An Ultimate Guide to Copper Sheet

Copper, a naturally occurring non-ferrous metal, has been an essential part of human civilization for centuries due to its significant properties and adaptability. Due to its remarkable adaptability, widespread electrical and warm conductivity, and particularly rich appearance when exposed, copper has typically advanced to mechanical and creative levels. From its origin in the production of gadgets to its flow importance in electrical applications, copper has stayed a principal surface in mechanical development and craftsmanship. Its forward congruity and regular regard for different parts are in accordance with what happens in the moving field of materials organization.

Table of Contents

ToggleHow Copper Sheets Are Made

The age of copper sheets includes a number of stages, from mining harsh copper minerals to collapsing the copper into inclined sheets. The copper sheets are guaranteed to meet the requirements of a variety of applications, which is greatly appreciated in this planning. A point-by-point layout might look like this:

Extraction and Mining Metal Mining:

Copper is mined either underground or open-pit. It can be used now but must be concentrated because it typically contains less than one percent copper.

Pulverizing and beating: The isolated metal is broken into small pieces and ground into a fine powder to eliminate the copper minerals in the waste shake.

Concentration: When chemicals are added to a frothy mixture, the ground mineral experiences buoyancy. The copper minerals come into contact with the examined pockets and then coast to the surface, skimming off as a concentrate containing between 20 and 30 percent copper.

Copper Refining and Purifying Cleansing:

To remove the majority of impurities, the copper pack is refined in a more smoking. The wrapped item may have a matte finish and a fluid texture made up of 60 to 70 percent copper. The matte experiences a modification organized in a converter radiator, where see at or oxygen is blown through the liquid surface to oxidize the extra press and sulfur. As a result, the pure copper content hovers around 98 to close to 100 percent. Electrolytic refining: Electrolytic refining uses a sifting process to energize copper. The enormous copper anodes are produced in an electrolytic cell containing a copper sulfate diversion arrangement. Pure copper is placed missing on cathodes when an electric stream is gone through the phone, bringing roughly 99.99% pure copper.

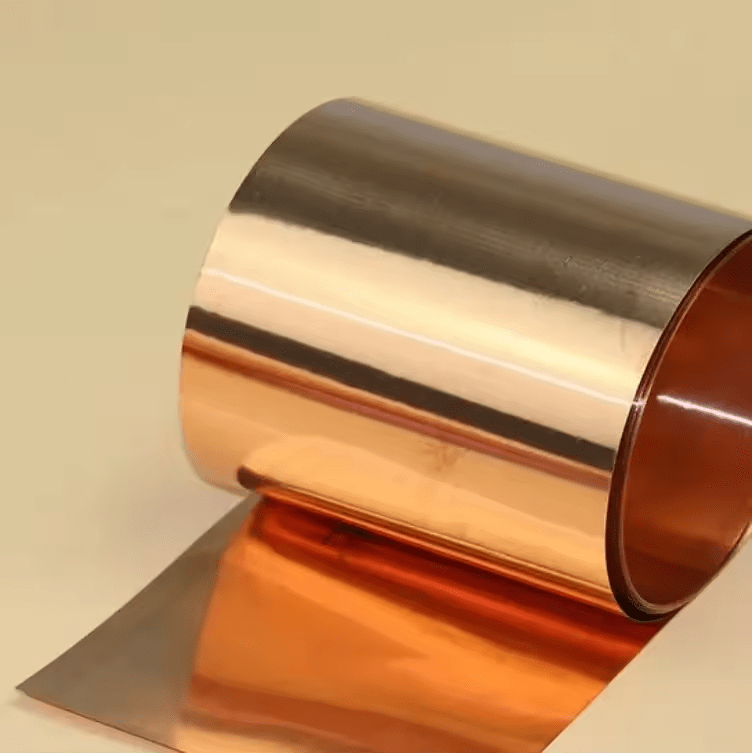

Copper Rolling and Casting:

Refined copper is transformed into colossal billets or pieces through incessant or semi-persistent projecting strategies. These pieces comprise the rough surface used for rolling. After being warmed to a high temperature, the copper pieces experience hot moving by moving plants. This process diminishes the thickness of the pieces and redesigns their mechanical properties.

Cold Rolling: Hot-moved copper sheets are helped and dealt with during cold moving to determine the necessary thickness and surface wrap. Cold rolling involves passing the sheets through a series of rollers at room temperature to increase the strength and hardness of the copper.

Copper Strengthening

Copper sheets may strengthen after cold-rolled to loosen the texture and lessen stress. The sheets are reliably cooled after being warmed to a predetermined temperature for solidification. This step ensures that the copper sheets have the expected mechanical properties and are simple to work with in the following applications.

