Beryllium Copper Stampings Guide – Everything You Need to Know

Table of Contents

ToggleWhat Is Beryllium Copper?

Beryllium copper is a precipitation hardening copper alloy applied in situations where strength and conductivity are important. It usually includes 0.5 to 3 per cent of beryllium, and minute impurities of nickel or cobalt. The alloy structure is very sensitive to heat treatment, which enhances tensile strength and hardness. Formability is also governed by temper condition, meaning that you select softer tempers when doing bending or forming processes.

Key Physical and Mechanical Properties of Beryllium Copper Stampings

- Electrical conductivity characteristics

- Thermal conductivity

- Fatigue resistance

- Corrosion and oxidation resistance

- Non-magnetic properties

- Non-sparking characteristics

- Malleability in annealed condition

- Ability to form complex shapes

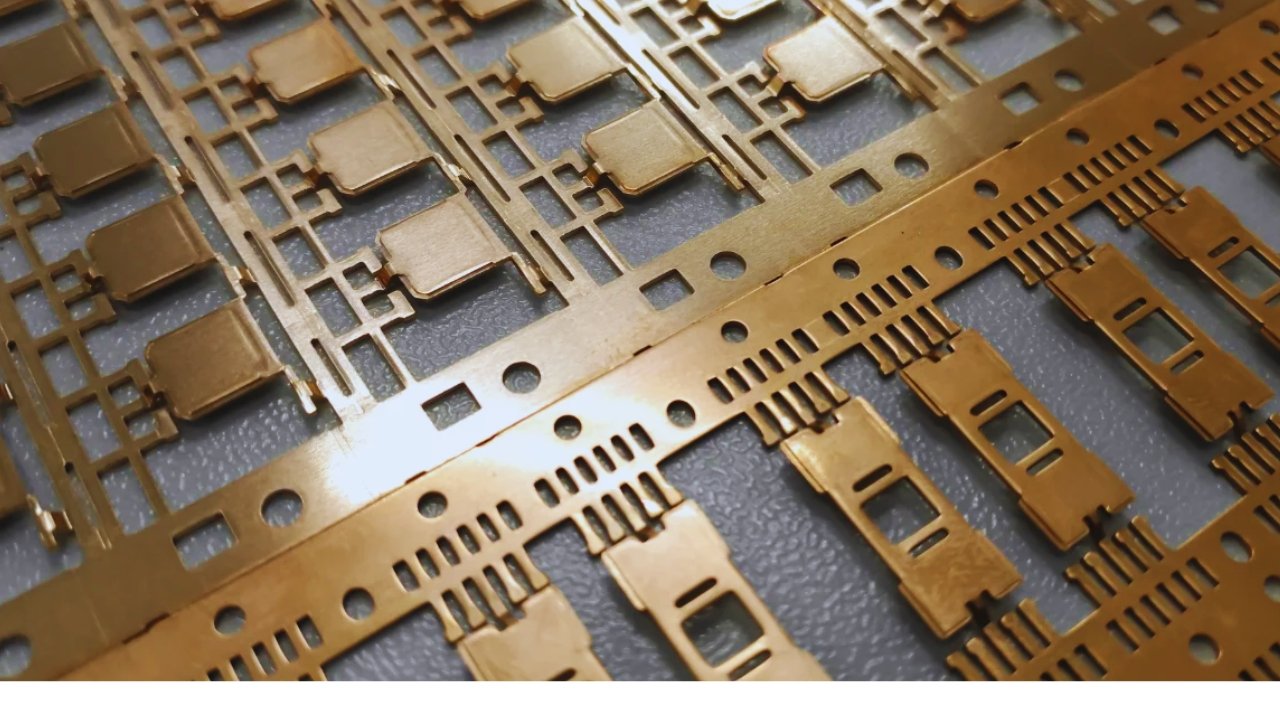

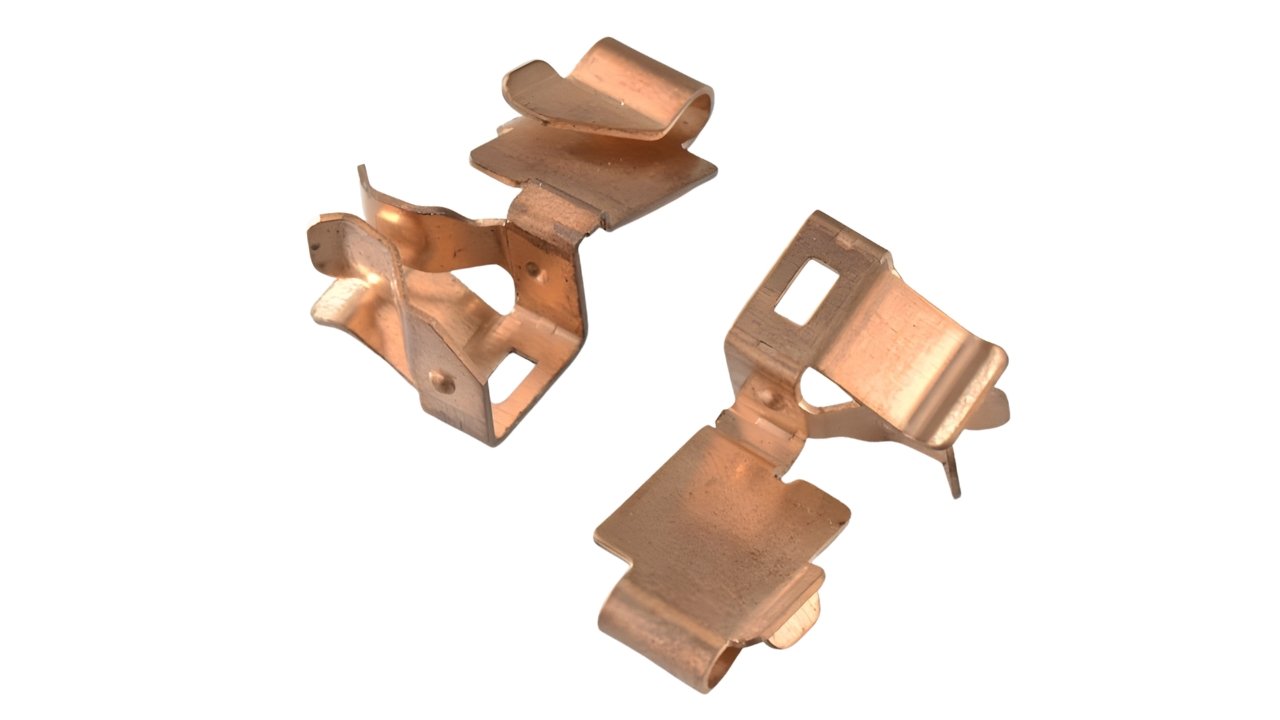

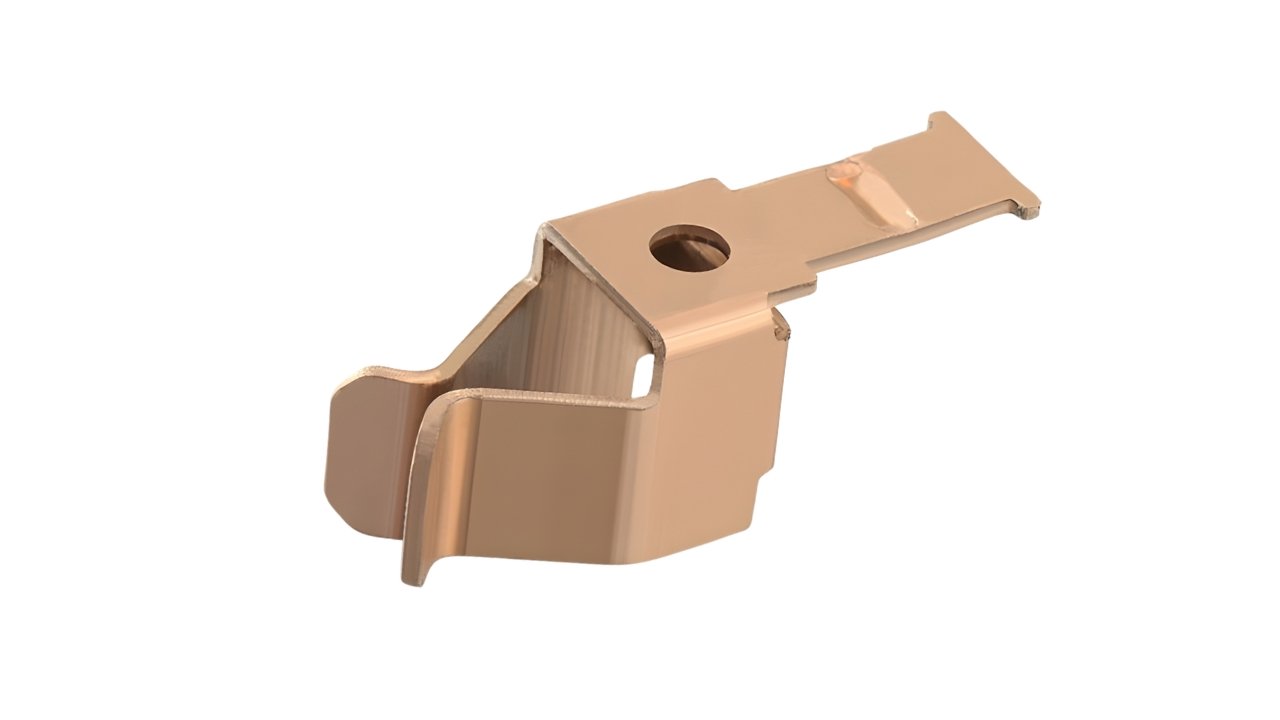

Understanding Beryllium Copper Stampings

Beryllium copper stampings are the accuracy metal forming that involves beryllium copper alloys. It aims at attaining strength, elasticity, and corrosion resistance to your parts. You maintain uniform shapes and close tolerances and improve functional performance. Knowledge of this process will assist you in choosing the proper materials and processes to produce stamped components that are dependable and durable.

Beryllium Copper Stamping Customized – Key Characteristics

- High Strength-to-Weight Ratio: Beryllium copper is a combination of high strength and low weight. You are able to create components that are able to sustain mechanical stress and remain lightweigh.

- Excellent Fatigue Life in Cyclic Applications: The copper beryllium alloy is sustained in repeated use. You have the advantage of longer life parts that are not easily cracked during high-cycle operations.

- Dimensional Stability After Heat Treatment: Beryllium copper retains its shape following heat treatments. Complex patterns can be stamped without distortion or warping.

- Recyclability and Sustainability Considerations: The material can be recycled repeatedly without any loss of property. You are involved in environmental friendly production and conservation of resources.

- Reliability in Harsh Environments: It resists corrosion, wear and high temperatures. Components can be relied on to work under harsh conditions.

