Sheet Metal Duct Fabrication – Types, Materials, Process, and More

The sheet metal duct fabrication has become an essential aspect of the current HVAC and ventilation systems. Properly designed ductwork provides a healthy indoor air quality, energy savings and efficient air distribution. With the changing techniques of fabrication between the manual shop techniques and the CNC-driven methods of precision, it is important to learn the basics. This guide includes types of ducts, materials, principles of design and ductwork fabrication. It provides decision-driven and practical information to engineers, contractors, facility managers, and manufacturers of HVAC systems planning and implementation.

Table of Contents

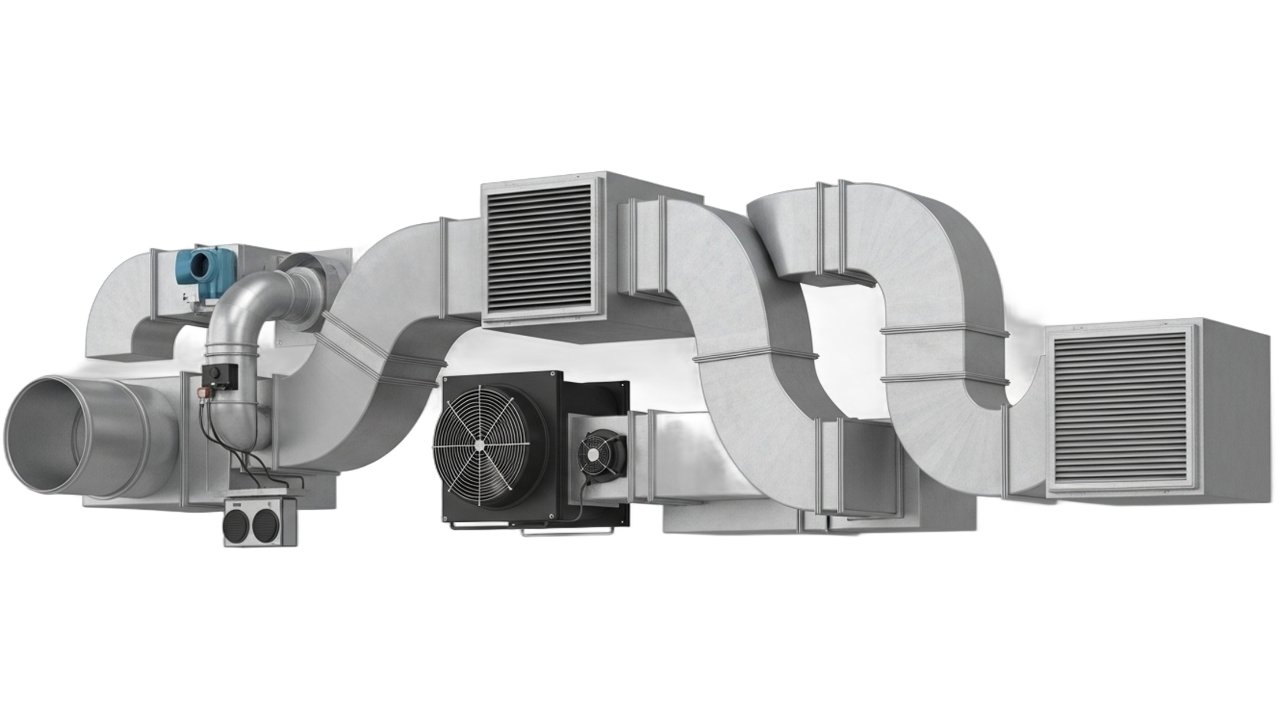

ToggleWhat Is a Duct System?

A duct system refers to a system of channels used to distribute air in a building effectively. The air duct metal sends cooled, heated or ventilated air to ensure the comfort of the indoors. Conditioned air is distributed to the rooms by supply ducts and returned to the system by the return ducts. Exhaust ducts eliminate smoke, stale air, or pollutants within a particular area. Knowing the operations of each duct will help you design, maintain or troubleshoot HVAC systems, making them energy-efficient, properly airflow and healthy indoor environment.

