Brass Sheet – An Ultimate Guide

Brass sheet is a versatile material that is a large part of the products used considering its shining gold tone and straightforwardness of machine shaping. It is sturdy, looks great, and won’t break with zinc and copper composition. That is the clarification it’s eminent in different associations like preparation, workmanship, and engineering & planning. This guide will look at the properties of brass metal sheet, the status of regularly used, and various approaches to cutting, shape, and finish it for different applications. In the event that you’re into specialties, design, or other relaxation pursuits, finding out about metal sheets can assist you with integrating this strange material into your induestries.

Table of Contents

ToggleWhat is a Brass Sheet?

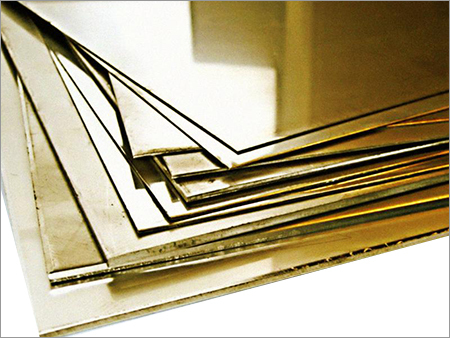

A metal sheet is a thin, level piece of metal created utilizing a compound of copper and zinc. It is esteemed for its solidness, convenience (bowing and molding), and brilliant color variety. The shine, pliability, and high quality of this fabric are well-known qualities. Tin or different metals can be added to the metal to make it less hard. It is useful in districts by the ocean where sea salt can rust metal. It can endure salt harm. You’ll find it in all that from instruments to entryway handles and regardless, building supplements.

Brass metal sheets are available in various thicknesses, going from slight foils to thicker plates, and they come in different sizes and surface fulfillments. They can be smooth, finished, cleaned, or covered, contingent upon the arranged application. Industries like engineering, development, auto, hardware, broadcast communications, marine, aviation, and improving expressions all utilization metal sheets. They are made into electrical connectors, structural components, roofing materials, instruments, gems, enriching things, modern parts, and different items.

Advantages

Metal sheets are respected for their novel blend of properties, counting:

- Metal faces deterioration way better than different various metals, especially in barometrical and marine conditions.

- Since metal is so flexible, it is not difficult to shape into different arrangements by bowing, cutting, stepping, and machining.

- Metal wraps a warm, beautiful variety that lends wrapped objects a captivating appearance. It can too be cleaned to a tall sparkle or treated with different surface envelops by the state of mind for improving.

- Brass Metal is an excellent conductor of force and heat, making it suitable for use in heat exchangers and electrical components.

- Metal may be areas of strength for a with exceptional mechanical properties, counting quality, hardness, and robustness.

- Metal consolidates a moo coefficient of scouring, which makes it sensible for applications where sliding or turning parts are integrated, similar to course and pinion wheels.

- Metal may be a recyclable surface, which construes that metal sheets can be perpetually reused toward the completion of their benefit life, decreasing waste and customary impact.

- Metal has normal antimicrobial properties that forestall the development of microscopic organisms and different microorganisms on its surface. This makes metal sheets reasonable for applications where cleanliness is basic, for instance, therapeutic and food preparing stuff.

Brass Metal Sheets Types

Yellow Type

Yellow brass sheet is made of 60-70% copper and 30-40% zinc, sometimes with a little bit of other stuff in it. It is used in various projects and is not difficult to recognize because of its radiant yellow tone. Yellow brass is very useful because it can be used in so many different ways. It is durable, looks good, and performs well.

Red Type

Red Sheet, also known as high brass, has a reddish hue because it contains 85 to 90% more copper. This material is frequently used in plumbing for connectors, valves, and pipes due to its superior resistance to rust. It is perfect for applications where steadfastness and long-lastingness are most significant as a result of its solidarity and capacity to continue to look new. The production of bullet casings requires cartridge sheet.

Cartridge

It is made of 70% copper and 30% zinc, with small amounts of other metals like lead or tin for improved performance. This material is reliable in difficult firearm situations. For firearms to work appropriately, the exact makeup is pivotal.

