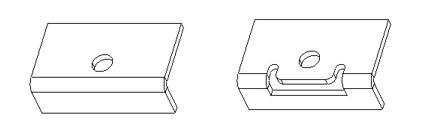

| Rough Edges | – Implement finishing techniques to eliminate sharp edges for safety and aesthetics. |  |

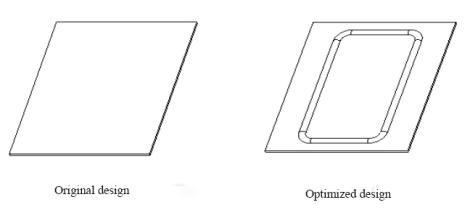

| Design to Improve Strength | – Optimize geometry to enhance structural integrity and material utilization. |  |

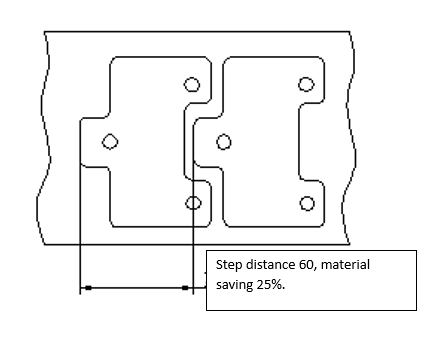

| Design to Reduce Costs | – Utilize nesting and standardization to minimize material waste and reduce expenses. |  |

| Avoid Sharp Corners | – Minimize sharp corners to prevent injuries and reduce mold wear. |  |

| Avoid Long Cantilevers | – Optimize design to prevent material waste and ensure structural integrity. |  |

| Optimize Punching Hole Spacing | – Maintain proper distance between holes to prevent deformation during bending. |  |

| Optimize Punching Hole Size | – Ensure hole size is sufficient for durability and mold longevity. |  |

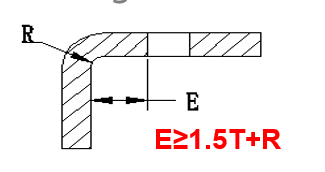

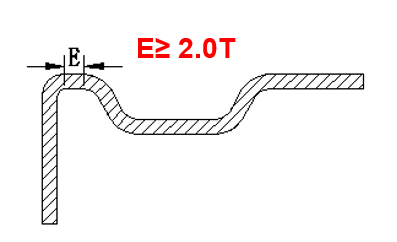

| Avoid Holes Close to Bend Edges | – Maintain adequate distance to prevent interference during folding. |  |

| Avoid Small Blanking Gaps | – Optimize gap size to prevent material interference and improve mold life. |  |

| Ensure Adequate Bend Heights | – Optimize bend height to prevent deformation and ensure dimensional accuracy. |  |

| Bending direction | – Bend it perpendicular to the direction of metal fibers,if bending parallelly,easy to break. |  |

| Unable to bend | – Avoid bending failures caused by the inability to clamp material at the root of the bend. |  |

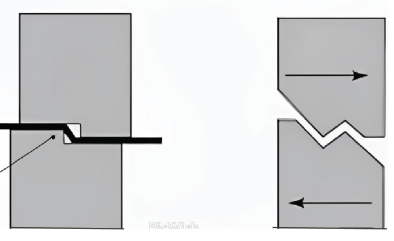

| Fastener is too Close not able to bend | – Avoid bending failures caused by fasteners being too close to the bending gap |  |

| Avoid Bending interference | – Due to sheet metal bending tolerances, sufficient clearance in the bending direction must be ensured to avoid interference and bending failure |  |

| Ensuring bending strength | – Bending the sheet metal along the longer edge as much as possible to enhance bending strength. |  |

| Avoid complex bending | – The more complex the sheet metal bending process, the lower the bending accuracy, and complex bends may result in material waste. |  |