Types of HVAC Duct Fabrication Systems

HVAC Rigid Ducts

Rigid ducts are constructed with rectangular, square or circular sheet metal. They provide high performance and low leakage with durability. You can enjoy simple insulation and service life. Weight makes it difficult to install in tight spaces. Such ducts are applicable in commercial and residential systems that demand efficiency and structural stability.

Flexible Ducts

Flexible ducts are made of insulated cores held by coils of plastic or metal. They are easy to bend around barriers making installation easier. You enjoy agile handling and reduced initial expenditures. There is an increase in pressure loss when ducts kink or stretch. These ducts are ideal in short-run installations and in small spaces.

Spiral Ducts

In spiral ducts, the metal used is formed in a cylindrical shape with continuous spiral seams. The design enhances efficiency of airflow and minimizes leakage. You can perform well with minimum duct work material. Some layouts are restricted due to circular shape. These ducts are appropriate in exposed systems, as well as in long straight airflow paths.

Oval Ducts

Oval ducts in sheet metal duct fabrication combine the airflow efficiency of round ducts with the advantage of space saving rectangular designs. They are suitable in low ceiling or narrow spaces. You have better airflow than rectangular metal ducts of the same size. Fabrication and standard fittings are more complicated. These ducts are applicable to projects that have limited space and aesthetic requirements.

| Duct Type | Shape / Composition | Advantages | Limitations | Aspect Ratio | Typical Pressure Class | Lifespan | Common Materials |

|---|---|---|---|---|---|---|---|

| Rigid Ducts | Rectangular, square, circular | Durable, good airflow control, low leakage, easy to insulate | Harder to install in tight spaces, heavier, more fabrication labor | Rectangular/square: ≤ 4:1 | 0.5–2 in w.g. | 20–30 years | Galvanized steel, aluminum, stainless steel, carbon steel |

| Flexible Ducts | Flexible insulated cores with plastic or metal coil | Easy to install, bends around obstacles, lightweight, cost-effective | Higher pressure loss, susceptible to kinks, shorter lifespan | N/A (flexible shape) | 0.5–1.5 in w.g. | 10–15 years | Aluminum foil with fiberglass insulation, plastic ducts |

| Spiral Ducts | Cylindrical spiral-formed metal | Efficient airflow, less leakage, lightweight for length, aesthetic | Limited to circular design, custom fittings may be needed | N/A (circular) | 0.5–2 in w.g. | 20–30 years | Galvanized steel, aluminum |

| Oval Ducts | Oval/capsule-shaped metal | Space-saving in low ceiling areas, better airflow than rectangular | Harder to fabricate, limited standard fittings, joining challenges | Aspect ratio varies; usually ≤ 4:1 | 0.5–2 in w.g. | 20–25 years | Galvanized steel, aluminum, stainless steel |

HVAC Ductwork Fabrication – Performance Requirements

Airtightness

Adequate ductwork should be used to avoid air infiltration to ensure efficiency of the system. You are to examine all joints and make high-quality seals. Keeping airtight ensures that the environment is not contaminated, enhances air circulation and preserves indoor air quality in sensitive environments.

Structural Rigidity

Ducts should resist changes in pressure, mechanical forces and vibrations without deformation. Rigidity can be ensured by appropriate material and appropriate supports. Structural integrity eliminates sagging, lessens maintenance and enhances system reliability and noise performance.

Thermal Compatibility

Ductwork HVAC must not be able to bend or distort due to changes in temperature. During design, you can consider the insulation and the expansion of the material. Proper thermal compatibility minimizes energy wastage, condensation, and possible harm to adjacent buildings.

Hygiene and Cleanliness Standards

Ducts should not allow growth of microbes and debris to accumulate. You ought to be access-designed and cleanable. Adherence to hygienic standards safeguards the air quality, minimizes health hazards, and extends the lifespan of the system in general.

Design Principles for Sheet Metal Duct Fabrication

Importance of Proper Duct Design

Effective duct design enhances the efficiency of the system and reduces the energy consumption. Proper ducting layout minimizes wastage and errors in installation. It influences the lifecycle cost and reduces maintenance requirements. Accuracy of measurements provides a smooth airflow. Co-ordination with fabrication teams minimizes errors and increases the reliability of the system as a whole.

