Melting Point of Gold – The Ultimate Guide

Gold refers to yellow and soft metal featuring high malleability and ductility. It has the ability to conduct heat as well as electricity. Gold has an atomic number around 79 with abbreviation for the element as Au. It features unmatchable luster and radiance. In todays age Gold represents a symbol of power and wealth. Different industries ranging from jewelry, to finance as well as electronics utilise this metal for different purposes. One key aspect that impact the application of Gold is melting point of gold. Getting familiar with this aspect is crucial for effective molding as well as refining specially for targeted industrial sectors. The purpose of this blog is to offer insights on Golds melting point, melting process, factors affecting it and much more. Let’s get started!

Table of Contents

ToggleWhat is the Melting Point of Gold?

To understand the melt point of Gold first get familiar with melting point concept. It refer to a point at which material shift in state from solidity to liquidity. Please note this is true at standard atmospheric pressure.

It is crucial to note have familiarity with the gold melting point in different units of temperatures:

- Melting point of gold in Celsius (10640C)

- Melting point of gold in Fahrenheit (19470F)

- Melting point of gold in Kelvin (1337.33K)

At these temperatures (10640C/1337.33K/19470F) the gold in any form experience a shift in state from solidity to liquidity.

Factors That Influence the Melting Point of Gold

Various factors exist that affect the melting point of gold in degrees Celsius are:

Level of Purity

The melting point of 24 karat gold or pure gold is 10670C. On the other hand if the gold is not pure then the melting point decreases. For instance if the Gold is in alloyed form with either nickel or copper or silver. Then these alloys change the atomic structure of the gold and ultimately lowers the melting temeprature of pure gold. For example 18K gold comprises of 25 percent alloys and 75 percent pure gold. The melting point of 18K gold is lower that that of 24K gold.

Melting Pressure

The pressure directly influence the melt point of gold. If the surrounding pressure increases then the melting temperature of the gold also increases and vice versa. This is because under lower pressure the structure of the atoms become less compact and vice versa. Therefore it varies the melting temperature.

Size of The Particles

The size of the nano-particles greatly impact the gold melting point. Presence of large number of small size particles contribute to greater surface to volume ratio. The larger surface area indicates the presence of large number of atoms over the surface than within the particle. This ultimately lowers the melting point of gold nanoparticles because you need much lower energy to transition the solidity to liquidity.

Chemical Environment

In chemcial environment number of things can influence the melt point of gold such as:

- If there exists reactive gases while heating the gold such as chlorine or oxygen. Then these gases can influence the energy you need to melt the Gold. You can experience lower melting point as these gases weaken up the bonding.

- The fluxes (which refers to the substances that purify the Gold) impact the temperature at which Gold melts. These fluxes form up compounds with Gold. This ultimately lower the melting temperature.

Structural Defects

The structural defects present within the Gold that you are going to melt affect the melting point. The non-uniform presence of crystal structure or existence of grain boundaries can contribute to lower melting point. You can overcome this if you control the quality of the gold. The pure gold does not have any affect of grain boundaries of dislocations.

What is the importance of Melting Point of Gold?

The following key points will clear up the importance of the melting point of Gold:

Precision Manufacturing

No matter if you are operating the jewelry business or electronics business getting familiar with melt point of Gold is crucial. This will help you cast or mold qualitative and precision products.

Effective Quality Control

To build a strong reputation in the market as a manufacturer, you need to offer flawless products. The melting point of Gold can help maintain quality and form during the entire manufacturing phase.

Alloys Creation

If the end purpose is to blend two or more alloys with Gold. Then you cannot do so accurately without knowing the melting temperature of the gold. The main reason of blending these alloys is to impat specific characteristics. These characteristics includes color, or even strength.

Effective Recycling

Knowing the melting point of the Gold allow you to experience effective recycling. The scrap gold possess impurities or unwanted materials. With aging the color or luster reduces. You can renew it by recylcing which involves melting and casting the gold into new shapes or designs.

