Melting Point of Steel – An Ultimate Guide

You cannot deny the importance of the steel in various industries. It serves a key role in the form of equipments or accessories in aerospace, construction, automotive, as well as manufacturing. Using the steel in these industries require a crisp understanding of the melting point of steel. Getting familiar with melting point of steel assist in making reliable, and dependable equipments. This way you can save up in the long run by avoding accidents, repairs, and frequent replacements. The key objective of this blog is to guide you through steel and its grades melting points, melting process, composition, comparison with other metals, and much more. Sounds exciting? Let’s dive right in!

Table of Contents

ToggleFactors Influencing the Melting Point of Steel

Carbon Content

The proportion of carbon that exists in steel is very significant in the sense that it can dictate the actual melting point or temperature of steel. The one shortcoming of the carbon percentage is that, as the percentage rises, the melting point reduces. Low-carbon are known to melt at high temperatures than high-carbon steels like tool steels. For instance, mild steel which contains approximately 0. 2% carbon melts at a higher temperature than steel with 1%.

Alloying Elements

Various alloying elements including manganese, chromium, nickel, as well as molybdenum. Presence of these elements may increase or decrease the melting point of steel. For example the nickel and chrome raises the melt temperature while the presence of maganese decreases it. Apart the presence of these elements transform the properties of these materials.

Impurities

Any material which in unnecessary or alter the composition of the metal is refer to impurity. These undesirable elements impair the strength of steel and thereby increases the level of its failure at relatively low temperatures. Impurities should not be present in large quantities so as to produce high-quality steel that has a consistent melting point especially in corporate uses.

Thermal Treatment

Heating technique plays a key role in transforming element strucutres just like annealing or tempering. Annealing removes stresses in steel and makes it less resistant to melting while tempering increases the steel’s ability to be toughened even if the amount that the temperature is raised to reduce its melting point. The treatment method you select determines how the steel will perform in relation to heat.

