A Complete Guide to Aluminum Sheet Metal Fabrication

Table of Contents

ToggleAs the world is constantly progressing towards new and advanced solutions, it is also promoting innovative technologies that are cost-effective and must be sustainable and eco-friendly. If we particularly talk about manufacturing industries like aerospace, marine, packaging and automobiles, their demands for specific materials have increased. They need lightweight and strong materials to cater to all the manufacturing needs. Aluminum sheet metals play a significant role in it.

So, let’s start with the basic things of the sheet metal fabrication process and get a better understanding of this process.

How to Define Sheet Metal Fabrication?

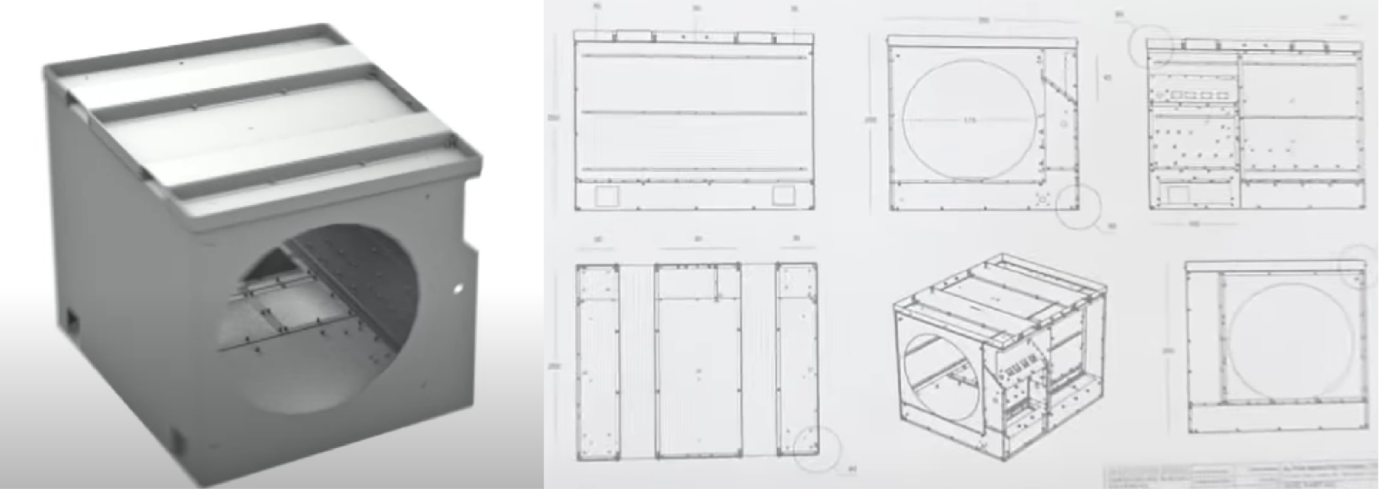

This process includes the conversion of long and flat metal sheets into the required shape. It comprises of several steps like cutting, bending, shaping, and assembling metals. These processes apply to manufacturing industries to make products like car bodies, aircraft panels, HVAC systems, appliances, and more.

Additionally, it starts with cutting the sheet to the specific shape. Different tools like shears, plasma cutters, or laser cutters help in cutting the sheets. After that, the metal sheets may undergo a bending or forming process. Besides this, welding, punching, drilling or finishing processes can also be carried out to complete the fabrication process, which depends upon the specific demands and applications.

Furthermore, if we talk about Sheet Metal Fabrication, the most crucial step is to identify which metal or material we are using to mould and make desired products. This selection is usually based on the versatility, strength, and durability of sheet metals.

What is the Definition Aluminum Sheet Metal Fabrication

It is the manipulation or conversion of the aluminum sheet into a required form or product.

By comparing other metals with Aluminum, we get to know that Aluminum is quite popular. The main reason for this choice is its lighter density, cost-effectiveness, flexible nature and range of options for grades. For instance, high-strength Aluminum is effective for the aerospace industry. While corrosion-resistant aluminium alloys are best fit for the marine industry. Because they are highly weldable and weather-resistant.

Complete Aluminum Sheet Metal Fabrication Processes

The Aluminum Sheet Metal Fabrication is an intricate method. It requires multiple precision equipment, well-experienced labourers and expertise in working with aluminum metal. It undergoes several steps like bending, cutting, welding, punching, or any other based on the production requirement.

So, Here we will discuss all the steps one by one to get the proper insights of this process.

Design of Product

The Aluminum sheet metal fabrication starts with the design of the final products. In this phase, we get an estimate of the specifications and requirements of the product. This may include particular dimensions, required tolerances, material specifications and considerations for manufacturability.

2D and 3D Designing of Final Product

Moreover, the engineers or designers use tools like Computer-Aided Design (CAD). They consider factors like structural integrity, functionality, aesthetics, and regulatory compliance, and create detailed drawings and models of the desired products. So, designing is the foremost and most essential step to start the fabrication process.

Material Selection

Once the design of the product is finalised, the second step is material selection. The Aluminum sheets are available in multiple grades. These grades are assigned based on their thickness. They define the application of the aluminum sheet in different product making. So, the material you are selecting must meet the product requirement. Several factors also influence your material section. These factors are generally mechanical properties, such as strength, ductility, and corrosion resistance. Here is a list of the best aluminum grades for the metal fabrication process and their applications in different industries. So, choose the grade that suits you best.

| Aluminum Grade | Properties | Best Applications |

| 1100-H14 | High ductility, a good option for drawing and welding | Drawing, welding |

| 3003-H14 | Affordable, highly corrosion-resistant | General fabrication, automotive parts |

| 5052-H32 | High formability, corrosion resistance | Tanks, chassis, marine parts |

| 6061-T6 | High strength, weldability, corrosion-resistant | Aircraft parts, automotive, boats |

| 2024-T3 | High strength-to-weight, aerospace use | Aircraft structures, aerospace components |

| 5083-H321 | Excellent corrosion resistance, marine use | Shipbuilding and marine parts |

| 7075-T6 | High strength, toughness, aerospace use | Aircraft components, high-performance equipment |

| 6063-T5 | Good extrudability, formability | Window frames, architectural structures |

Different Aluminum Grades and Their Industrial Applications

Shape Selection

In some cases, the customers demand their custom aluminum sheet metal. So, they can configure the aluminum sheet metal, in different shapes such as Rectangles, Squares, Triangle (various versions), Circle, Divided Circle, Rectangle with centred holes, Ring, Frame, Angle, Z Channel, Hat Channel, U Channel and Tray/Box.

Based on the shapes, the customers can further choose the thickness, tolerance, surface finishes such as anodizing, and powder coating. Moreover, they can choose additional fabrication processes like bending, punching, or welding.

Cutting the Sheet Metal into Desired Shape

After selecting the desired shape and material of the custom Aluminum sheet metal, The next most important step is cutting Aluminum. This process can be carried out using two methods, i.e. Shearing or Non-Shearing Method.

Cutting of Aluminum Sheets

4.1. Shearing Methods

Aluminium is relatively flexible and an excellent conductor of heat. That is why, many industries use heat application to cut it into small pieces. But, sometimes, it does not bear high heat conditions. So, another way is used to cut the sheet metals i.e. Shearing. In this method, the aluminum sheet metal is cut through force. There are several ways included in the shearing method such as;

- Blanking: During this method, you simply punch the sheet and cut it into smaller parts. So, after punching, you can easily use die and extract the metal.

- Punching: Just like the blanking process, it also allocates the shear force and gets the metal piece present in the die section.

- Sawing: Sawing helps in cutting the sheets. So, it gradually cuts the sheet metal and makes a sequence of incisions. You only apply friction or shear force and segregate the tiny fractions. This saw could be of several types. Thus, these all types offer different services and help the cutting process easier and smoother.