Research Advancement

In case if you are a researcher and want to strengthen your knowledge on materail chemistry or material sciences. Then in this case the melting point of Gold serve as base. You can understand how material behaves under certain condistions with different compositions.

Comparing the Melt Point of Gold With Other Metals

- Melting point of gold and copper – Gold 10640C and Copper 10830C

- Melting point of gold and iron – Gold 10640C and Iron 15380C

- Melting point of gold and platinum – Gold 10640C and Platinum 17680C

- Melting point of gold vs silver – Gold 10640C and Silver 9610C

- Melting point of gold vs steel – Gold 10640C and Steel 15380C

- Melting point of gold vs Aluminum – Gold 10640C and Aluminum 6600C

- Melting point of gold vs Titanium – Gold 10640C and Titanium 16680C

| Sr. No. | Metal | Melting Point (Celsius) | The Melting Point (Fahrenheit) | Melting Point (Kelvin) |

| 1 | Gold | 1064 | 1947 | 1337 |

| 2 | Copper | 1083 | 1981 | 1356 |

| 3 | Iron | 1538 | 2800 | 1811 |

| 4 | Platinum | 1768 | 3214 | 2041 |

| 5 | Silver | 961 | 1762 | 1234 |

| 6 | Steel | 1425-1538 | 2617-2800 | 1698-1811 |

| 7 | Aluminum | 660 | 1220 | 933 |

| 8 | Titanium | 1668 | 3034 | 1941 |

Through the above table you can witness that the melting point of Gold is lower than the copper, iron, platinum, steel, and titanium. But is higher than aluminum and silver.

Understanding the Melting Temperature of Different Gold Grades

The gold has different grades available. Uncover insights on

- Melting point of 24 karat gold

- Melting point of 22k gold

- Melting point of 18k gold

- Melting point of 14k gold

- Melting point of 10k gold

the meting temperature of all types of Gold grades available. You can witness the melting point in different temperature units along with purity and impurity percentage in the table below:

| Sr. No. | Gold Grade | Melting Point (Celsius) | The Melting Point (Fahrenheit) | Melting Point (Kelvin) | Purity Percentage | Other Alloys Percentage |

| 1 | melting point of 24 karat gold | 1064 | 1947 | 1337 | 99.99% | 0.01% (impurities) |

| 2 | melting point of 22k gold | 961 | 1762 | 1234 | 91.67% | 8.33% (usually silver, copper, or zinc) |

| 3 | melting point of 18k gold | 920 | 1688 | 1193 | 75% | 25% (usually silver, copper, or zinc) |

| 4 | melting point of 14k gold | 840 | 1544 | 1113 | 58.33% | 41.67% (usually silver, copper, or zinc) |

| 5 | melting point of 10k gold | 780 | 1436 | 1053 | 41.67% | 58.33% (usually silver, copper, or zinc) |

Melting Gold – Step By Step Process

By following the belo step by step process you can effectively melt the gold efficiently:

Dealing with preparations

Ensuring the appropriate safety is paramount. Make sure you have safety gear with you. The key safety gear items include goggles, safety suits, gloves, etc. Apart also ensure the safety of the working area. Make sure the place at which you are working has adequate space for mobility as well as proper ventialtion.

