Stainless Steel Bending – The Ultimate Beginners Guide

Stainless steel bending plays a critical role in producing high precision and strong parts in the industries. In construction, in the world of automobiles, or in medicine, it is crucial to know how to do it right. You are prone to cracks, bad finishes or even structural collapse without the right knowledge. This guide provides you with important concepts, bending processes, equipment, best practices, challenges, grade comparisons, and practical applications in order to make informed decisions. It is time to start exploring so that your projects will gain long-term strength, accuracy, and performance.

Table of Contents

ToggleWhat Is Stainless Steel Bending?

Stainless steel bending is the mechanical process of deforming stainless steel so that it takes the required shape without cracking or structural breaking. It is pressed until the steel folds- sometimes in an elastic manner, it rebounds, or in a plastic manner, where it retains the new form. Bending is typically angle-altering, forming reshapes the surface and folding creates sharp edges. It is vital to know these differences to select the appropriate method, tools, and techniques to achieve project successes in addressing certain project requirements.

How to Bend Stainless Steel?

Understand Your Material

Before the stainless steel bending, check the grade and thickness. These forces make the force required, flexibility and the method of bending.

Clean the Surface

Clean grease, dirt or debris using a good degreaser. Clean surface enables the marking to be accurate and prevents flaws in bending.

Mark Bend Lines

Mark the specific points of bends with a scribe, chalk or marker. Good lines can help in proper, consistent turns.

Select Bending Method

Choose cold bending of thin sheets, or heat bending of heavier ones or tight-radius bending.

Choose the Correct Tools

Depending on the type of material and project, use press brakes, tube benders or a vise.

Set Up Equipment

Test your choice of tools that need to be selected to the thickness of stainless steel and bend specifications. Ensure that the working environment is secured and clean.

Align and Bend

Insert the steel on the right side by the mark. Shape or beat by heat.

Measure and Adjust

An angle of bend is to be checked using an angle finder. Bend or refine a little to an accuracy.

Cool and Check

Heat the steel and allow it to cool gradually. Test the final bend to determine whether it contains cracks, spring-back or has any surface damage.

Finish the Bend

Wipe the kinked part and repeat with other bends. Repolish or refinish, as necessary.

Why Is Bending Stainless Steel Challenging?

Bending stainless steel is not easy due to the fact that the metal is very strong and it work-hardens fast and is hard to bend. It is also difficult because of its natural springback in that the material is likely to revert to its original form, and that influences accuracy. Surface finish is significant too–scratches or marks might interfere with look and actions. Poor bending may lead to cracks or structural deficiency. It is because of these reasons that stainless steel bending needs the right tools, expertise and accuracy in order to produce an accurate and high quality product.

Fundamental Principles of Bending Stainless Steel

In bending stainless steel, deformation occurs because one of the layers stretches and the other compresses under the force of the bending process. Important are the ductility, elasticity, and work hardening. Ductility is the ability to bend without cracks though elasticity permits the metal to spring back unless it becomes plastic. Beyond the elastic limit the bend becomes irreversible. Knowing the stress-strain curve, you can predict such transition and gain a better control over the bending process.

Key Factors Influencing Bending Stainless Steel sheet metal

Material Grade and Metallurgy

The initial process in stainless steel bending is the choice of the appropriate grade. Alternatives such as 304, 316, 430 stainless steel and 201 differ in properties. An example is that 316 is more resistant to corrosion, but requires additional force, and 304 and 201 are easier to bend. The important considerations are the yield strength, the elongation and the tensile strength since certain grades of stainless steel harden quickly and are difficult to bend.

Bending Strength and Force Requirements

The greater the force necessary to bend, the stronger the materials. In order to know the amount of tonnage you will require, you will need to know the amount of tonnage needed according to the type of material, the thickness or bend angle. Such errors should be avoided by always planning tooling and machine capacity.

Bend Radius and Bend Angle

Minimum inside bend radius is determined by the material thickness and hardness. The smaller radii tends to crack, whereas the larger ones mitigate that potential. Choose how much flexibility or structural strength your application will require and make a wise choice.

