Transformer vs Switchgear – The Detailed Comparative Guide

Transformer and switchgear are two crucial foundations of the contemporary electrical power system, but they are used with very disparate aims. Whereas transformers are concentrated on voltage conversion and efficient transmission of power, switch gear is designed to protect the system, control the system, and ensure a safe operation. It is important that engineers, planners, and facility managers understand how these components work, where they are applied, and how transformer vs switchgear are different. This guide disaggregates their functions, usage, technical variations, and selection criteria in order to make informed choices.

Table of Contents

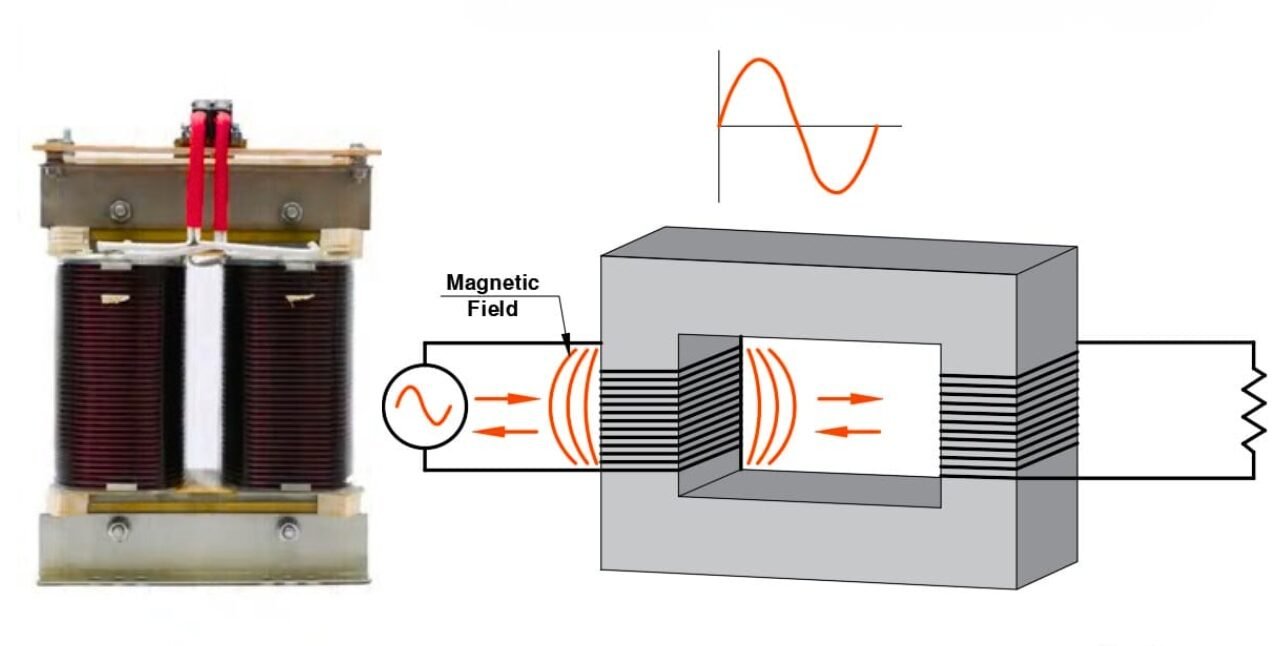

ToggleWhat Is Transformer?

A transformer is a non-portable electrical device that induces energy transfer between circuits by the use of electromagnetism. In the broader context of power systems, transformer vs switchgear comparison highlights the distinction between equipment designed for energy transformation and devices intended for control, protection, and isolation of electrical circuits. It works in accordance with the law of Faraday, in which the alternation of magnetic flux generates voltage in coils. Transformers are only used in alternating current since it is AC that produces the necessary varying magnetic field. You rely on transformers to raise and lower voltage so that you can transmit power efficiently. They minimize I 2 R losses in long lines. Electrical isolation is also offered by transformers to enhance the safety of systems, and to safeguard sensitive equipment under operation.

