A Complete Guide to Sheet Metal Riveting | Its Applications and Techniques

Sheet metal riveting is essentially used in the fabrication process. It has numerous applications in various branches, such as automotive, aerospace, construction, and other manufacturing fields. Riveting has several advantages over other joining methods, such as the effectiveness with which the parts are joined, the longevity of the structure, and the amount of stress the joining exposes itself to through vibration. So in this article, we will discover knowledge about sheet metal riveting, including process, equipment, utilization, and precaution.

Table of Contents

ToggleHow would you Define Sheet Metal Riveting?

The fastening of two sheet metals is known as riveting. Whereby a rivet that is inserted between two or more areas of metal is deformed to join the metals together. Rivet is normally made of metal but can be made of other materials and is driven through the sheets to join them. So, the head of the rivet is compressed to ensure that the structure of the connected sheets has been altered permanently. It means that the structure cannot be disassembled without damage. So, riveting is particularly useful where welding cannot or should not be done. It may include when joining different types of metal, working with thin sheets, or where access to the join is very limited.

Step-by-Step Process of Sheet Metal Riveting

Here is the step-by-step process involved in sheet metal riveting.

1. Preparation

Before starting the task, check that you have all the required accessories, i.e. rivets, rivet guns or squeezers, rivet sets, and bucking bars. Besides this, always make sure you wear the necessary safety gear. Mark the location of the hole where you need to insert the rivet, properly on sheet metal pieces. It can be done using a layout tool, ruler, and center punch. Besides this, It is essential for accurate positioning.

When there are some marked locations. It is possible to use a drill press or a handheld drill. It helps make holes of the correct size. On this, it is important to check that the size of the hole needed is equal to the diameter of the specified rivet.

2. Inserting the Rivet

It’s important to choose the right type of rivet and the size that is suitable for the particular use. Then slide the flat end of the rivet through the small hole in the sheet metal pieces. Make sure that the head of the rivet is on top. So, you can apply force on its head.

3. Setting up the Riveting Tool

Select the best riveting tool depending on the type of rivet that you need in the project. Besides this, check how accessible is the working area. These tools include the gun for both the solid rivets and blind rivets, plus the rivet squeezer where there is no room for a gun. Choose the right rivet set or die that matches the size of the rivet. Additionally, check that the rivet set is adequately seated on the head of the tool. So, it can avoid its movement during its use.

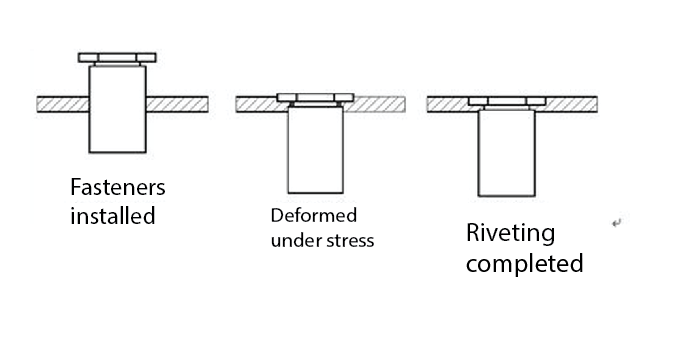

4. Deforming the Rivet

Place the riveting tool in a manner that is completely aligned with the head of the rivet. Then apply pressure to keep the rivet head locked.

- If using a rivet gun: Place the bucking bar in such a manner that its flat perpendicular end rests on the opposite end of the thin sheet metal. Pull the trigger on the rivet gun. It will help force the tail of the rivet into the blank of the rivet. Continue hammering to make sure it is flattened all around. Additionally, it sets properly against the adjacent sheet metal surfaces.

- If using a rivet squeezer: Place the squeezer jaws over the head of the rivet. Now press it gently to exert pressure on the rivet’s body. Make sure that the two jaws of the rivet are properly positioned. So, they do not wear off or cause any harm to the main rivet.