Springback Effect

When bending, stainless steel springs a little. This is due to the elastic properties. In addition, you are to overbend to check and offset springback. The effect is reduced through the use of fine tools and changing the angle of bending.

Bending Allowance and Bend Deduction

You must be aware of the quantity of material being stretched in bending. Bending allowance and deduction give you the ability to know what kind of flat pattern you want. To get better accuracy in design, standard formulas are applied.

Stainless Steel K-Factor

In bending, the neutral axis is K-Factor. Common stainless steel bending values of K-Factor range between 0.30 and 0.50. You will use this in CAD and CNC systems to make sure your flat layouts provide the right results.

Surface Finish and Protective Considerations

Stainless steel bending is likely to have scratches and galling. Urethane or plastic dies are protective films or soft tooling materials that should be used always. Lubricants also help to avoid damage and are applied to increase tooling life. Surface finish should be your priority especially when it is a visible or hygiene application.

Stainless Steel Sheet Bending Techniques

V-Bending

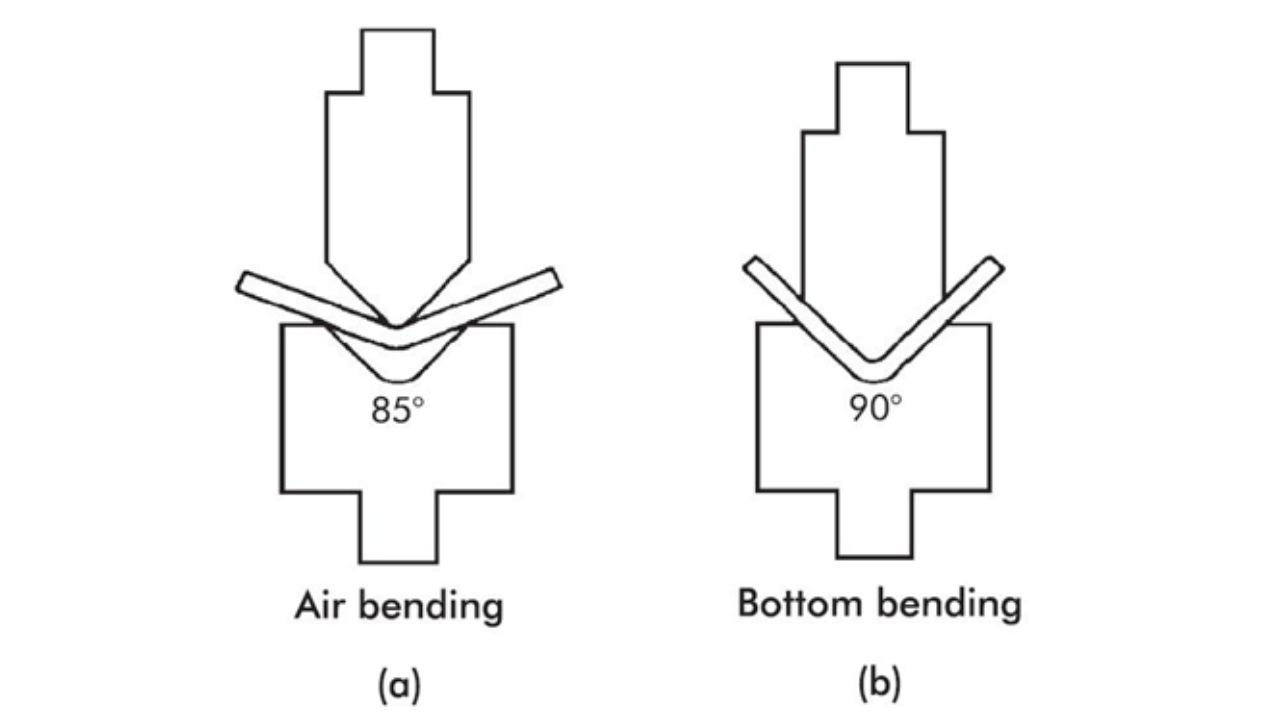

V-bending is one of the most popular bending methods of stainless steel sheets. You stamp the metal in a V shaped die using a punch and it bends exactly. Simple and complex parts are really working well with this method. You will find it perfect in general sheet metal fabrication where cost and simplicity are significant. V-bending is very effective at managing bend angles, especially moderate thicknesses.