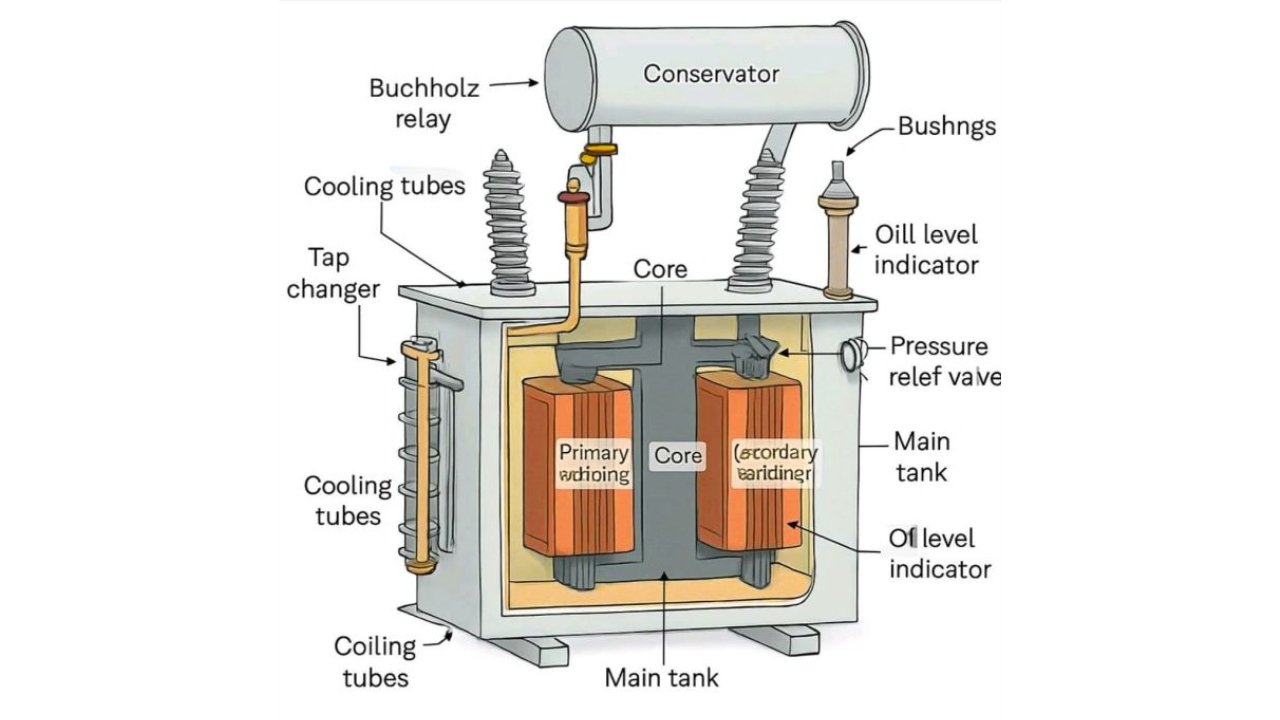

Main Components of Transformer

Primary and Secondary Windings

The strength is transferred between primary and secondary windings by electromagnetic induction. Aluminum saves money, whereas copper conductors are more efficient. Turns ratio regulates voltage conversion. You choose your winding design according to your load demand and thermal limits requirement.

Magnetic Core

Flux is directed through laminated layers of silicon steel by magnetic core. Laminations minimize the heating and eddy current losses. Flux paths are optimized to enhance efficiency. You get reduced noise, vibration, and constant levels of magnetic performance overall reliability.

Insulation Systems

Windings are insulated to prevent electrical stress and overheating. Oil-immersed designs give cooling and dielectric strength. Fireproof material enhances indoor safety. Solid materials isolate constituents and inhibit partial discharge failure during operation cycles conditions scenarios.

Cooling Systems

Cooling systems eliminate heat and preserve efficiency of the transformers. ONAN relies on natural oil circulation. ONAF provides forced air support. OFAF employs pumped oil flow. Continuous operation periods cycles conditions Air-cooled transformers are based on the ambient airflow.

Types of Transformers and Their Applications

Power Transformers

Power transformers facilitate long distance transmission of electricity. They have very high voltage ratings at which they operate effectively. In a Transformer vs Switchgear comparison, power transformers are specifically designed for voltage transformation and continuous energy transfer rather than protection or control functions. These are located in utility-scale generation plants and substations. These units increase voltage in transmission and reduce voltage close to load centers. Their strong insulation and cooling systems enable them to operate continuously with heavy-duty. You use power transformers to reduce transmission losses and stabilize grid performance.

Distribution Transformers

Distribution transformers provide end users with usable voltage. Pole-mounted and pad-mounted transformers are common. These units provide services to residential and commercial premises. They transform medium voltage power to low voltage supply. Small size enables it to be installed close to consumption points. Your system will have better voltage regulation and safer distribution of energy.

Isolation Transformers

Isolation transformers are used to isolate circuits to enhance performance and safety. They lower voltage spikes and electrical noise. You frequently apply them in medical devices and delicate electronics. Ground faults and interference are prevented by electrical isolation of devices. Signal stability and operational reliability are also increased by these transformers. You have safer operation and cleaner power delivery.