Airflow Engineering Considerations

All spaces are ventilated adequately through calculations of air volume (CFM). Maintaining speed is less noisy and more comfortable. Knowledge of static, velocity and total pressure regulates loss of friction. Equal pressure drop will guarantee effective operation and minimize the use of fan energy.

Duct Classification Criteria

Ducts are categorized based on pressure, velocity and application. Types of low, medium, and high pressures inform the selection of materials. The grouping based on velocity influences the noise and energy efficiency. System differences between comfort ventilation and industrial systems are applications to optimize their performance.

Duct Sizing Methodologies

In sheet metal duct fabrication equal friction, static regain and velocity reduction methods are used in duct sizing. Rectangular to round ducts can be converted to equivalent diameter with precision. The use of these techniques guarantees uniformity of airflow, less turbulence, and design efficiency.

Spatial and Architectural Constraints

Installation problems arise due to ceiling voids, retrofit areas, and layouts during new construction. Ducts should correspond to structural, plumbing, and electrical systems. Early planning of constraints prevents conflicts and expensive reworking in construction stages.

Sheet Metal Ducts – Common Shapes and Configurations

Round Ductwork fabrication

Round ducts are very efficient aerodynamically, with friction and pressure losses minimized. They cost less in terms of material and increase acoustics. They are ideal in long-run and high-velocity systems, harder to install in tight spaces and may require fittings that are specialized. Knowing their advantages can make you attain good airflow and less noise but without wasting the materials.

Square and Rectangular Sheet Metal Ductwork

In Rectangular and square ductwork, ducts occupy less space, and maximize wall and ceiling designs. Aspect ratios influence airflow and therefore, planning is important. Leaks and turbulence are avoided by exact sealing and support. These ducts provide flexibility of layout though joints need to be paid attention to ensure efficiency and uniform air distribution—benefits inherently associated with sheet metal duct fabrication.

Oval Duct Systems

Oval ducts combine efficiency in airflow and space-saving. They can fit in small or low-clearance space without compromising performance. The lack of accessory options and customized production should be planned. Correct transitions maintain a smooth airflow. Oval ducts are useful in cases where round duct efficiency is required in small areas.

Transitions and Fittings

Airflow is directed by transitions and fittings such as elbows, tees, wyes, reducers, and plenums. Proper design reduces turbulence and pressure loss. When chosen and installed properly, efficiency and system life is enhanced, and air is delivered quietly and in a consistent manner in either a simple or complex layout.

Duct Fabrication Sheet Metal Materials

Material Selection Criteria

The choice of material determines the duration of reliable duct system operation. You measure the resistance to corrosion depending on moisture and chemical contact. Temperature tolerance is used to ensure ducts can accommodate equipment or exhaust heat. In sheet metal duct fabrication mechanical strength helps in pressure, vibration and handling stresses. The final choice is determined by hygiene needs, cost, and material availability.

Galvanized Steel

Galvanized steel has a coating of zinc that secures the base metal. You usually pick ASTM A653 G90 or G60 grades of coating in galvanized steel ducting. It is durable, cost effective, and has extensive accessibility. You can use HVAC ductwork fabrication in homes and commercial sectors. Nevertheless, this can be shortened by acidic or salty conditions.

Aluminum

Aluminum offers lightweight strength and makes the duct installation easier. You enjoy natural corrosion protection and water resistance. Ordinary alloys are ASTM B209 1100, 3003, and 5052 series. Aluminum HVAC duct fab is effective in areas where weight is a consideration. You tend to use it in cleanrooms, marine HVAC, and specialty ducts.

Stainless Steel

Stainless steel provides high quality corrosion and structural stability. Duct systems are usually done with grades 304 or 316. Flat surfaces facilitate hygiene and protect against chemical assault. Such properties are appropriate in kitchens, laboratories, and pharmaceutical facilities. You are willing to pay more with respect to durability and cleanability.