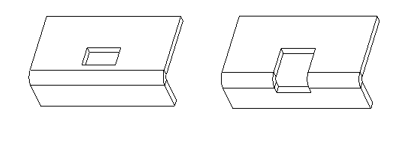

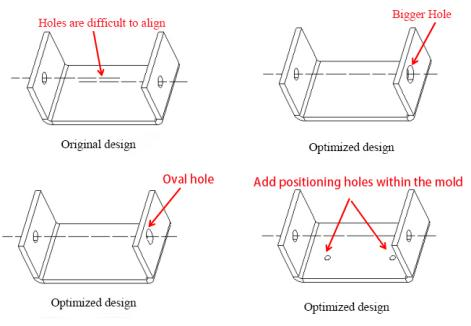

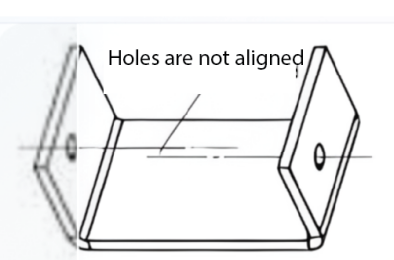

| Avoid multiple bending. | – Holes on multiple bending are difficult to align |  |

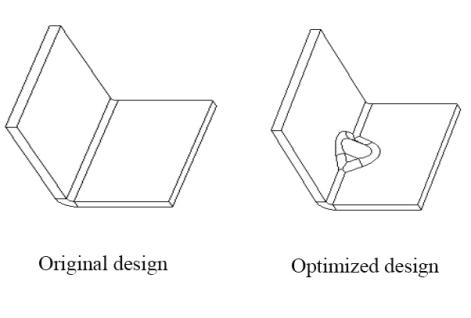

| Enhancing bending strength | – Add bending, flanges, or hemmed edges |  |

| Enhancing bending strength | – Add triangular reinforcement ribs at the bending |  |

29 Common Problems of Sheet Metal Bending With Reasoning and Optimal Solutions

Sheet metal bending is an easier and cheaper technique to make different geometries from sheet metal parts. But, when we deal with the bending process. The number of chances for problems increases. So, let’s discuss every possible problem encountered in sheet metal bending. Besides this, we will also discuss the possible solutions to mitigate the issues.

| Sr. no | Problem | Cause Analysis | Solutions | Simplified Drawings |

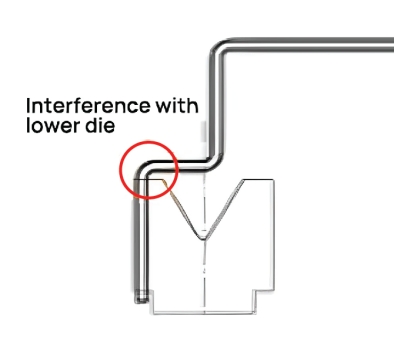

| 1 | Challenges in Bending Groove-Type and Multi-Bend Workpieces | – Groove width larger than leg height – Interference between workpiece end and upper die/slider – H1>H or B<V/2 for multi-bend | – Use goose-neck upper die – Perform reverse pre-bend – Select the appropriate lower die and bending sequence |  |

| 2 | Bend Cracking | – Bending parallel to grain direction – Small bending radius – Small R-angle of the lower die – Poor material performance | – Rotate sheet metal during cutting – Increase upper die R-angle – Use a lower die with a large R-angle – Choose high-performance materials |  |

| 3 | Uneven Bending Edge | – No line pressing or pre-bending – Inadequate material pressure – Uneven die fillet – Low height | – Design line pressing or pre-bending techniques – Increase jacking force – Even clearance in die and polish fillet – Keep minimum height |  |

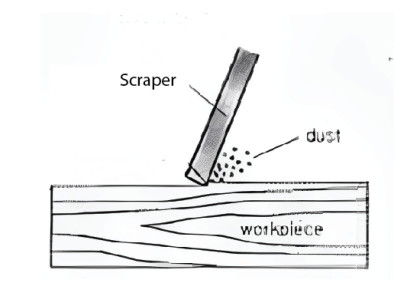

| 4 | Workpiece Scraping After Bending | – Unsmooth material surface – Small convex die-bending radius – Small bending clearance | – Improve concave die smoothness – Increase convex die bending radius – Adjust bending clearance |  |

| 5 | Cracks at Bending Angles | – Small bending radius – Grain parallel to the bending line – Burr of work blank extending outward – Poor metal moldability | – Increase convex die bending radius – Change blanking layout – Make burrs at the workpiece’s inner fillet – Anneal or use soft material |  |

| 6 | Hole Deformation during Bending | – Elastic bending causing hole positioning deformation – Friction-induced deformation on the surface – Hole slipping during bending | – Use shape bending – Increase cover board pressure – Add pitting plaid to cover the board – Increase friction |  |

