How to Cut Aluminum Sheet Metal at Home – DIY Guide

Cutting aluminum sheet metal can be challenging. You will also be frustrated and uncertain as to how to start. However, you don’t need to struggle. If you do not know the correct cutting techniques and safety practices then you will not cut clean and accurate every time. In this guide, discover most effective methods and the best tools that will allow you to make the process easier and safer. Whichever level of experience you are at, you will know you can cut aluminum sheet and become a pro.

Table of Contents

ToggleUnderstanding Aluminum Sheet Metal

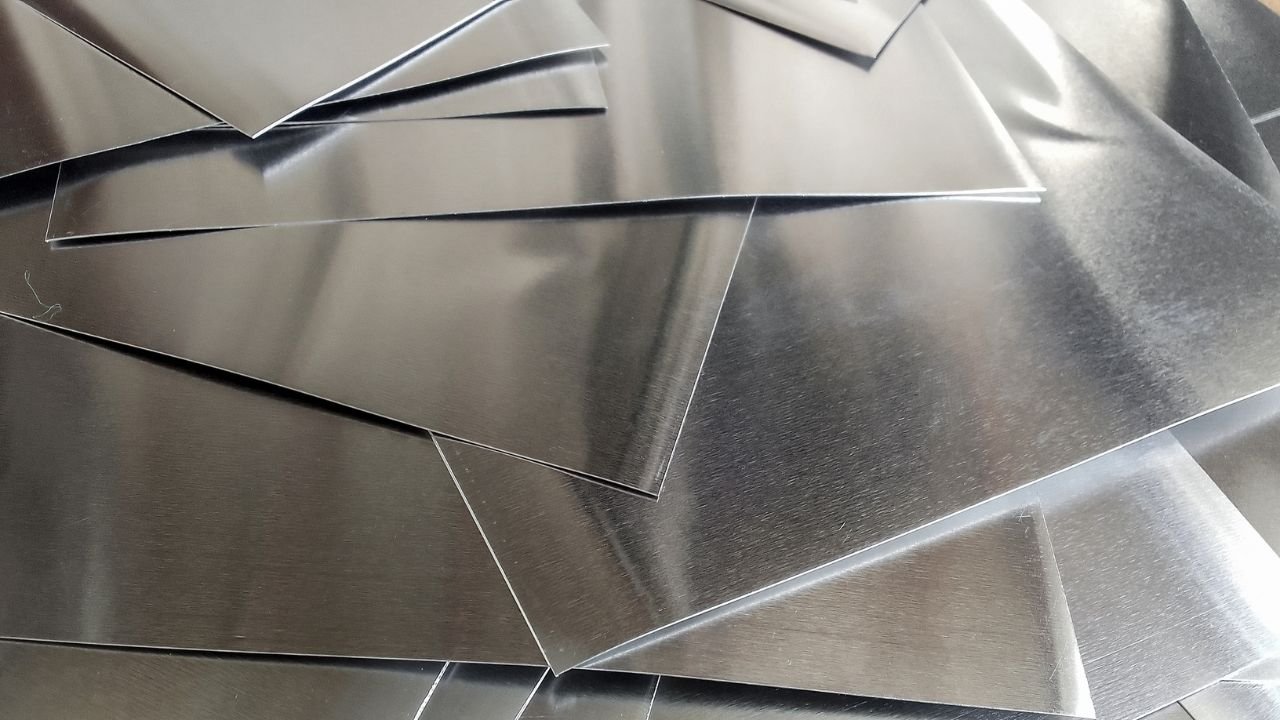

Basics of Aluminum Sheet Metal

The durable and lightweight properties of aluminum sheet metal. It’s lighter than most other metals but offers great strength, so you’ll find it easy to handle. It is corrosion resistant and suitable for outdoor applications. Whether for crafting the finer details or heavy duty industrial projects, there are numerous thicknesses and grades to choose from to accommodate your specific needs.Aluminum Sheet Metal Properties

Aluminum sheets are very versatile and can be adapted to many applications. The lightweight properties save on transportation costs and increase efficiency in a number of industries. Even at a weight, they are still very durable and will last a long time. You will also like their flexibility as aluminum can be fashioned into intricate designs and yet shaped and made into the form you want. It is heat and electrical conductor and is the go to material for electronics and insulation.

Aluminum sheets can be used for almost anything.