5. Inspecting the Joint

When you attempt to tighten the rivet. It is essential to have an instrumental check to guarantee that the joint is well-aligned and tightly tightened. Moreover, check that the head of the rivet is well-leveled. Now observe the structures, i.e. craters or defects on the riveted region. They will portray a sign of the process of installation of rivets. For better efficiency, you can use added rivets or other necessary tools to avoid any issues.

6. Finishing Touches

This step includes the cutting of any of the extra pieces from the tail of the rivet. It can be done with the help of a metal trimmer or burr. To check the edge’s bounding, the rivet head is free from roughness or edges. These edges are commonly referred to as burrs. Here, you can eliminate them using a file or an abrasive pad. Moreover, you can use a protection layer or a sealant over the riveted area. It helps increase both strength and rust prevention.

Safety Precautions

Safety precautions are mandatory to follow while dealing with sheet metal riveting. So, you can;

- First, check that the face, hands, and forearms are protected by safety glasses or goggles and gloves respectively. It helps avoid injuries due to flying debris and cuts.

- Moreover, it is highly recommended to pay close attention to proper handling and usage of power tools. You must be properly trained in operating pneumatic rivet guns. So, you can carry out the process without any damage.

Tools Used for Sheet Metal Riveting

Some of the popular tools can be used for sheet metal riveting. So, their explanation is as follows:

- Rivet Gun: A Rivet gun- a pneumatic tool used to set a solid rivet to its required place. It is usually obtained by applying successive or continuous impacts on a rivet’s tail end.

- Rivet Squeezer: A rivet squeezer is a handheld tool that is used when operating spaces. Besides this, it is widely used in regions where a rivet gun is unable to be used.

- Rivet Set: It is used during riveting to maintain the head of the rivet in the correct position for the shaping.

- Bucking Bar: It is usually used in the shape of a bar. So, it is placed under the tail end of the rivet to correct its position. Additionally, it does not bend or deform at an early stage during riveting.

- Drill Press: A drill press is used in sheet metal work to drill holes in them in anticipation of their Rivet attachment. It helps to make sure that the holes are well-aligned.

Types of Rivets Use in Sheet Metals

Here are some commonly used types of rivets used in sheet metals. Besides this, there are also their benefits, enlisted below.

| Type of Rivet | Characteristics | Benefits |

| Solid Rivets | One-piece rivets with a head and a tail | High strength, permanent connection, reliability |

| Blind Rivets | Two-piece rivets with a mandrel and a tubular body | Easy to install, suitable for blind-side applications |

| Tubular Rivets | Hollow rivets with a head | Lightweight, watertight seal, decorative finish |

| Drive Rivets | Rivets with a split shank that expands upon installation | High strength, vibration resistance, wide grip range |

| Flush Rivets | Rivets with a head that sits flush with the surface | Smooth finish, aerodynamic, reduced risk of snagging |

| Structural Rivets | High-strength rivets designed for structural applications | Exceptional strength-to-weight ratio, ideal for heavy-duty tasks |

| Peel Rivets | Rivets with a mandrel that splits into legs upon installation | High shear strength, excellent joint integrity |

| Huck Bolts | Combination fasteners that consist of a bolt and a collar | High clamp force, resistant to vibration and loosening |

| Self-Piercing Rivets | Rivets designed to pierce and join materials simultaneously | No pre-drilling required, suitable for thin and lightweight materials |

Different Sheet Metal Riveting Techniques

These techniques are a green connection method where materials are connected to sheet metal. These materials can be such as nuts, screws, etc. They are attached through methods like pressure riveting, swelling riveting, extrusion, or pull riveting. So, let’s discuss them in detail.