Air Bending Stainless Steel

Contrary to bottoming and coining, in air bending the punch does not strike the sheet fully against the die. It clamps the sheet between die edges to create the bend, and has air space beneath. It provides you with greater tooling flexibility and reduces force requirement. It is wonderful in producing various angles using a similar set of tools.

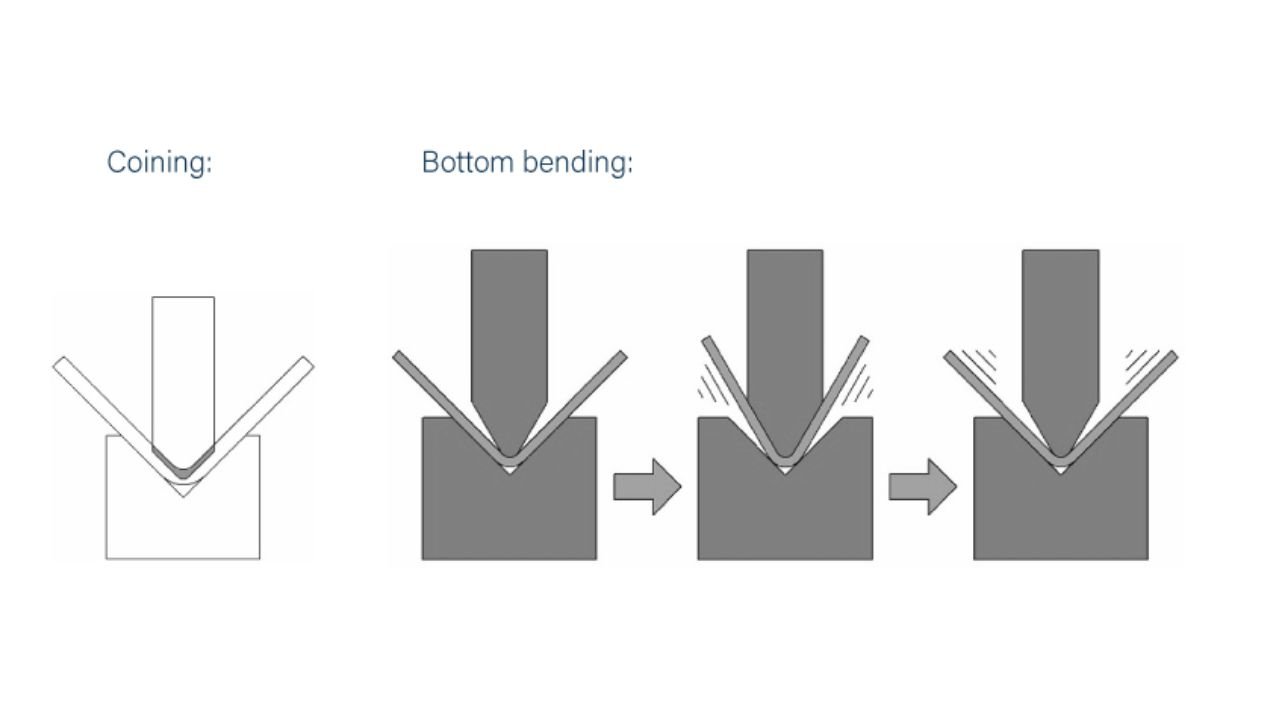

Bottoming and Coining

The bottoming presses the sheet to completely fill the die cavity and the coining presses the metal to fill the die cavity to hold the bend angle. Air bending needs less force than these methods, although you have more accuracy and less springback. They are most appropriate to use when you require sharp straight constant bends in components which must have tight tolerances.