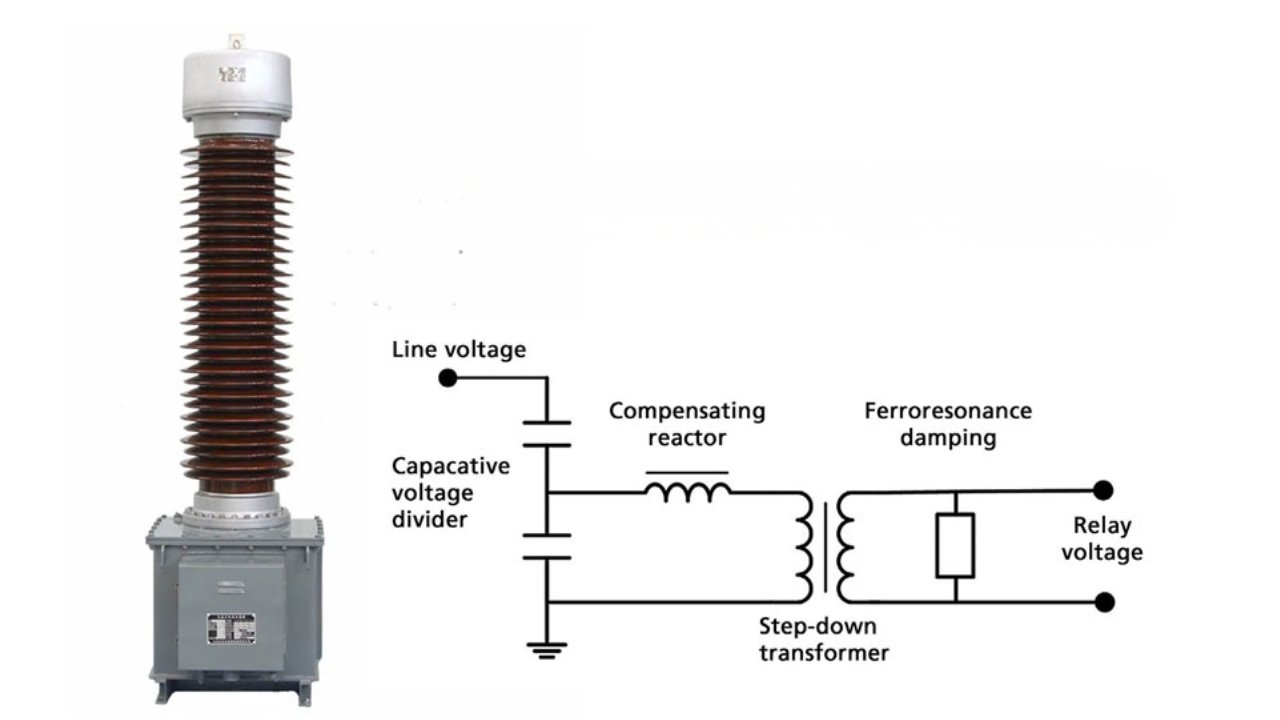

Instrument Transformers

Instrument transformers assist in monitoring and protection systems, clearly distinguishing transformer vs switchgear roles in power networks. Current transformers are used to measure current. System voltage values are measured by voltage transformers. You apply them in metering and relay protection. Such units convert high electrical values to manageable signals. You guarantee the safety of the system by being accurate in electrical measurements.

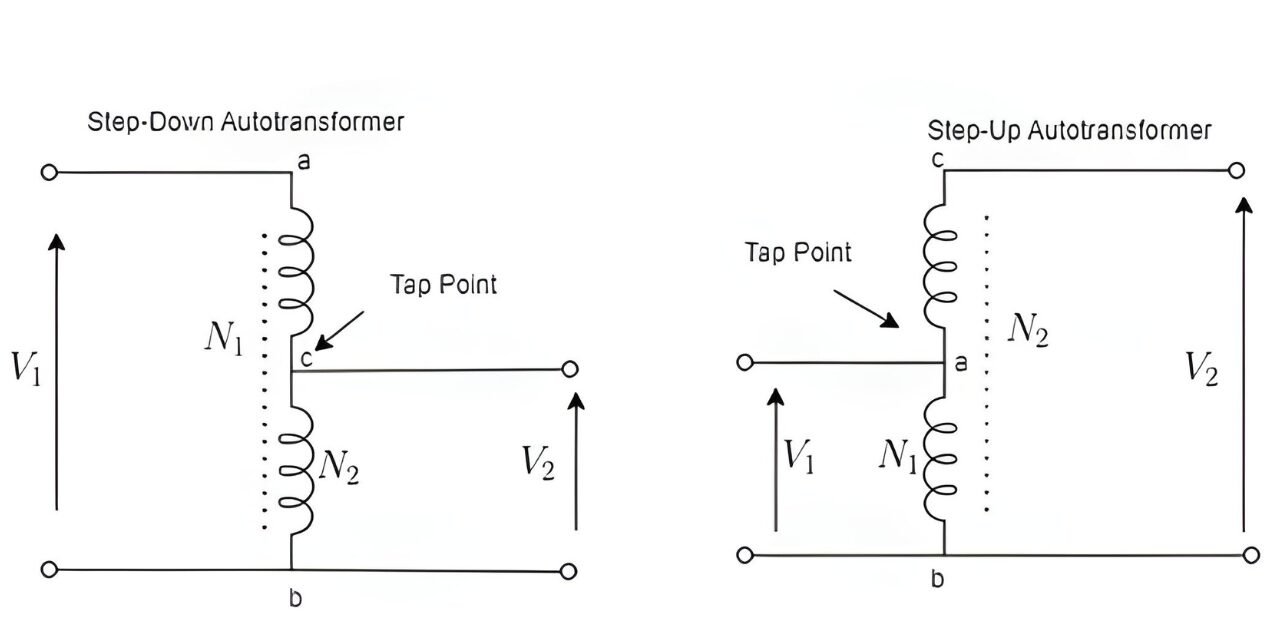

Auto Transformers

Auto transformers have the same winding on the input and the output. This design is efficient in cost and energy. They are used by you in voltage regulation work. They facilitate applications such as motor starting and grid interconnection. Small size enables ease of installation and less material consumption. You have voltage control at reduced operation costs.

