Tube Laser Cutting – Materials, Process, Machines, and More

Tube laser cutting is evolving, allowing metal tube cutting to be faster, accurate, and repeatable. Being aware of the basics will assist you in fulfilling the objective. The guide covers the principles of lasers, specific processes involving tubes, supported materials, types of tube laser cutting machines and their practical use. You will also understand the comparison of fiber and CO2 laser, the features of equipment that are most important and how to select the appropriate system to suit your production requirements.

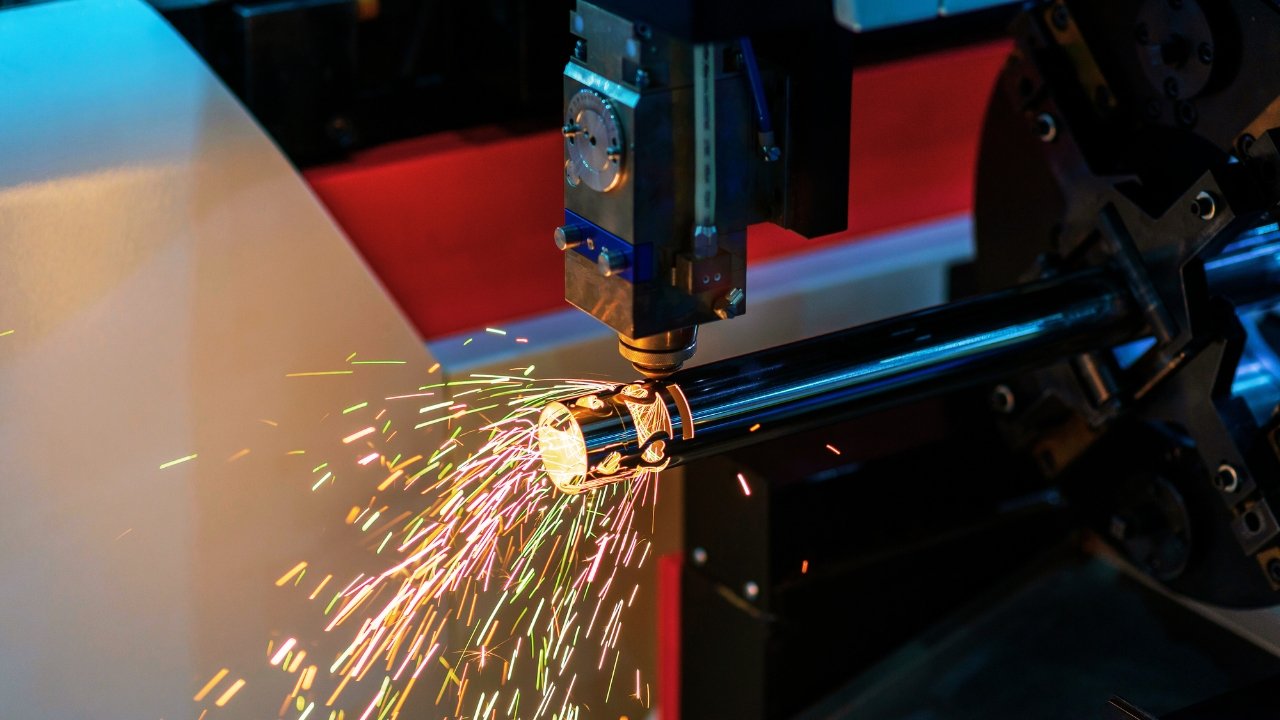

What Is Laser Cutting?

Laser cutting involves coherent light which is amplified and concentrated into high-energy. This energy fuses, evaporates or burns material with great precision. Computer- guided systems allow you to adjust the beam path to achieve consistency. Laser cutting does not exert any mechanical force on the workpiece, as compared to conventional thermal cutting. Fiber lasers are primarily used in industrial systems because they are faster and more efficient and CO2 lasers are used on thicker non-metal materials. Older and specialized laser varieties continue to serve specialized industry applications.

What Is Tube Laser Cutting?

Metal tube cutting is a process that involves the application of focused laser beams in order to cut hollow and structural parts with high precision. You insert metal tubes in the CNC-controlled systems that rotate and place profiles automatically. The process produces clean edges, sophisticated slots and precise joints. Tube is different to pipe in terms of dimensions and purpose. Pipes are pressure rated and tubes are dimensional tolerated. Laser systems work round, square, rectangular, and custom structural profiles effectively and with precision.

Tube Sizes, Shapes, and Profiles

Standard Tube Lengths and Industry Norms

The standard tube lengths differ depending on the region and supplier. Six-meter and twelve-meter formats are common all over the world. American markets like twenty-foot sections. Make sure to check tolerances and straightness. The correct choice of length enhances handling efficiency, minimizes scrap, and facilitates the correct process of cutting operations.

Supported Cross-Section Shapes

The round, square, rectangular, oval, and custom profiles are supported by manufactures. You select shapes, according to load direction and design requirements. Complex profiles need to be aligned accurately. Effective selection of shapes enhances the distribution of strength, eases assembly, increases visual homogeneity, and facilitates laser cutting processes.

Open vs Closed Profiles

The channels, angles, and beams are open profiles. Tubes and hollow sections are considered as closed ones. Clamping techniques will need to be changed. Open shapes require further assistance. Correct handling eliminates deformation, enhances dimensional stability, preserves surface quality and provides uniform machining accuracy.

Material Tube Types for Laser Cutting

# | Material | Characteristics | Hardness (Brinell HB) | Reflectivity | Typical Laser Thickness Range (mm) | Notes / Cutting Considerations |

1 | Carbon Steel | Strong, affordable, widely used; easy to weld and form | 120–180 HB | Low | 0.5 – 20 mm | Cuts easily with both fiber and CO2 lasers; minimal reflectivity issues |

2 | Stainless Steel | Corrosion-resistant, durable, moderate toughness | 150–220 HB | Low to medium | 0.5 – 12 mm | Weld seams may require sensing; fiber lasers preferred for speed and quality |

3 | Aluminum | Lightweight, non-ferrous, good corrosion resistance | 40–100 HB | High | 0.5 – 8 mm | High reflectivity requires fiber laser; heat conduction can cause warping on thin tubes |

4 | Copper | Excellent electrical/thermal conductivity, non-ferrous | 35–120 HB | Very high | 0.5 – 6 mm | Reflective; fiber laser mandatory; CO2 lasers ineffective; may require slower cutting speed |

5 | Brass | Alloy of copper & zinc; decorative and functional | 55–150 HB | High | 0.5 – 6 mm | Fiber laser recommended; reflective; careful power adjustment needed for quality edges |

6 | Titanium | Lightweight, high strength, corrosion-resistant | 220–350 HB | Medium | 1 – 6 mm | Harder to cut; slower feed rate; fiber lasers preferred for precision and heat control |

7 | Nickel Alloys / Inconel | High-temperature resistance, tough, corrosion-resistant | 200–400 HB | Medium | 1 – 6 mm | Hard material; slower cutting; fiber lasers with precise parameters necessary |

8 | Composite Tubes | Metal-matrix or layered tubes | Varies (50–300 HB) | Varies | 1 – 6 mm | Laser feasibility depends on metal content; reflective or coated layers may require process tuning |

How Tube Laser Cutting Machines Work

Step 1: Tube Loading

The machine is loaded with raw metal tubes manually or using automated systems. The tube is fitted lengthwise so that it can be cut properly at the beginning.

Step 2: Clamping and Positioning

The tube is firmly held by CNC-controlled chucks. These chucks focus the tube and enable the accurate rotation and linear feeding of the cutting operation.

Step 3: CNC Synchronization

The CNC controller coordinates tube rotation, tube feed and cutting head movement. Such coordination allows one to cut around the whole tube circumference accurately.

Step 4: Laser Generation and Delivery

Fiber laser produces a powerful beam that is directed to the cutting head via a fiber-optic cable with less loss of power.

Step 5: Beam Focusing and Head Control

The laser beam is narrowed to a specific position by the cutting head. Automatic focus control keeps the cutting conditions optimum and tilting heads permit bevel cuts where necessary.

Step 6: Piercing

The laser penetrates the wall of the tube with controlled parameters. Assist gases are used to spray off molten material and defend the cutting optics.

Step 7: Cutting

The tube rotates and feeds as the laser tracks predetermined toolpaths. Holes, slots, contours, miters, end cuts, etc. are highly precise.

Step 8: Weld Seam Detection and Compensation

The weld seam of the tube is detected by sensors or cameras. The machine changes cutting position and parameters to sustain quality along the seam.

Step 9: Tube Straightness Compensation

Bowing or dimensional differences in tubes is detected by touch probes or vision systems. To ensure accuracy, the CNC system automatically adjusts.

Step 10: Part Separation

The tube is split and the completed parts are detached. Part drop controlled controlled part drop controls damage particularly with long or thin-wall parts.

Step 11: Part Unloading

Conveyors, bins or automated sorting devices are used to unload finished parts. Efficiently handled are parts of different length.

CO₂ Laser vs Fiber Laser in Tube Cutting

Laser Generation and Beam Delivery

Fiber lasers produce light with the help of diode modules and transmit beams with the help of fiber-optic cables, making them highly suitable for fiber laser tube cutting. Reduced optical components minimize errors in alignment and losses in transmission. CO2 lasers use gas excitation and beam delivery using mirrors making the systems more complex. Fiber delivery also ensures consistent quality of the beam and enhances cutting stability and reliability in operation.

Beam Quality, Wavelength, and Power Density

Fiber lasers generate smaller beam diameters to enhance better kerf control and accuracy. A greater power density provides smoother edges and narrower tolerances. CO2 lasers produce broader beams which restrict fine detail accuracy. In most industrial metals, Fiber wavelengths are good absorbers, which increases laser cutting speed and thermal efficiency.

Cutting Performance Comparison

Fiber lasers provide higher cutting speeds and reduced piercing times. Fiber laser tube cutting enhances the production capacity. CO2 lasers are slower in piercing and contours modification, which lowers throughput. Fiber systems deal with more complicated geometries with increased motion stability yielding higher accuracy and repeatability.

Material Compatibility

Fiber lasers can be used safely to treat reflective materials including copper, aluminum, and brass and eliminate the risk of damage. CO2 lasers are more susceptible to reflection and need extra protection. Both systems are efficient in cutting steel and stainless steel according to the thickness and application requirements.

Energy Efficiency and Operating Costs

Fiber lasers have increased wall-plug efficiency and less power consumption, which decreases the operating costs. Gas excitation losses make CO2 lasers more energy-consuming, making them more useful and costly to cool. Fiber systems require smaller chillers and less complex cooling, which enhances cost effectiveness in the long run.

Advantages of Tube Laser Cutting

- Speed and Efficiency

Tube laser cutting is extremely quick and a large amount of batches can be cut within a short time. Automation reduces delays, stream lines production and increases throughput overall.

- Superior Precision

The lines that are cut by the process of tube laser cutting machine are very precise and have smooth edges and you can achieve the same result each time. Tight tolerances reduce the additional finishing operations.

- Reduced Labor Intensity

Automation saves the human resources and minimizes the errors that can be made and hence you can attain uniformity in quality. Rather, you can spend people in more productive tasks and administration.

- Cutoff Reflective Materials

Fiber lasers can handle reflective metals and can be used to laser cut tube made of metals like copper or brass without the necessity of damaging the equipment. Good edges are made continuously.

- Reduced Setup Times

Minimal or no fixturing and quick repositioning can save you set-up time, allowing you to easily switch between designs. This flexibility improves the rate of production and workflow.

- Capacity to produce full parts that are ready to assemble

Tube laser cutting components can be assembled or welded. You can integrate components into production and this saves time and money.

Challenges and Limitations of Laser Tube Cutting

- High Initial Investment and Machine Cost

CNC laser cut tube systems entail a high initial capital investment due to part and cutting accuracy. A prudent budgeting is necessary to ensure that there is efficiency in the long run of operations and to avoid unnecessary expenses. - Maintenance Considerations (Fiber vs CO2 Maintenance Differences)

The fiber lasers also need fewer services than the CO2 systems that need regular servicing of the mirror and adjustments. You will maintain good schedules to prevent downtime and maintain high performance. - Material Inconsistencies (Bows, Weld Seams, Surface Defects)

It may also vary in cutting accuracy because of differences in tube straightness, weld seams, and surface finish. Scrap and defects must be minimized before cutting by examining materials. - Limitations on Maximum Tube Thickness and Diameter

Laser power limits the cutting of very thick or large-diameter tube. To be accurate and effective, you should consider design limitations. - Safety Considerations in Laser Operation

Strong lasers are hazardous to the skin and eyes and the environment. In working, you can expect to observe very strict protective measures and safety precautions.

Industry Applications of Laser Cutting Tubes

Automotive Applications

Tubular components are used in automotive engineering to enhance performance and safety. High strength and low weight are useful in chassis parts, exhaust systems and frames. Tubular designs increase fuel efficiency, durability, and crash resistance. They are applied in mass production and custom vehicles by manufacturers to provide a uniform quality and dependability over time.

Aerospace Applications

Lightweight and high-strength of tubular structures are demanded in aerospace applications. Steel tube laser cutting enables the production of precision tubes used in fuselage supports, wing frames and engine mounts to achieve the best strength to weight ratios. Tubes can resist extreme conditions and enhance the aerodynamics and fuel efficiency. Tubing of high quality is in line with stringent safety standards on commercial and defense applications.

Furniture and Design Applications

Contemporary furniture has made use of ornamental tubular forms in furniture such as chairs, tables, and shelving. Minimalist aesthetics are obtained by designers without compromising strength. Tubes allow a modular construction and shape. Residential and commercial spaces are guaranteed of durability of laser cut tubes using high-quality materials that provide both aesthetic and practical value to their users.

Industrial Machinery Applications

Tubular frames, supports, and enclosures are used in industrial machinery to provide stability during load and vibration. Tubes are lightweight with high strength and durability. They ease the construction and maintenance of complex systems. In industry, structural accuracy and long-term performance are guaranteed through precision tubing.

Prototyping and Small-Batch Production

Prototyping involves tubular components to make quick, accurate cycles. Small-batches production has easy customization and quick assembly. Tubes permit cost effective adaptation prior to large-scale manufacturing. Precision tubing is a time- and resource-saving approach to quality that produces professional outcomes.

Comparing Tube Laser Cutting to Sheet Laser Cutting

In the comparison between tube and sheet laser cutting, the power demands vary widely with precision tube lasers generally requiring more max kW to cut thicker and complex profiles. Precision and edge quality are dependent on beam diameter and cutting strategies. Tube lasers are also good with three-dimensional shapes providing you with versatility that sheet lasers do not provide. The speed of cutting is not the only factor of productivity, but loading and unloading also influence the productivity, and therefore the workflow must be optimized to achieve its highest possible output.

Top 5 Laser Tube Cutting Machines

Trumpf TruLaser Tube Series

Trumpf TruLaser Tube Series provides high accuracy in cutting demanding tubes. Its high levels of automation reduce human labor and increase throughput. The embedded software ecosystem allows you to program complex shapes without effort. The machine guarantees accuracy throughout long production cycles. It is capable of working with an extensive variety of tube sizes and materials.

Bystronic ByTube Series

Bystronic ByTube Series is flexible and user friendly to operate. Its automation modules are customizable to the fluctuating production needs. Cuts can be programmed and monitored easily without a lot of training. The machine offers uniform accuracy when it comes to both small and large batches. It strikes a balance between power reduction and operational simplicity to be used daily.