- Compatibility with Plating and Finishing Processes: Beryllium copper can be coated and finished. You end up with high quality of surfaces both functional and decorative.

Comparison with Other Copper Alloys

When choosing copper alloys for beryllium copper stampings, you must weigh strength, conductivity, cost, and formability carefully. Material selection affects stamping quality, durability, and long-term performance. Down below is the comparison between key copper allows used in stamping:

Alloy | Strength | Conductivity | Cost Level | Formability | Typical Applications |

Beryllium Copper | Very high | High | High | Moderate (annealed condition) | Springs, connectors, critical contacts |

Brass | Low to moderate | Moderate | Low | Excellent | Decorative and light-duty parts |

Phosphor Bronze | Moderate | Moderate | Moderate | Good | Switches, springs |

Copper-Nickel-Silicon | High | High | Moderate | Good | Automotive connectors |

Pure Copper | Low | Very high | Moderate | Excellent | Bus bars, heat sinks |

Copper-Nickel | Moderate | Low | Moderate | Good | Marine applications |

Beryllium Copper Stamping Methods

Progressive Stamping

Progressive die stamping is an operation that incorporates several operations in one press cycle. You can make complicated components effectively using it. Every station does a certain operation, like cutting, bending or punching. High volume production with uniform accuracy can be obtained. This procedure saves on handling time and wastage of materials. It is applicable to automotive, electronics, and appliance parts. You have also an opportunity to design dies to fit specialized designs. Even complex geometries have tolerances that are tight. You will not lose speed with the right setup, and at the same time you will not compromise quality. You have the advantage of reduced defects and shorter production cycles.

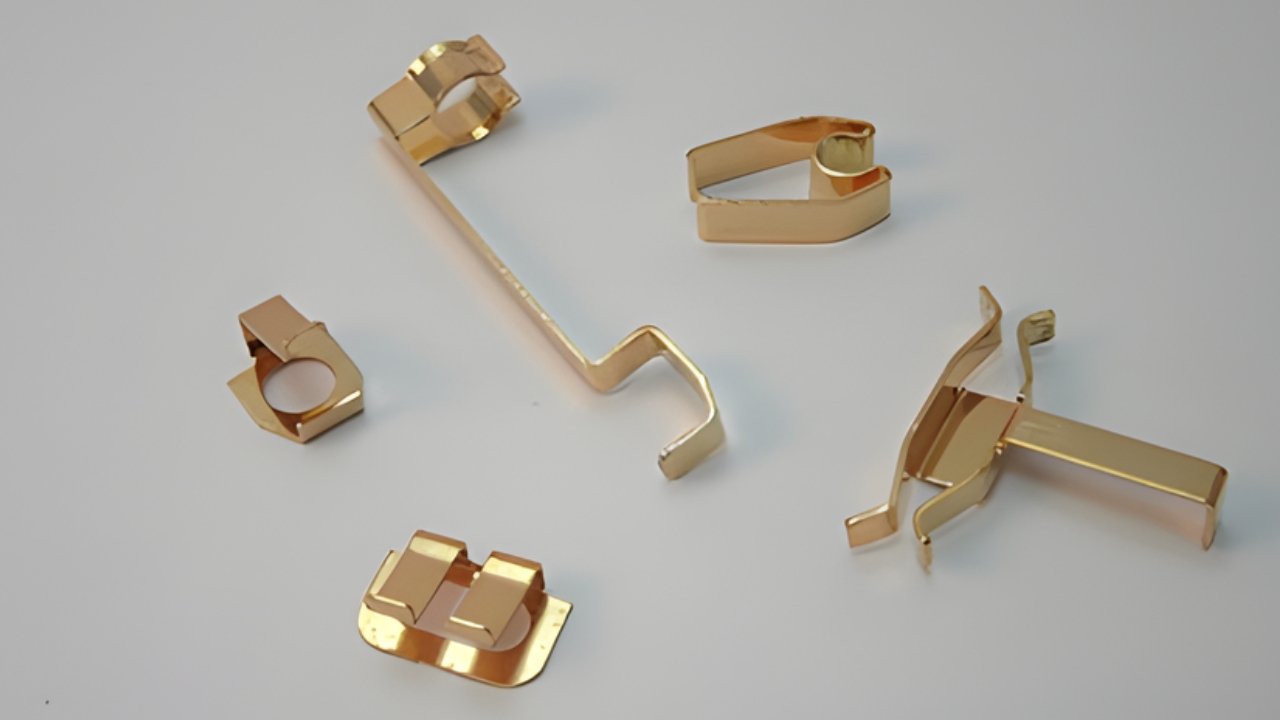

Fourslide Stamping

Fourslide stamping in beryllium copper stampings involves the use of four moving slides to form metal in different directions. You are able to make complex components that cannot be easily made using conventional presses. It is suitable when dealing with small to medium components that have complicated bends. You are able to make wire shapes, clips, and brackets. It involves very nice tooling and operators. It enables forming of multiple planes in one configuration. You get flexibility in diverse designs and prototypes. It is easy to handle materials as opposed to progressive die. You are able to minimize secondary operations without compromising the accuracy.

Key Stamping Operations

- Blanking

- Piercing

- Forming

- Coining

Core Stamping Operations and Their Purpose

Operation | Purpose | Key Considerations for BeCu |

Blanking | Cutting the profile | Tight clearances reduce burrs |

Piercing | Creating holes and slots | Proper venting prevents deformation |

Forming | Creating bends and shapes | Must be done in softer temper |

Coining | Adjusting contact surfaces | Improves contact force and precision |

Customized Beryllium Copper Stamping Process

Step 1: Material Selection and Coil Preparation

The selection of the appropriate grade of copper beryllium alloy and temper guarantees the maximum strength and conductivity. The thickness and width of the coils should be similar to your stamping needs. Use of appropriate lubricants lowers the friction and avoids surface damage during stamping. Direction of grain is a very essential factor in bending and forming, which will assist you in preventing cracking and ensure even mechanical properties.

Step 2: Tooling and Die Design

Tool steel or carbide inserts of high quality increase the life of the die and ensure accuracy. Dies coating is used to reduce wear and galling. Tolerances are very important and you can obtain the exact dimension and uniform quality of parts. Die design guarantees efficiency in the mass production.

Step 3: Blanking and Piercing

Blanking cleans up the outer profile of the part. Piercing forms slots, holes, and features with critical features. Burr control eliminates assembly problems and ensures dimensional stability. Close inspection guarantees the uniform quality in every stamping batch.

Step 4: Forming and Bending

Forming is done in an annealed state so as to minimize the risk of cracking, which is essential for maintaining the integrity of a beryllium copper stamping part. You have to manage deformation in order to avoid warping. Spring-back is used to maintain the desired shape of parts. Constant shaping enhances functionality and assembly fit.

Step 5: Coining and Feature Refinement

Coining varies local thickness in order to enhance contact force. Small details are smoothed out to enhance dimensional accuracy. This is done to improve electrical connectivity and keep parts within design requirements.

Step 6: Heat Treatment and Age Hardening

Age hardening increases mechanical properties and stability. Oxidation is inhibited by controlled atmosphere furnaces. Dimensional stability is taken care of to prevent distortion. To ensure reliability in the critical application, you must check quality.

Step 7: Surface Finishes for Beryllium Copper Stampings

Surface finishing improves conductivity, resistance to corrosion and wear. Widely used finishes are gold over nickel, matte tin, silver plating, black oxide and passivation. Its selection is based on electrical requirements, environmental exposure, mechanical wear, and cost.

Step 8: Quality Control and Inspection

Strict checking guarantees performance of parts. Testing is performed in the form of conductivity testing, alloy testing, microstructure testing, dimensional testing, and surface testing. High-reliability industries require process control, and you are confident in every stamped part.

Industries That Use Beryllium Copper Stampings

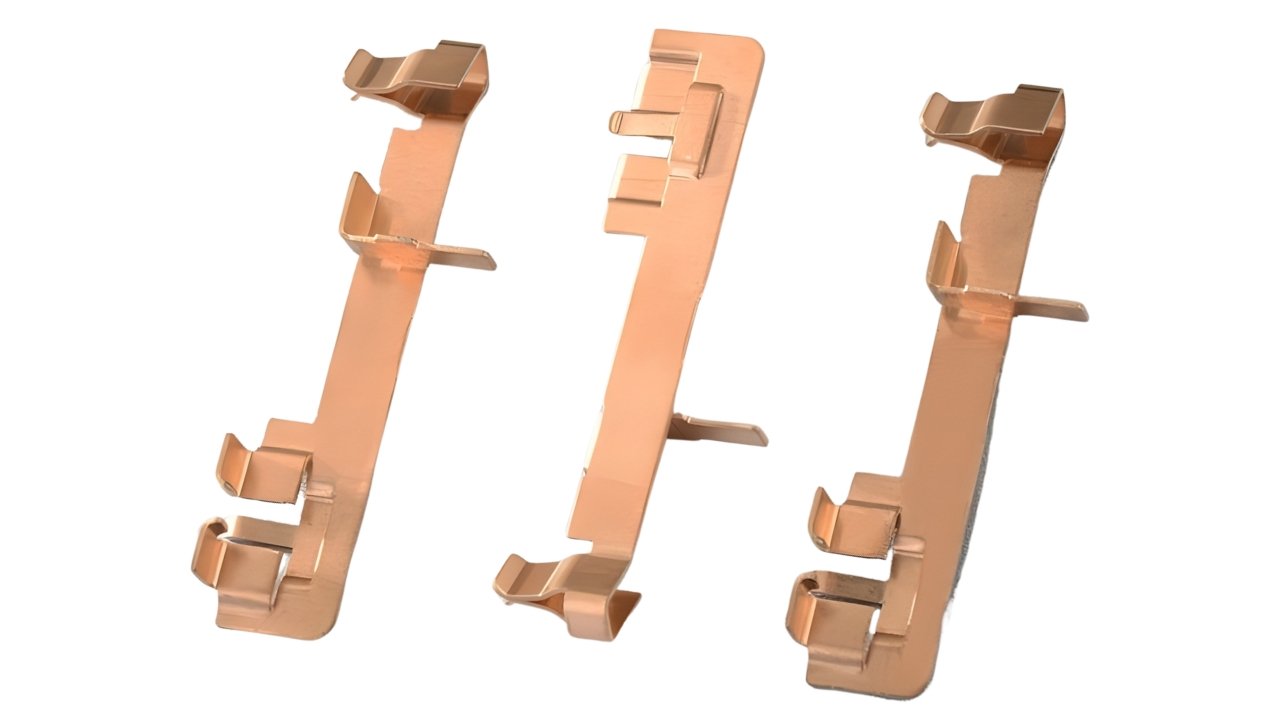

Electrical and Electronics

Beryllium copper stampings offer robust, tough and conductive components. Connectors, contacts, and switches provide high-quality performance. Relay components can be trusted to operate under repeated electrical loads.