Roll Bending

In roll bending, the sheet is slowly rolled to a curve in several rollers. You use it in series on large radius, or cylindrical shapes. This is best suited with architectural panels, tanks and curved enclosures. When you want curves that will be smooth and even, with no sharp angles, employ this procedure.

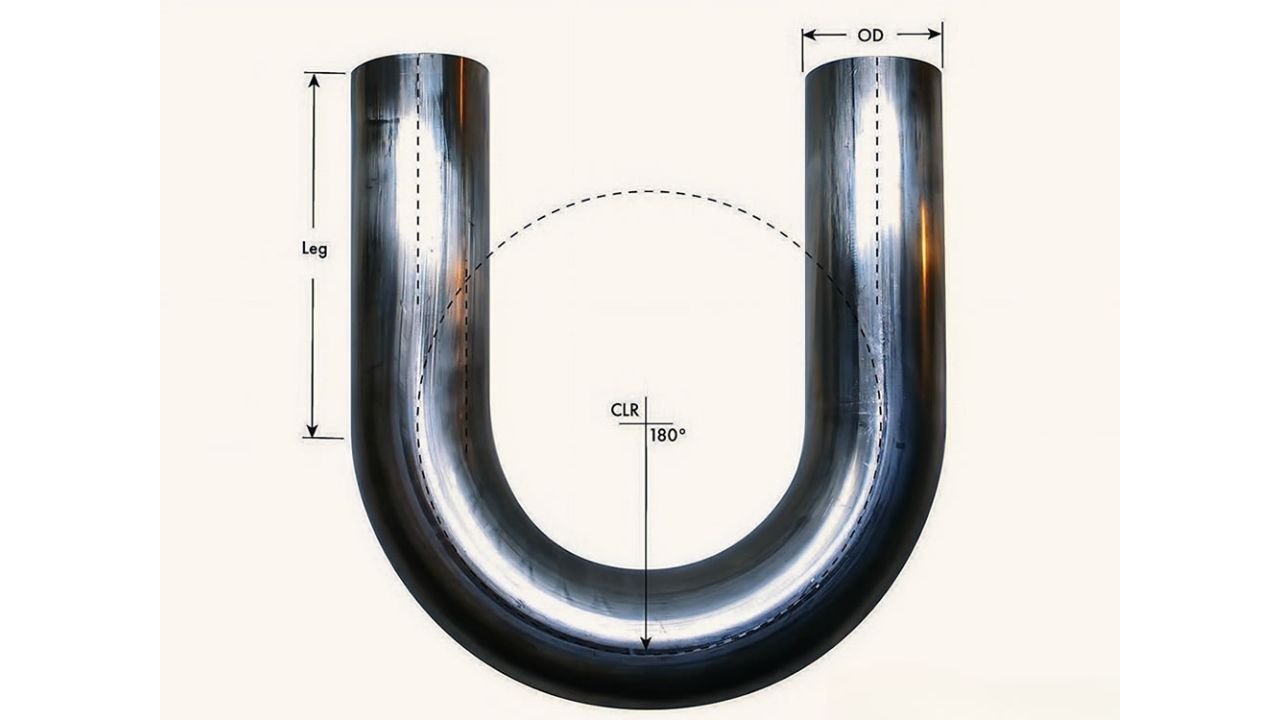

U-Bending

Stainless steel bending is not an easy task; it is very strong, fast work-hardening with springback which influences accuracy. Surface finish is also important as scratches or galling effect acts. U-bending, punch and die processes form durable U-profiles around brackets, channels or enveloping structures.

Rotary Bending

In the rotary or rotary draw bending, a roller rotating in the direction of the bend is utilized. It is handy when making tight radii, or odd geometry. The method reduces surface marks, and reduces springback, and is applicable to cosmetic parts, or polished finishes.