Carbon Steel and Specialty Metals

Carbon steel is used to hold heavy-duty and high-temperature duct systems in industries. You use coating materials to minimize the risk of corrosion. These ducts are effective in process and exhaust ventilation. Decorative and antimicrobial advantages are provided by specialty metals such as copper. The selection of these materials balances on performance, coatings, and cost.

Material | Key Properties / Selection Criteria | Common Grades / Coatings | Advantages | Limitations | Applications / Notes |

Galvanized Steel | Corrosion-resistant, strong, moderate temperature tolerance | ASTM A653, G90/G60 coating | Durable, cost-effective, widely available | Can corrode in highly acidic or salty environments | Residential & commercial HVAC ducts, general ductwork; thickness typically 0.45–1.0 mm (26–20 gauge) |

Aluminum | Lightweight, high corrosion resistance, moderate mechanical strength | ASTM B209 (1100, 3003, 5052 series) | Easy to handle/install, moisture & rust resistant | Lower rigidity, may dent under mechanical stress | Cleanrooms, marine HVAC, ornamental ducts; thickness ~0.5–1.5 mm |

Stainless Steel | Excellent corrosion & chemical resistance, high strength, hygienic | 304, 316, surface finishes No. 2B / No. 4 | Resistant to acids & moisture, long-lasting, suitable for hygienic use | Expensive, heavier than aluminum, harder to cut | Kitchens, pharmaceuticals, laboratories, chemical exhaust; thickness ~0.5–2 mm |

Carbon Steel & Specialty Metals (e.g., Copper) | High-temperature tolerance, strong, can be coated, antimicrobial potential | Carbon steel: A36, coated; Copper: C101, C110 | Excellent strength, can handle industrial heat, decorative or antimicrobial (copper) | Requires coatings for corrosion, heavier, costly for specialty metals | Industrial HVAC, high-temp exhaust, decorative ducts; thickness ~1–3 mm (carbon steel), 0.5–1.5 mm (copper) |

Duct Sheet Metal Fabrication Process: Step-by-Step

Step 1: Measurement, Layout, and CAD Integration

Sheet metal duct fabricationrelies on correct measurement and design. Planning may be manually planned or CAD/CAM planned. The Building Information Modeling (BIM) improves coordination and reduces the volume of waste products. The integration of CAD data into the making is effective and minimises errors and aligns ducts with architectural and MEP designs.

Step 2: Cutting Operations

Holes and duct tolerances are done through cutting of sheet metal. Shearing, laser cutting or plasma cutting can also be used depending on the requirement of the thickness and accuracy. Laser cutting will provide clean edges and plasma will cut thicker metals. Successful cutting saves scrap time, offers consistency and fits. You will be expected to match cutting methods and project demands to plans.

Step 3: Forming and Shaping

HVAC Duct components are bending sheets to shape operations. Press braisers, roll forming tools and spiral formers form strauss or curved parts. The oval duct equipment is precise in working with special profiles. Proper forming of the product guarantees correct sizing and airflow performance. The bend radii and tolerances should be controlled to prevent deformation or leakage and increase the efficiency of the systems.

Step 4: Assembly and Joining Techniques

The duct sections are joined through lock seams, welding or mechanical fasteners. Pittsburg and snap lock seams form powerful, air tight joints. Heavy-duty systems are welded in such ways as TIG, MIG, or spot welding. Assembling by riveting in reachable places. You need to choose joining methods depending on duct type, duct thickness and pressure needs.

Step 5: Fabrication of Different Duct Types

The workflow of every duct type is different. The spiral ducts have continuous seams, whereas straight round ducts do not have spirals. Rectangular metal ducts require accurate corner assembly and alignment. To avoid warping, you have to adhere to correct sequencing. Proper management, allowances, and seam preparation can guarantee continuity on airflow and ease of installation.

Step 6: Sealing and Airtightness Treatment

In this step of sheet metal duct fabrication, sealing enhances airflow and energy efficiency. You co-apply sealants, rated tapes, to seams, joints and fittings. Internal and external insulation contribute to acoustics and thermal control and eliminate condensation, respectively. Fiberglass, elastomeric foam and mineral wool are common materials. You must deal with the risk of condensation to achieve the standard of leakage.

