Sheet Metal Parts Assembly

Masion is here to serve you with comprehensive assembly manufacturing. We provide top-notch services for various sheet metal parts and electronic structural components. Besides this, we are also;

- ISO 16949-certified manufacturer

- 400+ employees

- 100 assemblers for parts assembly

- Provides high-quality assembly services for custom batch production.

- Offer design services for the electronic part structures.

+86-18969433502

sales@sheetmetalmasion.com

Over 400+ Employees

6+ Assembly Lines

30,000 m3 Total Factory

Masion - Your High-Precision Sheet Metal Parts Assembly Provider in China

Masion has 17+ years of experience with the provision of sheet metal part assembly services. We have a team of experts to give you prompt, effective, and efficient assembly services. Besides this, Masion offers a complete assembly solution to fully focus on the project development with no worries

Explore our Sheet Metal Parts Assembly Solutions

Masion is not limited to one service. We provide an extensive range of assembly services for our clients. Our service caters to your all assembly needs regardless of the product you have. So, if your product is tubes or sheets, automatic lifting desks, computer enclosures, X-ray inspection casings, gun safes, kiosk enclosures, machine enclosures, etc. Masion is here to you a complete set of assembled parts. Our facility has 6 highly advanced automated assembly lines. Besides this, we have 100 skilled and professional assemblers. They help you with large-scale projects along with customized assembly services for your brand.

Let’s have an overview of our detailed sheet metal assembly services.

Materials We Use:

Aluminum

A1100P-O, A1050P, AL2024, A5052H32P,

AL5083, AL6061T, AL6063T5, AL7075, AL1050, AL1060

Carbon Steel

SPCC, CRS, SAPH440, SPCD, SPCE

Stainless Steel

SUS301, SUS302, SUS303,

SUS304, SUS316, SUS420, SUS430

Cold galvanized steel

Q195, Q215, Q235, Q255, Q275

The Equipment We Have:

- Automatic Assembly Conveyor

- Automatic Assembly Plate Conveyor

- Fixed Assembly Workstation

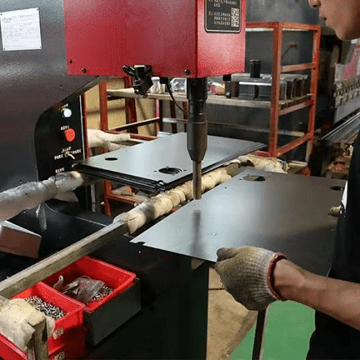

- Riveting Machine (PEM)

- Bolt Welding Machine

- Fixed Assembly Workstation

- Riveting Press

- Standalone 4E Riveting Machine

Our Assembly Contents

- TIG and MIG Welding

- Robotic Welding

- Spot Welding

- Laser Welding

- Riveting

- PEM and Rivet Nut Insertion

- Motor Assembly

- Metal Pipes Assembly

Our Assembly Products

- Standing Desk

- Automatic Standing Desk

- Gun Safe

- Kiosk Enclosure

- Machine Enclosure

- X-ray Cabinets & Enclosures

- Computer Case

- Energy Storage Equipment Casing

Why Rely on Masion for All Sheet Metal Assembly Needs?

Masion is one of the best service providers of customized sheet metal assembly. We have highly advanced equipment and a team of experts to get high precision in sheet metal manufacturing. Besides this, Masion has 17+ years of experience in this field and can easily get rich experience in sheet metal assembly production. Moreover, we’re here to offer you more efficient and cost-effective solutions.

DFM Design Support:

We design in-house production of molds, assembly fixtures, and inspection. These all help us in simplifying the assembly to cut costs of assembly.

Project Specialization:

We give technical advice for your various projects professionally. Professional engineers and designers will be utilized in all phases, i.e. sample confirmation, mass production, and delivery to avoid interruption of the process.

Professional Assemblers

There are 50-100 assembly mechanics with professional training. So we can quickly assemble products, increase assembly efficiency, and ensure quality.

Short Lead Times, High Efficiency:

All sheet metal work, including assembly, is done in-house as other matters concerning the production line are efficiently managed. Besides this, we always ensure that we have an adequate supply of conventional sheet metal materials. Our suppliers have been actively supporting our operations, to minimize transit time and, therefore, fasten sheet metal assembly.

High-Quality Control:

In the manufacturing of sheet metal assemblies, we maintain strict ISO 9001 and ISO 16949 quality management systems. So, you can receive accurate and high-quality products.

IP65 Waterproof Rating:

We can meet the high requirements of IP65 waterproof grade in sheet metal assembly. This may include a shell of energy storage, a battery pack, and a waterproof box for electrical equipment.

Sheet Metal Parts Assembly Techniques We Use

If we talk particularly about the manufacturing of sheet metal products. Then the assembly has quite a considerable importance. For instance, if the assembly is wrong, this is going to impact greatly on the quality and duration of the utilized sheet metal parts. Hence, to meet this problem, we employ different assembly techniques. Masion is not restricted to a technique only. We incorporate several assembly methods to assemble sheet metal parts quickly. Also, we ensure the dimensions, performance standards, and cost factors of each assembly part.

This method is the most common one for dealing with sheet metal parts. It is the best option for fasteners assembling using an automatic screwdriver. Besides this, it also serves for the disassembly of sheet metal parts or fasteners (nuts or screws). Moreover, it tests the proficiency of the assembler in such a way that screws or nuts must not have any cross-threading or damage. So, just after installation, a complete inspection is necessary to guarantee that screws or nuts are fitted well.

The most common applications for mechanical assembly are:

- Lifting tables assembly

- cabinet bodies assembly

Method #1: Mechanical Assembly

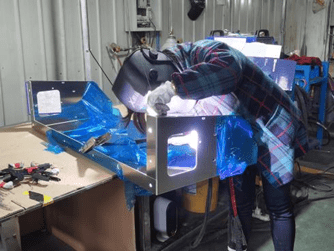

Multiple traditional techniques are now being used for welding purposes, i.e. TIG and MIG. These methods help us join the sheet metal parts concerning the material. These materials can be stainless steel, aluminum, copper, or cold-rolled sheet metal. So, welding ultimately increases the strength and rigidity between sheet metal parts. Besides this, it exceeds their lifespan as well. After this, our welding undergoes a visual inspection and checks if there are quality issues during welding, i.e. incomplete welding or leaks. Moreover, our expert team carries out tensile tests, X-ray inspections, ultrasonic testing, and other checks based on the client’s needs.

The most common applications for Manual welding assembly are;

- Joints apply in sheet metal cabinets

- Sheet metal reinforced areas

- Sheet metal parts corners or edges

- Sheet metal parts positioning

Method #2: Manual Welding Assembly

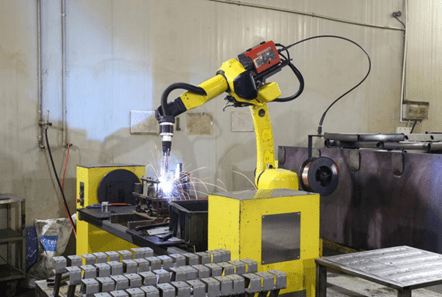

It is the most effective technique for welding. It gives consistently high-quality joints along with more efficiency. Besides this, It has many benefits, i.e. low cost, no need for human intervention, and high consistency in quality. Additionally, it needs large batch quantities for welding. So. Masion has around 20 robot welding machines along with 3 laser welding devices. These all help us meet the demands of mass production of sheet metal parts. Furthermore, this equipment guarantees high precision and efficiency as compared to manual welding. Robot welding has generally found its applications in large projects. Besides this, it can easily deal with complex sheet metal parts welding. It is a good option for large quantities and similar types of sheet metal parts. Because it helps improve the sheet metal assembly production efficiency.

The most common applications of Robot Welding are;

- Sheet metal cabinet seams

- Sheet metal positioning

- Sheet metal reinforcement position

- Sheet metal parts corner or edges

Method #3: Robot Welding Assembly

The riveting assembly has numerous applications in many industries. This method uses rivets instead of welding and is mostly used in aircraft fuselages, ship hulls, and sheet metal parts assemblies. This method also helps increase the strength and durability of joints. Moreover, it also helps increase the corrosion resistance and performs at both low and high temperatures. So, this method primarily includes pull riveting, expanding riveting, compression riveting, and spin riveting. The selection of riveting type is based on the assembly requirements of different sheet metal parts. In this aspect, Masion is here to serve you with various devices, i.e. riveting machines and rivet guns.

Here are some applications of riveting assembly;

- Sheet metal cabinet supports, shields, and baffles

- Sheet metal cabinet joints

Sheet metal part connections

Method #4: Riveting Assembly

Types of Inspection We Follow For Sheet Metal Assembly Parts

Material inspection:

- Material thickness measurement

- It is in analyses that find out consideration to the nature of the material, of which it is made (for example chemical analysis).

- Material hardness test

Dimensional inspection:

- Measurement of width thickness and height

- The pore size and the distance between poles basically will involve the use of measurement to acquire numerical values.

- Measurement of bending angle

- The degree of the plane and its straightness

Visual inspection:

- Surface smoothness examination

- Anti-corrosion coating and painting quality survey

- Welding quality inspection (appearance of the welding seam, splashing material, etc. )

- Transformed corner assessments, burr along with sharp edge assessments

Installation test:

- Component matched check

- Screw and nut fixing parts and methods of fastening them.

- Examination of the flexibility and position of activity parts

Function test:

- Electrical connection and diversion examination (applicable to electric sheet metal parts)

- Rotating and swiveling inspection of mechanical motion parts

- The functional test is related to an individual function of the device (for example, the lifting function of the lifting table).

- Annual check-up of the Electric standing desk motor

Welding test:

- Ultrasonic, X-ray, special potion, and other kind of welding seam detection.

- Welding intensity test

- Welding integrity examination

- Surface treatment inspection:

- Coating thickness measurement

- Surface adhesion test

- Corrosion resistance test

Environment and durability test:

- Salt spray test

- Temperature and humidity cycle test

- Durability and fatigue test

Special inspection inspection:

- A possible standard inspection recommendation to employ in the current setting is a specific size and shape measure.

- Checking the congruence between the positioning hole and the assembly holes

Color difference test:Test the sheet metal color if meet the demand from clients.

Our Sheet Metal Assembly Parts Certification

- ISO9001 Quality Management System

- ISO14001 Environment Management System Certification.

- TS16949 Automotive Industry Quality Management System

- FSC Forest Stewardship Council

- Patent 39 patents of invention

- CE CONFORMITE EUROPEENNE(As you need we could apply)

- RoHS Restriction of Hazardous Substances(As you need we could apply)

- SGS (As you need we could apply)

- TUV(As you need we could apply)

Sheet Metal Assembly Parts Gallery

Explore Our Industrial Applications For Sheet Metal Assembly

Sheet metal assembly parts are used in numerous applications in different industrial parts production. They are mostly met in our daily lives. These are employed in the construction of the electric vehicle charging station cabins, the banking and automatic teller machines (ATMs), and the new energy field as well. Moreover, sheet metal components are also used in industries such as robotics, fitness equipment, construction, machinery, consumer goods, etc. So, here are some commonly used sheet metal component applications in various industries such as robotics, fitness equipment, construction, machinery, consumer goods, etc.

- Medical equipment housing

- Operating table base and stand

- Medical cart

- Sterilization cabinet housing

- Hospital bed frame

- Medical cabinet and storage cabinet

- Testing equipment rack

- IV stand

- Biosafety cabinet

- Instrument panel and control panel

- Medical lighting stand

- Medical equipment stand and hanger

- Mobile ward partitions and screens

- Medical equipment base

Medical Industry

- Server cabinet

- Network cabinet

- Patch panel cabinet

- Battery cabinet

- Control cabinet

- Patch panel

- Switch panel

- Router panel

- Interface panel

- Lightning protection box

- Equipment mounting plate

- Dust cover

- Cable management tray

Communications Industry

- Computer housing, server housing, network equipment housing

- Router housing, switch housing, communication base station housing

- Refrigerator housing, washing machine housing, microwave oven housing, air conditioner housing

- Power adapter housing, charger housing

- Control panel, display housing

- Enclosures and cabinets for industrial control equipment, automation equipment, and electrical equipment

Electronics And Electrical Industries

- Solar panel mount

- Solar mount connectors

- Solar mount accessories

- Photovoltaic panel frame

- Solar control box

- Solar inverter mount

- Solar combiner box

Photovoltaic Industry

Check Out Our Other Manufacturing Solutions

Masion is therefore not a Sheet Metal Manufacturing but rather a fashionable brand for the manufacturing of Embossed Sheets. We are extending other techniques to satisfy your needs.

- Sheet Metal Fabrication: Individual approaches to different complicated projects in the field of sheet metal production.

- Metal Tube Fabrication: We provide custom processing service solutions for circular, square, and other special shape metal pipes.

- Laser Cutting: All our services correspond to custom requirements for different materials and shapes for precision laser cutting services.

- Plastic Injection: Masion offers services of manufacturing assembled injection molded parts and supporting processes.

- Stamping: Thus, we offer services in the manufacturing of progressive and compound molds for the precision stamping manufacture of parts.

- Contract Manufacturing: Masion offers solutions to Vertical Sheet metal production and assembly services for parts.

Frequently Asked Questions

Precision sheet metal manufacturing can create different types of sheet metal assemblies that include laser cutting, bending, welding, riveting, and surface treatment and/or sheet metal assembly, all of which are achievable, in one stop. For other structures such as Standing Desks, Automatic Standing Desks, Gun Safes, Kiosk Enclosures, Machine Enclosures, X-ray Cabinets & Enclosures, Computer Cases, Energy Storage Equipment Casings, Industrial Computer Cabinets, Server Cabinet Enclosures, Metal Mailboxes/Parcel Boxes, First Aid Cabinets, Defibrillator Cabinet/AED Cabinets, Fire Cabinets, Metal POP Displays, Tool Cabinets, Metal Storage Cabinets, and Medical Enclosures.

Its lead time is not constant as it depends on the project and the quantity to be produced. Typically, sheet metal assembly currently ranges between 30 to 45 days while others that are slightly more complex are between 60 days. The actual production schedule for sheet metal assembly shall be aligned with the production plan that we will prepare. So, you don’t have to be concerned about possible production delays. Just forward your project drawings to us and we shall come up with an accurate time estimate about your sheet metal assemblies for timely delivery.

Yes, normally we can reply to inquiries within one hour. You can send us the project drawings along with the dimensions, tolerances, material, and finish requirements, as well as the mechanical performance specifications. We can offer you the fastest quote.

Masion applies various materials in the sheet metal assembly processes. Therefore, each material has many applications, usage locations, and mechanical properties that are dissimilar from the others. Processing can be done based on the customer’s demand, and the competitive advantages of adopting professional personnel, techniques, and experience assure the fabrication of quality and precision in the sheet metal assemblies. Here are some material options we offer: Here are some material options we offer:

- Cold Rolled Steel

- Hot Rolled Steel

- Galvanized Steel

- Aluminum

- Brass

- Stainless Steel

- Advanced Assembly Equipment: The sixth is an automatic assembly production line for sheet metal handicrafts that we possess. We also have robotic welding assembly equipment, professional riveting assembly equipment, welding equipment, and so on, we are capable of assembling efficiently and with high quality.

- Professional Technical Team: We have DFM design as well as development engineers professional assembly specialists and tested inspectors adept at all Sheet metal assembly production.

- Rich Industry Experience: Established in 2004, with 17 years of development, specializing in sheet metal processing and assembling, and have cooperated with many big clients including Geely Auto, Li Auto, CRRC, Bull Group, Chisagess, INNOLUX, TUO PU, XUSHENG, AUX. We have many successful cases and rich technical experience.

- Large-Scale Production Capacity: We currently have over 400 employees out of which, more than 100 are assemblers 21 are inspectors, and 6 are automated assembly lines to meet your large volume sheet metal assembly requirement.

- Strict Quality Control: Executing compliance with ISO9001-2015 and ISO16949 quality management systems guarantees that the desired qualitatively developed assembly of sheet metal corresponds to your requirements or even surpasses them.

- Excellent Supply Chain Management: More than 100 suppliers stay with us for a long-term partnership, and we also work on a sound supply chain of materials supply and quality guarantee.

- Custom Sheet Metal Assembly Services: Custom Sheet Metal Assembly Services:

Concerning project diversification and complexity, we have prolonged our services to the customization of projects as per your needs in terms of design, sheet metal fabrication, and assembly with a guarantee that the assemblies will conform to your design specifications.

Masion has equipped many sophisticated tools in sheet metal assembly that can support the efficiency, accuracy, and high quality of the assembly production for the projects. Here are some of our key equipment:

- Automated Assembly Conveyors: As with any furniture product, there should be ingredients for high-efficiency automated assembly lines, like in the construction of standing desks, where each part assembled is precise and fast.

- Automated Plate Conveyors: Used for assembling the sheets of metal used for computer cases and other products, for complicated assembly.

- Fixed Assembly Workstations: Mainly used in both manual and semi-automatic applications and offer trends and accuracy.

- Riveting Machines (PEM): When it comes to accurate and safe fastening of different sheet metal products.

- Bolt Welding Machines: Preventing the creation of weak and short-lived bolts in sheet metal structures.

- Press Riveting Machines: Anchored specifically to stand up to heavy riveting and consequent application, to make sure that it is a strong and tough one.

- Individual 4E Riveting Machines: For exact and specific riveting operations giving excellent fastening.

- TIG and MIG Welding Equipment: Ideal for applications where stainless steel AC, AL, brass, cold rolled, and hot rolled steel is to be welded thereby promising strength and cosmetics.

- Robotic Welding Equipment: 20 robotic welding machines and 3 laser welding machines where large-scale assembly production is viable and precise.

- Spot Welding Equipment: spot welding of thin and small parts of sheet metal in a very short period.

- Laser Welding Equipment: An accurate type of welding for tricky and exhaustive work.

- Riveting Guns: For several fascinating operations, for example, blind riveting, best for several types of sheet metal joints.

Masion has services that cater to all the sheet metal assembly needs to assist with assembly services: Here are our main assembly services:

- Mechanical Assembly: Assembling any sheet metal parts and their fasteners such as screws, nuts, and others with automatic screwdrivers with an easy-to-disassemble and assemble characteristic. Ideal for assemblies that call for screw holes like standing desks, and cabinet bodies.

- Manual Welding Assembly: We operate using conventional methods of welding such as TIG, and MIG among other methods, and on different materials such as stainless steel, aluminum, copper, cold rolled steel, and hot rolled steel, among others. Typically used to make joints in the connections of sheet metal work; making it stronger and more rigid more often used in connection of cabinets, reinforcement of regions of contact, corners, and points of assembling.

- Robotic Welding Assembly: The efficiency is high, it does not cost a lot, the quality is good, and you get the same results over and over, it is best suited for projects that involve a large volume of similar items. Ideal for seams of the cabinet, locations of points of support, places of reinforcement, corners or edges, etc.

Riveting Assembly: In general, fixing sheet metal parts with one or other type of rivets with processes like blind riveting, expansion riveting, press riveting, or rotary riveting. Resistant to moisture, good for cabinet brackets, protective plates, baffles, and strength connections.

Yes, our sheet metal assemblies take measures of high quality due to the set quality checks and adoption of superior technologies. Here are the specific methods we use to guarantee the quality of our sheet metal assemblies:

- Strict Quality Management System: We follow ISO9001 and ISO16949 quality management, deliver quality exam reports, and conduct quality checks on all the stages of the manufacturing process. These are process inspections, surface inspections, dimensional inspections, and the final assembly inspection to ensure that there is adherence to quality standards at all the steps of production.

- Advanced Production Equipment: Our facilities have fully automated assembly lines, robotic welding equipment, rivet machines, and guns. These tools improve the organization’s ability to effectively and accurately assemble the sheet metal assemblies hence enhancing quality control.

- Professional Technical Team: Our companies have in total of 136 well-educated professional R&D, design, and manufacturing engineers 22, rigorous inspectors 14, and a proficient professional assembly team of 100. The engineers then apply the recommendations to the design of the sheet metal assemblies to eliminate quality problems that can occur in the production process; the inspectors on the other hand ensure strict quality control checks while the assembly experts reduce the quality problems as they engage in their work.

Comprehensive Inspection Methods:

- Visual Inspection: It is important to understand that every weld and assembly is subjected to an initial visual check of no cold welds, missing welds, incomplete welds, or visible defects on the welds.

- Special Inspections: According to the customer’s requirements we carry out tensile tests, x-rays, ultrasonic tests, and special fluids to test the weld seams on the quality of welding and assembly.

- Precision Inspection: We also use measuring tools that are accurate in measuring dimensions and accurately and these include Micrometers, Calipers, Go-No-Go gauges, and CMM.

- Continuous Quality Improvement: We always update production data and customer responses, examine the quality of components, and upgrade changes to increase the quality and production of assemblies.

- Strict Supply Chain Management: Our supplies are thoroughly examined and regulated so that all the necessary materials and components like screws, nuts, and others for assembling products should correspond to the quality level.

- High-Quality Control Examples: DFM Design Support: We have a team of 22 Professional Design and R&D engineers that help you design the sheet metal assemblies right from the initial stages of the project while being fully aware of the likely obstacles when it comes to the actual fabrication so that designs that are impractical and complex can be avoided.

- IP65 Waterproof Production: The production. we can supply IP65 waterproof sheet metal parts, for example, energy storage battery cases, waterproof electric boxes, and so on, that assures our product’s good performance in severe conditions.

Our sheet metal assembling services include; standard and custom services taking advantage of the 17+ years of experience and technological adroit.

Advantages of Custom Services:

- Flexible Design Support: It also has our skilled R & D team that assists in DFM aspects ensuring that all the designs presented have minimized production complexities, low costs, and time for assembly.

- Advanced Equipment: It includes the use of robotic feeders, bending machines, laser cutters, CNC punching machines, and others to meet several diverse problems of customization.

- Material Choices: We operate with SS, aluminum, copper, cold-rolled steel, and hot-rolled steel.

- Multiple Assembly Processes: Mechanical assembly of these materials is another option in addition to the use of manual and Robotic welding as well as riveting.

- Strict Quality Control: The production process complies with ISO9001-2015 and ISO16949 standards and this guarantees quality at every step of production.

- Fast Delivery: Therefore, optimum management of production cycles and availability of materials guarantee a prompt response and consequently, shorter delivery times.

- Customization Process: Requirement Communication: What needs to be done is to consult with our sales representatives about your project. Give the design drawings, samples, or sketches. About dimensions and tolerances, as well as requirements for assembly and surface treatment, we make affirmations.

- Design and Evaluation: We revise and possibly modify your design to make it manufacturable and to reduce costs.

- Sample Production: We create prototypes, measure the size and spacing, perform required checks run tests, and issue reports and samples for your acknowledgment.

- Mass Production: Samples can be produced once they have been approved, and then mass production is done while adhering to high quality.

- Quality Inspection: Perform routine checks on the production where possible to check if all the parts are as per your desired quality.

Delivery and After-Sales Service: To ensure the timely delivery of the different production stages as well as extend support after sales have been made.

Yes, we offer detailed design solutions for sheet metal assembled parts.

Design Service Content:

- Concept Design: These concept designs are generated from your ideas and the application scenarios of your idea; they outline the primary structure, size, and purpose.

- DFM (Design for Manufacturability) Support: This results in the early optimization of designs as part of the strategies to cut the cost of production and make processes more effective.

- Detail Design: With the help of necessary computer programs (SolidWorks, AutoCAD, Pro/ENGINEER, UG) the products are designed with the focus on achieving accuracy of details and ease in manufacturing.

- 3D Modeling and Simulation: Here, we challenge dimensions & validate for manufacturability & look for assembly issues.

- Rapid Prototyping: This is done during the processes of creating the prototypes and the assembly tests to check and see the functionality and the dimensions both of which have to be by the requirements set.

- Design Optimization: Thus, the design is subject to improvement for mechanical performance and its manufacturability characteristics.

- Final Design and Drawing Output: We submit final design drawings for approval for production to avoid designers’ errors.

Design Service Advantages:

- Professional Team: We have 22 senior persons in the R&D and design divisions who provide high-quality technical design solutions.

- Advanced Tools: Our major software are SolidWorks, UG, AutoCAD, and Pro/ENGINEER for accurate designing and analysis.

- Comprehensive Support: Thus, we provide consulting and project coordination services along with other services from sketching until the last stage of production.

- Customized Solutions: Our designs are made to order to suit your needs and/or system environments within your organization.

- Quick Response: We provide optimization of designs which in turn eliminates long design cycles and processing times.

- Quality Assurance: It operates under ISO9001-2015 and ISO16949, which helps deliver steady designs and high-quality final assemblies.

Some factors are taken into consideration regarding the assembly. Let’s discuss them now;

- Assembly Feasibility: As the starting point of design our decision is about whether the assembly corresponds to requirement specifications and whether it is possible to assemble it. This will guarantee the fact that the product being assembled will be capable of meeting or satisfying the customer.

- Timeliness of Assembly: Sheet metal assembly processes are the acts of joining the fabricated individual parts which are formed via processes such as stamping, bending, welding, riveting, and correction among others. Therefore, the scheduling and timeliness of the entire production plan are vital since the scheduling is lean. Laymen believe that one percent is just one percent, but in a manufacturing assembly line, if such a percentage is not available, the assembly cannot be done within the stipulated time. In cases of constructing assemblies, it is expected that each component in the assembly has been produced according to its production cycle, and hence the schedule will fit this cycle to accomplish the assembly on time.

- Standard and Custom Components:

We offer both off-the-shelf and professionally developed constructions. This makes standard assemblies to be characterized by designs that are relatively near their final optimized form and highly standardized processes that imply little or no re-tooling. However, custom assemblies are known to add to the design period, thus resulting in a delay in production. Therefore, during the initial conceptual design of nonstandard assemblies, the issue of efficiency plays the most important role.

- Assembly Dimensions:

This is because in shaping the final product all sheet metal parts should be accurately measured. Hence, from the design phase, the issue of distribution of the assembly dimensions is also taken into consideration. In every process of production like stamping, bending, laser cutting, riveting, and welding measures should be taken so that none of the dimensions of a part interfere with the assembling process.

- Complexity of Assembly

One should also be aware of ‘over-engineering’ something in the initial designing phase since the larger an assembly whatsoever, the longer it will take to build, and hence the delivery time will be longer. It is challenging to coordinate certain assemblies, and every point needs to be matched and tested before assembly, which can maintain an expected delivery time. Hence, to produce high-quality sheet metal assemblies, complex designs are discouraged during the design process.

Sheet metal processing should be embraced in dealing with different industries because the metals used, or structures designed are durable, surface finishes are appropriately treated, and because of its malleability. However, there are some limitations: However, there are some limitations:

- Material Limitations: To laser cut a variety of materials in the marketplace, various laser cutting machines are used. Fiber laser cutting is also used on materials such as titanium alloys, brass, and copper to warrant the use of fiber laser cutting machines. They also determined that different materials could have quality problems when it comes to bending, welding, and cutting during the assembly. For instance, aluminum alloys bend or crack while welding or bending.

- Tolerance and Precision Requirements: Normal precision typically is in a range of ±0. 1mm (±0. 04’’). Achieving ±0. Machines being able to achieve tolerances of < 0. 05mm (0. 02’’) or less means that depending on the specific area, additional steps and expenses are needed.

- Structural Complexity: It is necessary to avoid complex designs because they influence dimensional accuracy and augment assembly challenges. Complex structures also increase the time of production and hence efficiency is lowered.

- Process Limitations: Some operations such as welding and riveting have their requirements concerning the thickness and the shape of the parts. Another disadvantage is that due to high temperature, during welding the material tends to deform, which is inconvenient in further assembly process.

- Equipment Limitations: Many press brake and sheet metal processing tools take the average thickness of the material which is not usually more than 20mm. Thicker or larger dimensions need specific equipment which in turn impacts assembly if the equipment is absent.

- Manual Operation Limitations: Fabrication of sheet metal items is a delicate task that needs to be handled by qualified personnel. Nursing or inexperienced workers, or those with restricted physical abilities, can compromise the quality of assemblies and their rate. Our assembly team has professional and experienced workers to give the best results.

- Design Limitations: There are design factors such as assembly operability, the feasibility of the process, the dimension of the assemblies, the time required to complete a particular design, and the design’s level of complexity. However, it is best to avoid both overcomplicating the design and to avoid unreasonable ones so that they can be assembled easily.

- Welding Limitations: Certain materials for instance aluminum alloys may allow the heat-affected zone when welding and therefore the performance of the material is affected. Passing through or increasing the heat during welding can change the dimension accuracy or lead to the formation of cracks.

Cost Limitations: Proficient assembly designs and methods raise the cost of production. Procurement of equipment likewise sees the use of special materials and additional processes increasing the costs. Another factor that should not be overlooked where feasible designs’ selection is concerned is the last one that deals with the design phase: The performance cost balance.

Yes Of course, we can, for if you have your design drawings would be glad to work with them or if you have no specific design we have some designs of our own that can be used. However, a sample fee may be charged based on the complexity of the initial sample request made by the student. Sample approval is to be followed by a 100% sample fee returned after the placement of an official order.

Yes, we have fast sheet metal assembly services. Our facility allows for flexibility in sorting out the procedure of making your product; if you require fast production depending on the design drawings, then it can be made possible. Three-sides-bolted structure frame designs, state-of-the-art automatic assembly line systems, and over 100 highly skilled assembly staff guarantee efficient and high-quality assembly. Small and big orders are accepted in our company, and we provide clients with high-standard, precise, and high-quality sheet metal assemblies within the timeframe set. We’ll soon follow up with more information if you get in touch with us for more details.

For the small and medium assemblies, the MOQ could be to the tune of several hundreds if not thousands, for the large assemblies it could be as low as one piece. For the relative assembly, the minimum order of production can be n10, n50n 100, or any other number as per the need of the company. Our objective is to deliver the maximum possible utility move you ahead of rivals and enable you to use market penetration strategies.

Yes, our sheet metal assembly plant is accredited to ISO9001-2015, ISO16949, iso14001, FSC, and other permits. For any extra certifications which may be required please contact us.

We are ISO14001 Environmental Management System certified, which shows compliance with Environmental Management Systems internationally. This certification guarantees a systematic approach to the management of effects on the environment, the usage of resources, and proper management of wastes. We do not indicate services For REACH or RoHS certification, please get in touch with us.

Yes Indeed, we are in a position to manage and or handle materials fed from customers. Here’s how we handle it:

- Material Reception and Inspection: Depending on the nature of the customers, foreseen materials are inspected and checked to conform to the processing specifications and quality standards that the company observes. This also embraces specification, hardness, surface finish, and the like.

- Processing Compatibility: The following are the types of materials to which our equipment and processes apply, stainless steel, aluminum, copper, and cold-rolled sheets. Dependent variables include material properties which are changed to attain the desired results on the processing parameters.

- Storage and Management: Some materials may corrode or be destroyed in some way. So, we make customers’ contributions a point of emphasis by ensuring that they are stored properly. That is why our ERP inventory management system follows materials at all the stages of their processing.

- Custom Processing: By the given drawings and technical conditions, individual manipulation is carried out to achieve the desired characteristics in the result. While in this stage, communication is frequent to update and discuss on the state of the processed outputs.

- Quality Assurance: When the customer provides materials, we keep to ISO9001-2015 and ISO16949 standards, hence the quality of the products. Dimensional, appearance, surface treatment, strength, salt spray, and mechanical performance tests are made to meet the quality requirements for products.

Our sheet metal assembly manufacturing factory for 17 years has ISO16949 quality management system certification and has served many clients. Other successful examples of such cooperation are with companies such as Bull, CRRC, LiXiang Auto, Geely Auto, Chisagess, Innolux, Tuo Pu, AUX, and Xusheng.