Understanding the Types of Electrical Boxes. Which One Do You Need?

Picking an electrical box becomes difficult when you need to choose from multiple varieties. You may face safety problems and installation problems when you pick the wrong electrical box. Choosing a wrong electrical box leads to overheating, electrical shorts, or inadequate ground protection. When you select an incorrect electrical box your connections become unstable and create lasting safety dangers. The NEC regulations create an added level of difficulty to follow. This manual breaks down the electrical box selection process by analyzing the benefits and specifications of each type for secure and dependable installs.

Table of Contents

ToggleSelecting the Right Electrical Box

Deciding which electrical box to pick creates a challenging choice due to numerous available options. Make your choice easier by looking at these important selection criteria.

Identify Your Device Type

Different electrical devices need to use separate protective enclosures. Make sure your electrical box fits perfectly with your device to operate safely.

Consider Weather Resistance

Pick weatherproof boxes when using them outdoors. Standard enclosures cannot resist damage from rain, dust, and severe temperature conditions. Weatherproof boxes shield wiring from moisture and environmental elements while keeping the system operational.

Explore Specialized Options

These electrical boxes have unique features for their designated functions. Finding the proper type of electrical box enhances safety and performance particularly when you need it for ceiling fans or media systems.

Assess the Material

Metal boxes stay strong under tough conditions and connect to ground power better than other materials. Plastic electrical boxes stay rust-free and perform well inside building spaces. Choose electrical boxes according to your environment and electrical needs. Please review key characteristics of a few metal materials down in the table.

| Material | Description | Advantages | Typical Applications |

| Stainless Steel | Extremely resilient and strong. Excellent chemical protection and rust inhibitor. High resistance to physical impacts. | Withstands harsh environments. Superior corrosion resistance. Durable. | Industrial and outdoor applications. |

| Carbon Steel | Strong and lightweight. Easier to modify (drilling, etc.). | Cost-effective compared to stainless steel. Good protection for moderate requirements. | Applications with moderate protection needs. |

| Aluminum | Good thermal conductivity, rust-proof, and very lightweight. Easy to machine. | Lightweight. Corrosion resistant. Durable. Low maintenance. | Aerospace, transport, and communication industries. |

| Galvanize Steel | Steel coated with zinc for increased corrosion resistance. | Economical. Suitable for indoor and outdoor use. Withstands adverse weather. | General purpose indoor and outdoor applications. |

Check Cable Entry Compatibility

Make sure the box contains enough openings for your wiring to enter. The installation process becomes more challenging when the box does not support your selected wiring method.

Application

Pick a closed indoor box for locations without water damage. Place outdoor-proof boxes in places that regularly get wet.

Work Type

New work boxes join wall studs before putting up drywall. Old work (or remodel) boxes help you install electrical connections directly onto drywalls. Select the box that matches your renovation or brand-new installation.

Size & Volume

Having too many wires in a single box creates dangerous heat buildup. Choose a wire box with enough space to hold your wiring safely and securely.

Mounting Type

Surface-mounted boxes excel at protecting exposed wiring installations within garages and basements. Flush-mounted boxes install within walls to produce a smooth appearance.

Weight Capacity

To support heavy ceiling fans and light fixtures you need electrical boxes with stronger mounts. Standard boxes work to hold electrical wiring for lighting switches and power sockets. Pick the appropriate weight rating to stay safe.

Types of Electrical Boxes

Junction Box

A junction box protects wire splices from damage and exposure. The container typically measures 4 inches square and comes in metal or plastic versions. The junction box offers enough room to wire together several connection points. Place it in an area that stays easy to reach instead of making it part of your walls or ceiling. Secure the junction box with a protective cover to protect against electrical risks. The junction box functions to join wires into circuits and build proper termination points. You need junction boxes to arrange and shield your electrical connections properly. Junction boxes protect buildings while keeping electrical installations legal.

New Work Electrical Box

Install a new electrical box as part of your project before you put up the drywall. The box attaches directly to wall studs to offer dependable support. This product comes in plastic and metal versions to match various installation conditions. Install it during new home building projects or when adding rooms to existing homes plus major construction work. You should attach the box to the wall before setting up drywall to make sure it stays solidly in place. It creates a steady base that prevents outlets and switches from shifting during normal use. Quality installation produces secure wiring that works well throughout the system. A newly built structure needs this box to create a professional installation that meets building codes.