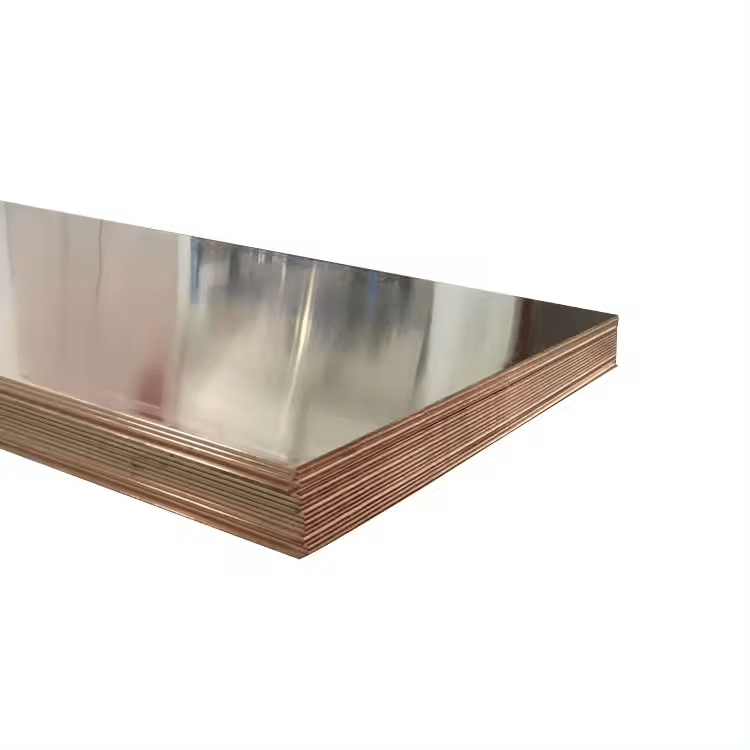

Types of Copper Sheets

Copper sheets come in a variety of shapes and sizes, and each one is ideal for a particular purpose due to its unique properties and components. The following are the most important types of copper sheets:

Copper Sheets with an Electrolytic Preposterous Pitch (ETP)

Impeccable copper more than 99.9% of the time. It has exceptional electrical and warm conductivity and radiation protection against decay. The applications include transformers, electronic components, electrical wiring, and typical building capacities.

Oxygen-deprived copper sheets (OFHC) Method:

Less than 0.001 percent oxygen and 99.95 percent pure copper. Its characteristics are its high immaculateness, exceptional ductility, and general electrical and warm conductivity.

Applications: First-in-class sound and video adjust, vacuum tubes, superconductors, and semiconductor age.

Copper sheets made of tall phosphorus (DHP) deoxidized

The substance phosphorus changes from 0.015 to 0.040 percent. High-level welding and joining properties, exceptional protection from crumbling Channels, heating plans, and mechanical tasks that require welding are combined in applications.

Composition of Commercially Idealized Copper Sheets:

Unadulterated copper is inside the run of 99.9 percent, and the taking-after aggregates are of different parts. It has remarkable adaptability, incredible conductivity, and resistance to breaking. Mechanical jobs, materials, cladding, and other designing applications are examples of applications.

Types of Copper Alloys

Producers amalgam copper with other metals to urge the most extreme benefits of copper. This produces various copper combinations with specific properties appropriate for different applications. Here are a few prevalent amalgams of copper:

Brass

In this, copper and zinc are combined (in changing extents). Its properties incorporate exceptional machinability, resistance to crumbling, and a gold-like appearance. Applications incorporate making strides in melodic resistance, plumbing fittings, and other things.

Bronze

Tin and copper must be combined (with nearby elements like nickel, manganese, or aluminum). Some of the properties combine strength, protection from wear, and extraordinary protection from disintegrating. Applications: Bearings, bushings, marine stuff, figures, and coins.

Bronze and aluminum alloy:

Copper-aluminum mixture with nickel (typically 5 to 11 percent) and press is tall, wears well, and can withstand decomposition, especially in marine environments. Marine adapt, substantial bushings, heading, and components for the siphon and valve are among the applications.

90-10 Cupronickel (C70600)

Copper and nickel in the blend (Cupronickel) contain the construction (routinely 70-30 or 90-10 degrees). Its radiant, warm conductivity, quality, and incomprehensible protection against deterioration by seawater are unparalleled. Characteristics: Shipbuilding, marine improvement, desalination plants, and money are among the applications.

Copper Beryllium (C17200)

The composition comprises copper, 0.5-2.3% beryllium, and other elements like cobalt. Among its characteristics are tall quality, hardness, unattractiveness, remarkable conductivity, and resistance to crumbling. Examples of applications are spring systems, electrical connectors, devices that don’t work right, and devices that won’t start.

Zirconium, copper, and chromium C18150

C18150 might be a mixture of copper and chrome zirconium that stands out for its superior wear resistance and workable quality at temperatures higher than chrome copper. It is ideal for applications requiring exceptional mechanical properties and bewildering assurance from remaining at elevated temperatures due to its excellent electrical conductivity and palatable mechanical quality. C18150 frequently hinders welding cathodes, control arms, electrical components, contacts, and studs. It is possible to cut the texture into level bars for a variety of applications with wider plate widths, which offer greater flexibility and comfort.

Phosphorus Copper Sheets (DHP, C12200)

Phosphorus copper sheets with the designation DHP (Deoxidized Tall Phosphorus) or C12200 are widely used in a variety of mechanical applications due to their intriguing properties. These sheets are mostly made of copper, and phosphorus makes up a small but significant amount (usually between 0.015 and 0.040 percent). The material’s resistance to hydrogen embrittlement increases as a result of its proximity to phosphorus. Because of this, it is an excellent option for applications in which hydrogen exposure may be a concern.

70-30 Cupronickel (C71500):

70-30 Cupronickel, known as C71500, is a blend commonly 70% copper and 30% nickel, with little augmentations of manganese and press to chip away at its properties. Due to its outstanding resistance to erosion, especially in seawater, this high-performance fabric is preferred for marine applications. The alloy’s widespread resistance to stretch erosion splitting and biofouling makes it more suitable for demanding applications.

Oxygen-Free Copper Sheets (OFHC, C10200)

Oxygen-Free Copper Sheets, more commonly referred to as OFHC (Oxygen-Free Tall Conductivity) or C10200, are prized for their exceptional electrical and thermal conductivity. These sheets are delivered utilizing a refining cycle that decreases the oxygen content to under 0.001%, bringing about a very unadulterated copper texture. C10200 is an excellent option for electrical and electronic applications where maximum effectiveness is required because copper’s conductivity is enhanced by the absence of oxygen and other pollutants. Furthermore, OFHC copper sheets are extremely ductile and resistant to erosion, making it simple to shape and weld them without affecting the fabric’s aesthetic appeal.

Pure Copper Sheets (C11000)

C11000 Pure Copper Sheets are widely regarded for their excellent electrical and heat conductivity, making them a common component in a wide range of mechanical and electrical applications. These sheets, which contain more than 99.9% copper, offer unparalleled execution due to their high faultlessness. Copper from C11000 is really versatile and can, without a doubt, be shaped into quick and dirty plans without losing its fortitude. Because of its durability and resistance to decomposition, the material is frequently utilized both inside and outside.

Advantages of Copper Sheet

Copper sheet enjoys various benefits. Things that are energetic and amped up for the following stage. Not ready to break or implode. It cultivates a guarded layer after some time. Developing its guardian from self-destructing, It shields its smooth thought and gives understanding for quite a while. A substance’s conductivity is its capacity to conduct electricity. Used to control heat transfer in hot applications like solar-powered chargers and heat exchangers. Utilized areas of strength for movement in electrical applications like busbars and electrical sheets. A great method for controlling and improving the situation. Adaptability is the ability to move around and twist without getting hurt. It is ideal for challenging assignments and building plans because it does not break when cut, curved, or shaped. Because it is so straightforward, businesses save time and money.

A distinctive dark brown-red color when not in use, making it intriguing to examine. Over time, it turns a dark green color. Popular for the manner in which things look outwardly (rooftops, drains, walls) and inside (edges, backsplashes). Attributes that make microbes bite the dust limit the development of creatures, contaminations, and the littlest living things. Favored for its simplicity and utility in essential areas such as kitchens, open spaces, and focuses. It supports halting the spread of contamination. It could very well be used once more without being altered, and something similar could be kept. When contrasted with not utilizing something by any stretch of the imagination, utilizing it again instead of discarding it saves energy and assets. Things can endure longer and require fewer substitutions on the off chance that it is improved to assemble methods.

How to Measure The Thickness of Copper Sheets

Copper sheets can be different thicknesses, regardless of when they are used as they ought to be. As a boss, we use mils, checks, or millimeters to measure the thickness of the copper sheets. A quick illustration of these tools—a scale or measuring instrument—is provided here. The American Wire Check (AWG) framework is regularly used to estimate the thickness of copper sheets. Copper sheets come in different thicknesses, for the most part between 24 measures (0. 0201 inches, or 0. 511 millimeters) and 16 measures (0. 0508 inches, or 1. 29.

The thickness of the copper sheet is determined by the gauge number. A 16-check copper sheet is thicker than a 24-measure copper sheet. Enormous number of an inch (used in assessing thickness or distance across). Mils are yet another tool for measuring thickness. One mil is the same as 0.0001 inch. Copper sheets typically come in thicknesses ranging from 0.0001 inch to 0.0002 inch. Mils provide a solid foundation that is suitable for creative and distinct endeavors. An estimation unit that is more modest than a centimeter is known as a millimeter.

The thickness of copper sheets is estimated to be millimeters around the world. The thicknesses of 0. 5 millimeters. 1 millimeter is the most well-known. 5 This straightforward strategy for speculation is frequently employed. Copper sheets can be as thick as 20 gage and as thin as 0. 5 millimeters. Copper sheets with a thickness of between 0.5 and 1 millimeter are essential for building and creating major areas of strength for things. These sheets are ideal for straightforward work like drawing, designing, enhancing, and creating changes since they can be successfully cut and changed.

They can change and make plans with simple tools and have numerous sizes and shapes. Thin copper sheets are also very helpful for small models and construction projects that only need a small amount of precision and fine detail. They require no extraordinary apparatuses to oversee or control since they are light.

Medium Thickness Copper Sheets (20-16 gauge or 1-1.5 mm)

Copper sheets with a thickness of 20 to 16 millimeters, or 1 to 1.5 millimeters, find a balance between flexibility and health, making them suitable for a variety of construction and development applications. These sheets are used as frequently as conceivable for texture, exploding, channels, and downspouts since they can endure the parts while being versatile and adequate to frame careful kinks and custom shapes. For naturally unstable open-air applications, their cooperation provides fundamental dependability and longevity. Besides, medium-thick sheets are used in inside plans for edges, backsplashes, and updating loads for a broad part of the time since they are both strong and secure.

Copper sheets with a thickness of more than 1.5 millimeters

Copper sheets over 1.5 mm thick and 16 degrees thick or thicker are used in modern business applications where quality and control are essential. Due to copper’s low conductivity, these thicker sheets are typically used in electrical and warm channels. They are also popular since they are being made for load-bearing applications like fundamental frameworks and extremely disturbing circumstances. These sheets are excellent for severe present-day settings since they are especially invulnerable to wear and disintegrate because of their basic thickness. They are difficult to cut and shape, but their durability ensures reliable quality and long-term performance in challenging applications.

How to Select the Right Thickness Workmanship and Popularity:

More lean sheets (24 to 20 degrees, or 0.5 to 1 millimeter) are always preferred for moving forward and making gems because they are flexible and easy to cut. Plan and Improvement: Due to their inherent dependability and durability, medium-thickness sheets (20-16 check or 1-1.5 mm) are frequently used for fabric, bursting, and other design applications. Advanced Use: Hard-core applications like electrical and warm channels may require thicker sheets (16 millimeters or thicker, greater than 1.5 millimeters) to withstand increased weight and wear.

Finishes for Copper Sheets

An arrangement of steps is required to wrap copper sheets and improve their appearance, solidity, and usefulness.

Polishing & Cleaning

Cleaning is one of the foremost common strategies for making a smooth, intelligent surface by mechanically or chemically expelling oxidation and flaws. This glistening completion is perfect for plan components, exciting things, and exceptionally high-quality applications where fashion is essential.

Patination

Copper can be given an aged and interesting appearance by finishing it with patination. Patina colors like green, blue, and brown result from various natural reactions or combinations of elements. Copper sheets given a patina can be utilized in building components, creative ventures, and inside plans to give a hand-tailored or imaginative shift focus over to the space.

Lacquer

Putting a shiny coating on something is called lacquering. Lacquer prevents metal from becoming rusty or dirty. To protect the copper, a clear or colored lacquer is sprayed or brushed on. Growing old Making copper sheets appear old or antique by accelerating their rusting. For instance, the perfect patina can be achieved by being open to strong emotions, man-made materials, or weather conditions. Old copper sheets are often utilized in fixing structures, making furniture, and making craftsmanship to show a feeling of history and character.

Brushing

“Wiping down with a brush” is a technique for smoothing and beautifying copper sheets, concealing any marks and making them more appealing. Smooth lines are drawn on the copper sheet’s surface with specialized brushes or abrasive pads. This method is used in interior design, furniture making, and industrial settings to make things look modern or industrial.