In construction projects, you’ll often find aluminum sheets. Thanks to their strength and weather resistance, they are also used in roofing, cladding and structures. Aluminum helps automotive industry lightweight vehicle parts, improving fuel efficiency. Aluminum sheets are great for DIY enthusiast looking for custom furniture, decorative panels to make, craft projects, etc. In addition to planes and cars, aluminum sheets also are used everyday items like soda cans, cookware and signage, to showcase their widespread utility.Preparing for Cutting

Selecting the Right Tools

It is imperative that the right cutting tools are chosen for clean and precise cuts. For manual work, think snips for thin sheets or hacksaw for thicker materials. Faster and more efficient cuts are possible with power tools, such as jigsaws and angle grinders. Choose the tool that matches the sheet’s thickness. For instance, thick sheets are usually more suited for heavy duty processing with power tools; whereas, thin sheets are often cut by hand with manual snips. Keep your tools sharp and in good condition, never let them become jagged.Measuring and Marking

Clean cuts start with accurate measurements. Mark precise lines with a tape measure or ruler. Tools such as a scribe, sharpie, or masking tape are invaluable for marking the cut line so it is clearly defined. It also helps prevent the material from fraying or scratching. To avoid errors that waste material, double check your measurements.Work Area Setup

Clean and stable workspace set up before cutting. Make the area safe by clearing the debris. When cutting, use a sturdy surface such as a workbench and clamp the sheet into place to avoid any movement. Vibrations are reduced and accuracy improves with proper support. Additional visibility and precision come from a well lit workspace.Tools and Techniques for Cutting Aluminum Sheet Metal

The right tools and techniques are necessary for cutting aluminum sheet metal producing clean, precise results. Here’s how you can achieve the best outcomes:Manual Cutting Methods

Using Tin Snips: They are good for cutting very thin aluminum (tin snips also work fine with plastic). They are affordable and easy to use. To achieve clean cuts, keep the snips taut and cut steadily along the marked line. Don’t force the tool into the metal, otherwise it will warp. Hacksaw Cutting: When cutting thicker sheets, a hacksaw works great for straight cuts. For aluminum, use a fine tooth blade. Place the sheet securely in place, and cut in slow, smooth strokes to avoid jagged edges.

Hacksaw Cutting: When cutting thicker sheets, a hacksaw works great for straight cuts. For aluminum, use a fine tooth blade. Place the sheet securely in place, and cut in slow, smooth strokes to avoid jagged edges.

Power Tool Techniques

Jigsaw Cutting: Select a blade intended for metal cutting. For curves, adjust the speed to medium, as things will feel more under control. Make sure the sheet remains stable and cut along your cut line. Angle Grinder: For precision use a thin metal cutting disc. Protective gear and control sparks by keeping the grinder steady. For small sections, this is a useful method.

Angle Grinder: For precision use a thin metal cutting disc. Protective gear and control sparks by keeping the grinder steady. For small sections, this is a useful method.