Specialty Transformers

Unusual industrial power needs are met by specialty transformers. Furnace transformers are used in high current demands. DC conversion systems are provided by rectifier transformers. Transformers between solar and wind power sources are renewable energy transformers. You rely on these units when you need customized voltage and current. These transformers are effective in specialized energy application.

What Is a Switchgear?

Switchgear is equipment used to regulate, protect and isolate power circuits in fault and normal conditions. In the context of transformer vs switchgear, switchgear actively participates in the process of functioning, identifying faults and acting immediately in case of abnormal electrical activity. You can use electrical switch gears to cut short circuits and damage equipment. It also helps in segmentation of the system, where faulty segments can be safely isolated. Switchgear facilitates switching of loads in order to equalize electrical demand. It offers safe points of disconnection during maintenance. This feature enables you to achieve operational continuity and enhance system reliability and safety.

Switchgear Main Components

Circuit Breakers

Circuit breakers are electrical devices that de-energize fault currents to prevent overload or short-circuing of an electrical system. You trust them to avoid equipment damages and fire hazards. They are vacuum, SF6, and air circuit breakers. Each type has varying voltage levels and operating conditions. Correct choice enhances safety, reliability and continuity of operation in the distribution networks.

Disconnect Switches and Isolators

Disconnect switches and isolators are used to visibly separate live equipment and power sources. They are used by you when working on maintenance in order to maintain safe working conditions. Instead of breaking fault current, they use manual isolation of circuits. Isolation is clear, minimizing accidental energization and safeguarding maintenance personnel.

Fuses

Fuses are the component of electrical switchgear that are simple overcurrent protective devices. Fuses melt when current passes beyond acceptable limits. You tend to equate fuses to breakers in terms of cost and speed of response. Fuses are quicker to react but they have to be replaced after use. Breakers are easy to reset, have a protection cycle.

Protective Relays

Protective relays monitor uncharacteristic electrical states with programmed fault detecting logic. You have the advantage of digital relays which provide high accuracy in measurements and quicker response. They cause breakers to isolate faulty areas. The sophisticated systems facilitate remote monitoring and system diagnostics.