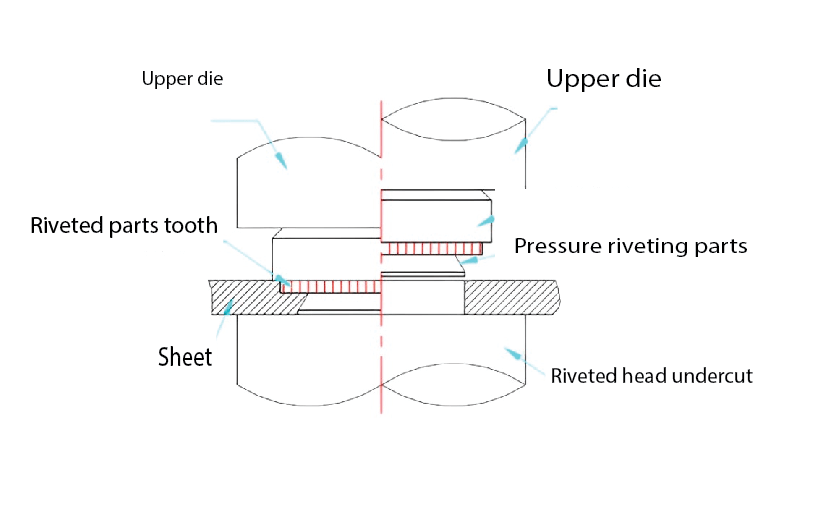

1. Pressure Riveting Technique

Pressure riveting uses tools and dies; placing a certain amount of pressure on the rivet components. Then it drives them partly or wholly into the skin. So, it can create a connection. The designs of the pressure rivet parts are either serrated or non-serrated.

The pressure rivet components are dependent on the serration.

This pressure is applied to the plane of the sheet metal. So, it can balance rotation and primarily supports the torque of the riveted connection. Furthermore, the portion of the rivet head is inverted to lock into the sheet metal. So, it can resist the pushing-out force. The plain shaft rivet does not include teeth on the pushed-in part. It mainly relies on the hexagonal form of this part. So, it can lock in position and handle the pushing forces of the rivet.

2. Swelling Riveting Technique

Swelling riveting means the use of specific equipment and molds during partial swelling of a rivet component. It helps make an interconnection with the sheeting. So, swelling riveting equipment is much the same as that of pressure riveting. However, the upper mold head is tapered to shape the insertion portion of the rivet. It applies sufficient pressure and creates a given taper in the part.

At present, swellings include circular swelling rivet nuts, hexagonal swelling rivet nuts, and swelling non-removable screws. The contact between the swollen components of the rivet and the sheet metal can only be made through circumferential deformation. It means it can easily hold the exertion of force in the pushing direction. But cannot bear much torque. So, you can overcome this limitation using the circular swelling rivet nuts. They are designed with serrations that create torque resistance by fitting into the sheet metal.

3. Extrusion Technique

Extrusion requires the use of dies and machines. So, it can bring a certain amount of pressure on a rivet from the side. The tools applied for the extrusion technique include those that are used in pressure riveting. So, only those tools have flat contact surfaces of the rivet and the riveting part on the upper and lower molds. Moreover, the head of the extruded rivet component is provided with arcs of thread. While the other end of the rivet has a flat surface fitted on the sheet metal where you can apply pressure.

This interaction between the divisions of the serration and the sheet metal allows the rivet to bear the rotational force of torque and some of the pushing forces. Furthermore, the body of the extruded rivet has some grooves. They enable it to interlock with the sheet metal. So, when you apply the push forces, it cannot budge easily. The difference between extruded rivet components and pressure/swelling riveting relies upon the heights of the edge assemblies.

4. Pull Riveting Technique

The pull riveting technique is particularly related to the style of the pull rivet nut. It is commonly known as the blind rivet nut or rivet cap. So, the basic idea behind the pull riveting technique is to use a tool, known commonly as a rivet gun. The is written into the bolt on the head of the rivet gun screw. When you fire the rivet gun, this forces the bolt to rotate. Then it causes the relative movement of the nut. This movement results in enlargement and distortion of the thin-walled area of the nut. Resultantly, it tightly compresses the sheet metal.

The benefits of the application of the pull riveting technique include that it is supported by single-sided access to the workpiece. So, it can be specifically valuable when working with heavy pieces.