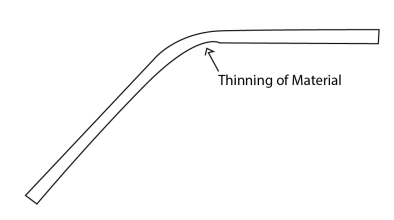

| 7 | Thinning of Bending Surface | – Small convex-concave die fillet – Small die clearance | – Increase die fillet radius – Adjust die clearance |  |

| 8 | Bulging or Uneven Workpiece Surface | – Tension causes material shrinkage and bulging – Inadequate pressure on the convex-concave die – Suboptimal techniques | – Provide adequate pressure – Match concave round angle radius to the workpiece’s excircle – Optimize techniques |  |

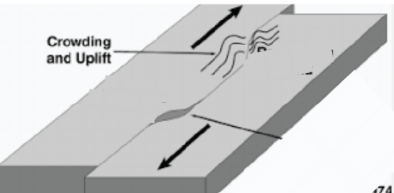

| 9 | Uneven Concave Bottom | – Uneven material – Inadequate contact area or jacking force – Lack of material support in the die. | – Level materials – Adjust support and increase force – Increase or correct material support – Increase shaping processes |  |

| 10 | Misaligned Holes After Bending | – Material rebound changing bending angle – Lack of correction process or inadequate die structure | – Increase correction process – Improve die structure to reduce rebound |  |

| 11 | Inaccurate Hole Positioning | – Incorrect unfolding sizes – Material spring back – Unstable positioning | – Accurately calculate the blank size – Increase the correction process or improve the die – Change methods or improve positioning |  |

| 12 | Non-Parallel Bending Lines | – Bending height less than the minimum – Expansion due to bending | – Increase workpiece height – Improve bending techniques |  |

| 13 | Width Deformation After Bending | – Inconsistent depth and shrinkage causing torsion – Poor material support during bending | – Increase bending pressure – Increase correction process – Keep the angle between materials and the bending direction |  |

| 14 | Deflection at Incisions | – Incisions causing straight edges to open and deflect | – Improve workpiece structure – Increase processing allowance at incisions |  |

| 15 | Material Slippage During Bending | V-groove width too large relative to bend size | – Use the centerline deviation method – Pad processing – Adjust groove sizes |  |

| 16 | Narrow Internal Bending Width | – Standard die width requirement not met – Insecure die fixation | – Negotiate for a wider bend – Special die processing – Secure the die on the base |  |

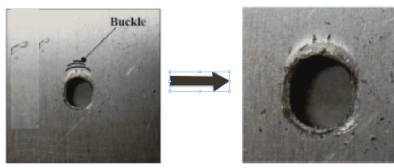

| 17 | Hole Too Close to Bending Line | – Hole proximity causes pull-through and distortion | – Increase bend size and trim hem – Expand the hole or modify – Use secant or crimping processing – Eccentric mold processing |  |

| 18 | Deformation at Drawn Edge | – The small distance between the edge and the bending line | – Use secant or crimping processing – Modify material size or use a special mold – Eccentric mold processing |  |

| 19 | Flattening Edge Rising After Flattening | – Poor flattening position or technique | – Bend upward angle before flattening – Flatten in steps – Press the end to bend the dead side – Flatten root part |  |

| 20 | Draw Bridge Breakage | – High draw bridge height causes stretching and fracture | – Lengthen process hole – Increase draw bridge width – Repair mold corners – Add lubricant |  |

| 21 | Processing Size Change During Special Mold | – Forward displacement during processing | – Minimize shadow in the picture – Replace worn parts with better positioning – Use back-initiating structures in mold |  |

| 22 | Inconsistent Blanking Size | – Error in project deployment or feeding size | – Distribute deviation among bends – Adjust V-groove size accordingly |  |