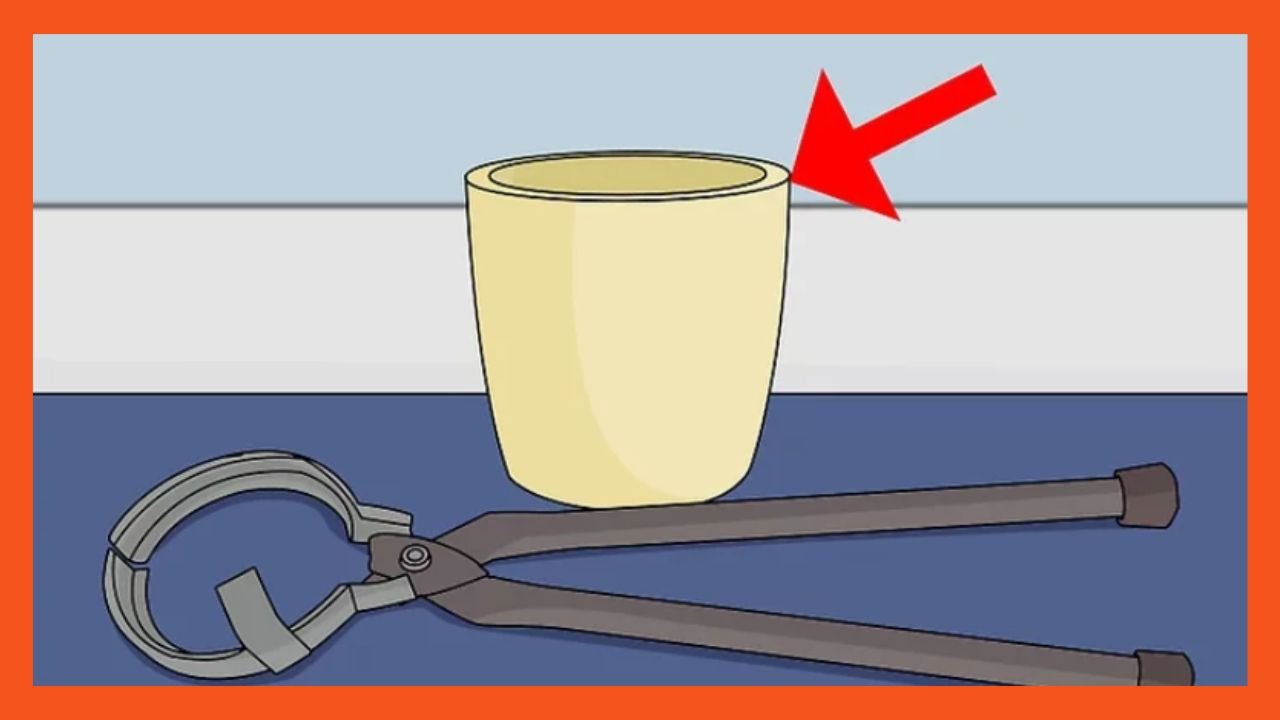

Crucible Set-up

The next step is the setting up of the crucible. In this step you need to put all the gold pieces that you have at hand within the cruicible. It is crucial to keep the gold clean and free from other materials as well as elements. To do so you need to use the flux. You can make use of borax as a flux. It keeps your gold pure and prevents any kind of adherence to the crucible walls.

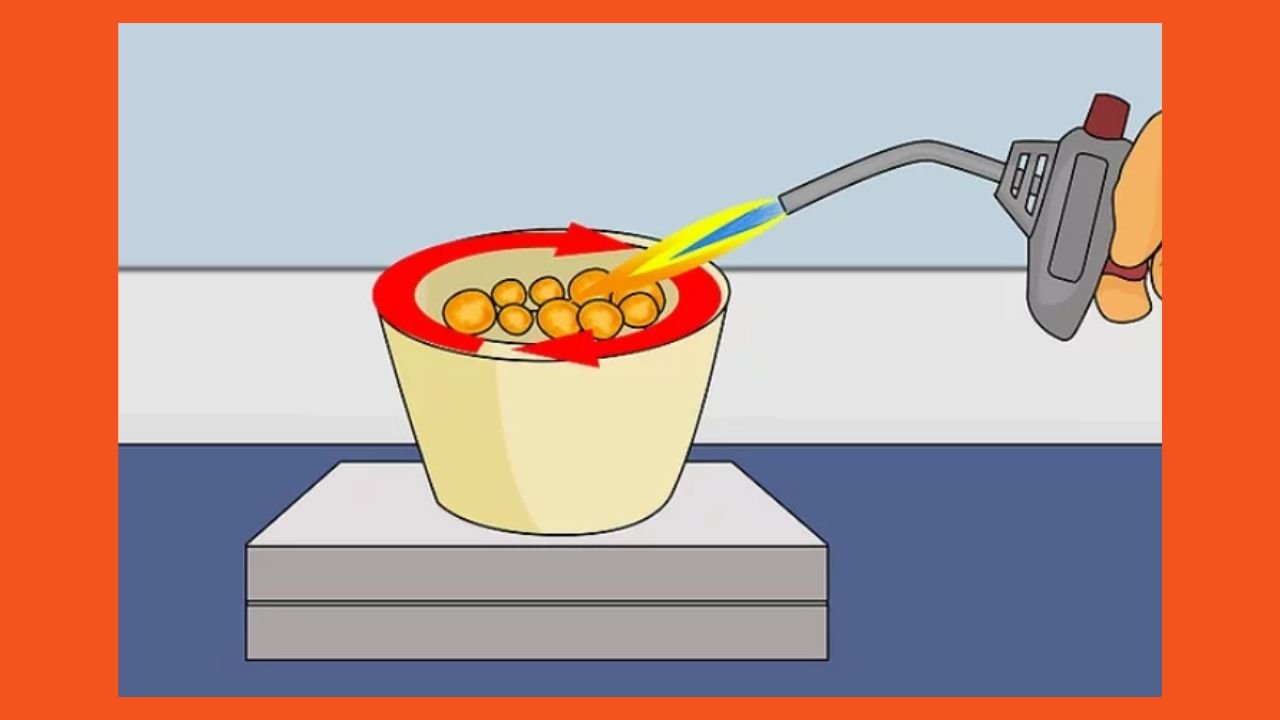

Heat Treatment

Heat treatment involves the heating of the gold piece that are present within the crucible. First you need to heat the furnace which refers to pre-heating. You need to heat it at 10640C. When the furnace reaches the desired temperature you need to put in the gold inside for melting. It slowly heats up and melt your gold.

There are two other ways that you can employ to melt the gold such as:

- By using the heating torch you can melt the gold pieces within the crucible. The torch cost less than operating the fiurnace. You need to evenly rotate the heating torch within the crucible, this will help spread the heat uniformly and melt the gold.

- The third method is employing an induction heater. You can use the electromagnetic induction to melt the gold as per manufacturer guidelines.

Melting

In this step you need to observe how the gold is melting. Firstly it transform from solid into paste followed by thick liquid and finally to the free flowing liquid. Please note at this step you need to use the heat-proof rod to make the homogenous mixture of the gold. Gently agitate the liquid, this way the unwanted materials gets to the top.

Impurities removal

Metal skimmer serves a key role in this stage. It allow you to remove the unwanted particles from the gold. The impurities aslo known as slag which comes to the top surface of the molten gold.

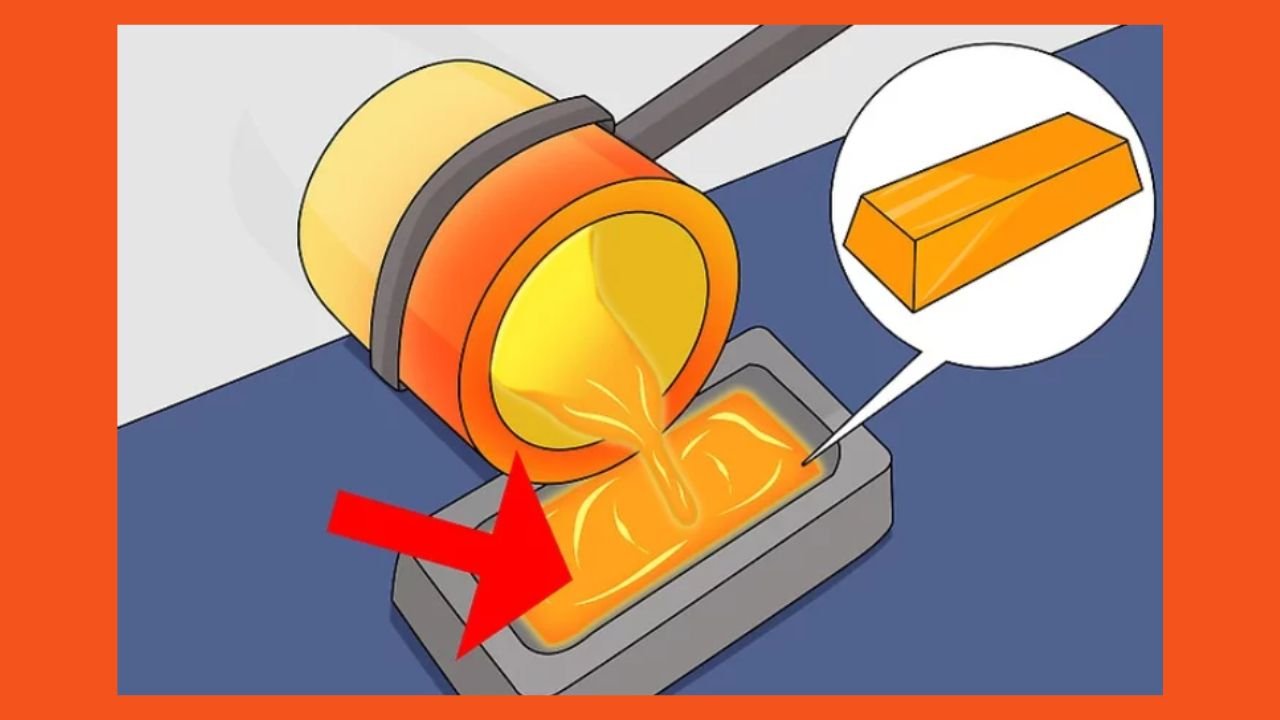

Pouring

Observe the molten gold, when it fully melts and all the impurties appear up on the molten gold surface. Then now is the time to remove the crucible from heating source. You can use tongs to do so.

You can use this molten gold to pour it into the molds to transform the shape of the molten gold to the desired structure. For instance it can be the ignots as well as bars.

Cooling

After putting the molten gold inside the molds now you need to let it cool. Cooling process time may lie in the range of a few minutes to the few hours. The things which affects the cooling process is surrounding temperature as well as mold size. Bigger mold takes longer time to cool and transform into mold. You can take the gold out of mold after comprehensive cooling process.

Finishing

You can assess the quality of the gold by examining the impurities as well as defects. After that you can subject your gold to the finishing. You can subject the gold to polishing as well as refining depending on the target applications.

Understanding Melting and Boiling Point of Gold

The point at which gold melts is 10640C, while the temperature point at which gold boils is 28560C. The boiling point is the point of temperature at which gold transforms from liquid to gaseous form. You can also note that the boiling point of gold is much higher than the melting point.

Achieving the melting temperature to melt the gold is easy as it require less energy while boiling point achieving require much energy. The larger equipment with higher heat you need to do so.

Why You need to melt the Gold?

There are number of reasons exist why you need to melt the gold. Some of the key ones are:

- You may need to extract pure gold or get rid of impurities

- By melting the gold you can subject it to refining, casting as well as molding

- You can repurpose the scrap or old gold into reusable ones

- Option exists to transform the gold into bars as well as coins for financial storage. Further you can use it for investment

- You can design the custom jewelry from the molten gold, like lockets, rings, gold sets, and much more

- Apart from the above uses you can also alloy the gold with other alloys to fulfill the targeted applications

How you can lower the Gold melting point?

You can lower the melting point of the gold by alloying it with other metals. The key metals that can assist in this regard includes zinc, copper, and silver. These alloy disrupt the original strcuture of the gold and decreases the melting point. This means you can melt the gold with just lower amount of energy.

Conclusion

No one can deny the importance of getting familiar with the melting point of gold. You can later apply it in casting, recycling, storage, custom designs, electronics, etc. The information mentioned above will help you with your purpose regardless of the industry to which you belong.

Read more: