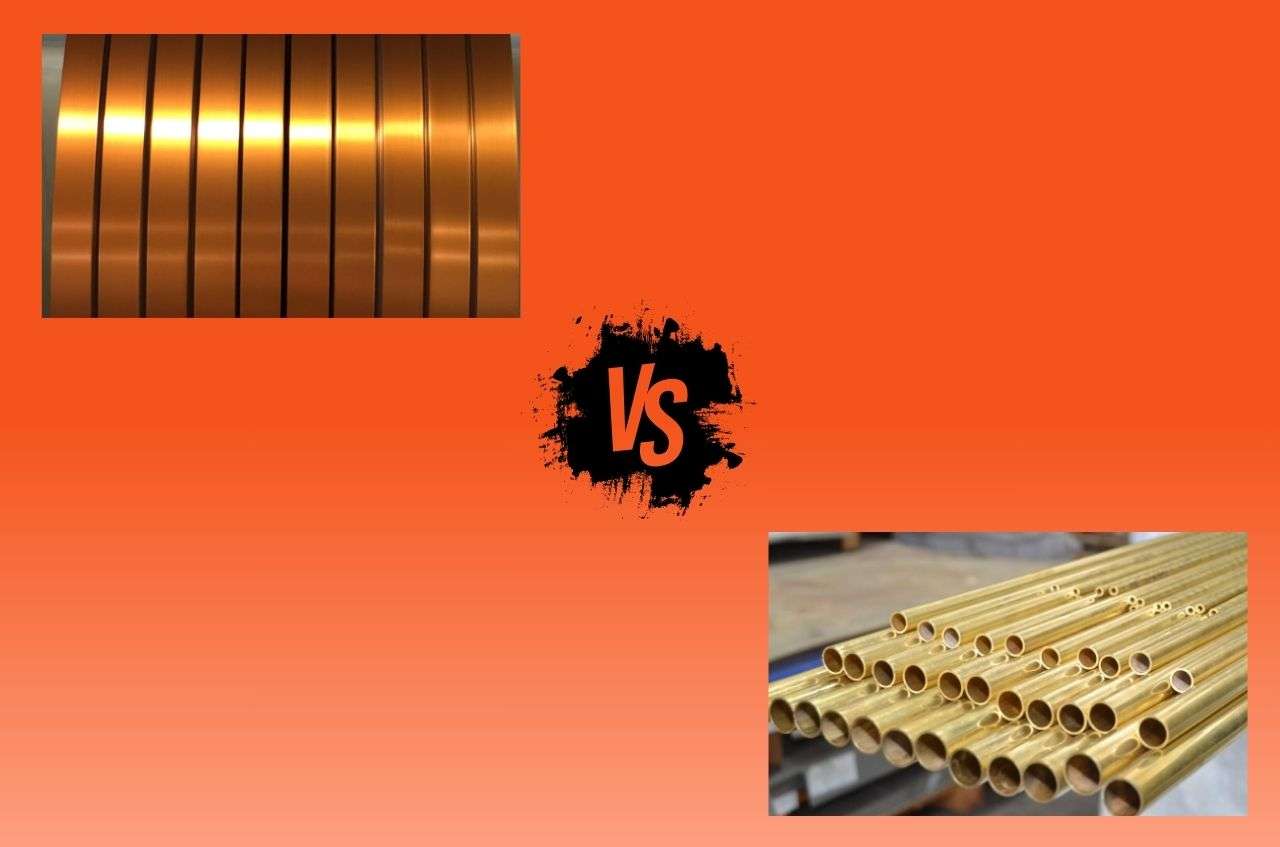

Red Brass Vs. Yellow Brass – Which One To Choose?

Dive into this comparative guide that aims at comparing and contrasting two types of brasses, their composition, physical characteristics and usage. As this article unviels difference between red brass vs yellow brass, it is necessary to consider the type of metallic alloy when selecting for particular task.

Table of Contents

ToggleWhat Is Red Brass?

Red brass’s typical composition is 85 percent copper; 5 percent of zinc; 5 percent tin and a small measure of lead. It is often applied in industries that necessitate strength and immunity to rusting such as pipes and fittings, hardware and marine, and some varieties of music instruments.

What Is Yellow Brass?

Yellow brass used in making cartridges and has more zinc content than does red brass. This material generally has 60% to 70% copper and 30% to 40% zinc, thus it shines like the color of gold. The most common type of this brass is characterized by high strength and ductility and is quite suitable for use in such applications where in addition to good mechanical properties, appearance is also an important factor. Besdies the shooting components and music equipment accessories, you can utilize the yellow brass in decorative accessories.