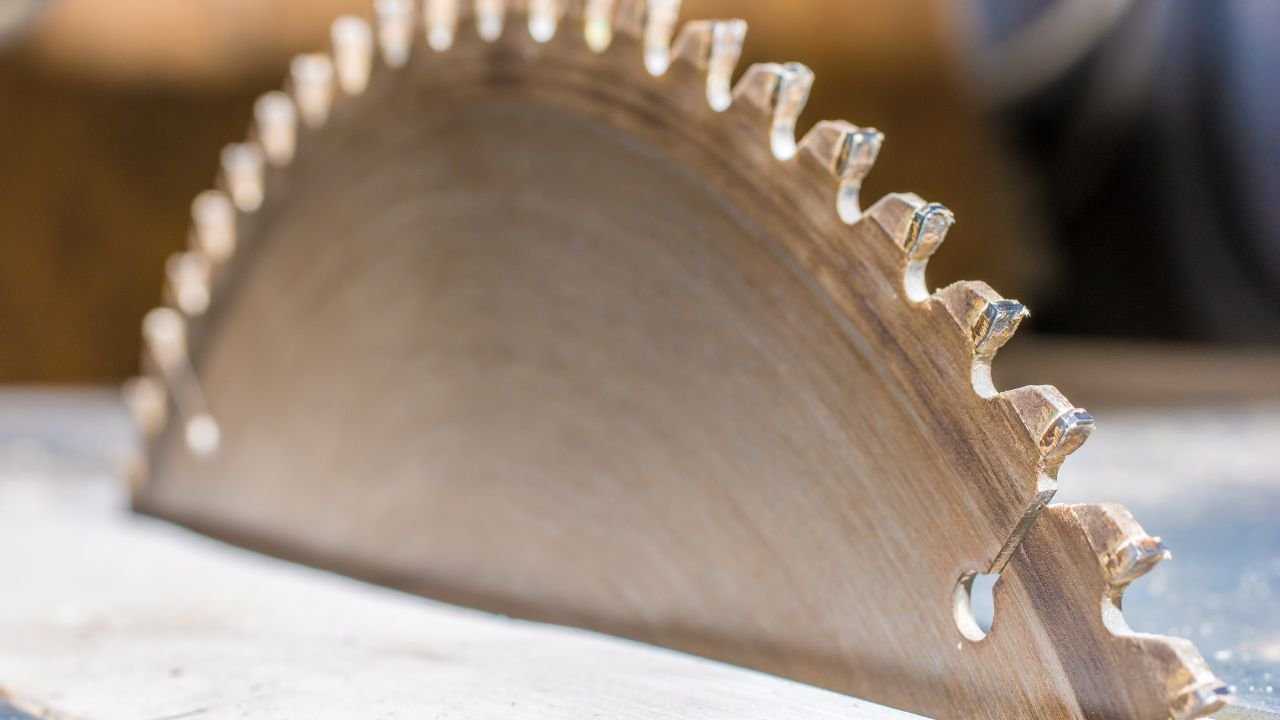

Circular Saw: Use a carbide tipped blade. To avoid overheating or rough edges, especially when cutting thicker sheets, you should maintain a steady feed rate.

Circular Saw: Use a carbide tipped blade. To avoid overheating or rough edges, especially when cutting thicker sheets, you should maintain a steady feed rate.

Advanced Cutting Options

Laser Cutting: For intricate designs, this is the go to method. Laser cutting is precise and there are no rough edges. Waterjet Cutting: It is ideal for minimizing thermal damage, produces smooth edges and thick sheets can be handled easily.

Waterjet Cutting: It is ideal for minimizing thermal damage, produces smooth edges and thick sheets can be handled easily.

Tips for Smooth and Accurate Cuts

Smooth and accurate cuts in aluminum sheets can only be done by paying attention to detail and using proper techniques. Follow these tips for professional-quality results:Maintain Blade Sharpness

For clean edges, sharp blades are necessary. Jagged cuts and uneven surfaces are caused by dull blades. Inspect your blade for wear (chipped edges, or resistance while cutting) regularly. Remember to replace or sharpen blades as needed for precision.Prevent Sheet Deformation

Aluminum sheet should be securely fastened down to avoid bending or warping. Clamps or a cutting table to hold material in place. Depending on the sheet’s thickness, adjust the cutting speed. Thicker materials incur less distortion at slower speeds.Handle Heat Generation

Heating from cutting may affect the structure of the aluminum. Coolant sprays or cutting fluids are used to minimize heat buildup. But taking short breaks while cutting long articles ensures smoothly cut articles without overheating.Use Specialized Cutting Blades.

Opt for the blades that have been designed specially for aluminum. The tooth patterns and coatings of these blades reduce friction and provide for precise cutting. Don’t use generic blades as they might not make the business cuts.Practice on Scrap Material

Before you cut on your final piece, test your cutting technique on scrap aluminum. It also helps you to refine your skill and avoid costly mistakes.Ensuring Safety While Cutting

Protect Yourself with Personal Protective Equipment

Utilize glasses for eye-effective protection and gloves for hands or pointed objects. If you’re working with noisy power tools, use ear protection. When it comes to loose fabric getting caught in machinery, opt for tighter fitting clothes.Handle Sharp Edges Carefully

Aluminum edges can be dangerously sharp after cutting. Files, sanding blocks, deburring tools can be used to smooth them to avoid injury. Before handling, check edges thoroughly to make sure all sharp points are removed.Avoid Common Hazards

Cutting aluminum does produce sparks and dust sometimes. To reduce the risk of fire, keep flammable materials away. Make sure your workspace has good ventilation that manages aluminum dust properly. And if you’re extra safety minded, add a dust mask for protection of your respiratory system.Maintain a Clean Workspace

Act immediately by clearing debris and offcuts. Having a clutter free environment eliminates trip hazards and improves productivity. Organize your tools to work safely and effectively.Post-Cutting Finishing Steps

Deburring and Polishing

First, deburr the aluminum sheet so that it becomes free of sharp edges and burrs from cutting. Precision deburring are done with files, knives or abrasive pads. Polishing provides a smooth and shiny surface for both décor and functionality. Fine abrasives or polishing compounds are applied to a soft cloth or buffing wheel for polishing. Adequate this process not only improves appearance, but it also reduces friction in functional components.Inspecting Cuts