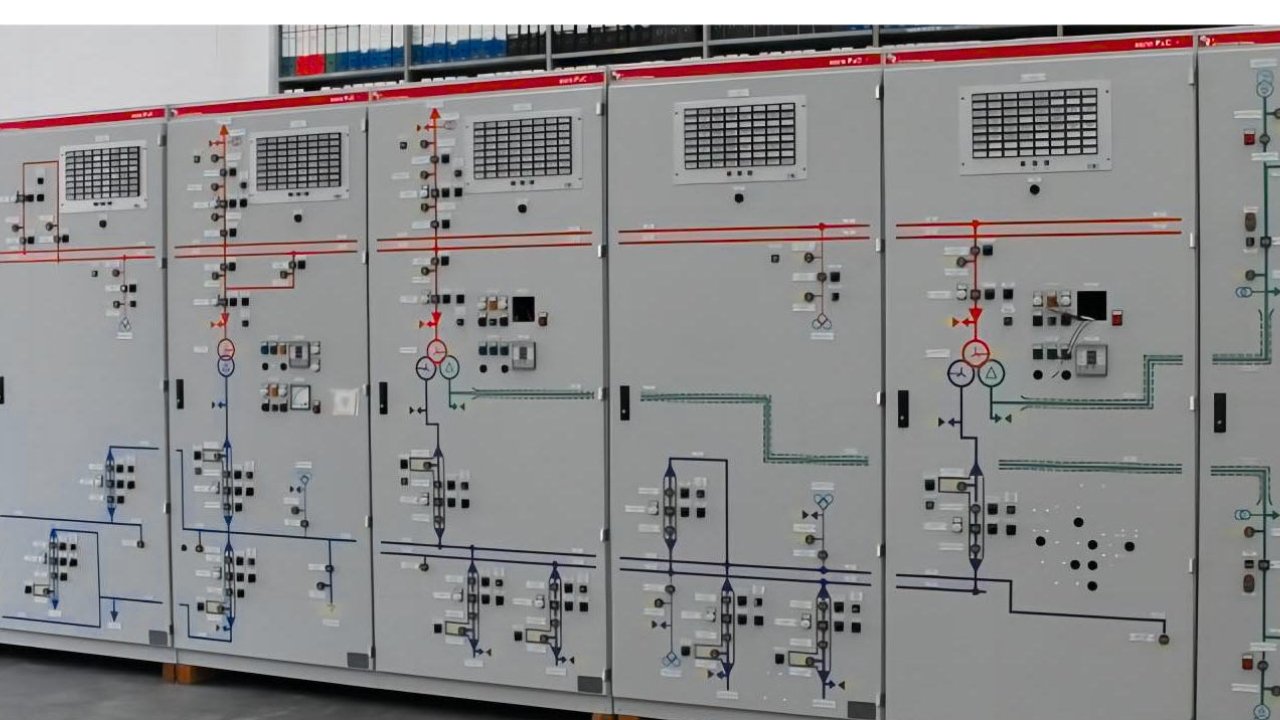

Busbars and Control Panels

Busbars serve as the primary support platform in the distribution of power in transformer switchgear assemblies. You rely on control panels in monitoring, automation and system control. They show voltage, current and operational status. Combined interfaces enhance efficiency and ease electrical management activities.

Types of Electrical Switchgear Based on Voltage and Technology

Low Voltage Switchgear

LV switchgear is used to manage circuits in residential, commercial and light industrial systems. You enjoy the advantage of small designs to install and maintain. Transformer vs switchgear differences are often discussed in this context, as it works on voltages up to 1 kV and is an efficient blocker of overloads. They are circuit breakers, fuses and contactors. Frequent checking will provide safe and reliable electricity. Low voltage switch-gear is appropriate in homes, offices and small factories where constant performance is required.

Medium Voltage Switchgear

MV switchgear is used to protect industrial plants and distribution substations. You depend on it to supply safe power between 1 kV and 36 kV. It handles fault currents and maintains networks. Components are circuit breakers, disconnectors and protective relays. Maintenance minimizes downtime and keeps it going. Medium voltage switch gear is applicable to factories, commercial complexes and utility networks with moderate electrical loads.

High Voltage Switchgear

In grid protection and transmission substations, HV switchgear is applied. You enjoy the fact that it can safely operate voltages beyond 36 kV. It guards lines and averts cascading failures. Major elements are circuit breakers, busbars, and relays. Proper installation guarantees stability and working safety. High voltage switch-gear is essential in long distance power transmission and high capacity networks.

Air Insulated Switchgear (AIS)

Air Insulated Switchgear employs air as the insulating material. In the context of transformer vs switchgear, it is cost effective and easy to install. It requires additional space because of clearances among live parts. The AIS can be easily inspected and maintained. Correct installation will provide safety of operation and fault prevention. It is applicable in an outdoor substation and a place with enough space.

Gas Insulated Switchgear (GIS)

Gas Insulated Switchgear Insulation with SF6 gas is used in small layouts. You enjoy its miniature size on urban and underground substations. GIS does not need much maintenance and is resistant to contamination. It is safe and reliable in operation. The closed structure offers reliability and permanence. GIS is appropriate in space-constrained, dense places.

Vacuum Switchgear

Vacuum switchgear involves the use of vacuum interrupters, which arc-quench effectively. You are green, and you are non-oil-consuming or greenhouse-emitting. It is applicable in medium voltage applications that have high frequency use. Low service costs are low maintenance and long life. Vacuum switchgear is compact and provides a safe and reliable performance in industrial and utility installations.