Step 7: Surface Treatments and Finishing

Surface treatments cover ducts and enhance appearance. Corrosion resistance and identification are provided with painting, and durable finishes are provided with powder coating. Exposed ductwork HVAC is improved through polishing. Ornamentation systems can require bespoke finishes. You have to make sure that it is compatible with metal type and that it can withstand environmental exposure in the long run.

Step 8: Quality Control, Testing, and Compliance

Quality control ensures that ducts are according to design requirements. You check dimensions, check seams, and perform air leakage tests. Defects are identified at surface quality checks. SMACNA, ASHRAE and codes compliance provide safety and performance. Standardized testing and documented inspections contribute to provision of reliable HVAC duct systems.

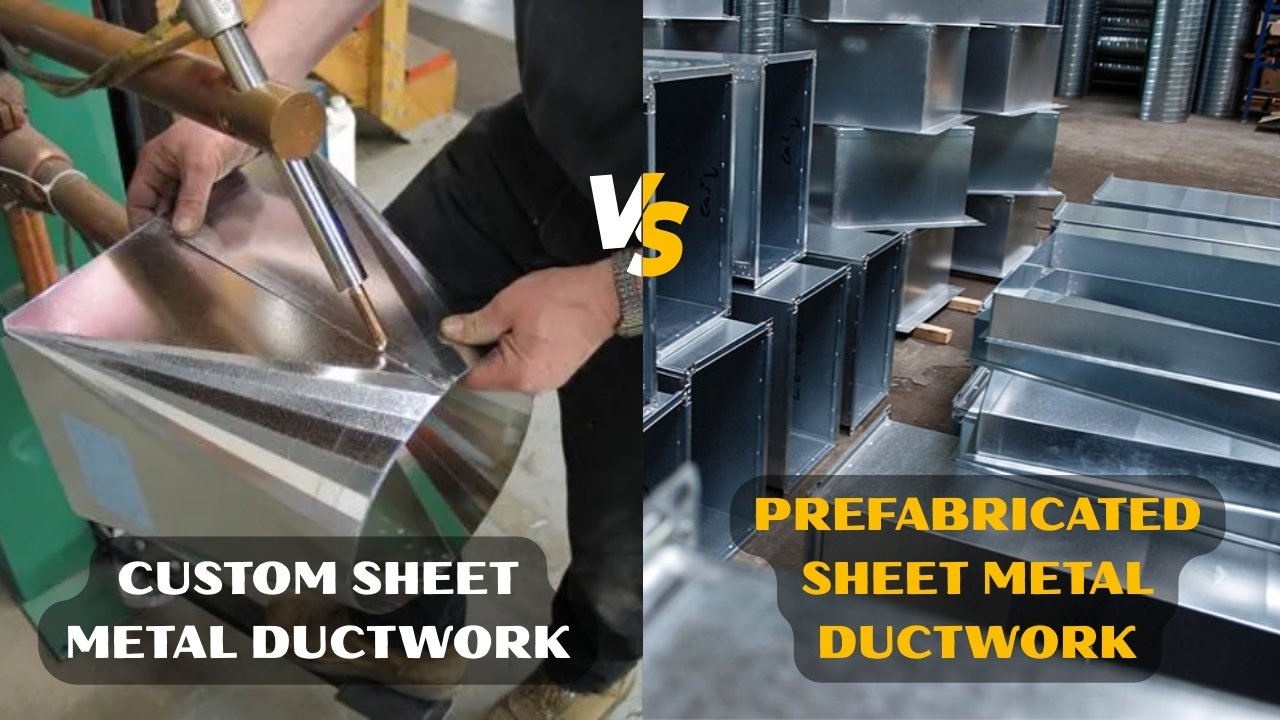

Custom vs Prefabricated Sheet Metal Ductwork

Precision ductwork Custom sheet metal ductwork is a perfect fit, which improves the performance of airflow and minimizes energy loss. You have the advantage of reduced installation difficulties and reduced leakage than the traditional prefabricated ducts that might experience space in competencies. Although custom sheet metal duct fabrication is usually more expensive in the short term, it offers long-term benefits in the form of greater durability, reduced maintenance and maximum energy efficiency. The need to select between custom HVAC ductwork and prefabricated ducts involves a trade-off between initial costs and lifecycle performance and operational reliability.