Chemical Composition of Red Brass Vs Yellow Brass

| Sr. No. | Element | Red Brass | Yellow Brass |

| 1 | Copper (Cu) | 85% | 60-70% |

| 2 | Zinc (Zn) | 15% | 30-40% |

| 3 | Other (Optional) Elements | Tin up to 5% Lead up to 5% Iron up to 5% | Lead up to 3% |

Understanding Red Brass Vs Yellow Brass Overall Strength

Red Brass

Due to red brass softness it is easier to shape and form and it hence if preferable for areas that entail complex carving or designing. Yet, it has the lower tensile strength more or less, which makes it unsuitable for use where there are expectations of a lot of mechanical demands.Yellow Brass

Due to the presence of higher amount of zinc, red brass exhibits the higher strength and hard characteristics. It increases the strength to make it ideal for usage in cases that involve strength and wear and tear to a considerable extent. This means that it can take more mechanical stress and hence it is more suitable to be used in industrial and mechanical purposes.Understanding the Mechanical and Physical Characteristics of Red Brass Vs Yellow Brass

Physical Charactersitics

Color

- Red Brass: Copper content is high in this type and gives it a reddish hue.

- Yellow Brass: Pure metal has bright yellow colour because of its high density of zinc.

Density

- Red Brass: Higher density due to the fact that those cables contain a higher percentage of copper.

- Yellow Brass: It has lower density as compared to red brass.

Melting Point

- Red Brass: It has generally a higher melting point.

- Yellow Brass: Melts at a lower temperature as it has higher amount of zinc content as compared to tin.

Mechanical Charactersitics of Yellow Vs Red Brass

Tensile Strength

- Red Brass: Relative weakness, which in terms of tensile strength is not as high as that of the steel products used for more stressful purposes.

- Yellow Brass: A tensile strength that is increased making it more ideal for any application that requires the material to be stronger.

Ductility

- Red Brass: Less brittle, this make it easier to shape it into various product form and dimensions.

- Yellow Brass: It does not feature any ductility.

Yellow Brass Price Vs Red Brass

In general, red brass is more costly than yellow brass mainly because of the presence of high amounts of copper in it. Nevertheless, apparent advantages of red brass over other types of the material as to corrosion and wear resistance and durability may make higher price corresponding to its usage in certain applications.Scrap Cost

The scrap price for specifically red brass is higher. This is mainly due to the association of copper. This make it to have more value in the scrap metal market. On the other hand, yellow brass scrap is cheaper, however, it is considered a sort of an asset since it is common to find. The prices of scrap brass depend on purity of the metal, the market trends, and the international prices of copper as well as zinc. It is possible to get the rates of current scrap prices for brass from a chart if one is available.

Insights on Corrosion Resistance

Red Brass

It has high copper content and with the addition of tin, it has increased ability to combat corrosive agents thus suitable for plumbing, boat accessories and other parts that are exposed to water and chemicals.Yellow Brass

The process of dezincification is also a type of corrosion in which only zinc atoms are dissolved in the solution leaving behind a material with large holes and hence weak in strength. Therefore, yellow brass will be relatively inferior when used in conditions where it comes into contact with corrosive substances for a long duration of time.Durability Differences – Red Brass Vs Yellow Brass

Red Brass

Due to its anti-corrosive and durability nature, it is used in places where it is needed to offer long service and durability. The presence of tin also improves its sturdiness making it ideal to use in down pipes, showers, around marine areas and such related purposes.Yellow Brass

However, due to its high strength and hardness it is applicable in mechanical application where the major demand is on its strength rather than on corrosion resistance. It is employed in ornaments, music instruments, and many more products that require beauty as well as strength.Similarities between Red Brass and Yellow Brass

- Composition: Red and yellow brass are copper-zinc alloy, Red brass contain more copper and Zn while yellow brass is relatively contain Zn more than copper.

- Workability: Despite the differences, both the types of brass are relatively easy to shape and to machine making them suitable to be used in many applications.

- Conductivity: Both are good conductors of electricity, though redbrass has better conductivity slightly by the virtue of having a few percentage more of copper.

- Aesthetic Appeal: Both the types of brass have a shiny look to it, and thus are used for appearance related application and components that will be visible.

Red Brass Vs Yellow Brass: Which Is Stronger?

Although they are both copper-zinc alloys, yellow brass is produced with slightly higher levels of zinc than red brass hence it is stronger. The rise in mechanical strength makes yellow brass suitable for situations where there is a lot of stress and the structure is weak. Corrosive actions act quickly on the Red brass, it is mainly due to the lesser hardness association. You cannot put this metal to usage in heavy demanding areas.Is Red Brass Better Than Yellow Brass?

Red brass appears to have certain advantages over yellow brass, depending on the use that is going to be given to it. Red brass has greater corrosion strength and is more durable therefore preferred where harsh conditions are likely to prevail or where the component has to last longer. Yellow brass is more suitable for mechanical shock absorption and ease of manufacturing since it contains higher strength and ductility.Applications of Yellow Brass Vs. Red Brass

Jewelry Applications

- Red Brass: It is used in fine jewelry since the material needs to be strong and possess an unconventional pattern.

- Yellow Brass: It forms an alloy similar to yellow gold, makes great appearances in costume jewelry and ornamental trinkets and can easily be shaped. It is cheaper, which is ideal for creating cheap jewelry for the large market.

Saxophone

- Red Brass: High-quality saxophone manufacture materials like red brass are used since they produce better sound and can last longer. It gives a warmer sound, which is desired by most hails of professional performers.

- Yellow Brass: Yellow brass is typical to standard saxophone models, but they are not as common in jazz artists’ customs as other metals. Its main advantage is that it produces a bright sound and its price is lower than that of the polished wooden cymbals; therefore, students and average-level musicians prefer such cymbals.

Trombone

- Red Brass: Larger professional trombones use red brass for its tonal warm and improved corrosion durability. Red brass is thus ideal for instruments which are often played and which are likely to change with the prevailing conditions.

- Yellow Brass: You can use yellow brass in student and inter mediator trombones due to its shining sound quality and low price. You can produce it much easier and it possess a satisfactory level of durability for the instruments designed for beginners.

Trumpet

- Red Brass: Red brass trumpets usually preferred by the professional musicians. They are mostly feature applications in professional music groups such as orchestras because of the quality of sound they produce.

- Yellow Brass: Yellow brass trumpets are beginner to intermediate level, and they do effect the sound of the instrument. They help in providing a bright tone and are cheaper as compared to other manufactures; therefore, preferred by students.

Aircraft Components

- Red Brass: Specified parts of aircrafts need red brass material for its features such as high corrosion resistance and durability. It is provided for the components that are installed in severe conditions, where consistent operation is required.

- Yellow Brass: The importance of yellow brass is paramount where you need higher level of strength and even higher weight bearing capacity. Specially those areas where corrosion resistance does not matter a lot. You should note that their mechanical properties make them suitable for sevaral applications in the aircraft industry.

Marine Components

- Red Brass: Red brass is particularly suitable for making marine component as the material has a higher resistance to corroding in seawater. Option exist to use in fittings, valve and other parts that are in marine environment service.

- Yellow Brass: Yellow brass has lower resistance for marine applications as compared to the common one above mentioned. At the same time, it has satisfactory corrosion resistance but is much more susceptible to dezincification, so it is not suitable for critical marine parts.

Electrical Plugs and Sockets

- Red Brass: Electronic equipment usually prefers the components with red brass because it has the best conduction feature. You can use it primarily with plugs, sockets, and other electrical connections that require immediate and steady stability.

- Yellow Brass: Conventional electrical equipment employ yellow brass because although it does not conduct electricity as well as copper it is comparatively cheap. You can use it in domestic and industrial fixtures and luminaries.

Automotive Parts

- Red Brass: Some auto applications that require parts of very high standard utilize red brass due to corrosion and durability. You can use it in the housing of components, which are vulnerable to weather conditions or work in testing conditions like cooling systems and electrical connectors.

- Yellow Brass: With regards to the properties, yellow brass has favourable characteristics for numerous automotive parts, and its high strength and fabricability make it a suitable material. You can use it in in fittings, valves, and other structural parts that require good mechanical properties together with the wear resistance.

Conclusion

It becomes important to know the fundamental differences between red brass vs yellow brass to make the right choice. Also, red brass has more copper content than yellow brass. Therefore has enhanced corrosion resistance and durability suitable for rough and esteemed applications. Yellow brass, containing more of zinc, is stronger and cheaper than other varieties of brass. This is why you can use it where mechanical strength required along with the brilliance of the metal. Knowing these characteristics and costs of the different types of brass. You can make the right decision depending on the projects you want to work on.