Naval Sheet

Naval Metal Sheet is sufficiently solid to endure unforgiving sea conditions and offers fantastic protection from rust. Copper, zinc, and a modest quantity of tin make up maritime metal, which is a durable metal. It is as often as possible used to develop ships, boats, and boat equipment and fittings. This material is ideal for items that will be used in the ocean for a long time because it resists rusting very well. It is vital for things utilized in the sea to not become corroded.

Free Cutting Sheet

It is ideal for applications requiring extensive machining because it is simple to machine free cutting sheet with added lead. Accuracy & precision instruments, vehicle parts, and plumbing fittings all utilize this material. Because it is simple to work with, it works well for making intricate parts that require extremely precise measurements. This helps to guarantee the high quality of the finished products.

Brass Shim Sheet

Brass Shim Sheet is a slight, adaptable material. Because it can be easily shaped to allow for precise changes, it is very important in building, making things, and machinery, where precise positioning and spacing are very important.

Architectural Type Sheet

Architectural type sheet is robust and has a one-of-a-kind finish. It is applied to structures that must last and look good for a long time. In architecture, brass is used to give buildings and interior spaces a nice, long-lasting appearance. Panels, trims, and accents can benefit from its refined appearance. To ensure that it performs admirably and lasts for long time in a variety of businesses and organizations, each kind of metal sheet is crafted with unique blends and characteristics tailored to its purpose.

When Selecting Brass Metal Sheets What You Need to Consideration

- Brass metal sheets are open in a loosen up of cost focuses, so contemplate the got similar with your spending plan and expand necessities. Offsetting got concerns with the predefined execution and appearance is essential because higher-quality brass sheet metal blends or concentrated wraps up may command the following cost.

- Pick a metal that accommodates your task’s particular requirements for quality, protection from eroding, and simplicity of machining. Contemplate how thick and what size you want for your project while additionally attempting to make as minimal waste as could be expected.

- Pick a completion that causes your task to seem more appealing. Check to see that the sheets can be easily bent to fit your shaping requirements.

- Choose a brass that achieves the best cost-performance ratio by taking your budget into account.

- Ponder the climate where your project will be and pick a metal that can oppose harm from rust and other regular elements.

- Additionally, select a brass material that complements any additional products that might be required. Via cautiously taking a gander at these parts, you’ll pick metal sheets that address the issues of your project and guarantee its prosperity.

Sheet of Brass – Tools You Need When Working

- Goggles and gloves for safety, clamps and vises to hold the sheets in place, tools to smooth out sharp edges, tools to bend the sheets, drills to make holes, tools to clean the surfaces, equipment for welding or soldering, and supplies to clean the surface before working on it are all necessary when working with sheet of brass. These machines ensure that the manufacturing process is safe and effective, producing finished goods of high quality.

- It is critical to be exact to get the right size. Twisting metal sheets to make bends, points, or shapes is many times done utilizing extraordinary devices, and it requires cautious control to try not to break or distorting the metal.

- High-speed steel or carbide drill bits and a sturdy drill are required for drilling holes in sheet metal brass. Oil and clamps are also needed to prevent the sheet from hardening and to ensure that the holes are clean and accurate. It frequently needs exceptional gear and numerous moves toward get the shape you need.

Welding, patching, or brazing are three methods for joining sheet of brass together. Every technique enjoys its benefits and interesting points relying upon the utilization and properties of the metal compound. Working on the look and nature of metal sheets by cleaning, sparkling, smoothing, and adding defensive coatings to make them more impervious to rust and more grounded. For engineering, decorative, and creative purposes, creating raised or carved designs on brass sheets adds visual appeal. Utilizing these methodologies accurately guarantees that things are made right and considers making various items in numerous enterprises.

Sheet Metal Brass – Tools Use to Cut & Shape

Shears

Shears are hand- or electric-powered instruments. They have razor-sharp blades designed for precisely cutting thin brass metal sheets. Hand-held manual shears are useful for small projects or jobs that require precise cutting. Electric shears are quicker and can cut brass into larger pieces. When cutting straight lines or gentle curves in sheets, these tools are extremely helpful. They are frequently used in manufacturing facilities like shops and workshops.

Snips

Snips, also called tin snips, are tools for cutting brass and other metals. They are used in aviation and can cut a variety of metals. These instruments are made to simplify it for individuals to cut through metal sheets and have sharp steel edges. There are different kinds of flight clips for various cuts on metal sheets. Straight, bended, or unpredictable cuts are undeniably remembered for this. They are frequently required for tasks like repairing automobiles, working with heating and cooling systems, and working with metal.

Hacksaw

A hacksaw is a hand tool with a sharp blade that can cut. Hacksaws are frequently used to cut metals. With the blade’s sharp edge, brass sheets of any thickness can be cut easily and precisely. Because they can cut straight lines and gentle curves, hacksaws are frequently used in workshops, garages, and construction sites.

Jisaw

A jigsaw is a tool with a fast-moving blade that cuts through objects. Jigsaws are valuable devices that can slice through wood, metal, plastic, and different materials. They are helpful for cutting sheets. A jigsaw can undoubtedly slice through thick metal sheets with a metal-cutting sharp edge. From that point onward, cuts can be made in straight or bended headings. In DIY, woodworking, and metalworking projects, jigsaws are often used.

Band Saw

A band saw is a tool with a long metal blade that loops and has teeth. These tools are frequently used to cut materials like metal, wood, and other things. They cut especially well through thick metal sheets. Band saws can cut through sheets of varying thicknesses in either a straight or curved direction. They are very good at cutting. In factories and woodworking shops, where metal, wood, and other materials are worked on, they are frequently used.

CNC router

A CNC router is a computer-controlled machine with spinning blades that can cut intricate designs and shapes into a variety of materials, such as brass. These machines plan the cutting and control how the cutting device moves utilizing specific PC programs. CNC switches are exceptionally precise machines that can over and over cut metal into a similar shape. Brass can be used to quickly make a lot of the same parts as well as one-of-a-kind, intricate pieces. These machines are regularly utilized in businesses like sign making, carpentry, and metal forming.

Water jet

Waterjet machines utilize strong water to definitively and exactly cut and slice through things like brass metal sheets. Waterjet cutting is a strategy that utilizations water to slice through objects without making them hot or harsh around the edges. Waterjet cutters are magnificent for cutting thick metal sheets and can precisely make many-sided shapes and plans. They are frequently used in the construction, automotive, and aircraft industries.

Laser Cutter

To rapidly and definitively slice through materials, a laser cutting machine utilizes a strong, restricted light emission. Laser cutting is a strategy for cutting items without contacting them. It utilizes no apparatuses by any means to make exceptionally exact cuts. Laser cutters can slice through thick brass sheets of metal to make complex examples and plans. Building things, making adornments, and settling on models all depends for their utilization.

Sheet Metal Brass Thickness Diversity

260 Sheet

260 Sheet alloy’s composition, which is roughly 70% copper and 30% zinc, can be seen in the number “260.” Because they don’t rust, are easy to work with, and look good, brass are used in many different industries.

They are frequently utilized in intricate details, electrical components, musical instruments, and building designs. Due to their unique properties, 260 Sheets are ideal for applications requiring rust resistance, flexibility, and strength. They are a good choice for building things because they are simple to shape, join, and work with to fit various designs.

353-H02 Brass

The 353 brass sheet metal has a thickness of 0.06 inches. This kind of thickness is frequently used when strength and flexibility are needed together. The “353-H02” code indicates the kind of sheet and how it has been treated. Copper, zinc, and different components make up metal amalgam 353. It is made to major areas of strength for be, to consumption, and easy to work with.

The “H02” indicates that the sheet has been strengthened and made more flexible by being worked on and heated. Sheets are used in a variety of industries, including automobiles, electricity, plumbing, and making things look nice. They also don’t rust, conduct electricity well, and look nice. Since it is the right thickness and strength, this metal sheet can be utilized to make various things. It can be shaped, cut, and joined to make things that meet specific design specifications.

464

464 is a unique variety. Copper and zinc make up the majority of brass, but the exact proportions can vary depending on the type. In order to ensure that it does not rust, is simple to work with, and is sturdy, Brass 464 probably contains a unique blend of copper, zinc, and possibly other materials. Because of their excellent conductivity, resistance to rust, and attractive appearance, brass are utilized in numerous industries.

Designs for buildings, electrical components, musical instruments, and decorations all make use of them. The materials and manufacturing processes of Brass 464 determine how it behaves. Depending on the requirements of the project, it can be chosen for jobs requiring strength, flexibility, and rust protection all at once.