5. Pressure Rivet Stud and Nut

Pressure riveting involves the application of external force. It works in a way that the component containing the rivet deforms the base material plastically. Moreover, it extrudes into the groove of the rivet screwed or nutted structure. So, therefore it provides an inter-component interconnection. There are two types of non-standard riveting nuts in this form; Pressure rivet studs and pressure rivet nuts are standardized. So, they can be purchased from local hardware stores or ordered online from various manufacturers.

This kind of riveted connection normally calls for high hardness conditions. Usually, pressure rivet studs use low-carbon steel, aluminum alloy sheets, and copper sheets. But for stainless steel and high-carbon steel sheets additionally. It is necessary to use particular high-strength pressure rivet studs.

6. Floating Pressure Rivet Nut

Certain types of rivet nuts have serious positional errors. These errors may occur because of the compounded nature of the structure of sheet metal chassis and the large tolerances accumulated on the surface. These positional errors can help denote some issues in the assembly of other components into the circuit. So, to overcome this problem, the floating pressure rivet nuts are a better option to utilize at these points.

Riveting Defect Types, Causes, Prevention, and Correction Methods

Here is the detailed table for the riveting defect types, reasons for these defects, measures we can take to remove them, and correction methods in sheet metals.

| Defect Type | Defect Illustration | Cause | Prevention Measures | Elimination Method |

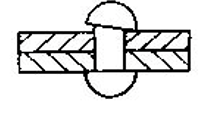

| Rivet’s head and upset head are not aligned on the same axis |  | 1) Riveting gun not held vertically. 2) Excessive air pressure bending the rivet shank. 3) Slanted rivet hole | 1) Start riveting with low air pressure. 2) Align the riveting gun with the rivet shank. 3) Ensure drilling and punching tools are perpendicular to the component | Replace rivet if eccentricity ≥ 0.1d |

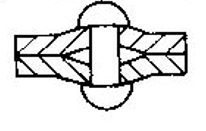

| Rivet’s head does not flush with the component surface |  | 1) Hole diameter too small or burrs on rivet shank. 2) Insufficient air pressure. 3) Insufficient clamping force or improper clamping | 1) Inspect hole diameter before riveting. 2) Remove burrs and oxidation from the rivet shank during pulling. 3) Stop riveting if air pressure is insufficient. 4) Start riveting with low air pressure | Replace rivet |

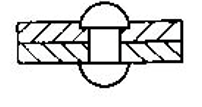

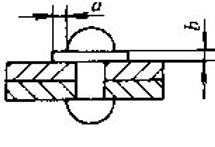

| Part of the rivet head is not flush with the component surface |  | 1) Misaligned riveting set2) Rivet shank too short | 1) Keep the riveting gun vertical. 2) Calculate the appropriate rivet shank length | Replace rivet |

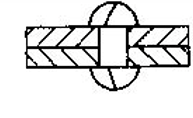

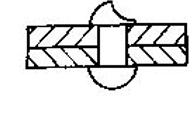

| Components being spread apart by rivet |  | 1) Components not tightly fitted2) Bolts not tightened or loosened too quickly3) Hole diameter too small | 1) Check component fit and hole size before riveting. 2) Tighten bolts and only remove them after riveting | Replace rivet |

| Rivet head forms protrusions and scores the material |  | 1) Riveting gun not held vertically. 2) Rivet shank too short. 3) Riveting set too large | 1) Keep the riveting gun vertical during riveting. 2) Calculate the appropriate rivet shank length. 3) Replace the riveting set | Replace rivet |

| Rivet shank bends inside the hole |  | Rivet and hole fit too loose | 1) Use appropriate rivet size. 2) Start riveting with low air pressure | Replace rivet |

| Cracks on rivet head and upset head |  | Poor plasticity of rivet material | Check rivet material quality and test its plasticity | Replace rivet |

| Burrs around the rivet head |  | 1) The Rivet shank is too long. 2) The riveting set is too small. 3) Riveting time too long | 1) Calculate the appropriate rivet shank length. 2) Replace the riveting set. 3) Reduce excessive hammering | Replace rivet if A ≥ 3mm, B ≥ 1.5-3mm |