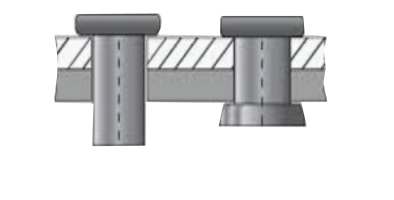

| 23 | Spalling or Loose Draw-Hole After Riveting | – Small R angle or burrs causing spalling – Misaligned holes or incorrect riveting methods cause deformation | – Use a larger R-angle for the center punch – Increase pressure and deepen broaching – Address hole alignment and riveting method issues |  |

| 24 | Skewed Riveting or Workpiece Deformation | – Lack of flattening during processing – Uneven force distribution | – Flatten workpiece during stud pressing – Use support frame – Adjust pressure distribution |  |

| 25 | Non-Parallel Sides After Offset Bending | – Incorrect mold calibration or adjustment – Unequal upper and lower die surfaces | – Recalibrate mold – Adjust gaskets – Use eccentric processing – Keep surface uniformity |  |

| 26 | Excessive Crease Depth | – Small V-groove or R-angle – Soft material | – Use a larger V-groove or R-angle – Use padding bending – Consider material properties |  |

| 27 | Spring back | – Elastic recovery after bending | – Use higher tonnage press – Adjust tooling |  |

| 28 | Surface Imperfections | – Tooling wear or damage – Poor lubrication | – Regular maintenance – Improve lubrication |  |

| 29 | Bend Angle Inaccuracy | – Die misalignment – Incorrect tooling setup | – Realign die – Check and adjust tooling |  |

Common Metals Used in Sheet Metal Bending

Sheet metal banding is suitable for various materials. So, let’s check the different metals with their properties and applications in different industries.

| Metal | Properties | Common Applications |

| Steel | A durable alloy of iron and carbon. | Automotive, construction, appliances. |

| Aluminum | Lightweight and corrosion-resistant. | Aerospace, automotive, electronics. |

| Stainless Steel | Corrosion-resistant alloy of iron and chromium. | Food processing, medical, architectural. |

| Copper | Ductile metal with excellent conductivity. | Electrical, plumbing, roofing. |

| Brass | Copper-zinc alloy with enhanced machinability. | Plumbing, hardware, musical instruments. |

| Titanium | Lightweight and corrosion-resistant. | Aerospace, medical, marine. |

| Zinc | Corrosion-resistant metal with various applications. | Galvanizing, coatings, automotive. |

| Nickel | Durable metal with high corrosion resistance. | Aerospace, chemical processing, electronics. |

| Lead | Dense metal with a low melting point. | Radiation shielding, batteries, roofing. |

| Tin | Soft, malleable metal with low toxicity. | Food packaging, soldering, coatings. |

What Safety Tips and Practices Can Be Used in Sheet Metal Bending?

Sheet metal bending needs proper safety to be carried out efficiently. So, there are a few safety measures that we can implement and avoid accidents in the workplace. These tips are listed below;

Use Personal Protective Equipment (PPE)

All workers who work on sheet metal bending must cover themselves with PPE. These PPE may include safety glasses, cut-resistant gloves, steel-toed shoes, and hearing protection. So, all of these lead us to avoid sharp edges and heavy equipment

Proper Tool Maintenance

Tool maintenance is necessary for the safety and overall performance of the process. So, it is mandatory to check and inspect all the operations and machinery equipment regularly. Besides this, if some tools need attention. They must be repaired timely. Moreover, you must use lubricants for smooth working. Along with this, clean the equipment regularly. Otherwise, they may lead to sticking or broken parts. So, they can cause accidents.

Employee Training

After opting for PPEs and tool maintenance, the third most important thing is constant learning for the staff and employees. It will help to increase the knowledge of how to use sheet metal bending equipment safely. So, you can provide effective training to all staff. You can teach them common bending techniques, tool use, and safety protocols. So, it will ultimately lower the risk of accidents and injuries at the workplace.

Knowledge about Material Selection and Handling

Every material has its unique mechanical and chemical properties. So, it is very important to understand them to carry out effective sheet metal bending. So, here are two measures you can take.

- Choose Appropriate Materials: Always choose sheet metals that can easily bend into the desired shape, have high ductility, and have optimal thickness. For example, aluminum can be cracked down on any blow.

- Optimize Bending Operations: Always make sure you use the right bending techniques to avoid defects and reduce stress on the material. Besides this, you can evenly distribute stress on the specific material. It can be done using specific materials.

Advantages and Disadvantages of Sheet Metal Bending

So, here is a short table. It will help us understand the benefits and limitations of sheet metal bending.

| Advantages | Disadvantages |

| Versatile for complex shapes | High tooling costs |

| Cost-effective for high volumes | Material limitations |

| Precision and tight tolerances | Design constraints |

| Strengthens sheet metal | Surface imperfections |

| Automated for efficiency | Springback effect |

| Customizable for specific needs | Production complexity |

| Minimizes material waste | Specialized skill requirement |

Applications of Sheet Metal Bending

This process is now widely used in several industries. Let’s discuss all the applications in the below section.

- Automotive Industry: Sheet metal bending is now widely used in the automotive industry. It helps in manufacturing metal parts, i.e. chassis, body panels, doors, fenders, and brackets.

- Aerospace Industry: Because it is lightweight and has durable properties, sheet metal bending is used to make structural components. These may include aircraft skins, wings, and fuselage sections.

- Construction: It is widely used in the construction industry. It helps in making roofing materials, gutters, flashing, and cladding. Besides this, it is also used in making HVAC ductwork, and structural components.

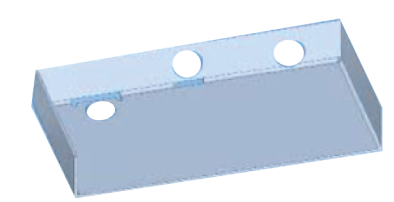

- Electronics and Electrical Enclosures: Sheet metal bending also serves to make electronic parts and electrical equipment. These may include control panels, junction boxes, cabinets, and housing for different devices.

- Furniture: It is widely used in furniture making. So, it makes components like frames, brackets, supports, and decorative elements.

- Medical Equipment: Sheet metal bending is also used in manufacturing medical equipment and devices. These may include hospital beds, medical carts, instrument trays, and cabinets.

- Defense and Military Applications: Sheet metal bending is not limited to local industries. It has wide applications in military and defense applications. So, it is used to make armored vehicles, weapon components, ammunition boxes, and military shelters.

- Telecommunications: Sheet metal bending is also a popular option for making enclosures and racks for telecommunications equipment, These mainly include the manufacturing of server cabinets and network cabinets.

Why Choose Masion for Sheet Metal Bending

Masion has 17+ years of experience in sheet metal bending. We are the leading company of sheet metal fabrication in China. Besides this, we have multiple units and different advanced machinery to use for the sheet metal bending process. We believe in customer satisfaction. So, we deliver in-time services with high accuracy and precision. Besides this, we have a quick turnaround. So, if you need bending services. You can reach out to Masion today. We will serve you each small or large project with equal attention. Get your quote today.

Conclusion

Sheet metal bending is widely used in a range of applications in different sectors. These sectors may include automotive, aerospace, marine industry, electronics and enclosures, appliances, and medical industries. Compared to other sheet metal manufacturing techniques, sheet metal bending is quite less expensive. Besides this, it gives accurate and precise metal parts. Additionally, it is made up of a die and a punch. The punch moves downward and exerts pressure on the metal part. Then the metal starts to bend and inject into the die cavity. Here it gets the shape of the die. So, it is quite a simple technique and offers multiple advantages as well. Furthermore, multiple techniques can be used to carry out the bending operations. So, the selection of technique may depend on the material used and client needs.

Frequently Asked Questions

Q1. Does laser-cutting increase the sheet metal bending precision and efficiency?

Absolutely yes. It improves the bending process. Laser-cutting provides accurate bending angles. So, they help reduce the secondary operations. Consequently, it reduces the cost as well. Besides this, laser-cutting also reduces material distortion and gives top-quality bends.

Q2. Does the Fiber Laser Cutting Determine the Waste in Sheet Metal Bending?

Yes, like laser-cutting, it also reduces waste. It is quite a fast technique and gives highly efficient results to improve the sheet metal bending process.

Q3. How much time does Sheet Metal Bending take to complete?

It’s quite a fast process. Sometimes, it can take minutes, and sometimes it takes hours for large projects. However, its completion time may vary due to different factors. These factors may include, part complexity, material thickness, and bending method.

Q4. What is the Accuracy of Sheet Metal Bending?

It is popular for its accuracy. So, if you use advanced technology. It can give the tolerances as tight as ±0.5 degrees. But this accuracy also varies with multiple factors. I.e. material properties, machine calibration, and operator skill.

Send Your Inquiry Today

+86-18969433502

sales@sheetmetalmasion.com