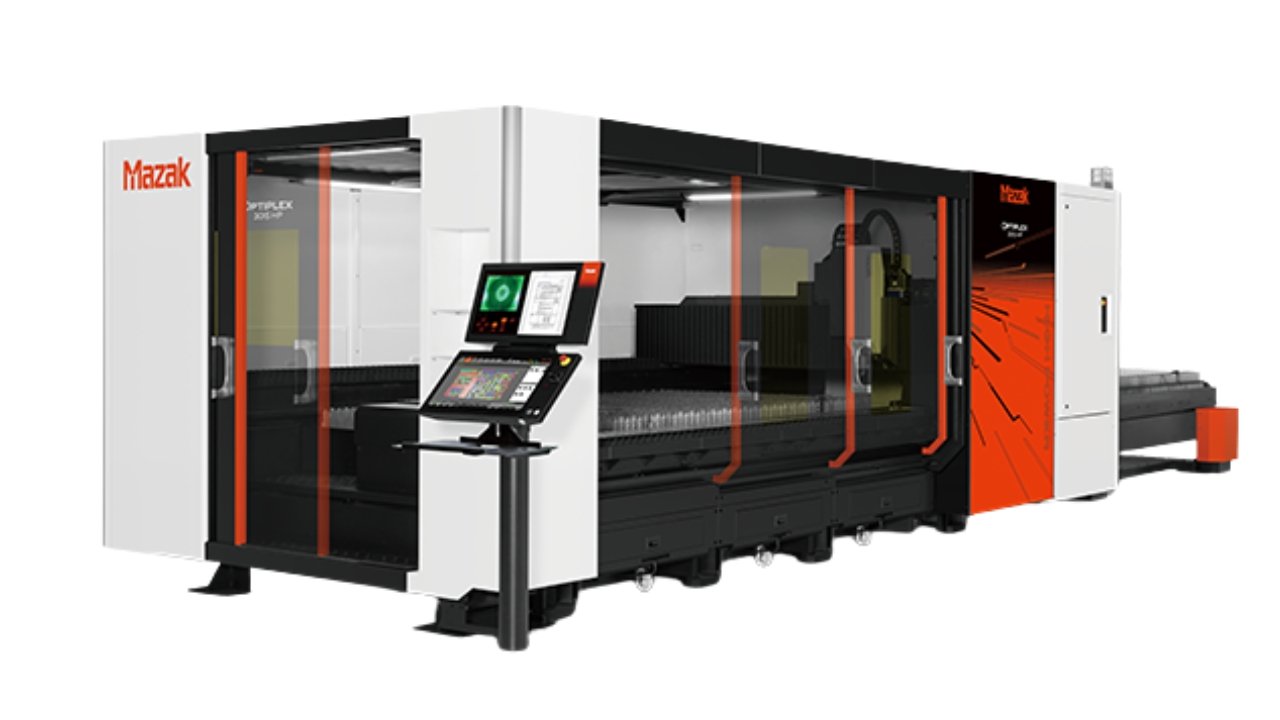

Mazak Optiplex Tube Series

Mazak Optiplex Tube Series is among the best tube laser cutting machines that is effective at high speed tube cutting. Its strong construction contributes to the long working periods and high workloads. You can add it to the current factory automation to have uninterrupted production. The machine ensures uniform quality, even where there is a fast-paced environment, and supports various tube shapes and thicknesses.

Amada ENSIS Tube Lasers

Amada ENSIS Tube Lasers are focused on the cutting of reflective and problematic materials. High-tech sensors automatically set cutting parameters to achieve accurate results. You can count upon solid manufacturer support and maintenance programs. The machine produces clean, precise cuts with the least wastage of materials. It is highly reliable and works effectively in complicated production settings.

Bodor Tube Laser Machines (BCL Series)

Bodor BCL Series offers affordable fiber laser tube cutting systems to cut tubes. Its expandable design expands with your production requirements. You are able to work with small to mid-sized loads without compromising quality. The machine has good performance with easy to use controls. It offers accurate cuts and balances budget and operational efficiency.

Choosing the Right Tube Laser Cutting System

- Define volume and complexity requirements: Find out the number of tubes you are going to work with in one day, and the complexity of the cuts. Consider the production objectives, repeatability and cross-cutting across angles in order to select a system to fit the current and future needs well.

- Material types and tube sizes: Choose what kind of materials and what range of diameter and wall-thickness you will be working with. Ensure that the laser system can cut all the alloys and sizes desired without compromising the quality of cut or the machine life.

- Machine automation features: Check loading and unloading, and rotation automation. Automated systems amplify throughput, reduce labor costs and promote precision by involving lengthy production periods.

- Total cost of ownership: Do not just consider the initial cost of buying but also examine amount of energy actually used by the tools, amount of consumables, maintenance and replacement costs. This ensures that it is cost effective in the lifecycle of the machine.

- Support, training, and service: Check local support, training and maintenance services. Quick reaction saves time wastage and ensures consistency in quality production.

Conclusion

Modern fabrication has been advanced with laser cutting of tube, which is fast, precise and versatile. Its compatibility with a range of tube materials, cross-sectional sizes, and elaborate profiles renders it indispensable in automotive, aerospace, furniture, and industrial use. The factors to be keenly considered when implementing a tube laser system include the volume of production, material needs, automation capabilities, overall cost of ownership and support. Through knowing these factors, you will have a consistent quality, efficient workflow, and long-term value. With the changing world of technology, tube laser cutting will go on influencing the fabrication processes by making them more cost effective. The working process of tube laser cutting machine is so accurate and fast in production that can easily meet the demands of various industries.