| Rivet’s head is too small, insufficient height |  | 1) Rivet shank too short or hole diameter too large. 2) Riveting set too large | 1) Adjust rivet length as needed) Replace riveting set | Replace rivet |

| There are scratches on the rivet head |  | Riveting set striking the rivet head | Hold the riveting gun firmly to prevent bouncing | Replace rivet |

| Misaligned round head of the rivet |  | 1) Riveting gun not held vertically. 2) Slanted rivet hole | 1) Keep the riveting gun vertical. 2) Ensure the rivet hole is perpendicular to the component | Replace rivet |

| Rivet head not hemispherical |  | 1) Rivet shank bent at start of riveting. 2) Rivet Shank not sufficiently upset | Start riveting with the gun vertical, use low air pressure initially, and increase air pressure when forming the round head | Replace rivet |

What are Different Types of Riveting?

The riveting process depends on the type of rivet and the applications. So, let’s discuss these types briefly here.

Hand Riveting: It is used mainly to deform rivets. So, it uses hand tools, i.e. hammers and bucking bars for deformation.

Air Riveting: It uses pneumatic rivet guns. So, it can give quicker and more consistent rivet deformation.

Hydraulic Riveting: It helps apply hydraulic pressure to high-strength joints. Besides this, it is common in heavy industries.

Orbital Riveting: It uses a spinning tool and deforms the rivet precisely. So, it has common applications in delicate stuff.

Blind Riveting: It involves inserting a mandrel through the rivet. Then they pull it to expand the rivet body.

Applications of Sheet Metal Riveting

Based on its multiple uses in different industries and components, sheet metal riveting provides several benefits. So, let’s discuss them here.

- Aerospace: Riveting is widely used in many processes of aerospace. They may include assembling aircraft skins, fuselage sections, and wings. They provide high strength and lightweight properties of riveted joints.

- Automotive: Rivets are commonly used in the assembly of body panels, frames, and structural components.

- Construction: The sheet metal riveting is employed in metal structures, bridges, and architectural elements.

- Electronics: It is used for assembling metal enclosures and different casings.

What are the Advantages and Disadvantages of Sheet Metal Riveting

Here is the detailed table for defining the pros and cons of sheet metal riveting.

| Advantages | Disadvantages |

| Strong and durable | Labor-intensive |

| Permanent fastening | Difficult to disassemble |

| No thermal distortion | Adds weight |

| Versatile for various materials | Requires access to both sides |

| Cost-effective | Can cause surface damage |

| High shear strength | Prone to vibration loosening |

| Fatigue-resistant | Tooling costs |

| Uniform load distribution | Potential aesthetic issues |

Best Practices for Sheet Metal Riveting

- The riveting process can be modified using many practices. These practices give high-quality riveted joints. So, let’s discuss them here.

- Make sure the holes are precisely drilled and free of burrs. It will help avoid weakening the joint.

- Choose the appropriate type and size of the rivet. So, you can use it for specific applications and material thicknesses.

- Always keep riveting tools well-maintained. So, you can get consistent performance.

- Then check and inspect riveted joints for proper deformation, alignment, and absence of cracks or gaps.

- Select the length of the rivet based on the total thickness of the connected parts. Also, consider the gap between the rivet hole and the rivet shank and the riveting method. Additionally, the rivet length for standard hole diameters can be calculated using the following formulas:

- Round head rivet: 𝐿=1.12𝑆+1.4𝑑

- Countersunk head rivet: L=1.12S+0.8d

- Semi-countersunk head rivet: L=1.12S+1.1d

- Flat head rivet: L=S+S1

Where:

- d – Rivet diameter (mm, standard)

- S – Total thickness of the connected plates (mm)

- S1 – Taper length (mm, see Table 1)

Table 1: Taper Length Values

| Rivet Diameter (mm) | 13 | 16 | 19 | 22 | 25 | 28 | 31 | 34 | 37 |

| Taper Length (mm) | 6.5 | 7 | 11 | 13 | 14.5 | 16 | 17 | 19 | 21 |

Comparison of Sheet Metal Riveting with other Alternatives

Here is a concise table that will help us understand the different approaches and methods, we can opt for instead of sheet metal riveting. So, let’s discuss all these alternative methods, their advantages, and their applications in the market.

| Method | Definitions | Advantages | Disadvantages | Applications |

| Sheet Metal Riveting | Joining metal sheets using rivets, deformed to hold materials together. | Strong, reliable joints; no heat distortion; simple process. | Permanent joints; holes weaken material; labor-intensive. | Aerospace, automotive, construction, electronics. |

| Welding | Fusion of metals using heat (arc, spot, laser). | Strong, continuous joints; suitable for various metals. | Requires skilled labor; heat can alter material properties. | Structural applications, heavy machinery, automotive. |

| Adhesive Bonding | Using adhesives (epoxies, acrylics, polyurethanes) to bond materials. | Even load distribution; bonds dissimilar materials. | Surface preparation is needed; limited temperature resistance. | Aerospace, automotive, electronics, composites. |

| Mechanical Fastening | Fastening with bolts, screws, clinch fastening, and threaded inserts. | Easy disassembly; no heat distortion. | Adds weight; requires precise alignment and drilling. | Construction, machinery, electronics, automotive. |

| Soldering and Brazing | Joining metals with lower melting point alloys (soldering) or filler metal (brazing). | Good electrical conductivity; joins dissimilar metals. | Lower joint strength; requires flux and cleaning. | Electronics, plumbing, metalwork, HVAC systems. |

| Clinching and Seaming | Mechanical fastening by pressing sheets together or folding edges to seal. | Fast; no additional fasteners or heat required. | Limited to specific applications and materials. | Packaging, automotive, HVAC, appliance manufacturing. |

| Magnetic Pulse Welding | Solid-state welding uses magnetic forces to join metals. | No heat-affected zones; joins dissimilar metals. | Requires advanced equipment; limited to conductive metals. | Automotive, aerospace, and electrical components. |

Why Choose Masion for Sheet Metal Riveting?

Masion is here to serve you with the best sheet metal riveting services;

- Extensive Experience: With 17 years of experience in the sheet metal industry. Masion provides its expertise and knowledge in every project.

- Specialized Riveting Services: Masion is an expert in riveting. So, our team guarantees high-quality and reliable joints for various applications.

- Quality Assurance: We commit to high-quality control processes. So, we guarantee that all riveted joints meet industry standards and customer specifications.

- Versatile Applications: Mansion is capable of handling a wide range of materials and thicknesses. So, we can deal with different industries, i.e. aerospace, automotive, and construction.

- Customer-Centric Approach: We always focus on understanding and meeting the specific needs of clients. So, we can provide customized riveting solutions.

Conclusion

In conclusion, sheet metal riveting is quite a fundamental method in advanced manufacturing. It gives a strong and reliable joint. So, they can be used in high-performance applications. These rivets come in different types and have different processes to deal with. Additionally, they help make strong and durable assemblies in the industries. So, it has many applications in different fields that need high-quality products. These are mainly aerospace, automotive, or construction industries.

Frequently Asked Questions

Q1. What materials are mainly used for rivets in sheet metal applications?

These rivets come in various types, including aluminum type, steel type, stainless steel type, and copper type. Therefore when choosing the material for the appliance, the following conditions have to be taken into consideration: environmental conditions, strength, tolerance, durability, and corrosion resistance

Q2. What types of rivets are commonly used in sheet metal riveting?

They are known as solid rivets, blind rivets, pop rivets, semi-tubular rivets, drive rivets, flush rivets, and the last one being self-piercing rivets. They both come in assorted forms and varieties depending on the type of joint that needs to be fastened.

Q3. What are the advantages of using rivets over welding for sheet metal assembly?

Riveting creates a strong and enduring connection between two sheets to another without the creation of heat-affected zones. It retains the original metallurgical characteristics of the sheet metal. So, this process is rather cheap and demands low amounts of resources, thus being rather effective for joining different metals and thicknesses and for easy control and repairs.