Aluminum Sheet Pressing

4.2. Non-Shearing Methods

Unlike Shearing methods, we do not apply any external forces on the sheet metal to cut it down into smaller parts. We use different applications like heat for cutting purposes. These non-shearing methods have different types, the following is three most common:

- Laser Cutting: In this process, the beam of the laser helps in cutting the sheet metal. The laser beam metals the focus point to a particular location.

- Plasma Cutting: This cutting method uses ionized gas or plasma to melt down the sheet. This plasma produces heat and ultimately cuts down the sheet into desired pieces.

- Waterjet Cutting: As you can get from its name, waterjet cutting uses a water jet having a high pressure of about 50,000psi at 600m/s. So, this pressure helps in cutting the sheet metal into the required shapes.

Aluminum Sheet Laser Cutting

Forming the Sheet Metal into Specific Shape

Once you are done with cutting, the next step is forming Aluminum Sheet Metal. Here, the sheet metal deforms and then reshape in a particular shape.

So, tere are the following methods usually used in forming aluminium sheet metal, such as;

- Bending: In this process, the aluminum sheet metal deforms or bends into a particular shape. This is usually done by exerting external forces along an axis. This process can only change the shape without affecting its natural volume. There are various techniques you can use to perform this task, such as; Rotary Bending (90-degree bending for sharp angles), V-Bending (use a V-shape die), U-Bending (using a U-shape die), Roll Bending (Roll the sheet) and Wipe Bending (bend internal radius with wipe-die).

- Hydroforming: In this type of forming, you particularly use a die and apply high-pressure fluid to stretch the aluminum sheet metal. This resultantly gives both concave and convex shapes. That is why it has a wide application in the automobile industry for body manufacturing.

- Curling: It is another form of forming sheet metal. During this process, you remove the burrs from the edges of the sheets and make them smoother. This method is usually used to provide hollow and round roll edges to the workpieces. It ultimately increases the strength of the piece and promotes safe handling as well.

- Ironing: In this process, the sheet metal gets consistent wall thickness. So, it has wide application in cans made using dies and punches.

Aluminum Sheet Bending

Joining Aluminum Sheet Metal

Just After forming, the most crucial step in Joining Aluminum Sheet Metal. In this process, several pieces join together to form a complex structure or desired product. So, several ways can be carried out to join these pieces, such as;

- Fasteners: these are temporary choices for the joints, which are particularly used to affix two or more aluminum sheet metals.

- Riveting: In this process, the aluminum sheet metals join using clips, known as rivets, temporarily. Here you drill a hole and insert rivets for joining sheets.

- Soldering: It also joins the two aluminum sheet metals, but does not melt the base metal. Instead of this, soldering joins sheets by heating the fillers until the metal becomes moldable.

- Welding: This method helps join the sheet metals. Here proper heat and pressure helps merge the two sheet metals.

So, welding can also be carried out using several techniques, such as Shielded Metal Arc Welding(electrodes pass current to form an arc), Metal Inert Gas Welding (use unbroken, melted wire electrode with shielding gas) and Tungsten Inert Gas (TIG) Welding (use tungsten electrode)

Aluminum Sheet Welding

Finishing of Aluminum Sheet Metal

So, once you perform the Joining process, a series of finishing of metal starts. This process enhances the metal properties. Moreover, the surface finish also helps in avoiding contamination and deterioration of the product. The finishing can also be of different types.

- Anodizing: In this method, you oxidize the surface by using several ways, such as;

- Type I: Add a thin layer on the surface of sheet metal using chromic acid.

- Type II: Here, add sulphuric acid to resist corrosion.

- Type III: Build a thick and hard coating. It will eliminate corrosion, weathering, and wear from the sheet.

- Bead Blasting: During this process, you use a thin abrasive i.e. glass beads or sand, under compressed air force for smooth finishing

- Brushing: This finishing method uses a brush with filaments to increase the surface quality of sheet metal products. Moreover, you can also eliminate burrs without damaging the product quality.

Aluminum Sheet Powder Coating

Types of Aluminum Sheet Metal in Fabrication

Aluminum has multiple applications in different industries and even households. It is quite thin, sturdy, has a high tolerance and is easily formable. Thus, it is easy to convert it into different shapes and structures. So, let’s deal with all the types available and check which types suit what application in the industry.

Pure Aluminum Sheet

This is considerably popular process in the sheet metal fabrication. They comprise 99% or more aluminum content. Moreover, hey are highly malleable, ductile, resistant towards corrosion and a good conductor of both electricity and heat. They are quite light in weight, which is why, it is the best option for the chemical processing field and marine industry.

Aluminum Alloy Sheet

Unlike Pure Aluminum Sheets, the Aluminum Alloys are composed of alloys like copper, zinc, manganese, or silicon. These alloys give aluminum sheet metal more properties, such as strength, corrosion resistance, malleability or ductility, and better thermal conductivity. The most known series of the aluminum alloy sheet is the 1xxx, 3xxx, 5xxx, 6xxx, and 7xxx series. These all have some specific applications. If you talk about its applications, these Alloy Sheets are widely used in construction, manufacturing, aerospace, and automobile industries.

Anodized Sheet

Anodized Aluminum Sheets have a durable oxide layer on their surface. This oxide layer is produced as a result of an electrochemical process known as Anodizing. That makes them more scratch and corrosion-resistant and also increases their wear resistance ability. Andozing also allows for colouring the aluminum surface with different dyes. Due to this, you can use them in decorative items, architecture, automobile and consumer goods industries.

Painted/Coated Aluminum Sheet

The coated or painted aluminium sheets have a protective coating of polyester, fluoropolymer, or polyurethane paint. This makes the aluminum sheet metal resistant towards weathering, UV radiation, abrasions and chemicals. These sheets are also available in different colours, textures and finishes. So, they are also used in architecture, signage, and decorative items. Additionally, they have wide applications in building facades, automotive components and home appliances.

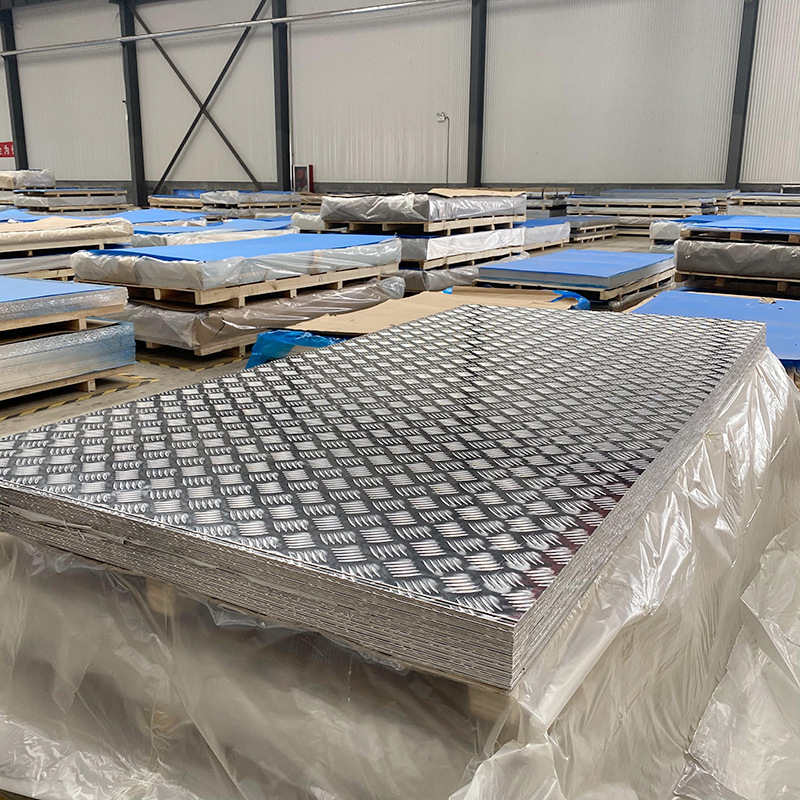

Embossed Aluminum Sheet

Embossed Aluminum Sheets are popular for their raised patterns and designs. These patterns are achieved when the aluminum sheet passes through the embossing rollers. The Embossing process helps the aluminum sheet in improving its stiffness, strength, and anti-slip properties. Moreover, if we discuss its applications, these sheets are widely used in interior designs, signage and packaging as well.

Perforated Aluminum Sheet

These Aluminum Sheets have regular holes, which is why they are known as Perforated aluminum sheets. These holes help in ventilation, filtration, or soundproofing. Moreover, they give high-flow of air, light diffusion, and sound properties. So, if we talk about their applications, these aluminum sheets are widely used in architectural screens, speaker grilles, and HVAC components.

Clad Aluminum Sheet

Clad Aluminum Sheets have several layers of different aluminium alloys or other materials. Their cladding improves their properties like strength, corrosion resistance, thermal conductivity, or surface finish. So, these sheets are suitable for industries such as aerospace, marine, electronics and automobiles.

Mirror Aluminium plate

The Mirror Aluminum plate undergoes polishing processes. So, they can get a high reflectivity surface similar to mirrors. These sheets are mainly used for decoration purposes in architectural industries. Moreover, they are also used in lighting fixtures, solar reflectors, and cosmetic packaging.

Honeycomb Aluminium plate

Honeycomb aluminum plates have a sandwich-like structure. These custom aluminum plate consist of aluminum sheets and are bonded to a honeycomb core, which is also made of aluminum or other materials. These plates have extraordinary strength-to-weight ratios. It makes them suitable options for aerospace, transportation, and architectural applications.

Brushed Aluminium plate

This custom aluminum plate passes through the brushing process and get the textured surface. They have fine lines on their surface which gives them a modern and decorative appearance. Moreover, Brushed aluminum plates are commonly used in furniture and automotive trim.

Aluminum Sheet Plate

Standards Related to Aluminium Fabrication

Here are some industrial standards for aluminium sheet metal fabricator.

| Standard | Description |

| ASTM B209 | Aluminum and Aluminum-Alloy Sheet and Plate |

| ASTM B221 | Alloys of Aluminum, Rods, Wire, Profiles, Tubes and Extruded Bars, |

| ISO 9001 | Quality Management Systems – Requirements |

| ISO 14001 | Environmental Management Systems – Requirements |

| ASTM B660 | Packaging/Packing of Aluminum and Magnesium Products |

Different Industrial Standards for Aluminum

Pros of Aluminum Sheet Fabrication

As we have discussed earlier, aluminum has many advantages that make it a smart. So, for a better understanding, here is a detailed comparison table of some common metals with Aluminum Sheet Metals. It will help us understand its advantages in the fabrication process.

| Property | Aluminum | Steel | Stainless Steel | Copper |

| Density (g/cm³) | 2.7 | 7.85 | 7.93 | 8.96 |

| Tensile Strength (MPa) | 110-570 | 370-870 | 520-860 | 210-220 |

| Corrosion Resistance | Excellent | Moderate | Excellent | Excellent |

| Thermal Conductivity (W/mK) | High | Moderate | Moderate | High |

| Electrical Conductivity (MS/m) | High | Moderate | Low | High |

| Formability | Excellent | Good | Good | Excellent |

| Weight (per unit volume) | Light | Moderate | Moderate | Heavy |

| Recyclability | Fully Recyclable | Recyclable | Fully Recyclable | Fully Recyclable |

Comparison of Aluminum with other common metals

From this table, we can see that Aluminum sheet metals can be a smart choice for the industries. It has a lighter density and excellent formability, which helps it to mould easily in different shapes. Moreover, Aluminum is fully recyclable, so it is considered an eco-friendly and sustainable solution. So, let’s discuss its advantages in depth;

Lightweight Nature

As from the table, we can compare the density of aluminum with other metals. Its density is usually a 1/3rd of steel, which makes it cheaper, less heavy, and easier to carry from one place to another. Moreover, its lower weight makes it a suitable option in the aerospace and automotive industries.

Corrosion Resistance

Aluminum makes an oxidizing layer on its surface. This layer resists corrosion. As you know, this metal is highly reactive towards oxygen. So, when it contacts the air, the oxidizing layer starts to reduce, i.e. 4-5nm. While, if you talk about iron, it oxidizes into rust and results in corrosion. Moreover, if you undergo a fine finishing, then this ability increases.

Aluminum High Strength-to-Weight Ratio

Aluminum has high strength-to-weight ratio. So, this means it has lighter weight and more strength. So, when it comes to weight concerns, aluminum plays a crucial role there. For example, in the aerospace industry, where there is a weight limit for the material used in manufacturing. Here Aluminum is considered a blessing in disguise. Moreover, not only weight, its strength also makes it a perfect fit for aerospace, as its yield strength ranges between 24-438MPa. While if you talk about steel, it (220- 1570MPa), is quite stronger, but its weight doesn’t support lightweight constructions.

Recyclability

Unlike other metals, aluminum can be recycled. So, it is considerably an eco-friendly and sustainable solution for manufacturing. So, the big industries simply can rely on it for a long time. They can make several products and once it deteriorates, they simply recycle it and use it again for manufacturing other products.

Disadvantages of Aluminum Fabrication

When we talk about the pros of Aluminum sheet metal fabrication, there are also some cons. So, let’s discuss them in detail;

Lower Melting Point

Aluminium melts at 660oC, while other metals have high melting points and they can stand the high heat for a long. So, when it comes to aluminum, its melting point becomes a challenge. During the welding process, when it is subject to heat, it can burn before melting. Moreover, it can also make aluminium sheet metal softer and reduce the mechanical strength at 200-250oC temperature. So, here you can say, aluminium is unstable at high temperatures.

Chances of Getting Galvanic Corrosion

As we have discussed earlier, aluminum is naturally resistant to corrosion. But sometimes, it gets in contact with electrolytic fluid. Here the chances of galvanic corrosion increase. The electrolyte helps to transfer the electrons of different metals and aluminum becomes susceptible to galvanic corrosion. In this case, you must choose the metal with the least values.

More Expensive than Other Metals

Aluminum is more costly. Moreover, its cost can make the process lengthy and expensive as well. So, to overcome this issue, manufacturers prefer to use alloys of aluminum, instead of pure aluminium. So, the aluminum alloys come in different grades and can serve for different purposes in different industries.

Significance of Tolerance in Aluminum Sheet Metal Fabrication

Tolerance has a major role in selection of sheets. It will help you in performing extraordinary functions and increase overall production efficiency.

| Tolerance Type | Tolerance Value |

| Hole Sizes | +/- 0.003” |

| Hole to Hole | +/- 0.005” |

| Hole to Edge | +/- 0.010” |

| Hole to Bend | +/- 0.015” |

| Bend to Bend | +/- 0.020” |

| Thickness | +/- 0.005” |

| Flatness | +/- 0.010” |

| Dimensional | +/- 0.020” |

| Weld Joint | +/- 0.010” |

| Corner Radius | +/- 0.003” |

| Surface Finish | +/- 0.002” |

Values of Tolerance for Metal Fabrication

Common Applications in Industries

Aluminum plays a significant role in industries. These industries can be of smaller to large sizes. So, here we are highlighting some sectors that are commonly using Aluminum sheet metals;

- Aerospace: Lightweight materials are the most suitable option for aerospace industries, So, Aluminum sheet metals have a lower weight-to-strength ratio. So, it ultimately finds its way into the aerospace industry for the manufacturing of wings, seats, bodies, and fuselages.

- Packaging: Food and other industries require frequent and excessive material for packaging. In this case, Aluminum plays a crucial role in it. It helps in preserving items for a long time. Thus, Aluminum is significant when it comes to making cans, foils and containers.

- Automotive: Aluminum is widely used in vehicles to make frames, bodies, wheels, electrical wiring, transmission components, and engine parts like pistons and radiators.

- Durable Goods: Various durable goods such as refrigerators, washing machines, dryers, and dishwashers incorporate aluminum components in their fabrication. So, aluminum has a significant role to play in this industry.

- Electrical and Electronic Applications: Aluminum is used in power grids. It finds its applications in electrical wiring, conductors, laptops, coffee makers, and other electrical and electronic devices as well.

Cost-saving Design Tips for Future Progress

If we take a real-time example, cost-saving is essential at both local and global scales. So, cost-saving designs in aluminum sheet fabrication will help us in achieving minimize material waste, less production time and also simplify assembly processes. So, here are some tips you can opt for in aluminum sheet metal fabrication.

- Do not use plating or welding

- Avoid the use of customized fasteners and go with basic fasteners.

- Avoid using complicated designs, shift to simpler designs.

- Choose fine tolerances and do not use specialized tools.

- Choose appropriate raw materials.

Challenges Appear in Aluminum Sheet Metal Fabrication

So, here are some challenges that appear while performing Aluminum sheet metal fabrication

- It is difficult to tackle it at higher temperatures.

- Some processes, like forming, harden the aluminum. So, it requires special handling.

- During surface finish the Aluminium is susceptible to scratching and corrosion.

- Aluminum has abrasiveness. It can lead to tool wear.

- Aluminum is quite a costly material. It makes it less accessible at the local industrial scale.

Alternatives to Aluminum Sheet Metal

If we consider the challenges and disadvantages, there are places where Aluminum is not the best choice to go with. So, in this case, there must be some alternatives that will improve the overall efficiency of sheet metal fabrication. Steel is a proper substitute for aluminum. It has exceptional strength and durability. Moreover, its melting point is greater than aluminum, so it can survive and handle extensive heat conditions. Titanium can also be an alternative to Aluminum Sheet Metals. Because it has a strength-to-weight ratio and a good corrosion resistent.

Aluminum Sheet Metal Fabrication

Moreover, it finds its applications in the aerospace industry. So, other than these, some composite materials, such as carbon fiber reinforced polymers (CFRP), can also be used because of their lightweight properties and can be used for high-performance sports equipment.

So, there are several alternatives to Aluminum. Each of them has their positives and negatives. So, the only need is to select the appropriate material to fulfil your requirements.

Choose Masion for Aluminum Sheet Fabrication

So, if you need basic or customized Aluminum Sheet Metal Fabrication, we Sheet Metal Masion, are here with premier choices for your needs. We have 17 years of experience in the sheet metal industry. So, our expert team can handle easy to intricate designs conveniently. Besides experts, we also provide modern production facilities in Ningbo, Zhejiang, China. These facilities are equipped with advanced technology and machinery.

Additionally, we offer different services. These include prototyping, detailed quality inspection and design services. We do not stop here. Sheet Metals also have vertically integrated management. So, we can streamline your process with high efficiency.

So, If you need Aluminum Sheet Metal Fabrication services in China, Steel Metal Masion is here to serve you. Contact us now

Conclusion

In summing up, Aluminum sheet metal fabrication gives extraordinarily efficient solutions for different industries. They are lightweight, corrosion-free, and good conductors. These properties make aluminium a must-have metal for almost all industries. It finds its applications in the packaging and manufacturing industries. But, where it has some advantages, it offers some drawbacks as well. So, taking both pros and cons into consideration, Aluminum is quite significant in the metal industry.

So, if you need the services for the Aluminum Sheet Metal fabrication. Just go nowhere. Sheet Metal Masion is here to provide all basic and custimized fabrication services in China. Contact us today.

Frequently Asked Question

Q1. What are the most suitable aluminum grades available for fabrication?

The best aluminum grade for sheet metal fabrication is 5052. Because it is highly malleable and ductile and has less chance of cracking during the forming process.

Q2. Is aluminum cheaper when it requires additional finishing?

Absolutely yes, it is less expensive than other metals and offers better features

Q3. Are aluminum gauges similar to steel gauges?

No, they are not. Aluminum gauges are different. Steel goes with the Manufacturers’ Standard Gauge, while, on the other hand, aluminum uses the Brown & Sharpe Gauge (American Wire Gauge).

Read more articles:

Send Your Inquiry Today

+86-18969433502

sales@sheetmetalmasion.com