Solution

Chinese Professional Plastic Injection Parts Manufacturer

We specialize in processing various complex plastic parts

•Internal design and manufacturing of plastic injection parts

•Assembly of various plastic injection parts for sheet metal components

•Providing assembly and packaging services for various plastic injection parts

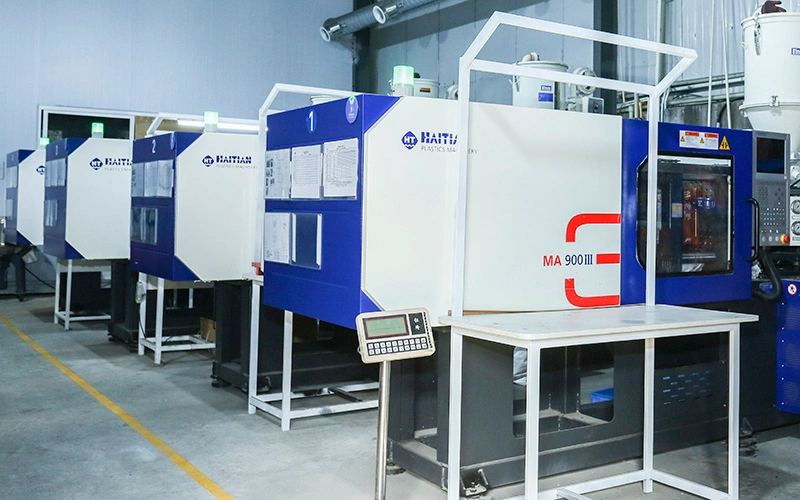

•Utilizing a 500-ton modern high-speed plastic injection machine

•Employing professional engineers and machinist specialized in the design, manufacturing, and assembly of complex plastic injection parts.

+86-18969433502

sales@sheetmetalmasion.com

Plastic Injection Solution

We offer outstanding plastic injection manufacturing services by inputting AutoCAD, .STP, and PDF design drawings into advanced equipment, followed by the production of high-quality injection molded products or components by our experienced professional team. We ensure that the injection molded parts meet your design requirements, and we are capable of producing challenging injection molded products.

Our plastic injection production process is stable, ensuring smooth operation throughout production. Our R&D design engineers possess exceptional technical expertise, enabling them to optimize molds for mass production in advance, reducing mold wear and extending mold lifespan. Additionally, our engineers conduct production process and plastic part structure analyses to ensure high-quality plastic injection production.

We are capable of producing plastic parts using various materials and can manufacture custom-designed plastic products with complex shapes. Our advanced R&D design engineering team ensures the realization of your plastic part designs.

After plastic injection, we conduct comprehensive quality inspections on the molded parts to ensure dimensional tolerances, shapes, and other specifications meet the requirements of the design drawings and achieve the high-quality standards demanded by our customers. Our in-house quality inspection team provides support for injection mold fixtures and inspection fixtures, enhancing inspection efficiency.

We offer a variety of sheet metal and plastic assembly services, assembling plastic parts, screws, nuts, custom sheet metal components, wooden boards, electronic components, and more. We provide robust packaging materials to ensure that your plastic and sheet metal assemblies are delivered to you completely without any damage during transportation.

Plastic Injection Production Capacity

Materials

• Standard Plastics

• Engineering Plastics

• ABS、PP、PE、HDPE、PA6、PA66、PC/ABS、FR4、PEEK、PTFE、POM、

• PP/GF、PA/GF、PMMA、PC、uPVC、PVC

• PBT+PC

• Thermoplastic Polyurethane (TPU)

• Thermoplastic Elastomer

Colors

• Customized Colors

• Pantone Matching System (PMS)

• RAL Color Matching System

• Masterbatch

• Precise Color Calibration

Machine

•plastic injection machine 90T

•plastic injection machine 120T

•plastic injection machine 200T

•plastic injection machine 300T

•plastic injection machine 500T

Secondary Processing

• Plastic Component Assembly Service

• Secondary Assembly Molding

• Insert Components

• Ultrasonic Welding

• Laser Marking

Surface Finish

•Pad Printing

•Silk Screening

•PVD Coating

•Heat Transfer Printing

•Sandblasting

Why Choose Us for Plastic Injection Manufacturing

We are a professional plastic manufacturer equipped with advanced equipment, technical expertise, and skilled professionals to ensure your project’s customized requirements. From initial plastic part design to plastic injection production, we provide full-cycle tracking to meet your needs. Here’s why you should choose us as your plastic injection manufacturer:

In-house design and mold manufacturing with DFM support:

Our in-house professional R&D design team can design and manufacture each of your plastic parts, providing support and assistance to your designs.

Complex process manufacturing:

In addition to simple plastic injection, our outstanding team can also perform complex plastic injection processes such as insert molding and overmolding to meet the requirements of complex plastic injection parts.

Customized plastic injection solutions:

With years of manufacturing experience and rich expertise, our engineers can meet your specific requirements for custom plastic parts, providing solutions from initial design to plastic injection processing.

Advanced equipment and technology:

Equipped with advanced equipment and plastic injection technology, along with multiple plastic part production lines, we can quickly handle your plastic part projects.

Quick response and timely delivery:

Our experienced sales team will quickly engage with you to streamline communication processes, expedite production, and deliver plastic parts to you promptly.

Certificate of Injection Plastic Parts

We’ve 17 years of experience in plastic injection manufacturing. Since then, we are complied with quality standards. Here are our certifications.

● ISO9001 Quality Management System

● ISO14001 Environment Management System Certification

● TS16949 Automotive Industry Quality Management System

● FSC Forest Stewardship Council

● Patent 47 patents of invention

● CE CONFORMITY EUROPEENNE(As you need we could apply)

● RoHs Restriction of Hazardous Substances(As you need we could apply)

● SGS (As you need we could apply)

● TUV(As you need we could apply)

Diversity of Our plastic injection Parts

Masion can deal with small to large-size plastic injection product manufacturing. We can deal with all the complex and simple designs quickly

Checkout our Another Manufacturing Solutions

Sheet Metal Fabrication

Metal Tube Processing

Laser Cutting

We’re here to provide you with custom solutions for various complex sheet metal manufacturing projects.

Masion gives custom processing services solutions for various shapes. They may include round, square, and special-shaped metal tubes.

Masion provides customized precision laser cutting services solutions. They are used for various materials and complex shapes.

Stamping

Sheet Metal Assembly

Contract Manufacturing

We deal with the production and manufacturing of progressive dies and compound dies. So, we provide solutions for precision stamping parts production services

We provide sheet metal parts assembly services, suitable for large, small, various projects complex sheet metal parts assembly.

We have Vertical Integration Production and Assembly of Sheet Metal Parts Solution.

Resources

Aluminum sheet metal fabrication converts long sheets into specific shape. So, in this article, we will give you a complete guide to this process and its demands in the manufacturing industry.

You can learn some tips for sheet metal design from this article. Understand the need, importance, and why the sheet metal design is crucial to play a key role in diverse industries.

This guide allows you to create good sheet metal parts. We will start with the basics then discuss design best practices. Sounds exciting? Let’s delve in deeper to uncover facts.

Frequently Asked Question

Q: Do you have any quality certifications for your factory?

We have obtained quality management certifications such as ISO9001-2015, ISO16949, etc., and strictly control the quality of plastic parts according to the quality system, thus enabling us to produce high-quality plastic products.

Q: How do you control the quality of your injection molded plastic parts?

Mold Design and Manufacturing: Firstly, we internally develop and design injection molds. Our experienced engineers with many years of expertise utilize advanced technology and sophisticated mold processing equipment to ensure the high precision and stability of the molds, thereby guaranteeing that the dimensional tolerances and shapes of the plastic parts conform to the design requirements on the drawings.

Material Selection: We procure genuine branded high-quality plastic pellets, and we meticulously select appropriate materials for the plastic parts. We also have traceability codes for raw materials to ensure no confusion in material usage. Moreover, the selected materials must meet the mechanical and chemical performance requirements of the design.

Plastic Injection Production Process Control: Our skilled engineers fine-tune the parameters of the equipment during the plastic part production process, such as temperature, pressure, speed, etc., to ensure uniform cooling, complete crystallization, full filling, and easy demolding of the plastic during the production process, thereby ensuring the stable quality of the plastic parts.

Full-process Quality Inspection: We conduct first-piece inspection, in-process inspection, and final inspection of the plastic parts. The inspection includes dimension inspection, appearance inspection, and for high requirements, we also conduct mechanical performance and physical performance tests, etc., to ensure that the products meet your requirements.

Employee Training: We regularly provide equipment operation training and quality training for operators to ensure that any problems discovered during the plastic part production process can be promptly identified and adjusted.

Q: Can you produce complex plastic parts?

Yes, our skilled engineering team and advanced equipment are proficient in injection molding processes such as insert molding and overmolding. We can produce various complex plastic parts. If you have even more complex plastic parts, you can contact us.

Q: Can you assist with plastic part design?

We have a research and development design team that can assist you with plastic design, provide design evaluations, and optimize production designs to facilitate manufacturing, reduce costs, and ensure that the products meet your usage requirements.

Q: What materials can your injection molding produce?

According to your requirements, we can process various types of plastic parts, typically including ABS, PP, PE, HDPE, PA6, PA66, PC/ABS, FR4, PEEK, PTFE, POM, PP/GF, PA/GF, PMMA, PC, uPVC, PVC, etc. If you have specialty plastics, you can contact us for further information.