Make sure there are no mistakes and check for quality and accuracy of your cuts. Check for jagged edges, uneven finishes, or dislodged tiles. Verify measurements using tools such as calipers or straight edges. Imperfections will appear if they exist and need to be fixed now. This will prevent you from having some issues during assembly or the final use.Cleaning the Aluminum Sheet

Thoroughly clean the sheet with a proper solvent to free it from oil, dust or cutting residues. Clean the aluminum with something that’s not abrasive. A mild soap and water mixture works well for stubborn residue. It is important to dry the sheet completely in order to avoid water stains or corrosion. Properly cleaned, this sheet is ready for finishing.Storing Cut Sheets

To avoid bending or scratching, store aluminum sheets properly. Lightly pad sheets and store them in a dry, flat area. Don’t build too high to limit the pressure. When stored properly, the integrity of your cut sheets is maintained.Troubleshooting Common Issues

Jagged or Uneven Cuts

Jagged edges can be the result of blades that are dull or cutting speeds that are incorrect. Check your tools for wear and sharpen. Slow cutting speed to ensure better accuracy on thicker material. Where you find rough edges, use a deburring tool or sandpaper to smooth them.Tool Malfunction or Wear

If they are not well taken care or maintained, tools could malfunction or wear out. Look for signs of dullness, crack, or instability on the blade. Keep the cutting accuracy by replacing the worn out blades immediately. Clean and lubricate your cutting equipment regularly to maintain moisture and prevent damage.Sheet Warping or Buckling

Thinner sheets or not applying clamping adequately cause warping. To avoid damaging your delicate sheets, adjust your cutting technique. Set up supports or clamps to keep the sheet stable as you cut it. It minimizes the distortion and improves the accuracy.Aluminum Sheets Overheating

When aluminum becomes overheated, it can become weak and discolor. It frequently occurs at high cutting speeds or without cooling. To prevent heat buildup, use a coolant spray or lower the speed. Keep tools sharp to reduce friction which increases the chance of overheating.Misaligned Cuts

Inaccurate measurements or tool instability are sometimes the cause of misaligned cuts. Make sure to double check your measurements before cutting. Prevent movement of tools during operation by securing firmly and stabilizing your material. Keep your blade always in line with your cutting line.Choosing the Best Cutting Method for Your Project

When selecting a way to cut, there are some key things to consider. They’ll guarantee that you get the best results.Factors to Consider

Project Scale and Sheet Thickness: The cutting method depends on the size and complexity of your project. If you’re working with larger projects or thicker sheets, you may need more powerful tools. Budget and Availability of Tools: It is important too, your budget. Although manual tools are cheaper, they require more time to be used. However, power tools and more advanced techniques such as laser cutting are expensive but have superior accuracy. Project Timeline: For a very tight time frame, power tools or automated methods like laser or waterjet cutting can help to speed up the process. Environmental Impact: Laser and waterjet cutting generate less emissions and waste, which is a more eco friendly alternative. If sustainability is your priority, consider this.Comparison of Methods

Manual vs. Power Tools: While manual tools require more effort and time, small-scale projects can be completed with the flexibility these offer. Faster and more precise than power tools are circular saws or CNC machines, but they can be costly and require skill. Specialized Techniques: High precision and intricate designs might be best achieved using laser cutting. In contrast, waterjet cutting is best for thicker materials, producing smooth edges with no heat. Select the most appropriate approach for your project.Applications of Cut Aluminum Sheets

DIY Projects

For your DIY creations, aluminum sheets are good. They’re great to use for furniture, signage, home decor, etc. They are lightweight and easy to handle, and are strong enough to last. If you’re looking to create a modern coffee table, or a custom made sign, then custom sheet will give your project that unique touch.Architectural Projects

The architectural applications of aluminium sheets are widespread. Facade cladding, roofing and decorative panels are also popular. Custom cut sheets provide room for innovative designs, creating a modern, sleek look while ensuring functional durability.Electronics and Appliances

It is commonly used in electronics and household appliances of cut aluminum sheets. It is made to make casings of phones, computers and other devices. Lightweight but strong, its longevity extends the life of products.Conclusion

In conclusion, how to cut aluminum sheet metal is a joggery affair if you don’t have the right tools, the correct methods, and even more so, the proper safety practices. For your project, you can pick from manual tools like tin snips or hacksaws or power tools like jigsaws and angle grinders. Always wear protective gear and secure materials for safety. This process can be both fun and rewarding for those with DIY fever, especially when you take care of the preparatory work. Explore other tools and methods to enjoy your aluminum sheet cutting projects. You can start your next project in confidence with clean cuts and creativity, knowing you have the knowledge to achieve precise cuts.