280

Most likely, Brass 280 refers to a particular mix of brass. Copper and zinc make up brass, but the proportions can vary depending on the type. Copper, zinc, and other components are mixed together to make Brass 280, which is strong, easy to work with, and resistant to rust. Because they are excellent conductors of electricity, resist rust, and have a pleasing appearance, heets are frequently utilized in a variety of industries.

They are used to decorate things, make electrical and plumbing items, musical instruments, and buildings look nice. The qualities of Sheet 280 will be affected by how and what it is made of. Depending on the requirements of the project, it can be chosen for jobs that require certain qualities, such as being simple to work with, having good shaping, or not easily being damaged by rust.

Type 360

Brass 360 is a combination of zinc and copper. The proportions may be affected by the type of brass. Metal Sheet 360 is contained copper and zinc, with possibly some other stuff added in, to make it impenetrable to rust, easy to work with, solid areas for and. Brass are utilized in numerous industries due to their durability, rust resistance, and aesthetic appeal.

They can be used in instruments, enrichment, electrical parts, plumbing, and structures. The characteristics of Sheet 360 are determined by the materials and processes used to make it. Depending upon the job needing to be done, it very well may be utilized for various things that should be easy to control, keep up with their shape, or not rust.

385

An extraordinary alloy type of brass sheet metal is brass 385. Copper and zinc combine to form metal. The bras sheet 385 is presumably made of a combination of copper, zinc, and conceivably different materials that make major areas of strength for it, to work with, and impervious to rust. Brass are used in a lot of different industries because they resist corrosion, conduct electricity well, and look good. Buildings, electrical components, plumbing fixtures, musical instruments, and ornaments all benefit from their use. It will in general be picked for different purposes since it might be easily machined, shaped, or shielded from rust, dependent upon what is expected for the undertaking.

C260

C260 brass metal, moreover called cartridge metal, is a kind of metal delivered utilizing around 70% copper and 30% zinc. This well-known combination of metals is easy to shape because it works well when it’s cold. Metal utilized in cartridges is impervious to rust and brilliant at leading power. It is frequently used for bullets, pipes, and musical instruments. Due to its decent bright variety, it is also frequently utilized in building and for aesthetic purposes.

C464 Brass

C464 brass Metal alooy, otherwise called Naval Metal, is a kind of metal that is for the most part made of copper, zinc, and tin in modest quantities. Because it is known to resist rust, especially in water, naval brass is an excellent choice for boat parts, propeller shafts, and valves. It can be welded without difficulty and is simple to use with machines. Additionally, it has strength for extremely intense. Numerous people like to use sea metal since it doesn’t get consumed successfully, especially in outrageous circumstances.

C360 Brass (Free-Cutting Brass)

Copper, zinc, and a follow measure of lead make up the C360 metal brass. Free-cutting metal is one more name for it. The compound is made simpler to work with when lead is added. It can be shaped, cut, and drilled into intricate pieces. Free-cut brass resists rust well and is excellent at transferring heat, electricity, and other electrical charges. It is utilized to make plumbing, electrical, and car parts, fittings, and connectors, in addition to other things.

C280

C280 brass, also known as yellow metal, is made up of about 40% zinc and 60% copper. It could likewise contain a few lead and iron, which would make it more grounded and simpler to work with. It is perfect for boat and boat parts since it doesn’t handily rust, particularly in water. It changes color over time to a distinctive yellow-gold color and becomes strong and flexible when heated. Various ways can be utilized to combine metal sheets. Along these lines, they can be made into a wide assortment of solid designs and are an adaptable material. Soldering is the process of joining metal components with melted metal.

Brass Sheets – Techniques Manufacturers Used to Join

Soldering

While joining at least two metal sheets, the most widely recognized strategy is to weld them together through soldering. By allowing it to liquefy between the surfaces and solidify, a metal-composite-assembled bind is used in this interaction to stick things together. It is necessary to remove dirt and get the pieces to stick together by applying heat and flux to the metal with a torch or soldering iron to clean it and get it to stick together. Due to their strength and ability to withstand high temperatures, solder joints are ideal for extremely hot applications.

Brazing

Like when you tie, brazing furthermore uses a metal to combine metal sheets. The metal that is joined by patching dissolves at a lower temperature than the metal that is being joined. In contrast, the joining metal melts at a temperature higher than the joining metal in brazing. Subsequently, welded joints are more solid and ready to endure higher temperatures than patched joints.