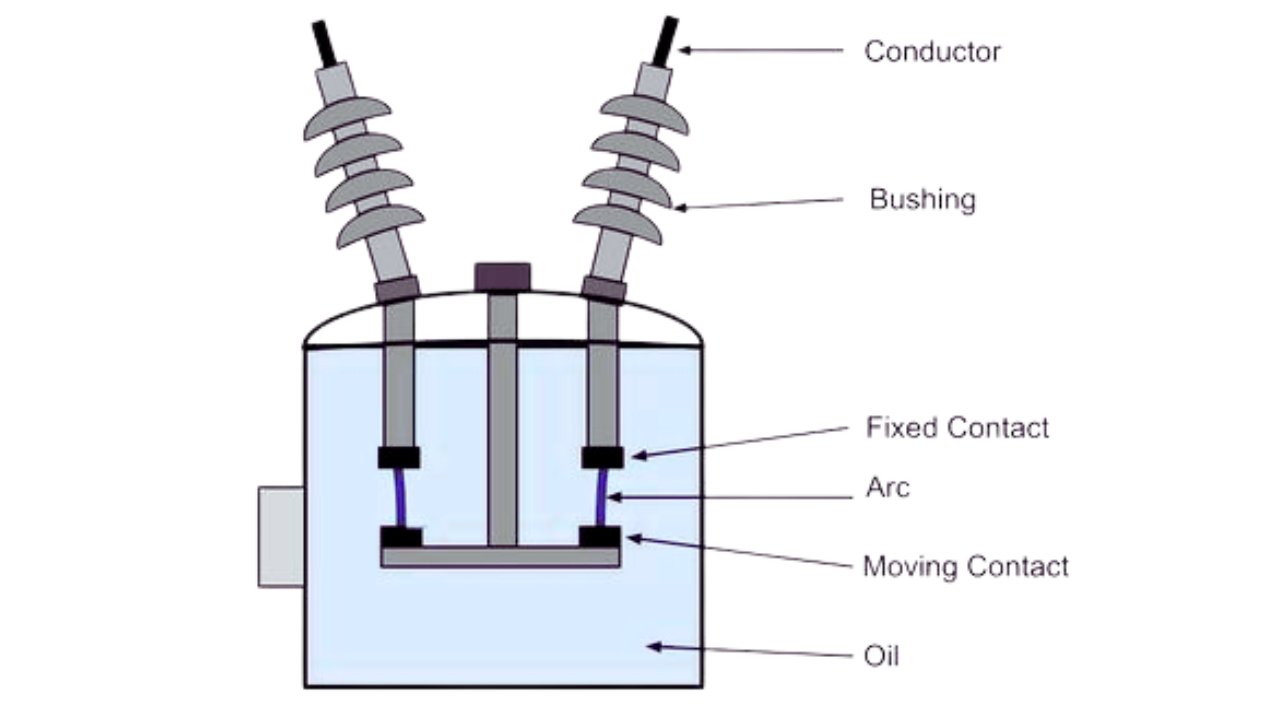

Oil Insulated Switchgear

In oil insulated switchgear, oil is used to provide arc suppression and arc safety. It has a high dielectric strength and can be depended to operate. It is found in legacy or older systems. Leaks and safety of performance are avoided through regular oil monitoring. Oil switchgear is proven to be durable in industrial and utility installations despite the increased space requirements and fire hazards.

Transformer vs Switchgear: Core Differences Explained

Primary Function Comparison

Transformers are used to convert voltages, to step voltages down or up. Switchgear controls fault isolation, control and protection. You use transformers to maintain smooth flow of energy, and switchgear to ensure that equipment is not damaged in case of a fault. They are both critical and have very different purposes. Knowing their functions assists you to develop stable, safe and efficient power networks in homes, industries or utilities.

Operational Mechanism

In the context of transformers vs switchgears, transformers use non-moving electromagnetic induction. Switchgear refers to mechanical or electronic switching of circuits. Instead, you depend on transformers to maintain constant flow of energy and switchgear to react to faults and maintenance requirements. The two mechanisms are crucial to power networks, which ensure a smooth operation and protection. Being aware of these differences enables you to keep and maximize the performance of these systems.

Component Architecture

Transformers focus more on the use of magnetic cores and electrical windings to convert energy. Switchgear is a combination of breakers, relays, and disconnectors. You count upon transformer switchgear to maintain the voltage stability and protect circuits against abnormal currents. Their architectures complement each other. Adequate knowledge will assist you in designing installations and sustaining the two devices effectively in a power system.

Functional Role in Power Networks

In context to transformers vs switchgears, transformers convert voltage levels effectively. Switchgear protects the network against overloads, short circuit and faults. You rely on transformers to provide steady supply of voltage, and switchgear protects assets and provides operational safety. They are both complementary, but with different purposes.

Operational Behavior

Transformers are continuous, and the voltage remains constant regardless of the load. Switchgear only operates on an eventual basis, such as faults or isolations. You use transformers to power your circuits continuously, and switch gears to shut down circuits and equipment when needed. The two behaviors are important to network stability. This knowledge is the assurance of safe, efficient, and predictable operation of power systems.

Installation Objectives

Transformers are deployed to control electrical loads effectively over networks. Switchgear is placed to identify faults and isolate affected areas. You use transformers to deliver energy and switchgear to provide safety and continuity. Proper positioning of the two devices is optimal. Correct planning will provide stability, protection and consistent operation of the network at normal and fault conditions.

Transformer vs Switchgear – Safety Role Comparison

Under high voltage, transformers ensure safety of insulation to prevent electrical breakdown. Switchgear provides fault interruption safety under abnormal conditions. You use transformers to guard against voltage failures, switchgear to guard against equipment and network damage. These switchgear transformer safety roles are complementary. Knowledge of them guarantees dependable, safe and sustainable functioning of power systems.

Parameter | Transformer | Switchgear |

Main Function | Voltage conversion | Circuit protection and control |

Voltage Range | 230 V to 765 kV | LV to HV (up to 800 kV) |

Power Rating | Rated in kVA/MVA | Not power-rated |

Current Capacity | Up to 10,000+ A | Up to 6,300 A |

Operating Principle | Electromagnetic induction | Mechanical and electronic switching |

Moving Parts | None | Breakers and isolators |

Fault Handling | Withstands faults | Interrupts faults |

Efficiency | Typically above 97% | Not efficiency-based |

Cooling | Oil or air cooled | Ventilation cooling |

Service Life | 30–60+ years | 20–40 years |

Grid Role | Enables power transmission | Ensures system protection |

Switchgear Transformer Installation Requirements

Factors of Transformer Installation

- Load capacity

- Cooling requirements

- Space and foundation

- Environmental exposure

- Noise considerations

Switchgear Installation Factors

- Arc flash safety

- Accessibility

- Grounding systems

- Outdoor and indoor installation.