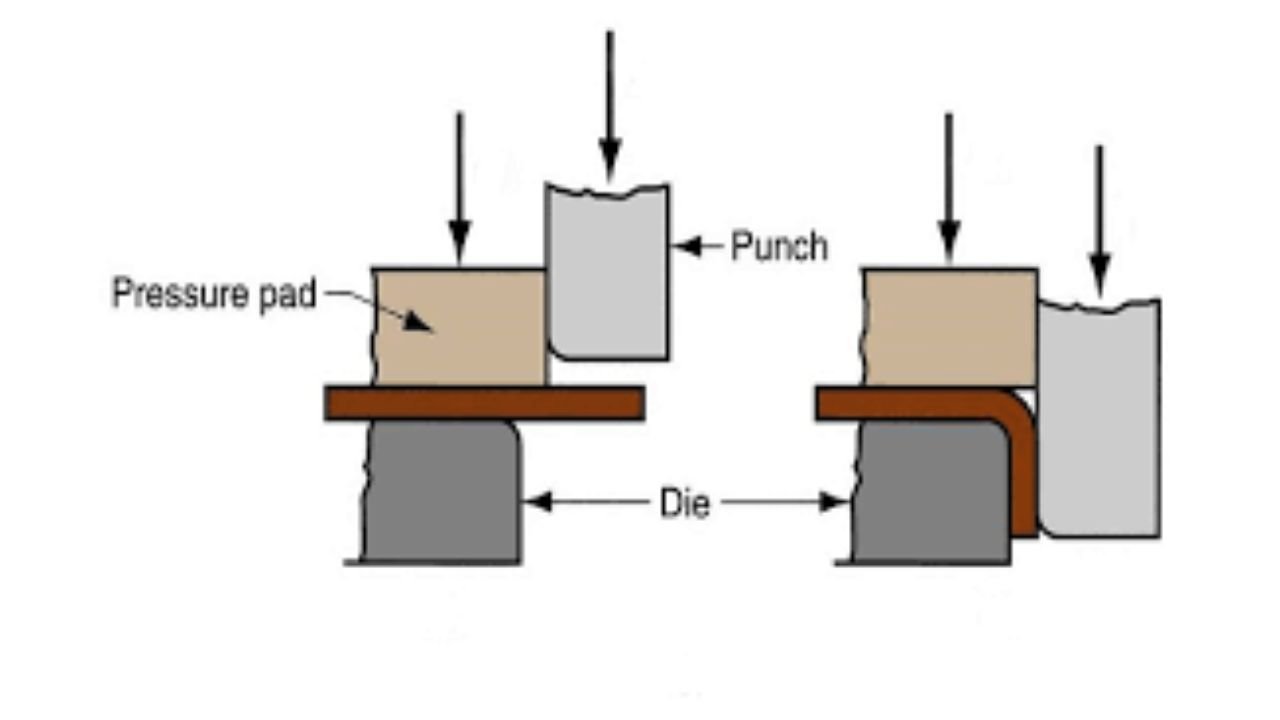

Edge Bending

Edge bending is the shaping of a sharp, clear edge of a sheet using a press brake. This method may be applied to shape brackets, stiffeners or box sections. It is a good alternative where you desire good clean bends along straight edges.

Stainless Steel Tube Bending Techniques

Stainless steel bending refers to the process of deforming stainless-steel tubes into the required shapes or angles through a range of different methods. These are either manual, heat, mechanical, mandrel or induction methods and are commonly used in various industries.

Mandrel Bending

Mandrel bending preserves the inner diameter of your tubes. This technique bends the tube with the assistance of internal mandrels. Close radii or cosmetic finish is needed, you have the advantage of such procedure. The process maintains the tube against collapsing or deformation, therefore your design is maintained with the strength and appearance you created it to have.

Compression Bending

When compression bending is being done, you have a fixed die and a pressure arm. This machine can always bend consistently and repeatedly due to its set up. The method is ideal in simple projects that require a few modifications to the equipment. You can retain the uniformity of every bend that you make in its easy mechanism.

Draw Bending

You can apply draw bending when you are using the pull through die method. You insert the tube into a die set that presses the tube into whatever shape you want. It is a typical practice in automotive, aerospace and heavy industrial piping. It provides you with the accurate bends when the conditions are challenging.

Rotary Draw Bending

Stainless steel bending is not an easy task; it is very strong, fast work-hardening with springback which influences accuracy. Surface finish is also very important, because scratches or galling effect work. Efforts such as U-bending, punch and die produce durable U-profiles in bracket, channels or structural enclosures.

Roll Bending for Tubes

Multi roller pass roll bending is offered to large radius bends and spiral shapes. The forms of tubes may be molded progressively to reduce stress on the material. This technique lets you draw up extremely detailed curves, and still adhere to your design preferences.

Press Bending

A press bending uses hydraulic or mechanical force on a die set. It is low cost with low setup cost. Therefore, you need to remember that it does not offer much control over the bending radius hence not appropriate to use on curved corners.

Induction and Heat-Assisted Bending

In induction or heat assisted tube bending you place controlled heating areas to soften the material. You use this method when you do not want to crack thick walled tubes or tight bends. This provides you with a competitive advantage of bending hard materials with certainty and precision.

How to bend stainless steel pipe?

Stainless steel pipe can be bent with the help of a pipe bender that is specially made to perform this job. You need to make certain that your pipe bender matches the diameter and wall thickness of your pipe.

Bending of stainless steel by heat-assisted

When and Why to Use Heat

Stainless steel bending can necessitate heat-assisted methods in the case of thick or rigid sections. Repeated deformation causes the material to become more brittle and heat is one of the ways to get over these consequences as you can harden the material. Heat application minimizes cracks and leads to a cleaner and more accurate bending.

Heat Bending Process

Selecting a heating process: Torch, induction or furnace will be based on the material thickness and the nature of the bends. You must also preheat the metal evenly to avoid hotspots. It is then molded with dies or hand tools, when hot and soft. Select and choose the right cooling method now. Annealing provides superior recovery of strength and stress relief, but is more complicated and more complex cooling is required.

Precautions and Post-Bend Treatments

To maintain quality of materials, avoid overheating. The excess heat can cause grain growth or surface oxidation. Reinforce after bending with controlled cooling, or annealing. In case oxidation occurs, you must clean the part also. It maintains the finished product tough, accurate and aesthetically clean.

Bending Equipment and Tooling

Types of Bending Machines

Various machines are applicable to different bending requirements. Manual press brakes are easy and suitable in low volume work whereas CNC press braves are used in intricate or repeatable bends with a high degree of accuracy. Roll bending machines create high-curve radius curves in tanks or architectural components. Rotary draw and tube benders are the best in the case of tubes or pipe having tight radii and little cross-section distortion.

Tooling Materials and Design

The right tooling influences both accuracy and finish. Depending on the bend profile you will use V-dies, U-dies, and radius dies. Durability, or to minimize wear and friction, select hardened tool steels or coated tools. Also be sure to check tool wear because worn dies will bend your parts. Maintaining your equipment correctly will increase its life and make it perform accurately.

CNC and Automation in Bending

Angles, force and radius are precise with CNC bending. It can be combined with CAD/CAM systems that allow you to design to production. Real time monitoring gives you the ability to adjust variables in the process in order to achieve a steady quality. At least, the important one is automation when you need efficiency and repeatability.

Common Applications of Bent Stainless Steel

Construction and Architecture Use

Bent stainless steel will be common in modern buildings. Due to its power and beauty, it is applied in railings, brackets or decorative panels. The corrosion properties ensure that the material will be long lasting outdoors and in the high traffic areas.

Automotive and Aerospace parts

Accuracy and consistency is what you count on in these industries. Stainless steel shapes are bent to form fuel lines, exhaust systems and structural aids. It was ideal in safety critical components because it has a high strength-to-weight ratio.

Food and Medical Equipment

In these industries purity is paramount. Frame, hygienic tubing and contact surfaces are made with bent stainless steel. It is easy to wash and bacteria resistant and meets high health standards.

Marine and Chemical Usage

Corrosion resistance is required in aggressive conditions. 316L stainless steel is used in marine rails and chemical tanks so that is the reason. It is salt water and reactive chemically good.

Furniture and Interior Designs

Bent stainless steel can also be used in custom enclosures, smooth handles or useful fixtures. It is long lasting performance style.

Challenges in Bending Stainless Steel Sheet and How to Overcome Them

Avoiding Cracks and Surface Defects

Unless you choose the correct inside bend radius, it will crack as it is being bent. A radius that is too tight leads to the threat of a fracture. Protective films or soft dies such as urethane can also be used to prevent surface scratches or galling. These minimize friction and aid in conservation of finish.

Dealing with Springback

Stainless steel bending is commonly associated with the problem of springback, in which the metal attempts to get back to its original form. This may disrupt the angle being aimed at, and accuracy may become more difficult to obtain. In response to this, material specific compensation is introduced and in most instances the metal is slightly overbent so as to achieve the required final shape.

Maintaining Dimensional Accuracy

Dimensional errors can influence the assembly and part performance. Using simulation software, you can foresee results prior to bending. Always ensure that you make proper pre bending calculations. They help you to fix the right bend allowances and deductions.

Preventing Warping and Distortion

When your bends are not balanced then you have warpage. Always attempt to use symmetrical bending patterns. Ensure that the material is firmly clamped and good fixturing is employed to keep it straight.

Best Practices for bending of Stainless Steel

DFM (design for manufacturability)

Start with fabrication in mind. You must consider material thickness, bend radius and tooling limits. Avoid tight turns or overly complicated turns because this can lead to cracking. Early implementation of DFM principles reduces the requirement of costly design changes in future.

Choose the Right Process for Shape Complexity

Not every shape can be bended with every technique. Rotary draw bending can be a better option in case you are bending complex angles. Press brakes or V-bending are effective in simple bends. The quality and efficiency can be achieved through ensuring that you match the process with the complexity of your design.

Test Prototypes Before Full Production

Pilot a prototype to production. It helps you to verify bend accuracy, springback behavior and surface finish. You can even modify tooling or process parameters directly in response to actual results. Prototyping will save you the cost of re-work or waste.

Apply Proper Finishing and Post-Bend Treatment

Bend your stainless parts, they might require finishing. When surface marks are present, you ought to remove them by polishing, or passivate to restore corrosion resistance. The treatments offer long term service particularly on medical, food grade or marine applications.

304 Stainless Steel vs 316: Bending Characteristics Compared

Bending Ease and Formability

Stainless steel bending is easier to work with 304 stainless steel. It is more ductile and is more adapted to cold bending without cracking. 316, however, is tougher and does not deform easily. In tight radius or thick, especially, it is going to need more pushing or heat to bend.

Applications Based on Grade

In case you are on ornamental, structural or non corrosive settings, you ought to select 304. It is applied extensively in appliances, architectural trim, etc., and in general purpose fabrication. However, the most appropriate one to use in case of marine, chemical, or food processing is 316. It has high with regard to corrosion resistance (particularly in the chloride rich or severe environments).

Cost vs Performance Trade-Off

You will notice that 316 is cheap compared to 304. It is cheaper and offers you a good strength and formability. But when you require high levels of corrosion resistance and longevity in your application, then the additional money on 316 would be worthwhile. Look at your budget, environment and performance requirements before deciding.

Conclusion

Stainless steel bending is essential in strength, accuracy, and fabrication design. Every process impacts quality, starting with material knowledge, choice of processes and use of equipment. Be it the sheets or tubes, good methods reduce defects and increase reliability. As the demand increases in construction, automotive and medical sectors, it becomes important to master bending. Stainless steel is hard and difficult to bend, but it can be bent with an expert touch, making difficulties into long service and accurate design where best practices are followed.

FAQs

Why is partnering with a top-tier China laser cutting machine supplier critical for successful stainless steel bending?

The success of any stainless steel bending operation is fundamentally dependent on the quality of the initial flat blank. As a leading fabrication manufacturer, we understand that achieving tight tolerances on the press brake starts with absolute laser cutting precision.

Which grades of steel used in making stainless-steel pipes?

Pipes are most often stained using 304 and 316 stainless steels. Grade 304 is all-purpose, pliable, readily welded and shaped, and 316 is resistant to salt water and chemicals. High-temperature applications are done with other grades such as 321 and 310s.

Does temperature affect bending 304 stainless steel rod?

304 stainless steel bending rods is sensitive to temperature. Cold bending is done at room temperature but prone to work-hardening and crack. Bending above 900 C is more safe and 400-900 C should be avoided to keep off the formation of carbide and decreased corrosion ability.

What grade are used for 3-inch stainless steel exhaust pipe bends?

The most standard exhaust pipe bends are 304 3-inch 304 and 409 304 is highly resistant to corrosion and has high durability in high-performance exhausts and the 409 is also effective in heat-resistance but corrosion occurs at a faster rate, and is commonly used in OEM exhaust.

Can I use 4-inch stainless steel bends in high-temperature applications?

Is it possible to use 4-inch stainless steel bends in high-temperature application? Yes, 4-inch stainless steel bends are capable of use in a high-temperature system, depending on grade. 304 can be used up to 870 °C (1600 °F) on exhausts and in industry, whilst 316 or 321 are more resistant to extended exposure to high temperatures and thermal fatigue.

What are the benefits of using 321 stainless steel mandrel bends?

The most optimal in high-temperature and high-stress applications include 321 stainless steel mandrel bends. It possesses various strengths including increased resistance to corrosion, increased resistance to tensile stress and tensile fractures compared to the 304 stainless steel.

Can bending stainless steel sheet by hand is possible?

The bend of stainless steel is dependent on grade and thickness. Simple tools are sufficient to bend thin sheets less than 1 mm, with harder ones such as 304 or 316 requiring harder tools.

What tools are used for bending stainless steel bar?

Stainless steel bar cannot be bent and returns to shape, which means that powerful and accurate instruments are needed. Bench vise and hammer can be used to bend thin (up to 6mm) bars, whereas heavier (6–12mm) bars require manual or hydraulic benders.

What grades are easiest for bending stainless steel wire?

Austenitic stainless steels such as 304 and 316 are easiest to bend in forms of a wire because they are ductile. Grades 302/304 are the most typical, a combination of strength and flexibility. In their specialized bending applications, 305 or 310 stainless steels are used to achieve increased formability.

How to bend stainless steel jewelry?

Stainless steel jewelry is hard and has to be bent carefully. Apply rounded sharp instruments such as nylon-jaw pliers, mandrels, or ring-bending instruments to prevent scratches. Thicker pieces can be bent using annealed stainless, whereas hardened or tempered require a special apparatus or heating.

What is the minimum bend radius for stainless steel sheet?

Minimum bend radius of stainless steel is dependent on thickness and condition. In the case of annealed sheets, it is equal to the sheet thickness (1x). Hard or cold-rolled sheets with thickensses around 1.5 to 2x will need a bigger radius, which averages 1.5 to 2x to prevent cracking.

How to bend stainless steel tubing without kinking?

In order to bend stainless steel tubing without kinking, appropriate equipment should be used like a mandrel or rotary draw bender to hold the inside wall. Choose the radius of a bend of around 2-3 times the tube outer diameter and apply gradual, consistent pressure to avoid collapse.

What sizes are commonly used for bending 316 stainless steel tube?

Usual tube bending lengths of 316 stainless steel tube are between 1/4 and 2 inch OD, most commonly 1/2, 3/4, and 1 inch. Up to 4 inches in size also bend, however, smaller diameters are most commonly used in applications such fluid lines, instrumentation, and exhaust systems because of ease of forming.

Read more on: