H Bracket – Concept, Applications, Materials, Manufacturing, Materials, and More

Selecting the incorrect H bracket type leads to problems with stability and high replacement costs. People sometimes pick H brackets without considering their load-bearing strength or appropriate setup which reduces their lifespan. Learning about different H bracket types and production methods helps prevent structural problems. This guide shows you how to choose H brackets that meet your specific requirements for building projects, furniture production, or industrial settings. This guide breaks down H brackets to provide you with complete information that helps you select the right product.

Table of Contents

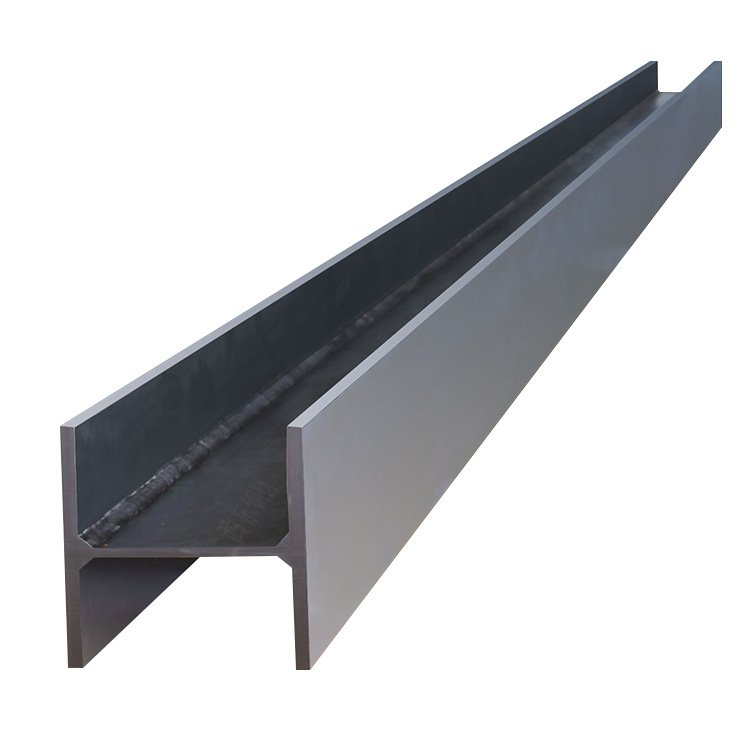

ToggleWhat Is an H Bracket?

H brackets are steel or plastic supports that have an H shape to strengthen structural designs. Two vertical bars stand parallel to each other while a crossbar connects them for strength. H brackets differ from L and T brackets by evenly spreading weight without supporting corners or joining perpendicular pieces. You can get H Brackets in multiple sizes and thickness levels with strong load handling that suits heavy-duty work like shelving systems and frame work.

Common Uses of H Brackets

Construction & Structural Support

H brackets strengthen beams, columns and basic framework elements. These components strengthen building structures throughout homes and businesses. The H bracket design splits weight across its surface area.

Furniture & Interior Design

You can attach shelves and cabinets to walls through an H bracket system. At the corners of wood panels these brackets link pieces together to create reliable desktops and table bases. Aluminum H brackets prove ideal because they offer both lightweight strength without weighing down installations.

Industrial Applications

Manufacturers employ metal H brackets to support their important machines and industrial equipment. These parts supply essential strength to keep the system working properly at all times.

Automotive & Mechanical Engineering

H brackets serve important purposes within automotive production. Engineers install H brackets to connect metal assemblies of engine systems and suspension parts. They act as shock absorbers and vibration reducers to keep vehicles stable.

DIY & Home Improvement Projects

H brackets make good DIY projects to build shelves and support curtain rods or decorative structures. Household projects benefit from these brackets because they attach quickly and deliver stable results.

Manufacturing Techniques Used in H Bracket Production

Manufacturing high-quality H brackets needs specific production procedures. The different production methods work best depending on specific materials and design specifications. This section explains the main production methods for H brackets.

Stamping

A metal press with dies forms the H bracket from flat metal sheets during the stamping process. Modern stamping technology lets us produce exact H brackets at an affordable price in large numbers. When you need to produce many H brackets consistently the stamping process works best.

Casting

Molten metal fills a mold to produce the H bracket design. The production method works best for intricate brackets and delivers good strength and longevity. Casting works well when you want to make a metal H bracket with detailed design elements.

Welding & Fabrication

Welding specialists join various metal pieces to produce the H bracket structure. Our fabrication method produces big and sturdy structures that stand up to intense usage. Welding produces the most durable H brace brackets for demanding projects.

Extrusion

A force pushes aluminum through a die mold to continuously produce H-shaped parts. This manufacturing method produces exact H brackets that resist corrosion and weigh very little. An aluminum H bracket made through extrusion offers excellent durability while remaining simple to work with across many settings.

CNC Machining

Specialized machines follow computer commands to craft H brackets by cutting through metal blocks. This fabrication method delivers top performance when manufacturing intricate and custom-built structures. CNC machines excel at shaping H bracket sign holders that need exact details.

Laser Cutting

A high-powered laser machine cuts through metal sheets to create exact H bracket forms. It delivers exceptional precision to handle complex design work. When you need to make small or detailed H brackets laser cutting creates the most accurate results.

Forging

A hammer and heat process transforms metal into H bracket shapes. The manufacturing process produces brackets that excel in toughness, durability, and resistance to impacts. H brackets made through forging deliver exceptional strength for demanding applications.

Bending & Forming

Sheet metal gets bent into an H shape through press brake or rolling machine operations. Using this technique saves money while helping you make H brackets fast and at scale. These brackets work well for making many metal shapes fast.

Types of H Brackets

Different H brackets exist for meeting particular applications. Knowing the various H bracket types enables you to select the correct one for your project needs.

Standard H Brackets

These standard H brackets deliver dependable support for projects that require medium-level loading. Workers use these brackets often to assemble furniture, build wooden frames, and construct basic support systems. They serve basic tasks in everyday life while maintaining consistent support without overstressing.

Heavy-Duty H Brackets

For heavier load requirements use heavy-duty H brackets. These brackets use high-strength steel or reinforced alloys to handle heavy loads in engineering projects. Heavy-duty H brackets bring long-lasting performance to industrial construction and structure reinforcement projects.

Adjustable H Brackets

When your setup needs to adapt easily use adjustable H brackets instead of fixed ones. You can adjust these brackets for both width and height which makes them useful for building modules and short-term applications. You should select these brackets if you plan to modify your setup later or work with different dimensional requirements.

Extrusion Aluminum H Bracket

Extrusion aluminum H brackets provide you with a corrosion-resistant option that remains lightweight. The aluminum extrusion production method delivers engineered H brackets that maintain consistent quality throughout their design. These brackets support lightweight construction and furniture work while adding structural stability.

Universal Metal H Bracket

This metal H bracket system works effectively for multiple installation projects. Pick from steel aluminum or stainless steel to utilize this flexible bracket that brings you both durability and adaptability. Choose these brackets when your project requires a dependable solution that works well in many situations.

Glass H Bracket

Glass H brackets exist to keep glass panels safe during interior and architectural projects. People use these brackets to install glass partitions, railings, and display setups. Installing these brackets on your glass project offers complete protection without showing any visible fasteners.

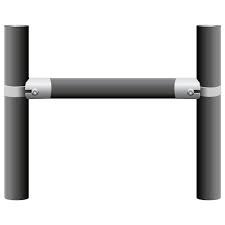

H Brace Brackets

People use H brace brackets most in fencing and farming setups. They connect to wooden posts to create stronger foundations for outdoor gates and support structures. These brackets help build strong fences and outdoor structures.

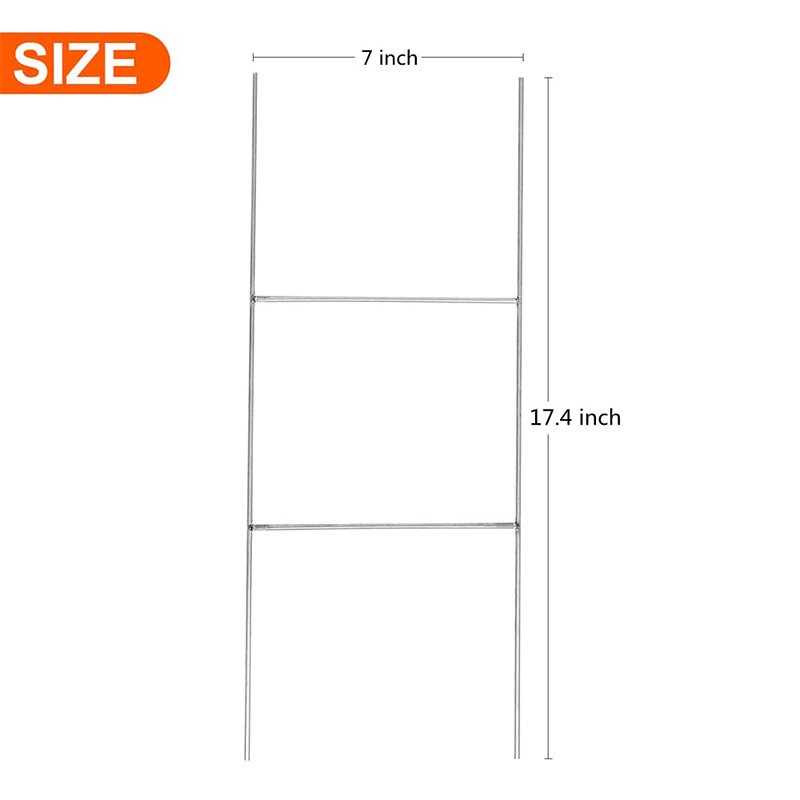

H Bracket Sign Holder

An H bracket sign holder becomes essential when you require reliable support for your sign panels or banner displays. These brackets work best when you need to display items for retail stores or to present information at public kiosks. These fixtures help you easily hang signage without movement concerns.

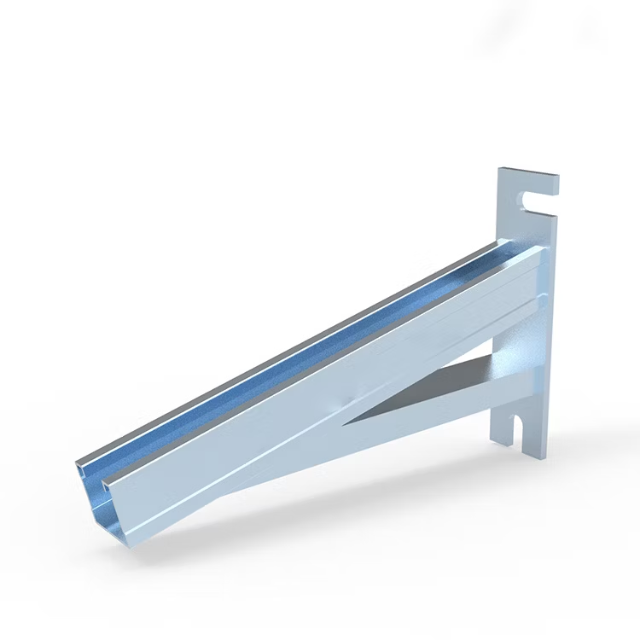

H Type Cable Tray Bracket

H type cable tray brackets enable successful electrical installation work. The brackets hold cable trays and conduits together to keep cables properly arranged and secured. These brackets work in industrial and commercial buildings to maintain secure cable positioning.

Solar Panel Aluminum H Bracket

Solar panel aluminum H brackets serve as the main support elements for solar panel mounting systems. These brackets stay strong even in outdoor environments because they are made from lightweight material that resists rust. Using these brackets during panel installation delivers the dependable support your project requires.

Stamped Metal H Bracket

The stamping process creates exact metal H brackets through efficient mass production methods. People use these brackets throughout automotive production and industrial settings to create items that need both exact alignment and long-lasting performance.

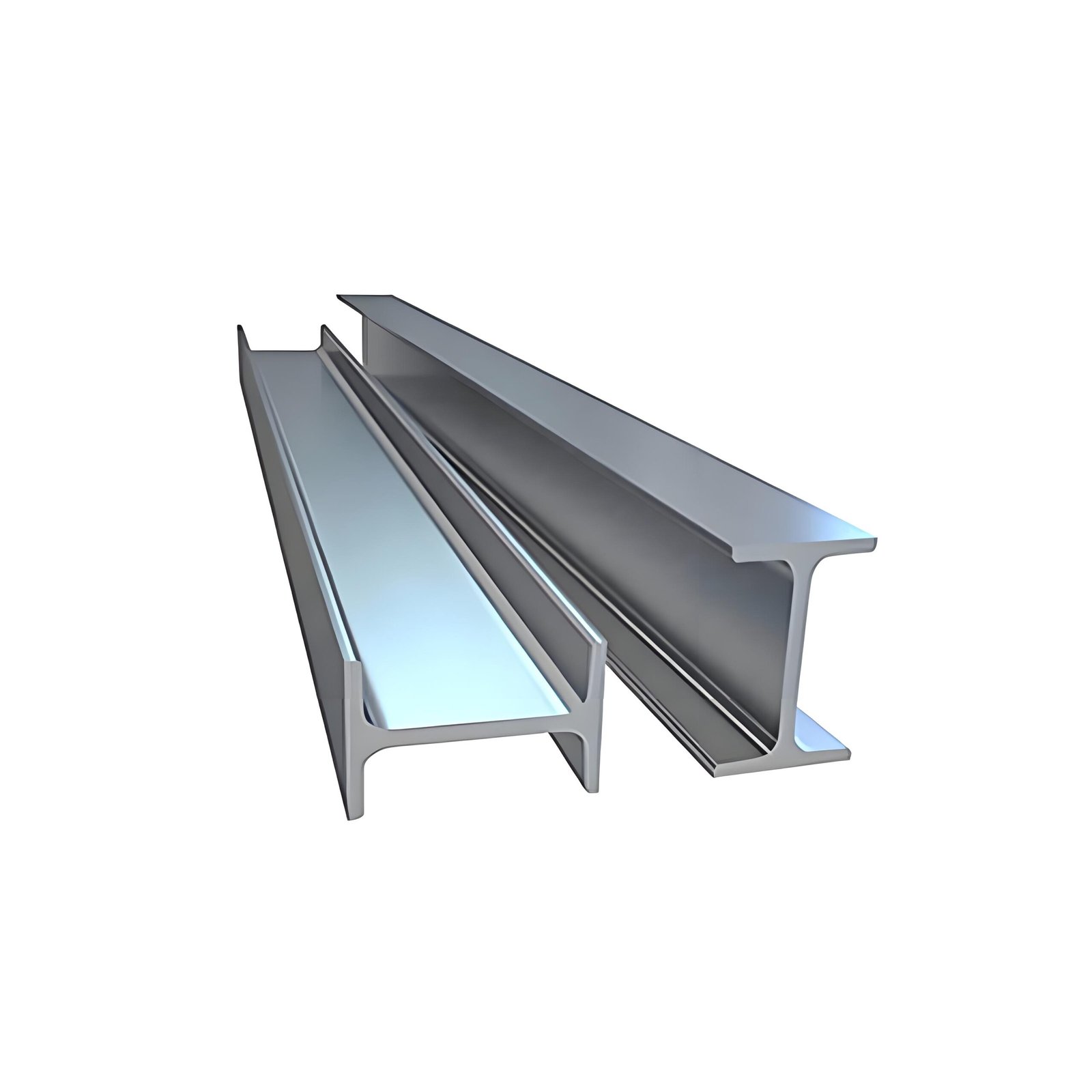

Steel Metal H Bracket

These steel H brackets handle heavy loads and structural support tasks. Builders use them for construction work and bridges and engineers include them in mechanical systems. When you need strong support for big-scale undertakings these brackets will deliver outstanding results.

Table H Stable Bracket

Table H stable brackets help keep tables and desks from wobbling and becoming unstable. These brackets stop furniture from leaning or collapsing to ensure your furniture stays strong throughout daily use.

Welded Metal H Bracket

Welded metal H brackets gain durability from the welding process. Construction companies and engineering professionals use these brackets for their heavy-duty projects. Choose welded brackets when you need hardware that can stand up to harsh settings.

Custom-Designed H Brackets

When you require a special H bracket for industrial construction or engineering applications custom manufacturing provides the ideal solution. Our expert team creates specific brackets to match your unique project needs using different production materials.

Materials Used in H Brackets

Underlying materials play a key role in determining the appropriate H bracket selection for your project. These are the main types of materials used to make H brackets.

Steel H Brackets

Steel stands out thanks to its strong resistance to wear and its powerful load handling ability. People use it extensively because the product holds up well under tough conditions. The weight of steel H brackets becomes a challenge in construction projects. Uncoated steel H brackets will weaken and rust quickly.

Aluminum H Brackets

Aluminum H brackets stand out because they weigh less and resist rust making installation and machining simple. These brackets work best when weight matters. The material lacks the power to handle weight-bearing tasks like steel does.

Stainless Steel H Brackets

Stainless steel H brackets perform best in outdoor or marine projects because they resist rust. This material wards off rust while providing an appealing look. These brackets cost more than steel and require special tools for installation.

Brass H Brackets

Brass is both resistant to corrosion and features a pleasing visual appeal. People regularly use H brackets in their decorative projects. Brass performs poorly under high-load situations because it remains softer than steel. They are also more expensive.

Galvanized Steel H Brackets

Zinc coating on galvanized steel H brackets makes them better at fighting against rust. Their strength and budget-friendly design can make the brackets too heavy while zinc coating needs regular maintenance to stay effective.

How to Choose the Right H Bracket – Factors to Consider

Several factors should guide your selection of H brackets. Follow these instructions to pair your H brackets with their intended applications.

Load Capacity

Pick an H bracket that can withstand heavy loads without failure. Your project needs this feature to stay secure and work properly.

Material Selection

Select your H bracket material to match the environmental conditions that will be present and affect structural strength. Steel and aluminum H brackets handle heavier loads better than alternative materials. Projects exposed to outdoor conditions need stainless steel or galvanized steel because these materials resist damage.

Thickness

While thicker H brackets handle heavier loads they require advanced installation knowledge. Choose the bracket thickness based on its load-bearing needs and installation requirements.

Mounting Holes & Fastener Compatibility

Check the bracket’s mounting hole locations to choose suitable fasteners. Choose bracket hardware that accepts your preferred screws, bolts, and anchor types. Our chosen setup creates a dependable connection between components.

Indoor vs. Outdoor Applications

Brackets designed for outside jobs must show resistance against rust and corrosion. A coating over aluminum H brackets guards your system from damage while ensuring lasting strength across multiple years of service.

Structural Requirements

Install the H bracket at the exact spot to support your work load. A correctly chosen H bracket enhances the part’s performance while making it last longer.

Bracket Size & Dimensions

Make sure your H bracket fits the area you have selected while making complete contact with all parts it touches. A properly sized bracket safeties building materials from suffering damaging pressures.

Flexibility & Adjustability

You can position H brackets anywhere for better installation. You can tackle multiple project types through the bracket’s adjustable setup which lets you arrange parts as required.

Cost vs. Quality

Decide which H bracket type will perform well under pressure and fits your available funds. Do not spend your budget on products that can handle light loads without breaking.

Step-by-Step Guide to Installing an H Bracket

You can assemble an H bracket fast through this setup guide. This guide shows you how to position H brackets properly.

Tools Required

Before starting H bracket installation you need a drill, screws/bolts, measuring tape, wrench, and level.

Installation Steps

- Identify the areas on your base where you will attach the H brackets. Position H bracket mounts straight across the base and maintain equal spacing to reach a level installation.

- Put the drill bit in the designated spots and start drilling. When you drill first then screw the screws they grip better while protecting the metal structure.

- Secure the metal H bracket with screws or bolts. Turn the wrench to hold the bracket steady.

- Check if the mounting bracket stays strong. Make sure the weight of the sign evenly spreads across the frame and check to see if it remains horizontal. Use a level to verify that your H bracket sign holder remains level.

- Adding paint or protection to your setup boosts its overall appearance especially when you plan to use aluminum H brackets.

Safety Tips for Installation

Put safety first before you start installing H brackets. Follow these basic guidance steps to achieve a dependable and secure H bracket setup.

Proper Weight Distribution

Spread the weight evenly over the H bracket surface during installation. This distributes the weight evenly to stop the support from breaking or giving way.

Use Appropriate Screws or Anchors

Use the right fasteners for your mounting surface. Your choice of screws and anchors will provide the best possible grip and stability for all your mounting projects including wood metal and concrete materials.

Pre-Drill Pilot Holes

Map out small pilot holes before drilling to protect materials from splitting. The process becomes easier and more precise when you drill pilot holes before mounting metal or aluminum H brackets.

Use a Level for Alignment

Line up your H bracket correctly. A level tool lets you maintain straight bracket placement during installation to avoid structural damage.

Secure Tight Fastening

Fully tighten screws or bolts into place. Winding screws too hard puts strain on both the H bracket and material underneath.

Inspect the Bracket Before Installation

Look for any signs of damage on the H bracket like cracks, rust spots, or other physical problems. A damaged H bracket cannot deliver proper support.

Test Stability Before Use

After installation push the bracket gently to make sure it keeps its position. The bracket will stay firm on its mount until you add its weight.

Maintenance & Durability Considerations

To make your H brackets last longer and work effectively you must perform routine maintenance checks. Here’s what you need to do:

- Check your H brackets Often

Check your H brackets through visual inspection to spot damage in their structure including cracks, warping, rust and mechanical defects. Determine if any screws or bolts feel loose and secure them properly.

- Protective Coatings for Outdoor Brackets

Brackets that stay outside need special protection through galvanization, powder coating, or anodization to resist nature’s elements. These protective coatings keep H brackets safe from rust and corrosion to make them last longer.

- Use lubricant to Protect and Maintain

Put anti-rust spray or grease on moving parts inside H brace brackets to stop them from rubbing and wearing down. Lubrication improves movement and protects hardware parts from environmental impact.

- Environmental Exposure Considerations

Use stainless steel or anti-corrosive materials to make your H bracket sign holder resistant to marine saltwater and high-humidity environments. This material holds up well against severe conditions and preserves its ability to handle weight.

- Avoiding Overloading

Keep H bracket use within the marked load limits. Keep the bracket load below its testing range to prevent destruction of the hardware.

- Replacing Damaged or Weak Brackets

Replace your aluminum or metal H bracket without delay if you spot substantial signs of damage. Your structure stays safe and strong through this practice.

Conclusion

The selection of appropriate H brackets determines how well structural components stay strong and last for years. Our exploration has reviewed all main H bracket information from basic terms to material choices and installation steps. Choosing an appropriate H bracket for your situation and surroundings helps prevent damage expenses and keeps the product running smoothly. Routine checks combined with correct repair work and reliable materials create strong H brackets that last longer. Choose brackets that will keep you safe while staying strong and functional through time.