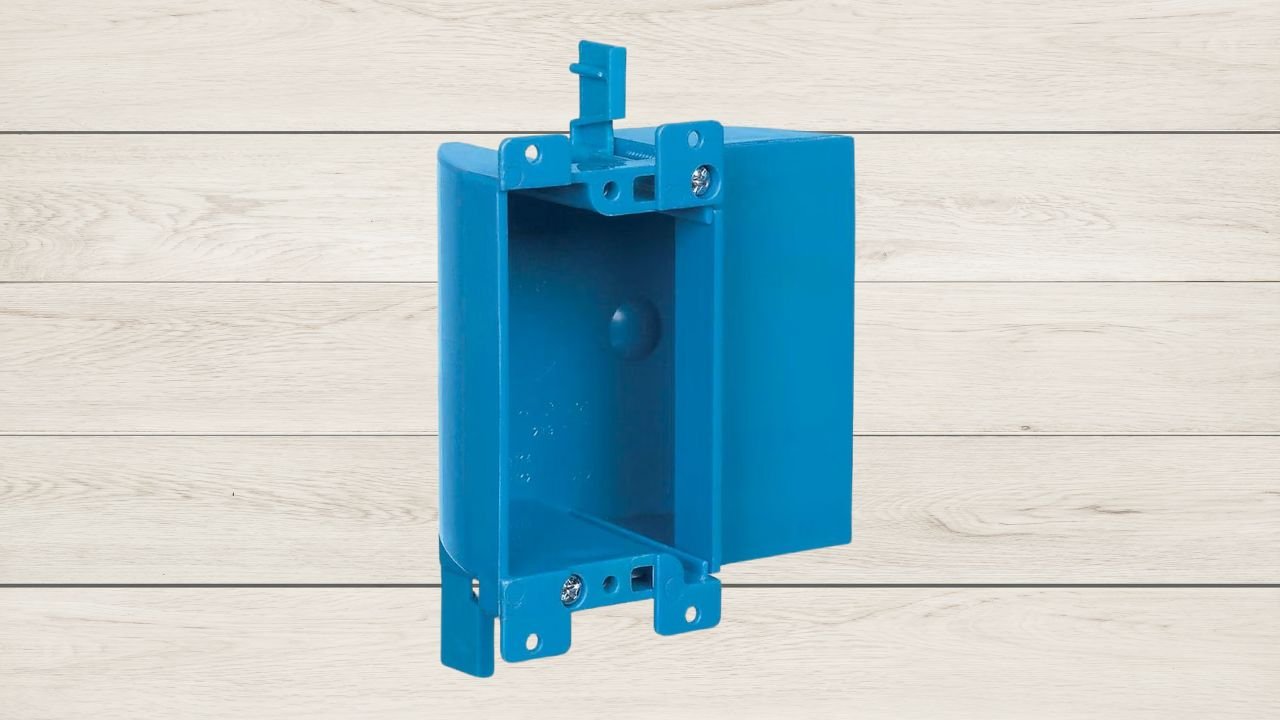

Old Work (Retrofit) Electrical Box

Old work electrical boxes let you install electrical items onto finished walls. You do not need to attach this product to studs during installation because it utilizes an alternative attachment method. This unit connects directly to drywall through built-in mounting wings. Install this type of box if you want to add electrical connections to walls that you haven’t already cut into. This product makes electrical upgrades easier for existing spaces. Buy a reliable model that handles bulky devices well. Check wall thickness before installation to make sure the box fits securely. This box helps you add more electrical outlets to finished rooms through simple updates instead of extensive renovation projects.

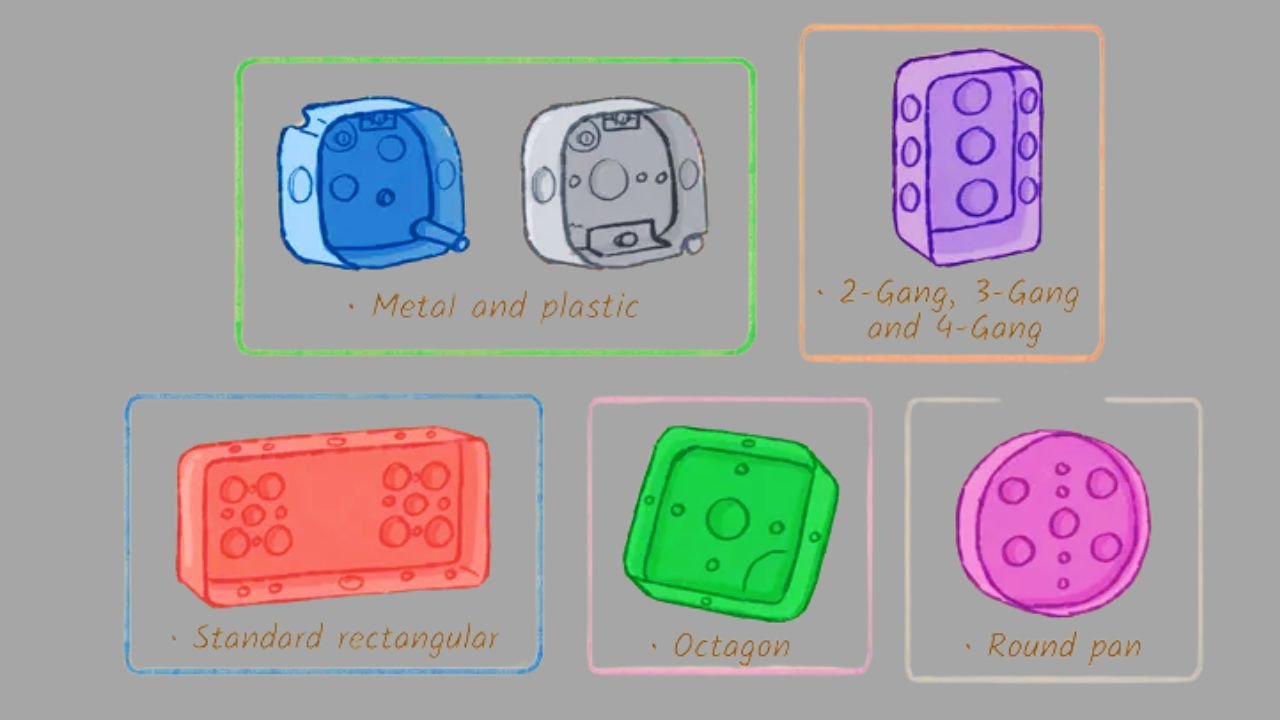

Standard Rectangular Box

The standard box supports one electrical component with a switch. The design measures 2 inches wide and 4 inches tall but the depth changes between different models. It comes as metal or plastic to match any space. Install gangable boxes that link together to create more device outlets when you require several of them. All basic electrical components require this basic box design. Utilize this box for regular building wiring setups when you want to attach one electrical component.

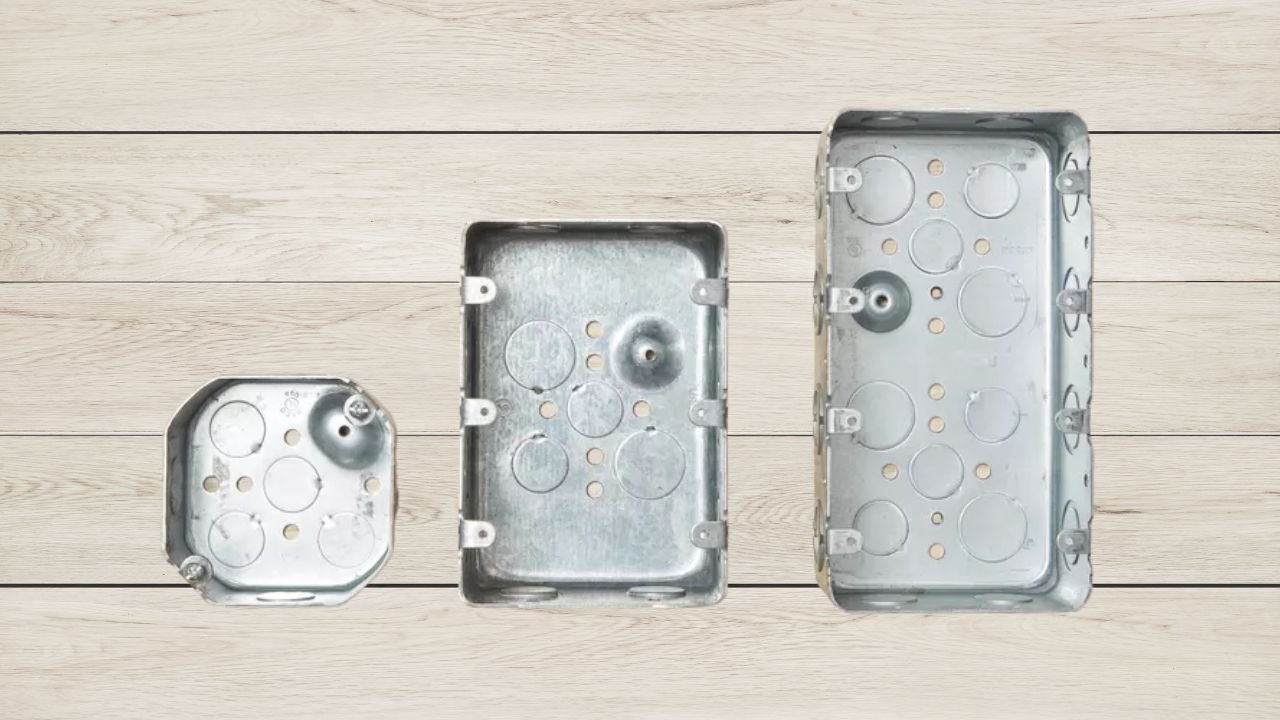

Multi-Gang Boxes (2-Gang, 3-Gang, 4-Gang)