Welding

The most common way of warming and squeezing two separate bits of metal together is known as welding. Brass parts can be joined with welding. It’s not unexpected utilized when a solid, smooth joint is required. Copper and zinc make up brass. Because brass’s zinc has a low melting point, welding it can be challenging and may result in weld holes. However, it is possible to successfully weld brass with the right tools and techniques.

Zip Fasteners

Instead of simply connecting metal parts, zip latches, also known as zippers, are typically used to fasten clothing together. By and large, brass is much of the time used to make areas of strength for zippers impervious to rust. It is utilized to make the slider and teeth due to its sturdiness and capacity to oppose rust. Brass components used in high-quality zippers are meticulously crafted and polished to prevent discoloration. Due to their strength, aesthetic appeal, and smooth operation, brass zippers are widely used in outdoor gear, luxury clothing, luggage, leather goods, and luggage. They are also stronger than other materials against rust.

Riveting

Using a short metal stick or bolt known as a rivet, riveting is a method for joining two or more pieces of metal together. The bolt, which is typically made of a sturdy metal like brass or a combination of metals, is inserted into pre-drilled holes and fits snugly. The finish of the screw is bowed and broadened to hold it set up and keep things intact, frequently by hitting it or utilizing an exceptional device. Brass, where welding could be harmful or cause damage, can benefit greatly from this method. It makes areas of strength for a long-lasting joint without the requirement for heat, in this manner protecting the material’s sharpness and appearance.

Adhesive Bonding

Special glue or resin is used to bond sheets together in adhesive bonding. This method works really well when you don’t need to worry about using a very strong security or when the surfaces you’re joining can’t be warmed. When joining various materials or securing brass sheets to non-metal surfaces, adhesive bonding is frequently used.

Notwithstanding, how the surface is ready, the sort of paste utilized, and the environmental factors can all influence how well paste keeps things intact. While using metal sheets, it is crucial for select the best association technique in light of the necessities of your task. Regardless of what you require, such as the capacity to withstand heat, flexibility, or strength, there is a solution for every situation.

How to Bend Brass Sheets?

Brass is a robust material that can be challenging to work with if it is not prepared properly. Warming up your metal sheet is absolutely necessary in order to ensure that it can twist without breaking. To make the metal more adaptable and milder, this strategy includes warming it to an extremely high temperature and permitting it to gradually cool.

Tin clips can be utilized to remove the ideal state of the huge metal sheet once your piece is sufficiently delicate. Clamps should be used to hold the piece in place before you begin to bend it manually or with a machine. While you work on it, this will hold it back from getting harmed or evolving shape. After that, press on specific areas and gently hammer around them to get the material to bend and take the shapes you want.

You can use a sturdy clamp or a heavy, flat object to make this step easier. Remember that assuming your piece is huge or thick, you might have to shape it on numerous occasions to keep it from breaking because of lopsided or unnecessary tension. After you have made all of the bends you really wanted, twofold truly investigate your work to guarantee it is right preceding progressing forward toward various advances like cleaning or adding plans to its surface.

Applications

Brass sheets are an adaptable material that is used broadly in various fields for various purposes. They are really great for many things, such as designing or making things work on account of their exceptional characteristics.

Use in Building & Constructions

Brass sheets are frequently used in building and construction because of their strength, durability, and attractive appearance. These materials can be used to build roofs, walls, doors, and windows, as well as decorative items like plaques and statues. Brass is a gold variety that gives buildings an extravagant appearance.

For Auto industry:

Brass is regularly utilized in vehicles because of its protection from scouring and absence of rust. It is frequently used in engine components like pumps, valves, and carburetors due to its resistance to high temperatures. Because they can be easily shaped into a variety of shapes, metal sheets are also used to make the exterior trims on automobiles.

In Electric appliances:

Brass metal is significant for making electrical gadgets like switches, connectors, fittings, attachments, and terminals since it is a decent conveyor of power. These components must have good conductivity in order to ensure that electricity flows smoothly without getting too hot or losing power.

Musical Instruments:

Because of their rich, deep, and resonant sounds, brass parts are used in a lot of musical instruments. The metal tubes that make up saxophones, trombones, and trumpets are known as brass. Cymbals, then again, utilize a particular sort of metal to utter their unmistakable sound.