DIY vs Professional Sheet Metal Fabrication

The use of DIY sheet metal fabrication is flexible but requires high skill and special tools. Poor bending, cutting, or welding may result in poor joints, safety risks, and material wastage. You may start DIY ducting with small simple projects using simple tools but more complicated designs need to be more precise and experienced. The professional fabrication shops have high level of machinery, quality and professional work. Professional services are ideal when the sheet metal work to be done is critical or large scale as you will experience less errors, faster production, and structural integrity.

Applications of Sheet Metal Ductwork Fabrication

- Residential HVAC systems

In homes, ducts made of sheet metal are efficient in distributing the cooled or heated air. They guarantee constant air movement, energy savings, and silence. You are able to adapt duct designs to suit narrow places and enhance indoor comfort. A good fabrication minimizes leaks and loss of energy and still ensures that the air quality meets the standards. - Commercial buildings (offices, malls, hospitals)

In Sheat metal duct fabrication, ducts are reliable in high airflow requirements in large buildings. You can make them to suit intricate layouts, with noise, airflow and pressure. Long-lasting materials can survive the continuous use, which minimizes the maintenance process. Proper fabrication guarantees adherence to building codes and proper ventilation in various areas. - Industrial ventilation and exhaust systems

The factories and workshops use strong ducts to eliminate fumes, dust, and heat. You are able to use heavy-duty designs that can withstand high temperatures and corrosive particles. The appropriate duct fabrication enhances the safety and efficiency of the work place, and upholds high standards of industrial requirements. - Cleanrooms and laboratories

Sheet metal air ducts keep the air in a controlled setting sterile. You will be able to combine special filters and sealing methods to avoid contamination. Precise fabrication guarantees the laminar flow and complies with the strict regulatory standards. - Specialty architectural and decorative ducting

Custom ducts in fabrication are used to improve the appearance of the building and ventilate it. You are able to develop shapes, finishes and patterns that are both functional and design oriented. Precision fabrication does not affect the airflow and does not hurt the appearance.

Choosing the Right Sheet Metal Duct Fabrication Partner

The selection of the appropriate fabrication of sheet metal duct fabricators will make sure your projects are of the right quality and quantity. Test their equipment and technology capabilities in order to work with the complicated designs. Test their expertise of materials to handle different metals and gauges appropriately. Check quality accreditation to check industry compliance. Assess turnaround time, scalability, and cost transparency to budget in a planned manner. Quality after sales services ensure that there is easy maintenance and problem solving ensuring your operations are not disrupted.

Conclusion

The proper design of sheet metal duct fabrication has a direct effect on HVAC performance, longevity, and indoor air quality. When you combine good design principles, choice of materials, and accurate production processes, systems will last decades. Every choice made, including duct type, duct work material, sealing and finishing, has an impact on the energy consumption and maintenance. To engineers, contractors and facility managers, investing in quality metal ductwork fabrication provides long-term savings in operation, regulatory compliance and healthier indoor environments in residential, commercial, and industrial applications.

FAQs

What Gauge is Best for Sheet Metal HVAC Ducts?

Most residential HVAC systems in sheet metal duct fabrication use 24-gauge sheet metal that is not only durable but also easy to install. You have the option of 22-gauge in larger commercial ducts that need additional strength and life cycle without compromising the airflow efficiency.

In Duct fabrication Which Shape Is Most Energy Efficient?

Round ducts offer less resistance to air and less leakage than those ducts that are rectangular. HVAC systems give you better air circulation, reduced power bills, and less noise.

How Long Does Sheet Metal Duct Fabrication Last?

Properly installed sheet metal ducts have a lifespan of 20-30 years or more. You ought to arrange inspections to avoid corrosions, leakages and loss of efficiency with time.