Multi-gang boxes combine multiple switches and outlets inside one housing unit. Steel or plastic materials are used to create multi-gang boxes which exist in two-, three-, and four-gang sizes. These devices create additional wirespace to handle heavier electrical loads in specific parts of your home. Allow enough space between wires to prevent them from becoming too close together. Install these boxes where you need to connect multiple switches and outlets in entertainment rooms or kitchens. Correct set-up helps avoid temperature overloads and electrical risks. You can use these electric boxes to fit multiple devices in one place.

| Sr. No. | Feature | 2-Gang Box | 3-Gang Box | 4-Gang Box |

| 1 | Description | Holds two switches/outlets. | Holds three switches/outlets. | Holds four switches/outlets. |

| 2 | Material | Galvanized steel or plastic. | Galvanized steel or plastic. | Galvanized steel or plastic. |

| 3 | Use Cases | Multiple switches/outlets in one location. | Multiple switches/outlets in one location. | Multiple switches/outlets in one location. |

| 4 | Ideal Locations | Kitchens, entertainment rooms, high-use areas. | Kitchens, entertainment rooms, high-use areas. | Kitchens, entertainment rooms, high-use areas. |

| 5 | Wiring Space | Sufficient for two devices. | Sufficient for three devices. | Sufficient for four devices. |

| 6 | Advantages | Flexibility, consolidates devices. | Flexibility, consolidates devices. | Flexibility, consolidates devices. |

| 7 | Considerations | Ensure adequate wiring space to avoid crowding. | Ensure adequate wiring space to avoid crowding. | Ensure adequate wiring space to avoid crowding. |

| 8 | Installation | Proper installation crucial to prevent hazards. | Proper installation crucial to prevent hazards. | Proper installation crucial to prevent hazards. |