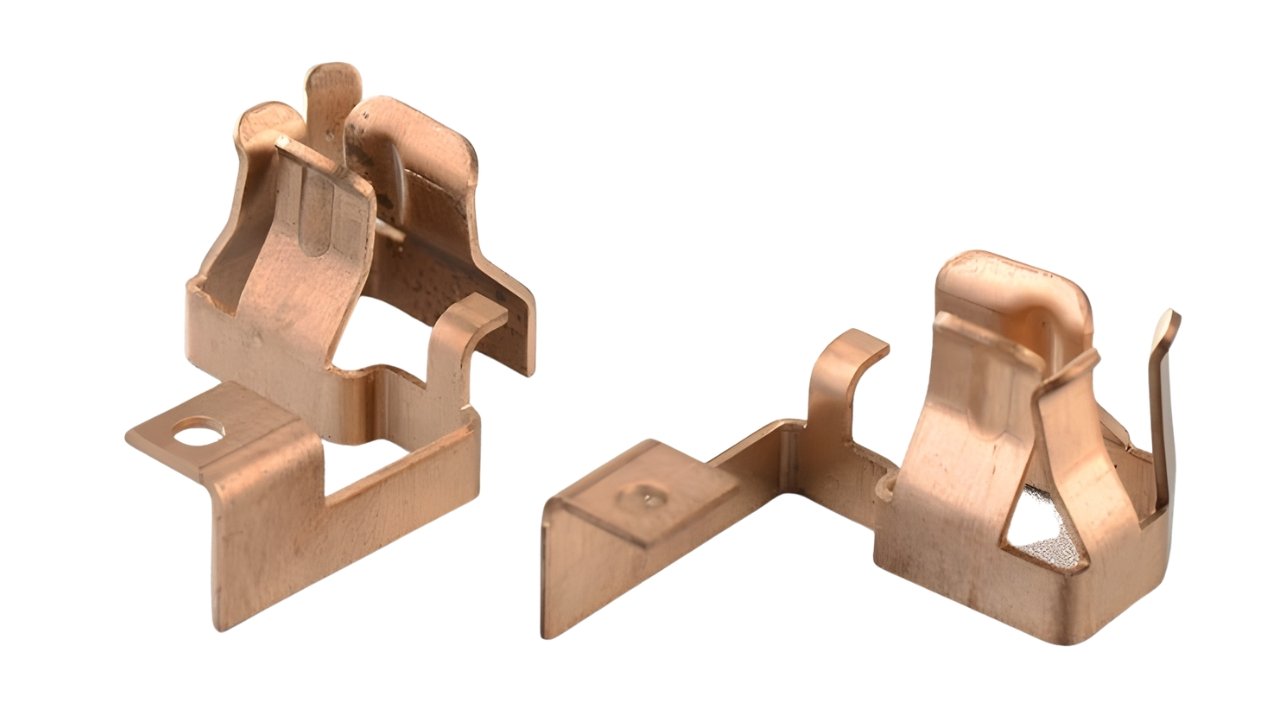

Aerospace

Beryllium copper stamping parts are strong and lightweight in aerospace. The sensors, battery clamps and engine parts are resistant to vibration and high temperatures. These stampings can be relied upon in critical safety parts.

Medical

Non-magnetic corrosion-resistant materials are needed in medical tools. Beryllium copper is used as surgical instruments, MRI-compatible parts, and catheter springs. You are able to be accurate and safe in sensitive medical use.

Defense and Energy

Military and energy industries require security in extreme conditions. Beryllium copper is used in explosion-proof equipment, in non-sparking tools, and in rugged connectors. You will be able to rely on these parts to perform in a safe manner.

Automotive

A conductor and conductive materials used in automotive systems must be durable. Beryllium copper is useful with engine sensors, EV battery contacts, and terminals. You may improve the work of the vehicles and withstand wear and heat.

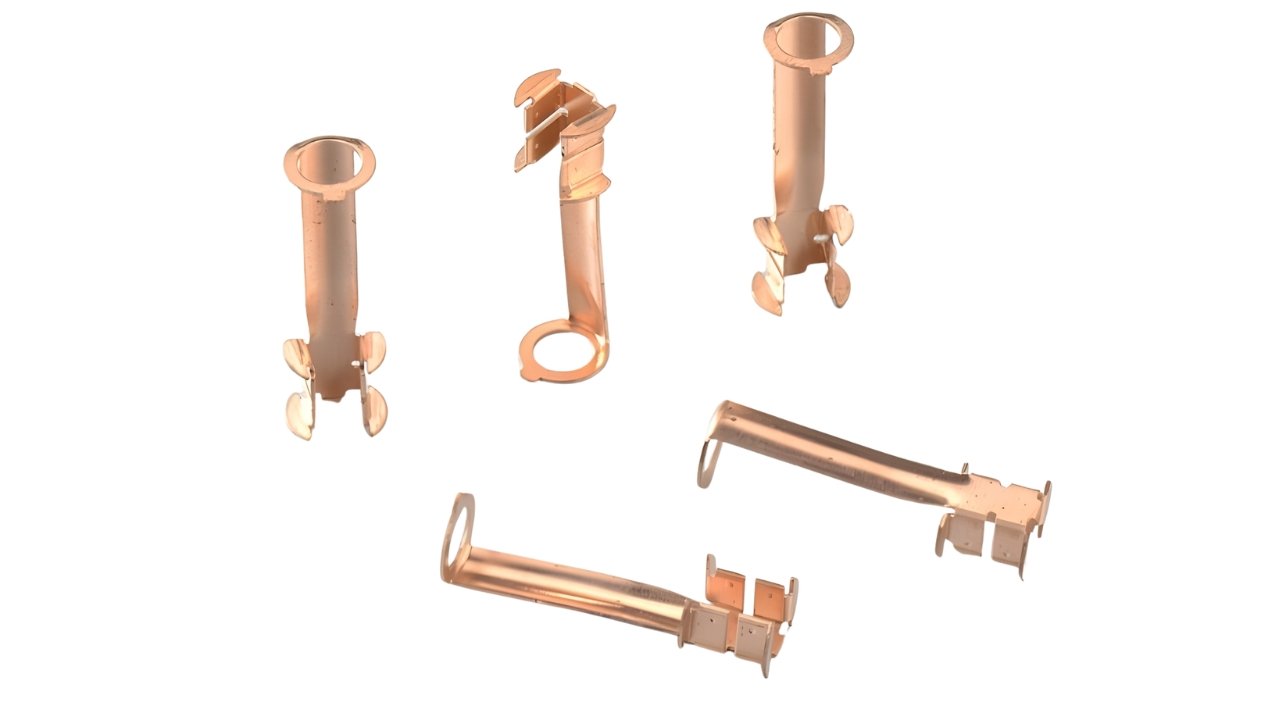

Common Beryllium Copper Stamping Parts

- Heat sinks: Heat sinks are effective in dissipating heat, and you have the advantage of the high thermal conductivity of BeCu. It keeps your machines cool.

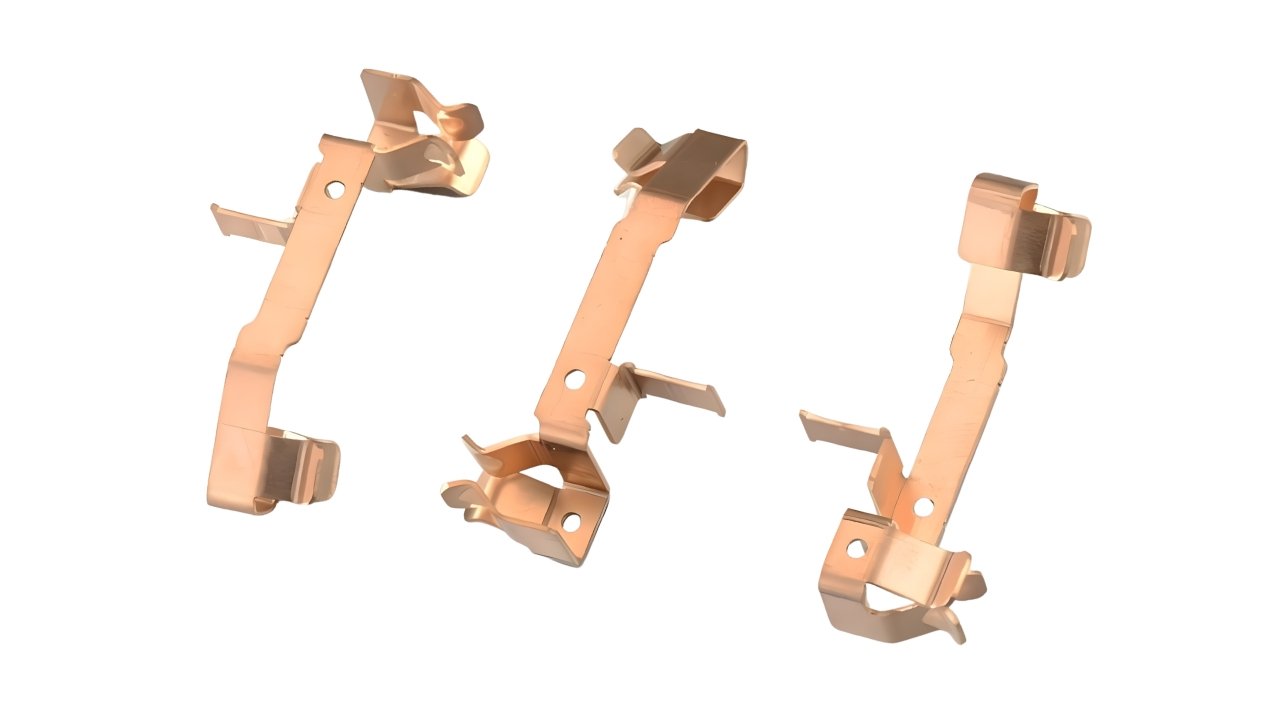

- Electronic connectors: Electronic connectors need to be durable and you will benefit with the high strength and corrosion resistance of BeCu.

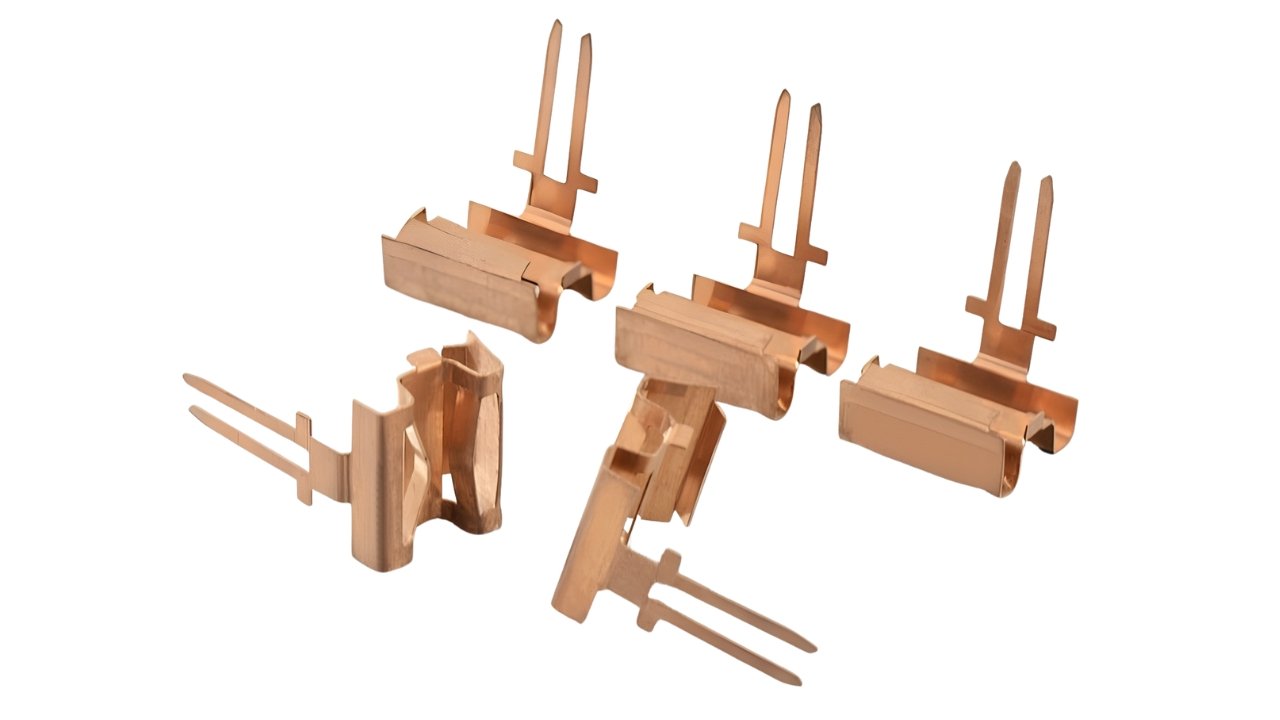

- Electrical contacts: Electrical contacts are dependable in carrying current. You can rely on the high conductivity of BeCu to avoid the loss of energy.

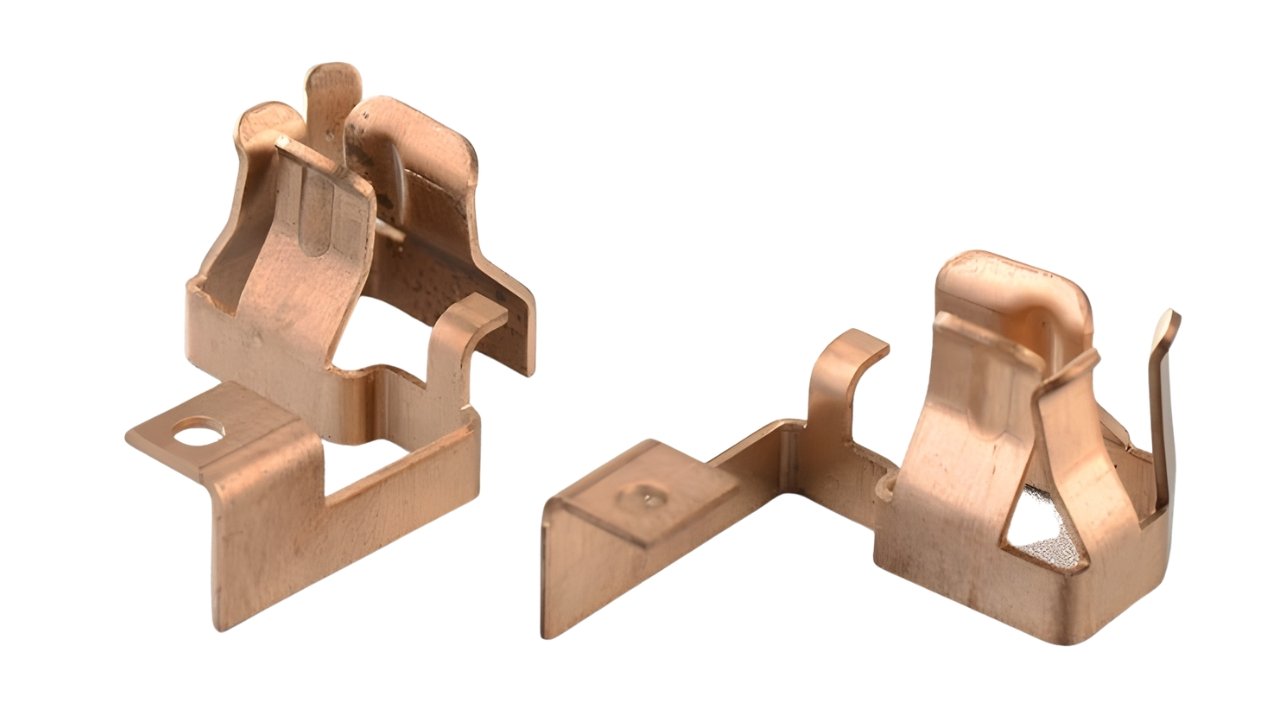

- Relay components: Relay components are efficient in switching and you enjoy long life courtesy of the fatigue resistance of BeCu.

- EMI shielding elements: EMI shielding prevents interference. You count on the conductivity and formability of BeCu to provide accurate protection.

- Switch components: Switch components must be resilient. You have the spring-like nature of BeCu and good conductivity.

- Spring connectors: Spring connectors are those that have a tight contact when under repeated stress. You depend on the elasticity of BeCu to provide stable performance.

- Small precision springs: Small precision springs offer precise tension. You benefit with the elasticity and dimensional stability of BeCu when you produce beryllium copper spring.

- Connect terminals: Connect terminals relay current with a high degree of reliability. You have the conductivity and mechanical strength of BeCu.

- Contact terminals: Contact terminals are long term contacts. You can rely on the resistance to corrosion and flexibility of BeCu.

- Crown spring: Crown springs provide constant force. You love the fatigue resistance and spring memory of BeCu.

- Spring connect: Spring connect components guarantee stable connections. BeCu elasticity provides you with steady performance.

- Spring contact: Spring contact sustains pressure during vibration. You count on the durability and high conductivity of BeCu.

- Beryllium copper spring terminals: Spring terminals are a combination of resilience and conductivity. You enjoy the power and corrosion resistance of BeCu.

- Connect: The connect components must be accurate and robust. BeCu can be relied on to keep good relationships.

Engineering and Design Considerations

- Design for Manufacturability (DFM): Reduce machining operations by simplifying components at the early design stage. You are to come up with assembly-friendly features. Complex geometries and tight tolerances should be avoided. You have to strategize on how to join and survive. You are able to match design and methods of manufacturing. DFM is cost and time saving.

- Bend Radii and Forming Limits: Keep the bends within material limits to avoid cracking. You ought to choose right radii in process forming. Check sheet thickness and bend radius. You should consider springback effects. Forming can be simulated in CAD. Correct radii reduce scrap.

- Contact Force Requirements: Design interfaces with sufficient force to be reliable. You are supposed to compute pressures so as to prevent surface overload. Take into account dynamic forces. You need to make sure that it can last. You may prototype to make assumptions true. Function is preserved by proper contact.

- Plating Allowances: Add dimensions with coating thickness. You need to change tolerances depending on the variance in plating. Lopses in deposition can have an impact on assembly. You should provide min-max thickness. Suppliers can be consulted on realistic ranges. Interference is prevented by proper allowances.

- Tolerance Stack-up: Test cumulative deviations in assemblies. You can find out the influence of every tolerance on fit. Take into account linear and geometric variations. There are critical dimensions which you need to take seriously. Tolerances can be tightened where they are required. Issues are avoided with proper stack-up.

- Material Selection Tradeoffs: Trade off strength, weight and cost and corrosion. Select materials that should be performance without overdesign. Take into account machinability and surface finish. You have to consider durability and budget. You are able to consider thermal and environmental effects. Correct selection increases life expectancy.

Sheetmetalmasion – Experienced Metal Stamping Manufacturer

Engineering Expertise

At Sheetmetalmasion, all stamping projects are driven with precision engineering, including the capability to supply beryllium copper stampings solutions for demanding applications. You receive professional advice on design, materials and tolerances. The problems are detected at an early stage to avoid expensive mistakes. Compound forms and alloyed metals are worked effectively. You have the advantage of elements that are of high quality specifications at all times. The staff makes sure that your products work effectively in the real world.

Process Optimization

Productivity is incorporated at each production stage. You have quicker production and less waste of materials. Bottlenecks are dealt with as they arise in order to ensure smooth workflow. Reliability and consistency are improved by automation and smart scheduling. You enjoy streamlined operations that save time and money. Each phase will keep your key elements on time.

Tooling Design Capabilities

Precision and longevity of any project is guaranteed with custom tooling. You receive instruments that suit your unique needs. The smart design reduces wear and maintenance. Consistency in accuracy is accomplished within several production runs. You are provided with stamped parts of a steady quality and fine finishes.

Quality Certifications

All processes at Sheetmetalmasion are regulated by strict quality standards. You can rely on parts to comply with industry and safety standards. Periodic audits ensure faultless production. During inspections, reliability and performance in the most demanding applications are guaranteed. You develop trust in the products that always surpass expectations.

Faster Production Cycles

Efficiency in time is a priority in all projects. You have the advantage of shorter lead times without loss of accuracy, especially when utilizing beryllium copper stampings customized solutions. Modern equipment and professional workers maintain the flow of work. Production planning predicts possible delays thus making sure the deadlines are met. You have a quicker market readiness of your products.

Reduced Risk in Critical Applications

Sensitive applications require accuracy and consistency. You enjoy extensive testing and strict quality control. Each component is checked to be in safe operation. Failure or recalls risks are reduced. Components can be relied upon to work perfectly under pressure.

Beryllium Copper Limitations and Considerations

- More expensive material than other copper alloys.

- Special heat treatment needs.

- Safety measures in machining or grinding (dust control).

- Demand of controlled manufacturing processes.

Conclusion

Beryllium copper will continue to be a critical material to be used in applications that require strength, conductivity and durability. Beryllium copper stampings relies on the selection of materials, stamping accuracy and high quality control. When you know such considerations, you can be confident that your components will last. To create complex designs, advanced stamping technologies such as progressive, fourslide are used to produce them efficiently. Collaborating with established wholesale beryllium copper stamping manufacturers, such as Sheetmetalmasion ensures streamlined production, accelerated cycle time, and low-risk in critical applications. In selecting the appropriate processes and skills, you optimize the positive impacts of beryllium copper in the contemporary industries.