- Cable routing

Selection Criteria for Transformers

In the context of transformers vs switchgears, the selection criteria for transformers differ from those of switchgear.

- Voltage Rating: Select systems primary and secondary voltage required to satisfy requirements. They should be made to ensure that it is compatible with equipment you already have so that the over volt or under volt problem does not occur.

- Power Capacity (kVA/MVA): Determine the anticipated load to determine an appropriate transformer with the necessary power capacity. You need to allow the expansion of loads room in the future.

- Load Characteristics: Choose the load to be steady, fluctuating or nonlinear. You must select a transformer which can be loaded with the highest allowable currents without overheating.

- Efficiency Standards: Take into account transformers which comply with national or international efficiency standards. You are conserving wastage of energy, cost of operation and meeting sustainability.

- Cooling: Choose natural air, oil or forced cooling based on the environment the cooler is operating on. You make sure that the transformers are properly regulated in relation to the temperature and that they are long lived.

- Environmental Conditions: Take into account ambient temperature, humidity and corrosive constituents. You must not allow the transformer to be compromised by environmental pressures at the performance cost.

- Regulatory Compliance: Check that it is either IEC or IEEE or local electric. You ensure that it is installed in a safe manner as per the law and is insurable.

Selection Criteria for Switchgear

- Voltage and current. The right sizing ensures that the equipment is operating at a stable condition and is not failing too early.

- Short Circuit Withstand Capability Check: Check the ability of the switchgear to interrupt maximum fault currents safely. Adequate withstand safeguards machines and workers.

- Breaking Capacity: It is also required to note the ability of the device to interrupt fault currents without breaking. Adequate capacity provides secure isolation of power in the event of an eventual crisis.

- Protection Coordination: coordinate switchgear with upstream and downstream protection equipment. Planned protection will minimize unnecessary travels and downtime.

- Safety Certifications: Select switchgear that is accepted. Certified equipment is safe and reliable to work.

- Environmental Suitability: Temperature, humidity and pollution during installation. Proper selection prevents corrosion, insulation failure or performance problems.

- Automation and Smart grid Compatibility: Smart grid compatibility with digital controls. Integration enhances future efficiency and scalability, as well as monitoring.

Transformer and Switchgear Maintenance

The overview explains transformer vs switchgear maintenance approaches, emphasizing diagnostic testing, mechanical upkeep, and risk mitigation to enhance electrical system reliability.

Transformer Maintenance

- Dissolved Gas Analysis (DGA): Measures transformer oil gases to detect early faults. You can tell when you are overheating or arcing to prevent failures. Routine DGA is to ensure that the transformers are well maintained in time and to enhance the life of the transformers.

- Oil Testing: Ascertain contaminants, moisture and dielectric strength of transformer oil. You are efficient and prevent the deterioration of insulation by organizing regular tests. The correct functioning of the transformer is maintained by the correct analysis of the oil.

- Temperature: Winding temperature and oil temperature. You will be capable of avoiding overheating and reducing thermal stress on components. Proper monitoring ensures safe handling and long life of loads.

- Load Management: Optimize loads of transformers within design constraints. You reduce the stress and get rid of premature aging. Effective load management improves performance and reliability.

- Insulation Resistance Testing: Test windings and ground insulation integrity. Weak points are identified at early stages to avoid electrical interruptions or short circuits. Regular testing guarantees efficiency and security in operation.

Switchgear Maintenance

- Inspection of circuit breakers: Routinely examine circuit breakers to ascertain the existence of damage or wear. You ensure the reliable operation and prevent unexpected power failures. Thorough inspections extend the lifespan of equipment and provide safety of the systems.

- Contact wear monitoring: Measure and analyze contacts as pitted or eroded. You prevent breakdown and provide the best conductivity. Proper monitoring reduces downtime and prevents electrical failures both of equipment and personnel.

- Relay calibration: Check and correct protective relays to be tripped. You correct fault identification and system coordination. Recurrent calibration prevents nuisance trips and contributes to the overall stability of the electrical networks.

- Mechanical lubrication: Coat moving parts and mechanisms with the correct lubrication. You reduce wear, friction and noises of operation. Lubrication should be done frequently to enhance performance and remove mechanical breakdowns and prolong service of switchgear.

- Arc flash risk assessment: test switchgear against arc flash. You are identifying the areas of high risk and implementing safety precautions. Repeated tests are used to ensure safety of personnel, compliance with requirements and lessening of dangerous electrical incidents.