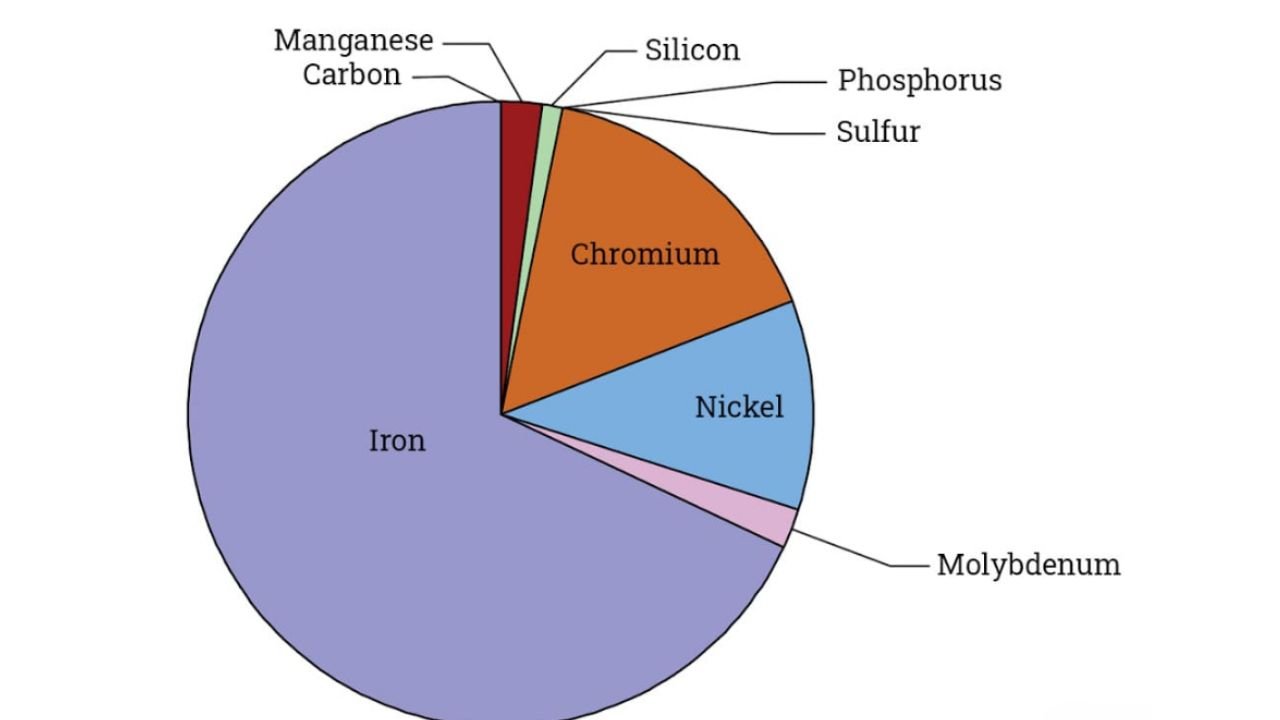

Understanding the Composition of the Steel

Uncover useful information on the key elements that make up steel. There are over six key elements with a percentage ranging from 0.01 to 99 percent. Please note that iron is the main element with the largest percentage of up to 99 percent. Further you can review the role of each element in the table below:

| Sr. No. | Element | Typical Percentage | Role |

| 1 | Iron | 98-99% | Base metal, provides strength and durability |

| 2 | Carbon | 0.03-1.5% | Affects hardness, strength, and ductility |

| 3 | Manganese | 0.2-1.5% | Improves strength, toughness, and wear resistance |

| 4 | Silicon | 0.1-1.0% | Deoxidizer, improves strength and electrical properties |

| 5 | Phosphorus | 0.01-0.05% | Improves machinability but can reduce ductility and toughness |

| 6 | Sulfur | 0.01-0.05% | Improves machinability but can reduce ductility and toughness |

| 7 | Alloying elements | Varies | Enhance specific properties like corrosion resistance, heat resistance, or toughness |

Standard Melting Points of Steel

The melting point of steel in various units of temperature are as follows:

- Melting point of steel in Fahrenheit is around 25000F

- Melting point of steel in Celsius is around 13700C

- Melting point of steel in Kelvin is around 1640

Melting Points of Specific Steel Types

Melt point of stainless steel

It has higher melting point than carbon steels within 1530 degrees celsius.

What is the melting point of low carbon steel?

Low-carbon steels are placed at a melting point range of 2,500 to 2,700 F. These steels contain lower carbon hence they have better ductility than high carbon steels. This means to melt them you need to acquire a relative higher temperature.

What is the melting point of medium carbon steel?

It melts in the range of 26000F up to 27500F. These steels are a mixture of ductility as well as durability.

Medium-carbon steel, containing 0.3% to 0.6% carbon, melts at around 2,600°F to 2,750°F. These steels offer a balance between strength and ductility.

Melting point of mild steel

Low carbon steel, also referred to as mild or plain carbon steel, has a melting point of between 2570 and 2700 degrees fahrenheit. It contains less carbon than the higher carbon steels which makes it easier to weld and shape, but it has lower tensile strength compared to the higher carbon steel.

Melting Points of Low Carbon Steels (Mild Steel)

Uncover insights on the melting points of all low carbon steel grades in the following table. Apart also get familiar with the reason for the listed melting point:

| Sr. No. | Steel Grade | Melting Point (°C) | Reason for Melting Point |

| 1 | Melting point of 1018 steel | 1420-1465 | Low carbon content, resulting in a relatively low melting point. |

| 2 | Melting point of 1020 steel | 1420-1465 | Similar to 1018, low carbon content contributes to a low melting point. |

| 3 | Melting point of 1030 steel | 1420-1465 | Again, low carbon content keeps the melting point relatively low. |

| 4 | Melting point of 1040 steel | 1420-1465 | Similar to other low carbon steels, the melting point is influenced by the low carbon content. |

Melting Points of Medium Carbon Steels

Uncover insights on the melting points of all medium carbon steel grades in the following table. Apart also get familiar with the reason for the listed melting point:

| Sr. No. | Steel Grade | Melting Point (°C) | Reason for Melting Point |

| 1 | Melting point of 1065 steel | 1420-1465 | While the carbon content is higher than low carbon steels, it’s still within a range that doesn’t significantly elevate the melting point. |

| 2 | Melting point of 1080 steel | 1420-1465 | The increased carbon content compared to low carbon steels might slightly raise the melting point, but it’s still within a relatively low range. |

| 3 | Melting point of 1095 steel | 1420-1465 | The highest carbon content among medium carbon steels could potentially lead to a slightly higher melting point, but it’s still within the general range for this category. |

Melting Points of Stainless Steels

Uncover insights on the melting points of stainless steel grades in the following table. Apart also get familiar with the reason for the listed melting point:

| Sr. No. | Steel Grade | Melting Point (°C) | Reason for Melting Point |

| 1 | Melting point of 440 steel | 1450-1500 | The presence of chromium and other alloying elements in stainless steel can slightly elevate the melting point compared to carbon steels. |

| 2 | Melting point of 410 steel | 1450-1500 | Similar to 440, the alloying elements in stainless steel contribute to a slightly higher melting point. |

Melting Points of Alloy Steels

Uncover insights on the melting points of alloy steel grades in the following table. Apart also get familiar with the reason for the listed melting point:

| Sr. No. | Steel Grade | Melting Point (°C) | Reason for Melting Point |

| 1 | Melting point of 4140 steel | 1450-1500 | The alloying elements in 4140 steel can slightly increase the melting point compared to carbon steels. |

| 2 | Melting point of 4150 steel | 1450-1500 | Similar to 4140, the alloying elements contribute to a slightly higher melting point. |

| 3 | Melting point of 4340 steel | 1450-1500 | The combination of alloying elements in 4340 can further elevate the melting point compared to simpler steels. |

| 4 | Melting point of 8620 steel | 1450-1500 | The specific alloying elements in 8620 can influence the melting point, but it generally falls within the range for alloy steels. |

Melting Points of Carbon Steels

Uncover insights on the melting points of carbon steel grades in the following table. Apart also get familiar with the reason for the listed melting point:

| Sr. No. | Steel Grade | Melting Point (°C) | Reason |

| 1 | Melting point of a steel | 1370-1530 | General range for steel, depending on alloying elements. |

| 2 | Melting point of a2 tool steel | 1450-1510 | High carbon content and alloying elements like chromium and tungsten increase melting point. |

| 3 | Melting point of a24 steel | 1400-1450 | Similar to A2 but with slightly lower alloying elements. |

| 4 | Melting point of a242 steel | 1400-1450 | Similar to A24, with variations in specific composition. |

| 5 | Melting point of a36 steel | 1370-1420 | Lower carbon content and fewer alloying elements than tool steels. |

| 6 | Melting point of ar500 steel | 1400-1450 | High-strength alloy steel, with a melting point influenced by alloying elements like manganese and silicon. |

Comparison of Melting Points: Steel vs Other Metals

By viewing the table below you can get a comparative analysis on: Melting point of aluminum vs steel

- Melting point of brass vs steel

- Melting point of bronze vs steel

- Melting point of cast iron vs steel

- Melting point of copper vs steel

- Melting point of gold vs steel

- Melting point of steel vs titanium

- Melting point of glass vs steel

| Sr. No. | Material | Melting Point (°C) | Applications |

| 1 | Aluminum | 660 | Aircraft parts, cookware, cans |

| 2 | Steel | 1371 -1593 | Construction, automotive, tools |

| 3 | Brass | 930 | Plumbing fixtures, musical instruments, hardware |

| 4 | Bronze | 900 -1050 | Sculptures, bearings, marine hardware |

| 5 | Cast Iron | 1150-1300 | Engine blocks, cookware, pipes |

| 6 | Copper | 1084 | Wiring, plumbing, cookware |

| 7 | Gold | 1063 | Jewelry, electronics, dentistry |

| 8 | Titanium | 1668 | Aerospace, medical implants, sports equipment |

| 9 | Glass | 1400 -1600 (varies) | Windows, bottles, optical lenses |

From the above table it is clear that the melting point of steel is higher than the melting point of the:

- Aluminum

- Brass

- Bronze

- Cast iron

- Gold

- Copper

But on the same side the melting point of steel is lower than the titanium as well as glass. Besides, you can get insights into the key applications of each metal present in the table above.

Melting Points of Various Steel Forms

The following table help you reveal insights on the melting points of different steel products along with their applications:

| Sr. No. | Steel Product | Melting Point (°C) | Applications |

| 1 | Steel beams | 1400-1500 | Construction of buildings, bridges, and other structures |

| 2 | Steel mesh | 1400-1500 | Reinforcement in concrete, fencing, and security barriers |

| 3 | Steel plates | 1400-1500 | Shipbuilding, machinery components, and structural elements |

| 4 | Steel wire | 1400-1500 | Fencing, cables, nails, and springs |

| 5 | Steel wool | 1400-1500 | Abrasive for cleaning and polishing |

| 6 | Steel can | 1400-1500 | Food and beverage packaging |

Process to Melt Steel – Step by Step

By following the process, you can melt the steel:

Preparation and Material Selection

First, select the grade of steel for the purpose of melting it. Other important factors to include are carbon percentage and any alloys like chromium or nickel which has a bearing on the melting point. Secondly, as a result of treatment of raw materials, there might be necessity to sort and clean them, especially if you intend to recycle steel. This cleans the materials so that during the melting process and after the process is complete, the final melted product does not contain any contaminants such as dirt, rust or unwanted metals.

Heating in the Furnace

It is possible to melt steel using various types of furnaces Since. Some of the types are Electric Arc Furnace also referred to as the EAF, Blast Furnace, and the Induction Furnace. After selecting, feed steel scrap or raw materials to the furnace. The heating process starts and rises to temperatures of 1370 to 1530 degrees Celsius. Depending on the type of furnace chosen, it has a certain energy efficiency and is designed for certain production ranges and types of material.

Melting Process

In the melting process, steel is subjected to heat that is above its melting point. Gradual heating is essential to ensure that there is no uneven melting of the given solid. When steel is heated there are chemical processes that begin to occur such as the reduction of iron oxide which produces gases. Scum forms through slag, which eventually floats on the surface. This type of slag, when removed, makes the molten steel to be ready for refining or what can also be referred to as the finishing process.

Refining the Molten Steel

As the steel melts, it is subjected to refining in order to make it better. Depending on how you want your steel more refined, you can add chemicals or fluxes. Modify the elements of the alloy by the addition of the other elements such as chromium or nickel among others depending on the intended use. Most of the trapped oxygen and other gaseous elements are driven out through degassing and this improves the overall strength and quality of the final steel product which minimizes imperfections.

Pouring the Molten Steel

After refining, the molten steel can be poured into moulds to form a desired shape or direct into an ingot mould. For continuous production, ensure that utilize modern continuous casting practices in which the molten steel forms long strands. This method works well and independently reduces the anisotropy and increases the stability and quality of the work. Correct pouring of steel reduces imperfections in the end product, which enables the manufacture of sturdy and durable products for physical operations.

Conclusion

It is important for any industry: Civil Engineering, Mechanical Engineering, Chemical Engineering, Metallurgy, Aerospace and etc. Understanding how such variables as carbon, alloying elements, and impurities affect the melting point of steel allows a welder or manufacturer to make better decisions during the various processes of steel-making and welding. Both stainless steel and carbon steel types benefit from understanding values such as the melting point point in order to work even better in projects.

Read More:

Does Stainless Steel Rust? Causes, Types, and Solutions

One Response