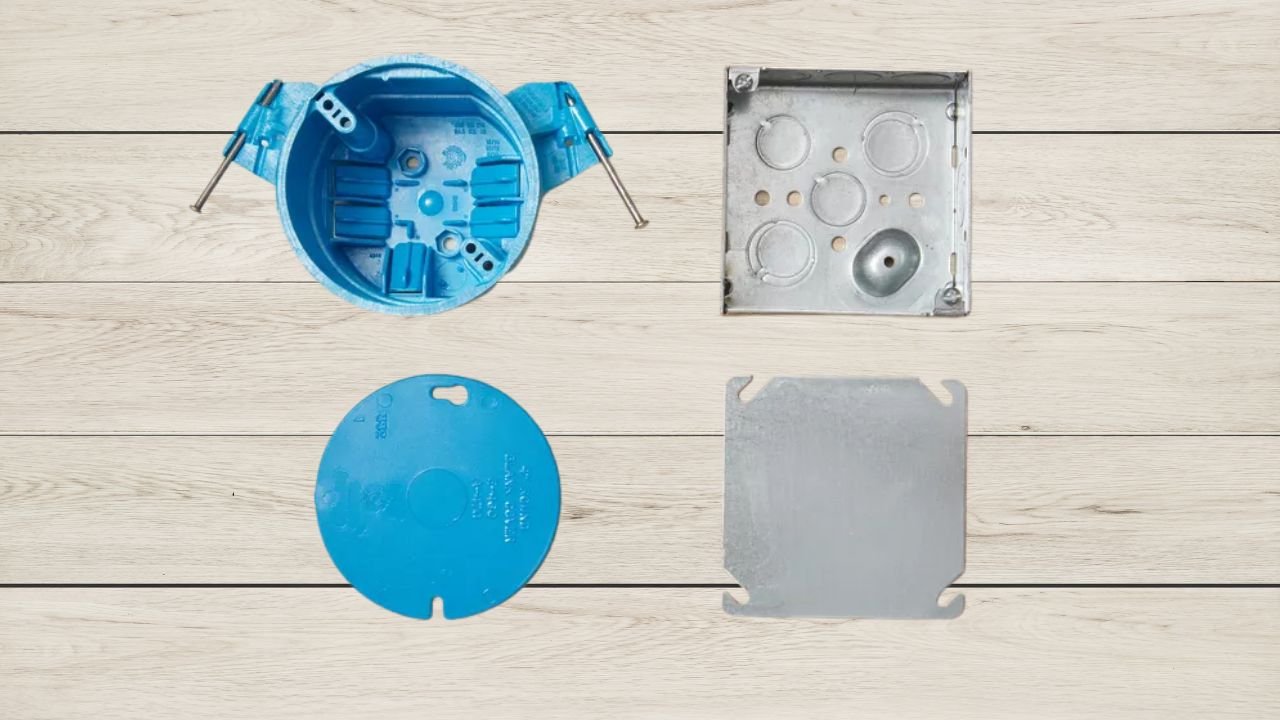

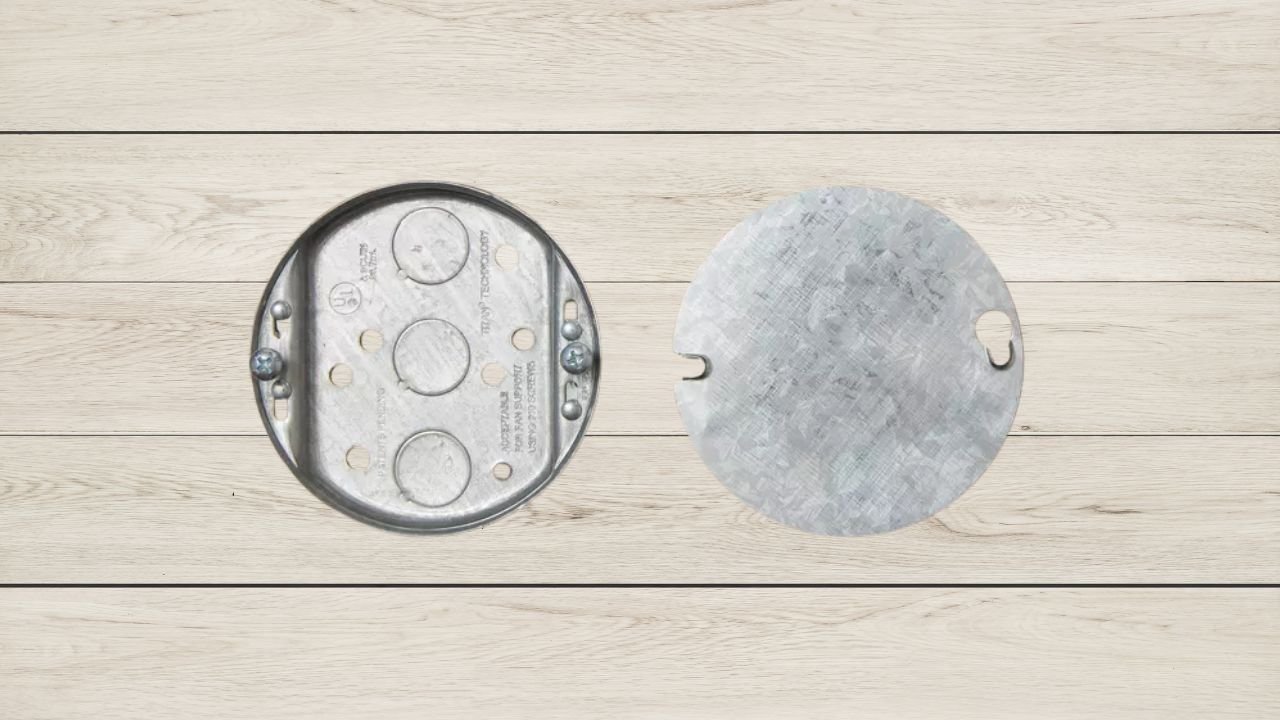

Round Pan Electrical Box (Pancake Box)

It provides a shallower structure featuring circular shape to support installation of light fixtures. The pan box typically measures between 0.5 and 0.75 inches deep and exists in both metal and plastic forms. Install this box on ceiling or wall to fit small lighting fixtures in tight spaces. Verify weight guidelines before starting installation to protect yourself from harm. This fixture type helps secure lightweight lights without creating deep wall or ceiling cuts. Make sure to fix the box directly to a solid stud base during installation.

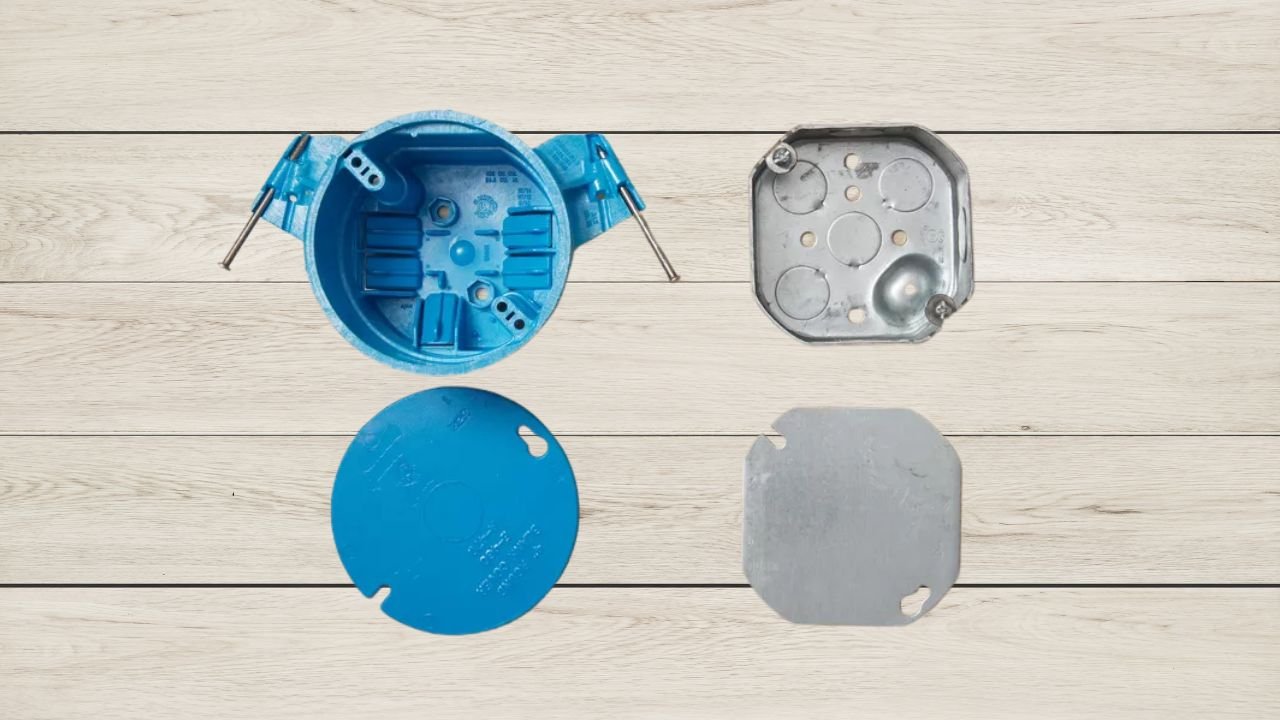

Octagon and Round Electrical Boxes

Octagon and round boxes have deeper dimensions than pancake boxes to accommodate more wire connections. They measure from 1½ to 3 inches deep and work best for lamp installations. They work as wiring connections to join electrical wires together. Place these boxes on walls or ceilings to hold fixtures up to 50 pounds. Fasten the electrical box securely to keep it from shifting or losing balance. Install metal boxes in high-heat spots for greater reliability.

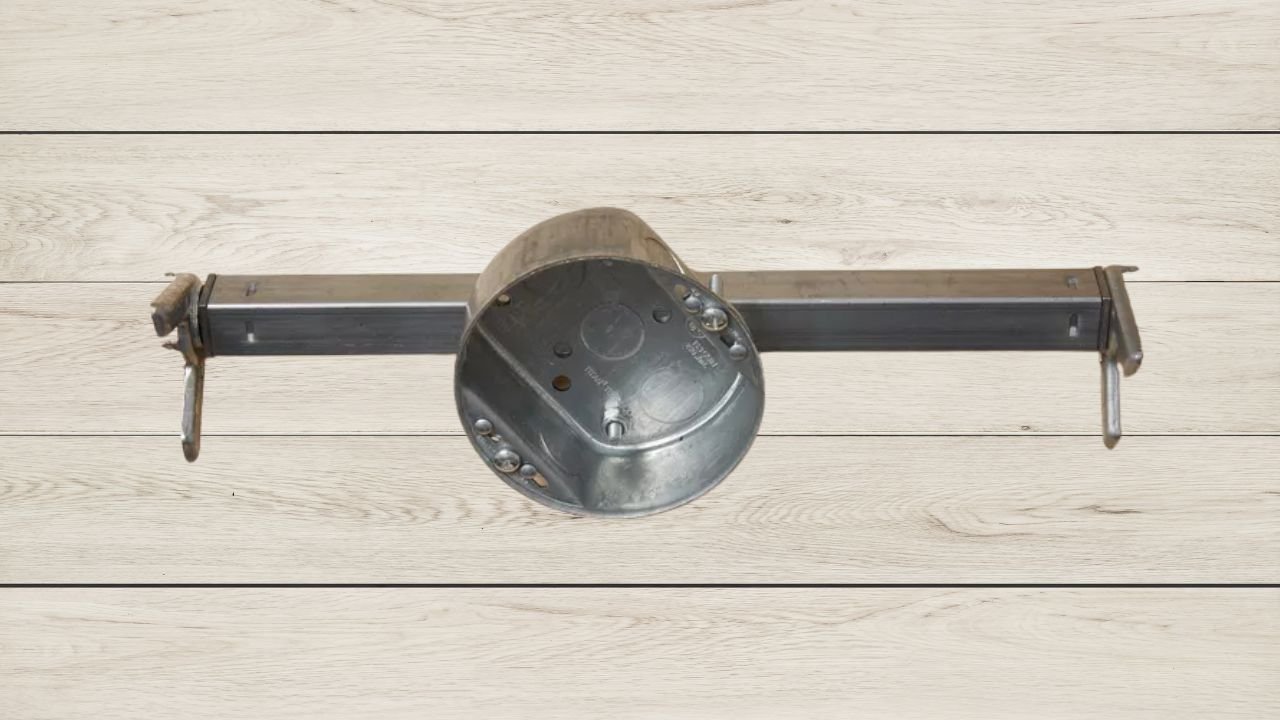

Ceiling Electric Box

A ceiling fan-rated box makes sure heavy fans and chandeliers remain safely mounted. Its round or octagonal shape measures 2⅛ inches in depth. UL-approved ceiling fan installations protect your safety. Install the box tightly on a ceiling joist or blocking to keep it stable in place. The box design prevents movement and maintains a stable fixture installation that lasts long term. When putting in a fan always choose a special fan-rated electrical box that can handle its heavy weight and movement.

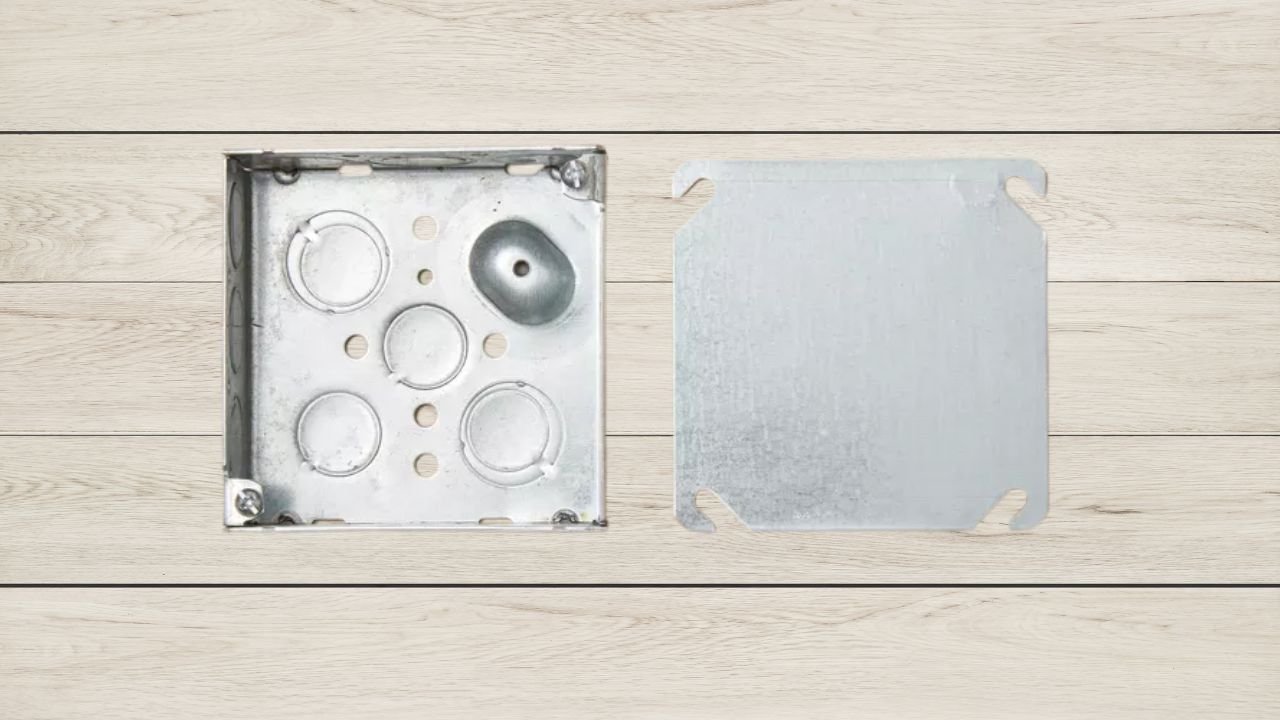

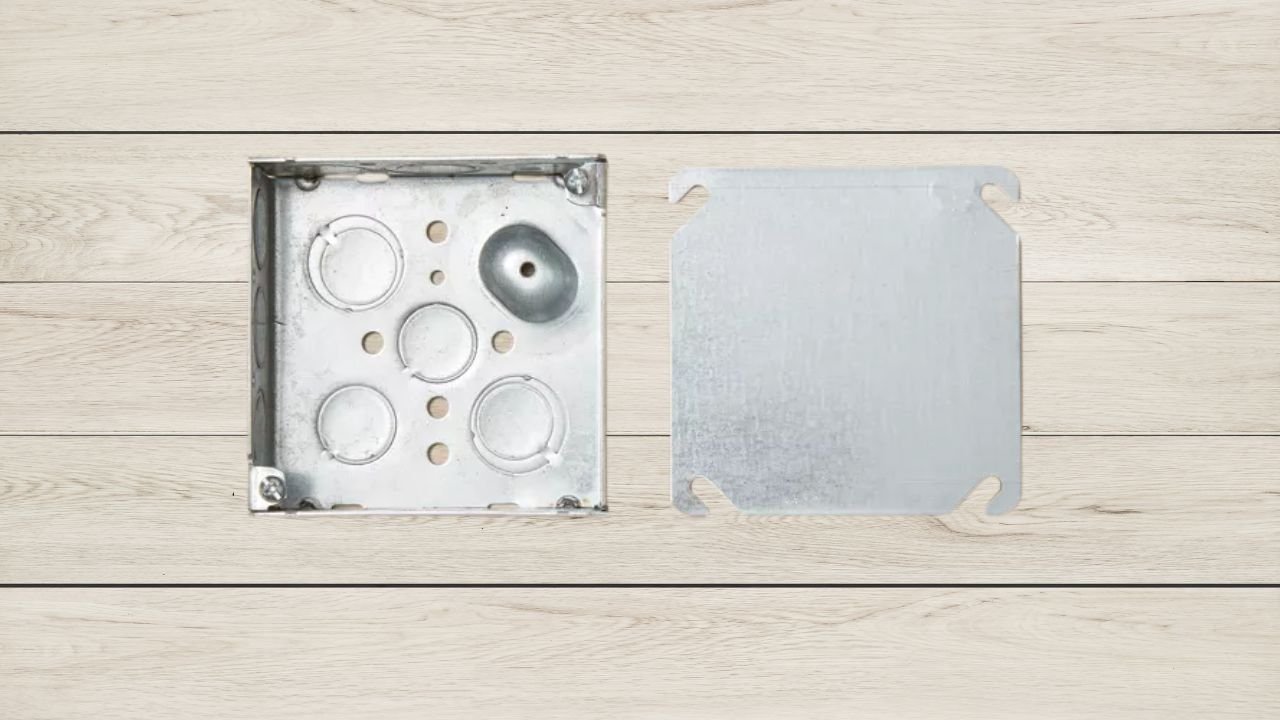

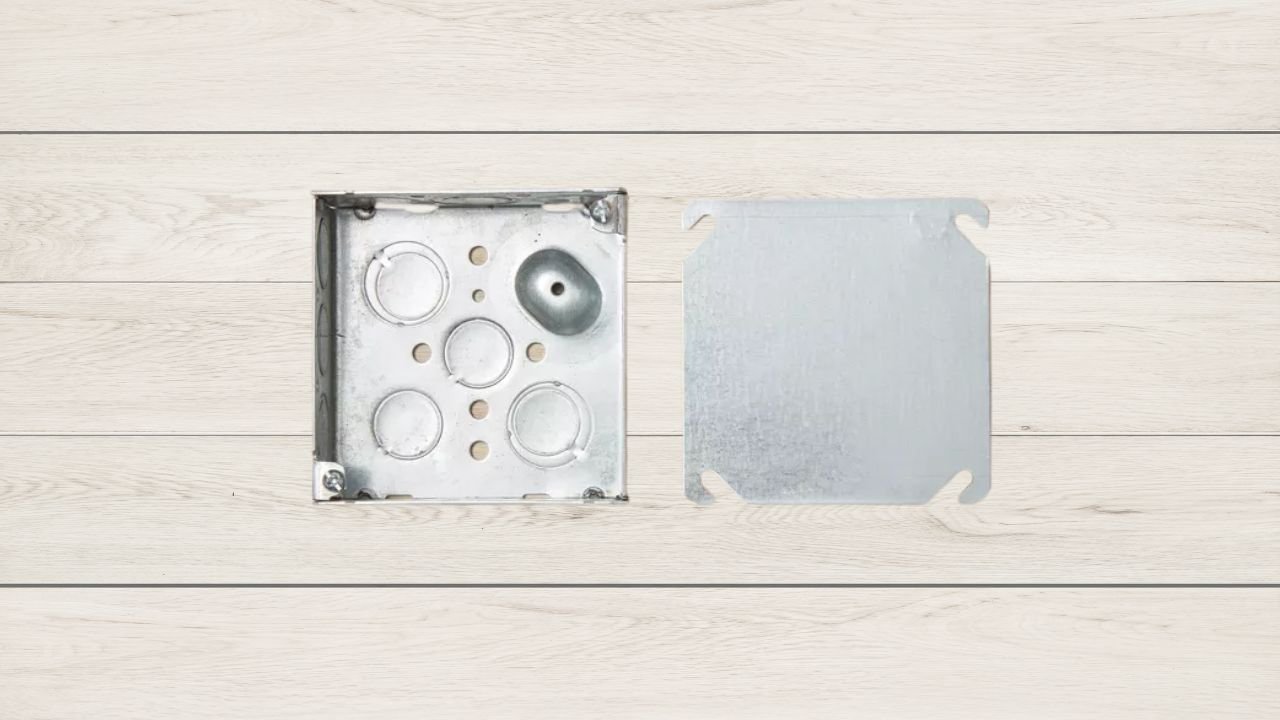

Square Electrical Box

The square electrical box creates room for connecting multiple electrical conductors. Standard depths for the product range between 1¼ inches and 2⅛ inches. The square electrical box helps keep wire connections secure and easy to manage. Choose this box type when you need additional space to join several wires together. Use this kind of electrical box when you have complex electrical circuits to work with. Stick to the code requirements to keep the box from getting too full. Make sure your box installation protects wire connections from harmful stress. This square electrical box becomes necessary when working with many wires in confined spaces.

Electrical Box Covers

Electrical box covers act as barriers to seal off wires and shield them from dust and water while blocking unintended handling. Junction boxes need blank covers and switches and outlets use cutout covers for protection. Follow the correct fitting to maintain safety standards and building codes. Electrical covers shield wires against damage and shield users from electrical risks. Turn these devices into barriers to cover unused openings or make it easy to install equipment. Fit them securely to keep insulation in place. Electrical covers protect both residential and industrial power systems.

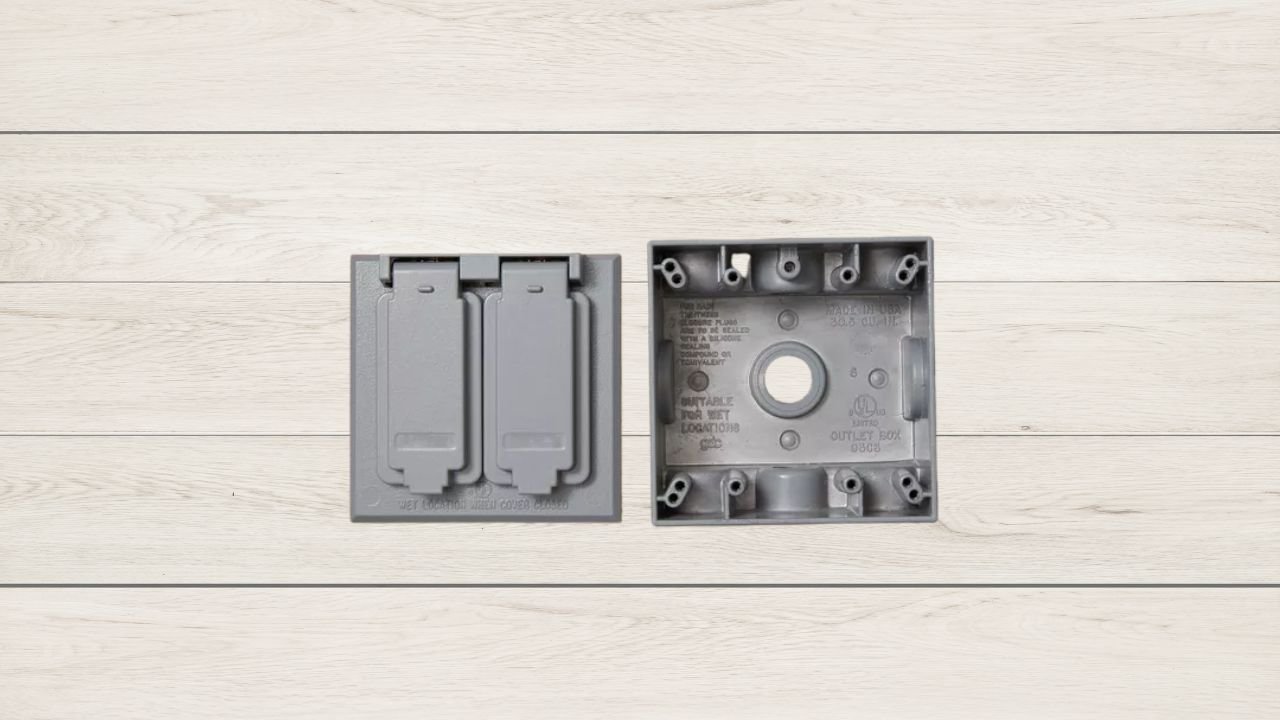

Outdoor Electrical Box (Weatherproof Box)

The outdoor electrical box guards wiring connections against weather conditions. Manufacturers make these boxes out of high-impact PVC or aluminum to withstand harsh weather conditions. Weatherproof boxes create an air-tight barrier to block water and other foreign particles. Install damp or wet rated coverings during your installation. Make sure all connections fit snugly to block water from entering. This product line works well for both outdoor electrical installations and lighting systems. They create a safe and reliable way to power your outdoor areas. Pick a protective material that works well in your specific environment. Check enclosure integrity daily and replace seals when they show signs of damage to guarantee water tightness.

Box Extenders

Box extenders make electrical boxes bigger while keeping them at their standard wall position. They attach to an existing electrical box without a back panel. You need to install extenders made of the same material as your electrical box to connect them correctly. Use them when wall materials push electrical boxes below the wall surface. Keep wires easy to reach and space them appropriately. They protect you from electrical code rules by extending electrical boxes so they stay at the right depth. They help us upgrade projects when wall coverings switch. Secure each connector firmly so wires stay in the right positions.

Shallow Box

An electrical box built for shallow spaces fits tight installation locations. Standard electrical boxes for tight spaces measure between ½ inch and 1 inch deep and exist as either plastic or metal models. These electric boxes handle minimal wiring that works best with single switches or outlets. Place these boxes in narrow wall cavities and hidden spaces when regular electrical boxes don’t work. Install flat devices and think ahead about wire placement to stay under capacity limits. Older homes with weak walls need these electrical boxes to keep the space safe. These devices ensure safety by organizing electrical wires in small spaces effectively. Select a model tested and approved for your installation site to ensure product durability.

Deep Electrical Box

A deep electrical box lets you manage more wires and connections within its space. The range of depths from 2-1/8 inches to 3-1/2 inches ensures proper wire placement and avoids overcrowding issues. The metal or plastic electrical boxes sometimes feature built-in wire clamps to keep cables safely organized. Install deep boxes when working with numerous conductors, splices, or GFCI units. They help the system dissipate heat better to prevent heat damage. Thicker walls benefit from these boxes and protect you from electrical code violations. Leave proper space between wires while making sure electrical connections remain easy to reach. Secure all electrical wires according to installation standards to avoid hazards and maintain order.

Pull Box

A pull box offers a dedicated area to pull electrical conductors and join them into new assemblies. These boxes come in various sizes with square or rectangular shapes made from metal or plastic materials. Knockouts in pull boxes make it possible to bring wires into and out of the box for intricate wiring setups. Place pull boxes in conduit runs when you need to pull wires over long distances. Keep these boxes within easy reach because you cannot hide them behind walls. Select a pull box size that matches your conductor numbers and provides enough space for wiring bends to make installation easier. You can find these boxes frequently in commercial buildings and major electrical networks. They make it easier to access and repair connections at the end points of wiring.

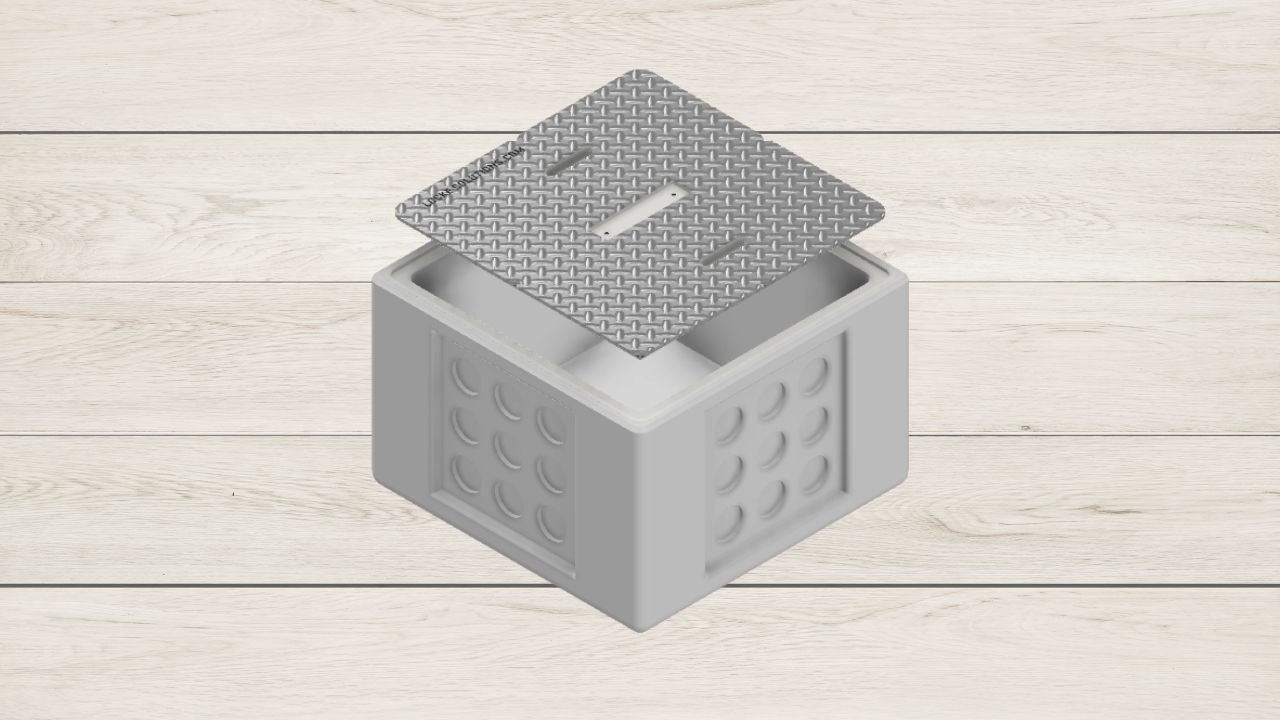

Floor Box

Floor boxes let you put electrical outlets straight into your floor surface. Metal or plastic floor boxes feature built-in weatherproof covers to shield them from dirt and liquid leaks. The system protects against foot damage while letting you access power quickly. Position floor boxes before placing furniture to keep power access clear. Mount your floor box flush with the flooring to achieve a smooth installation. Use covers that meet safety standards to shield the outlet from water damage. These boxes function well in living rooms, conference rooms, and kitchen islands. They function as a discreet energy supply that benefits both business and home environments.

Metal-Clad Cable Box

MC cable boxes are built to support metal-clad cable installations. The housing unit uses steel or aluminum to support armored conductors safely. The built-in cable clamps on MC cable boxes maintain tight connections that make the cables both fireproof and long-lasting. Put these boxes in industrial and commercial locations to keep critical equipment safe. You must correctly ground the box to follow safety requirements during installation. Use measurements to confirm the box’s filling capacity matches with NEC requirements. These boxes serve best when conduit installation proves difficult. These systems deliver durable protection for fire-rated walls and withstand intense impacts in demanding areas.

Metal vs. Plastic Electrical Boxes

Choose electrical boxes that protect against harm but remain simple for users to access and use. Switchgear made from metal and plastic impacts your installation through different performance benefits and issues. Learning the distinct features will help you identify the right solution for your project.

Metal Electrical Boxes

Pros.

- Fireproof and durable: The metal construction of these electrical boxes keeps users safe as it resists extreme heat better than other materials. These boxes retain their functionality even after facing minor physical harm.

- Ideal for metal conduit installations: Connecting metal electrical boxes to metal conduit makes strong electrical connections without special work because the parts fit perfectly together.

- Provides grounding capabilities: Metal outlet boxes join forces with metal conduit to protect electric systems and help users avoid dangerous electrical contacts.

- Stronger and impact-resistant: Metal electrical boxes protect electrical systems in commercial areas because they stand up better than other materials to physical stress.

- Handles high temperatures well: Metal materials keep their form and strength better than plastics when exposed to extreme heat.

Cons.

- Higher cost: You need to pay more for metal electrical boxes due to their higher cost than plastic alternatives.

- Sharp edges: Handling metal boxes requires caution. Take special care when you install metal box edges because their edges can injure you.

Plastic Electrical Boxes

Pros.

- Lightweight and budget-friendly: You can transport and install plastic electrical boxes faster while keeping project expenses low.

- No grounding required: Plastics act as electrical insulation materials that require smaller wiring setups.

- Built-in clamps: Plastic electrical boxes have built-in wire clamps that maintain secure connections without sliding.

- Resistant to corrosion: Plastic stands up to rust and corrosion protection that makes electronics safer to use in wet areas.

- Easy installation: Installing plastic boxes goes faster because they need basic tools and simple set-up processes.

Cons.

- Not fire-resistant: Plastic electrical boxes become ineffective as fire protection when they get too hot in environments at risk of fire.

- Brittle under stress: The operating life of plastic cases decreases when you apply specific pressures or tighten screws too much.

How to Choose the Right Electrical Box

Picking the proper electrical box protects you from electrical hazards while making wiring work better. Choose an electrical box based on how you plan to use it plus its compatibility with your wiring system and installation environment while meeting NEC standards.

Purpose-Based Selection

Every electrical box serves a precise setup purpose. Selecting appropriate electrical boxes helps protect against electrical risks and attaches components safely.

- For outlets and switches: Use standard rectangular or gang boxes when installing electrical fixtures. These basic styles work with one or more switches and outlets in standard areas.

- For light fixtures: Use boxes made in round or octagonal styles. They provide strong support for light fixtures and make wire connection work easier.

- For heavy loads: Install ceiling fan-rated boxes. Ceiling fan-rated boxes support additional weight and movement to stay securely in place for years.

- For wire splicing: Use junction boxes. These special containers guard wire connections and keep them secure.

- For outdoor use: Choose weatherproof outdoor boxes. Weatherproof outdoor boxes keep electrical parts safe from water and foreign material.

Compatibility with Electrical Wiring

Your electrical wiring determines which electrical box is best to install.

- Romex (NM-B cable): Plastic or metal containers work equally well for this purpose. Plastic boxes stay light and fight corrosion yet metal boxes give stronger electrical connections.

- Metal conduit: Requires metal boxes. These electrical boxes offer enhanced lifespan and secure electrical fastening.

Installation Environment

Where you will install your electrical system decides which electrical box type you will need.

- New construction: Use new work boxes. These connect directly to the framing or studs early in the drywall installation process.

- Existing walls: Choose old work boxes. Their adjustable mounting tabs allow you to fasten them inside finished walls.

- Limited depth space: Install box extenders. Standard boxes may not fit deep enough areas so these extension kits help expand space.

NEC Code Compliance and Safety

Following NEC rules helps protect people and meets building codes:

Choose electrical boxes that meet the specific requirements for their application. The box selection needs to match the system and surroundings including fireproof designs for dangerous areas.

- Secure all connections: Fasten wires properly with cable clamps while following grounding steps and using secure connections.

- Use covers to protect wiring: Never leave electrical boxes open. Covers act as a barrier to protect against electrical shocks and shield wires from harmful external elements.

Conclusion

Your selection of an electrical box impacts both safety and power performance. Select your electrical box based on material features and space placement before putting it into position. A poor electrical box selection may lead to problems with overheating or electrical shorts. You must follow electrical regulations and work with authorized equipment. If your electrical work includes difficult wiring or unknown elements then it’s best to contact experts. Correct electrical box installation helps avoid problems and saves money on system repairs. A correct selection of electrical boxes safeguards your system from failure while protecting sensitive data. Spend time choosing the best solution.