Switchgear vs Transformer – Lifespan Comparison:

The life span comparison of transformer vs switchgear is given below:

Transformer Expected Service Life

Transformers have a service life of 25 to 40 years under normal maintenance. Lifespan is a factor of load, temperature, insulation and care. Poor cooling or overloading reduces life whereas inspections and oil testing increase it. You must check on insulation and keeping frequent peaks minimal in order to maximise service. Proper transformer capacity and constant operating environment have a direct effect on long-term operation.

Switchgear Anticipated Life

The typical lifespan of switchgear is 20 to 30 years, which depends on mechanical wear and frequency of use. Aging is accelerated by contact erosion, switching stress and environment. Durability depends on technology type such as vacuum or SF 6. You are to do regular testing and lubricating. State-of-the-art designs using high-end materials can assist you in increasing life and minimizing unanticipated breakdowns.

Common Operational Challenges and Failures

Transformer Challenges

- Overheating

- Oil contamination

- Insulation aging

- Moisture ingress

- Partial discharge

Switchgear Challenges

- Arc flash hazards

- Mechanical failure

- Contact erosion

- Environmental corrosion

- Insulation breakdown

Transformer vs Switchgear – Industry Applications Comparison

Utility Power Networks

Sound systems are fundamental to reliable power distribution. Transformers, switchgear, and transmission lines should also be efficient. Scheduling helps reduce time wastage and energy loss. Monitors can be used to monitor load balancing and fault management in order to guarantee a consistent supply.

Manufacturing Factories

The heavy equipment and machinery require constant power. By using switchgear and transformer you can work on high current loads and get protective systems functioning. Energy consumption is optimal, which enhances the quality of production. You can use automation and monitoring devices to prevent disruptions.

Renewable Energy Systems

There is a special integration needed in hydro, wind, and solar installations. Transformer vs switchgear considerations play a key role at this stage, ensuring proper coordination between power conversion and protection equipment. Inverters, controllers, and storage systems must be maximized. Optimal energy capture is associated with good design. You can follow long-run performance.

Data Centers

Servers and cooling systems need to be continuously powered. You must employ redundancy and backup systems. Good energy distribution gets rid of outages. Stability The heat and electrical load is controllable.

Commercial Buildings

Lighting, HVAC and office equipment demand stable energy. You must adjust circuits and protection equipment. Good management keeps the operations costs down. You can trace systems to the maximum efficiency.

Infrastructure Projects

The transport systems, bridges and tunnels require secure power systems. By using switchgear and transformer you should match the amount of energy supplied to the project schedules. Good planning will not result in delays and will be safe. You can have systems of monitoring that work 24 hours.

Cost Comparison and Investment Considerations

In the context of transformer vs switchgear, a comparison of cost and investment is presented below:

- Initial Equipment Cost: Before committing any purchasing decision, pay close attention to the initial cost of the equipment in terms of quality, specification and durability.

- Installation Cost: It involves installation costs, labor costs, and calibration costs to ensure that there are no delays in the preparation of the operation.

- Maintenance Cost: It is applied to maintain normal maintenance, replacement of parts, and untimely repair to maintain the same performance over time.

- Operational Efficiency Impact: Assess the equipment level based on productivity, energy consumption, and workflow and this will affect the efficiency and output of the entire process.

- Total Cost of ownership (TCO): Add all the costs, purchase, installations, maintenance and operations to understand the overall financial implication properly.

Conclusion

In conclusion, transformer vs switchgear are the foundations of modern power systems, which are complementary although they have dissimilar functions. Transformers are effective in managing the voltage and the transformer switch offers safety, control and protection of the circuit. Their differences, how they operate and what they require in maintenance should be known to be sure that the system is reliable, safe and efficient. Strategic choice, proper installation and regular maintenance maximize performance and life. With good integration, engineers and planners may have the capability of offering stable, resilient, and future-ready electricity infrastructure in industries and utilities.

FAQs

How do transformers and switchgear improve energy efficiency?

Transformers are useful in raising or lowering the voltage without using a lot of energy. The comparison analysis of Transformer vs Switchgear highlights how transformers manage voltage levels while switchgear focuses on protection, as switchgear prevents faults, and this ensures that power flows smoothly. You can optimize your system and save money and improve the overall energy efficiency.

Which is more critical: transformer vs switchgear?

Voltages are converted to switchgear and voltages are converted to transformers to isolate and protect equipment. The two play a crucial role in safe and dependable operation. You can not prioritize one because performance is influenced based on well integration of systems.

Can a power system operate without switchgear?

Switchgear secures your system against fault and overload. Without it, machinery and human beings are in danger. You might get a temporary job, but long-term stability and security are lost.

How often should transformers and switchgear be maintained?

Maintenance ensures that the equipment is dependable and it becomes less inclined to malfunction. The inspections prove helpful in detecting the wear, overheats, or insulation issues early. Depending on the way the system is used, manufacturer schedules are to be followed and changes are made.

Are smart switchgear and digital transformers worth investing in?

Smart switchgear and digital transformers monitor your system in real time. They recognize failures, predict errors and increase control. You have less down-time, more power saving and more durability.