How to Clean & Care Copper Sheet

Simple methods for keeping copper sheets gleaming and keeping them from evolving in variety. Clean the region with warm water and a tad of delicate dish cleanser. Clean the copper sheet gently with a soft cloth or sponge to remove dirt from its surface. To avoid water spots, wash the sheet with warm water and dry it with a soft cloth. There are some effective methods for removing stains. Many individuals blend salt and lemon.

Simply halve a lemon, sprinkle it with salt, and rub it on the stains. After you complete the process of washing it with warm water, utilize a delicate material to dry it. Vinegar and salt can also be combined to form a paste. Before washing and drying, apply it to the stains, wait a few minutes, and gently wipe it off with a cloth. Baking soda and lemon juice can also be combined to make a thick mixture. After that, apply the paste to the copper sheet, allow it to sit for a while, scrub it gently, and then wash and dry it.

To make your items shine, you can use a natural flour, salt, and vinegar cleaner. Combine equal parts of these trimmings to make a thick paste. After applying the paste to the copper sheet, allow it to sit for thirty minutes. Then, dry it and clean it with water. Copper sparkles can be used per the manufacturer’s instructions to improve and enhance the professional appearance of your business. Protecting copper sheets prevents color fading and maintains their aesthetic appeal.

You can frequently clean the surface with soap and water to prevent the color from changing. Applying a thin layer of beeswax, carnauba, or copper protectant to the surface is one way to avoid stains. To make the wax sparkle, gently rub it with a soft cloth. Copper sheets should be kept in a dry spot and enclosed by paper or plastic to avoid stains, particularly if you intend to store them for quite a while. Strong cleaners and rough pads can scratch the surface of copper sheets, so avoid using them.

Cleaners with solid odors or salts that smell bad should not be used because they can harm copper. Use soft cloths to clean and dry the copper to avoid scratching it. You can also protect the copper from fingerprints and oil by wearing gloves. Using these techniques, you can keep your copper sheets looking new for a long time.

How to Bend Copper Sheet?

When you curve copper sheet metal the correct way, it makes an exceptional impact. To twist copper sheets, first determine how thick the sheet is and then pick the right apparatus to twist it. Sheet metal brakes or hand seamers can be used to bend thin sheets, while bench-mounted vises or power tools may be needed for thicker sheets. Pick a location for the sheet’s fold. Then, secure the copper between the clamp or tool.

Check to see that the lines you want to bend are centered on the edge. To get to the right spot, gently pull along the curved line, increasing pressure as necessary, taking care not to snap or bend the metal. Tap the curved copper gently with a wooden or plastic hammer to twist it without hurting it. Always wear gloves to keep your hands safe from being cut by sharp metal edges. Assuming you really want to twist the copper into complex shapes or tight bends, heat it up in advance to make it simpler to work with.

How Much Copper Sheet Cost?

The thickness of the metal, its size, the amount of demand, and the supplier all influence the price of copper sheet metal. Thin metal sheets, typically ranging in thickness from 0.5 to 1 mm, can be purchased for between $20 and $50 for small pieces and $100 and $200 for larger ones. Small bed sheets range in price from $40 to $80, while larger sheets range from $150 to $300. Smaller sheets of 16 gauge or thicker (over 1. 5 mm) can cost $60 to $150, while larger sheets can cost $200 to $400. The quantity of copper mined, economic conditions, and a variety of other factors influence the price of copper over time.

Additionally, items purchased at regular stores typically cost more than those purchased at discount stores. It is possible to save a significant amount of money per item by purchasing a large quantity from a reputable supplier at once. Copper sheets of superior quality for specific applications cost more than those used for all applications. Excellence and goodness are also significant. The cost of good treatments like patina or protective coatings can go up. For instance, a major piece of thick copper from a web-based store could cost $120 to $200, while a more modest piece could cost $30 to $40.

Depending on the economy, larger and thicker copper sheets, such as a 16-gauge 48″ x 96″ sheet, may cost $300 to $600 from a specialty supplier. Comparing prices from online metal stores, specialty metal suppliers, and local home improvement stores are all helpful when purchasing copper sheets. You can look for discounts to save money when you buy many things at once. You can save money by buying things at low prices and keeping an eye on prices. Consider the transportation costs, particularly for enormous sheets or large orders, since they can influence the all-out cost. Considering these factors, you can select the best copper sheet metal for your requirements.

Conclusion

In conclusion, copper sheets are extremely useful in a variety of ways. They are vital in numerous organizations since they have extraordinary characteristics like being impervious to mileage, adaptable, and great at leading power and intensity. Professionals and enthusiasts alike can utilize copper sheets to enhance their projects’ performance, strength, and aesthetic appeal. Copper sheets are still popular due to their beauty and utility. They can be used for electrical projects, creative design, and practical development.