Use in Furniture

Metal is perfect for making many-sided plans on furniture like bureau handles or table legs since it is not difficult to shape. Because of its golden hue, everything it touches looks fancy and expensive.

Jewelry Making:

Metal has been used to make gems for a long time due to the fact that it is less expensive than gold and looks as sparkling. For studs, arm bands, and pendants, precise plans are made with metal sheets.

Find in Marine Industry

Brass sheets are frequently used in ships and boats because they do not rust in saltwater. They are used to make different parts for ships, like propellers, fittings, valves, and construction plates.

For DIY Projects:

Metal sheets are much of the time utilized by a many individuals who like to make things at home to make cool designs or little things like plate and light holders for DIY projects. It is simple to cut, shape, and connect with simple tools because it can be used in multiple ways.

Types of Finishing & Polishing

Metal sheets are frequently treated with exceptional finishing and cleaning strategies to make them look decent and safeguard them from getting messy and corroded. Smooth and shiny surfaces are frequently achieved through buffing and cleaning. It makes use of cleaning products, buffing wheels, or soft cloths. You can apply a clear enamel coating to the shiny brass to prevent it from changing color.

This will safeguard it from residue and dampness. To make something look more present day, you can utilize harsh brushes or cushions to make a smooth, matte completion that is less inclined to show fingerprints and scratches. Chemicals are used in the patination process to change the color of brass so that it looks old or antique. The colors can be dark brown, green, or black. Brass is smoothed out by sandblasting with particles that move quickly.

This is useful for setting up the metal for medical devices or giving it a matte completion. Metal sheets can likewise be covered with different metals like nickel or chrome to make them more impervious to rust and give them a smart look. Albeit not as normal, anodizing can be utilized to make a defensive layer on metal, which can likewise be colored to offer more variety choices. Each plan can be changed in accordance with explicit issues relying upon the utilization and climate the metal will confront.

Conclusion

Metal sheet is a tough material that opposes rust, has a decent appearance, and can be utilized in various ways. Brass sheets come in a wide variety of shapes and sizes, including C260, C464, C360, and C280. Each type has its own remarkable attributes. Sheets of metal are used in various industrie to make electrical things, plumbing apparatuses, marine equipment, beautiful structures, and different things.

You will actually want to pick the best metal sheet for your undertaking and guarantee its prosperity assuming you are know about the different kinds and capabilities they can serve. Working with metal sheets can be fun and satisfying if you have the right devices and ability to use them. You can produce long-lasting, beautiful, and useful goods. Masion specializes in customizing a wide range of sheet metal processing solutions to meet your specific project requirements. We provide a one-stop shop for all of your fabrication needs thanks to our expertise in the production of sheet metal, the processing of metal pipes, and the assembly of plastic components.

FAQs

Can sheet metal brass be soldered or welded?

Brass can be soldered or welded if the right tools and methods are used. Brazing, patching, and welding strategies like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are normally used to join metal sheets.

How do you maintain brass metal sheet?

Brass can be kept up by standard cleaning to empty earth, oil, and stain. For cleaning, you can use water and a gentle cleanser, or you can use commercial brass cleaners. Brass surfaces that have become discolored can be brought back to life with a brass clean.

What are the limitations of using sheet of brass?

The price of brass can be higher than that of steel or aluminum, for example. In specific circumstances, metal might encounter dezincification, heading to corruption of mechanical properties. Over time, brass’s appearance can be altered by developing a patina or changing color.

Where can you purchase sheets?

Sheet brass are available from metal suppliers, gear stores, and online retailers represent considerable authority in metal things. It’s fundamental to choose a real supplier like masion to ensure the quality and consistency of the metal sheets.

What types of brass metal sheets are available?

There are a couple of kinds of sheets, isolated essentially by their zinc substance. Normal types consolidate 70/30, additionally known as cartridge brass metal, which is more malleable, and 60/40, which offers extended quality and hardness.

What are the main properties of brass sheeting?

These sheets are known for their disintegration opposition, adaptability, and flexibility. They are also very warm and electrically conductive, and they look like shining gold.

Are sheets brass magnetic?

No, sheets of Brass are not magnetic because they are mostly made of non-magnetic materials like copper and zinc. So, they do not attract other metals.

Send Your Inquiry Today

+86-18969433502

sales@sheetmetalmasion.com