Aluminum Welding – Principles, Processes, Challenges, and More

The aluminum welding is essential in the contemporary engineering, fabrication, and production processes because of the lightweight, strength, and corrosion resistance of aluminum. Nonetheless, welding the aluminum is quite different than the welding of steel due to its metallurgical characteristics, oxide coating, and thermal characteristics. This full 2026 manual covers the basics of how to weld aluminum, including material knowledge, alloy types, temper, weld process, welding challenges, and best practices to ensure professionals can manage to produce a strong, reliable, and high-quality aluminum weld throughout the industries.

Table of Contents

ToggleAluminum and Its Alloys: Metallurgical Fundamentals

The chemical structure of aluminum is simple and it is found in large quantities in the crust of the earth. It is low density and provides you with great strength-to-weight. Passivation is a natural oxide layer that enhances corrosion resistance. Aluminum is also a good conductor of heat and electricity. Pure aluminum is too soft and not strong enough to be used in demanding applications. The performance is enhanced by alloying elements. Metals that add to strength and durability include copper, magnesium, manganese, silicon and zinc. Wrought alloys of aluminum are classified under a four-digit system. Every number determines structure and coding. The 1000 series is a form of commercially pure aluminum.

Aluminum Alloy Series and Weldability

Series | Main Alloying Element(s) | Typical Tensile Strength (MPa) | Heat Treatable | Corrosion Resistance | Weldability | Typical Applications |

1xxx | ≥99% Aluminium (pure) | 70–185 | ✗ | Excellent | Excellent | Electrical conductors, chemical equipment, piping |

2xxx | Copper | 185–430 | ✓ | Poor–Fair | Poor | Aerospace structures, forgings, high-strength parts |

3xxx | Manganese | 110–280 | ✗ | Very Good | Excellent | Cookware, heat exchangers, roofing, cladding |

4xxx | Silicon | 170–380 | ✓ / ✗ | Good | Excellent | Welding filler wire, automotive parts |

5xxx | Magnesium | 125–350 | ✗ | Excellent | Very Good | Marine structures, pressure vessels, bridges |

6xxx | Magnesium + Silicon | 125–400 | ✓ | Good | Very Good | Extrusions, automotive frames, architectural uses |

7xxx | Zinc (often with Mg, Cu) | 220–750 | ✓ | Fair | Poor | Aerospace, armour plate, sports equipment |

Aluminum Temper Designations and Their Welding Implications

Purpose of Temper Designations

Temper designations are used to describe how processing practices are used to regulate strength and ductility in aluminum. You use these tempers to foresee material behavior in the fabrication. The choice of temper is important in the welding process since heat may lower the strength, make the heat-affected region soft, and alter mechanical performance. Knowledge of tempers guides you to the correct alloy welding processes, and post-weld processes to make dependable joints.

Basic Temper Types

- F (As fabricated): Metal remains untreated after shaping. You get natural properties from manufacturing processes.

- O (Annealed): Heat treatment softens the metal. You gain maximum ductility and improved formability.

- H (Strain hardened): Controlled cold working increases strength. You trade some ductility for hardness.

- W (Solution heat treated): Temporary unstable condition after heat treatment. You must age it further.

- T (Thermally treated): Heat treatment strengthens the alloy permanently. You achieve stable mechanical properties.

Sub-Divisions of H Tempers

H Temper | Description | Annealing Level | Strength Effect | Typical Applications / Notes |

H1x | Strain hardened only | None | Medium–High | Sheet and plate where strength > ductility |

H2x | Strain hardened then partially annealed | Partial | Medium | Improved ductility with controlled strength |

H3x | Strain hardened and stabilised | Stabilised | Medium–High | Good dimensional stability, elevated temp use |

H4x | Strain hardened and coated (painted/lacquered) | None | Medium–High | Packaging, architectural panels |

Sub-Divisions of T Tempers

T Temper | Heat Treatment Description | Aging Type | Strength Level | Typical Notes / Uses |

T1 | Cooled from hot shaping, no solution treatment | Natural | Low–Medium | Basic strength, good formability |

T2 | Hot shaped → cold worked → naturally aged | Natural | Medium | Improved strength over T1 |

T3 | Solution heat treated → cold worked → naturally aged | Natural | Medium–High | Aircraft sheet, good fatigue resistance |

T4 | Solution heat treated → naturally aged | Natural | Medium | Good formability, often formed then aged |

T5 | Hot shaped → artificially aged | Artificial | Medium–High | Extrusions, no solution treatment |

T6 | Solution heat treated → artificially aged | Artificial | High | Most common, high strength (e.g. 6061-T6) |

T7 | Solution heat treated → over-aged (stabilised) | Artificial | Medium | Improved dimensional & thermal stability |

T8 | Solution heat treated → cold worked → artificially aged | Artificial | Very High | Maximum strength, reduced ductility |

T9 | Solution heat treated → artificially aged → cold worked | Artificial | Very High | Higher strength than T6, less common |

T10 | Hot shaped → cold worked → artificially aged | Artificial | Medium–High | Extrusions requiring extra strength |

Why Weld Aluminum?

There are definite benefits to weld the aluminum where the weight, durability, and performance are of concern. You get a lot of weight loss over steel, which enhances efficiency in transporting and structures. Aluminum has a natural resistance to corrosion, and this enables you to increase the lifespan of the product without using heavy finishes. It provides good mechanical performance in relation to its weight, and therefore, designs are light and durable. You also have an excellent thermal and electrical conductivity. Its weldability allows elaborate design, allowing more freedom to design and manufacturability.

Is Welding aluminum Hard?

The process of aluminum welding is challenging due to the high thermal conductivity that causes the heat to run out of the weld area fast. You need to use more heat input, thereby elevating the risks of distortion and warping. Hydrogen is absorbed easily by molten aluminum, and confined gas creates porosity as it solidifies. Humidity and contamination of surfaces aggravate this problem. Aluminum is also toughly oxidized and can not fuse properly unless it is clean after thorough cleaning. Hot cracking as opposed to hydrogen cracking is based on the alloy composition and proper filler selection to make the welds stable.

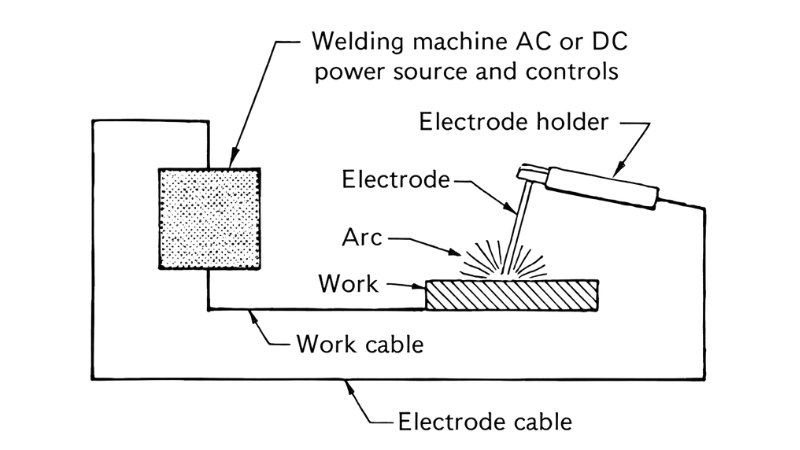

Arc Welding Processes for Aluminum

Arc weld for aluminum is effective in most of alloy series and provides strong and durable joints. You need to remember its limitations with crack sensitive alloys where inappropriate heat or technique may result in defects. Effective control means good welds and durability.

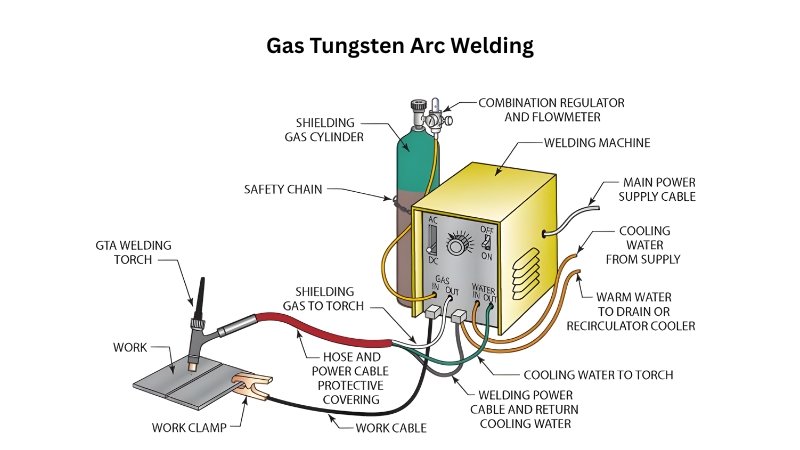

Gas Tungsten Arc Welding (GTAW / TIG)

GTAW involves the use of a clean, precise tungsten electrode that is non-consumable. AC welding offers oxide cleaning effect, thus suitable to aluminum. The process is suitable to both thin and thick sections, and it provides great control of heat input. Although it provides better quality of weld, TIG welding of aluminum is slower and needs high skill of the operator. When the settings and technique are optimized, you can obtain smooth defect-free welds.

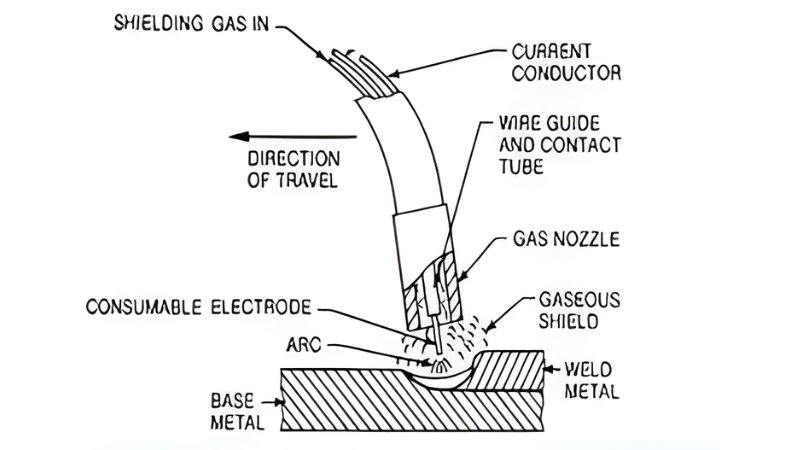

Gas Metal Arc Welding Aluminum (GMAW / MIG)

GMAW supplies a consumable wire into the weld pool continuously to facilitate rapid production welding. You would either choose spray or pulsed spray transfer based on the thickness of material and joint design. MIG welding of aluminum saves operator fatigue and enhances deposition rates. The cleanup process is usually small, but can have spatter. When using proper parameters, you enjoy high quality of the welds and increased productivity.

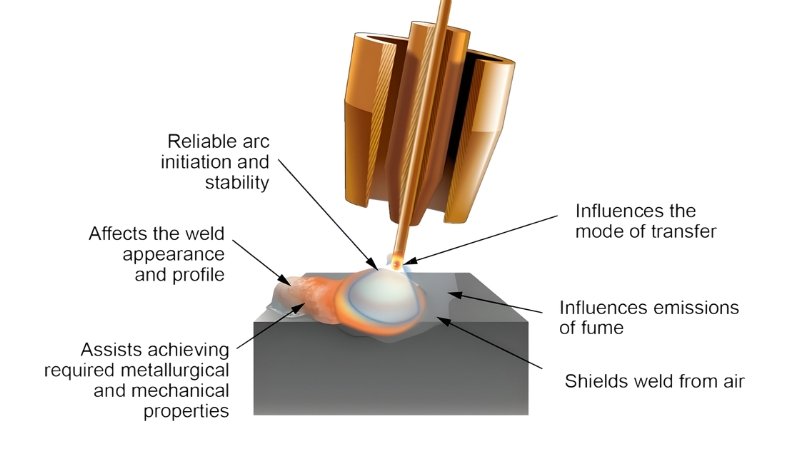

Shielding Gases for Arc Welding Aluminum

Shielding gas helps to prevent oxidation in the weld pool and provides a stable arc performance. Most welding requires the use of 100 percent argon. Argon-helium blends enhance heat input and enhance penetration on thicker parts. Helium by itself gives high heat input to demanding applications, and permits deeper welds and higher travel speed. The quality of welds can be maximized by choosing the right gas depending on thickness and welding technique.

Advanced Fusion Welding Processes

Laser Beam Welding

Laser Beam Welding provides high power density and fast travel speed to obtain accurate metal welding. It provides a keyhole weld, which enables deep penetration with little distortion. Regulating the zone affected by heat inhibits undesired microstructural alterations. In crack-sensitive alloys, filler metal addition to strengthen the joint and minimise the chances of cracking during cooling can be done. Through this process, high quality and accurate welds are guaranteed in difficult applications.

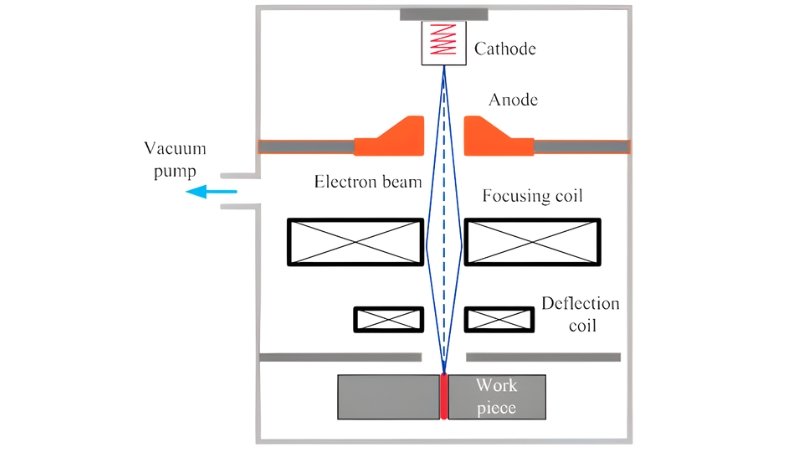

Electron Beam Welding

Electron Beam Welding is run on a vacuum condition that minimises contamination and enhances the quality of the weld. It has a high penetration, which is why it is optimal in thick aluminum and other dense metals. You have the advantage of excellent control of weld geometry and low distortion. The vacuum environment improves fusion and the process is appropriate in cases of high-integrity components where reliability and strength are paramount. It facilitates strong joints in strenuous industrial use.

Solid-State Weld for Aluminum

Solid-state aluminum welding is a process whereby metals are joined without melting and maintaining the integrity of the base material. You enjoy the minimized cracking and porosity, which makes your joints stronger and more trustworthy. This increases the resistance to fatigue and preserves original mechanical properties of the alloy during fabrication.

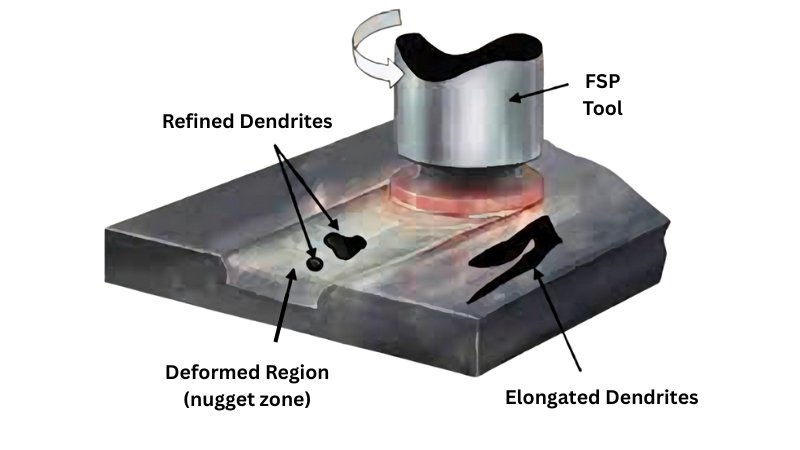

Friction Stir Welding (FSW)

Friction Stir Welding is a solid-state welding process that is used to join plates and sheets. The rotating tool causes heat, which softens material and pushes flow across the joint. The aluminum welder tool shape and pin geometry influence the quality of the weld, microstructure and strength. FSW creates high-strength, defect free, and excellent dimensional accuracy joints. It can be applied in aerospace, shipbuilding and automotive panel assembly, instead of traditional fusion welding or fasteners, with high performance and high reliability.

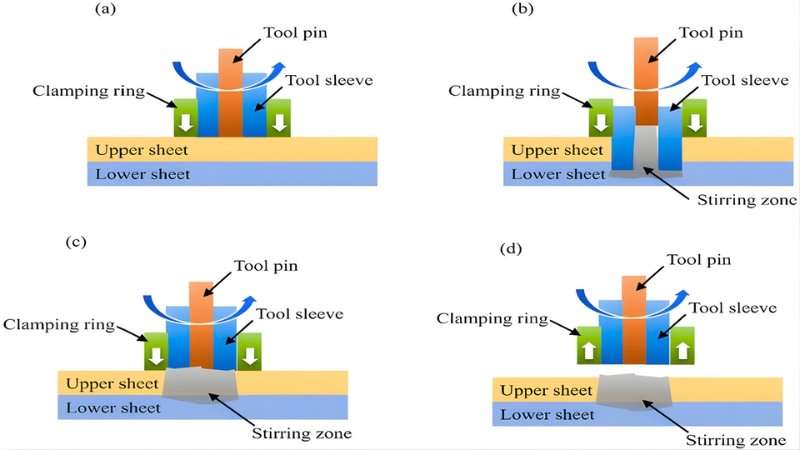

Refill Friction Stir Spot Welding (RFSSW)

RFSSW substitutes rivets on sheet metals with a plunging and filling tool movement. It produces powerful spot welds that do not penetrate sheets, minimizing weight and distortion. It is used in both automotive and aerospace industries to provide resistance to fatigue, surface quality, and assembly efficiency. You are able to obtain high performance joints that are reliable and corrosion resistant with smooth surfaces in complex structures.

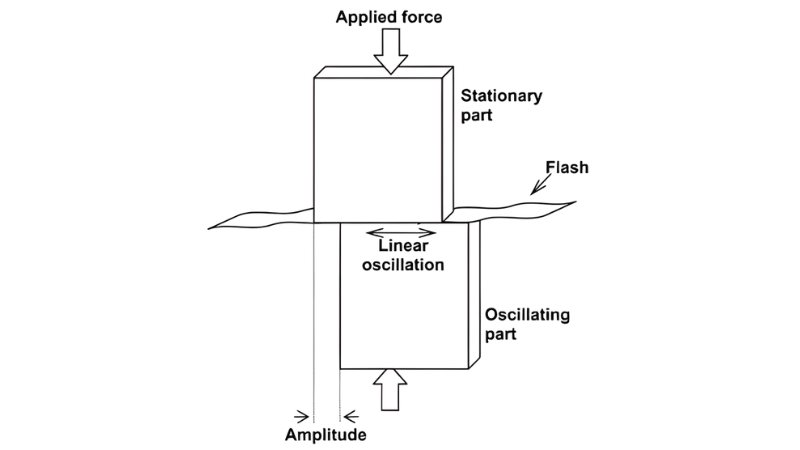

Linear Friction Welding (LFW)

Linear Friction Welding is a welding technique that joins parts through vibrating of one part against another under pressure to produce heat that softens material and eliminates oxides or contaminants. It facilitates near-net-shape production and provides flawless and robust bonds. LFW can be employed in aerospace, automotive and power-generation components, with uniform microstructure, high strength, low post-process and low residual stress.

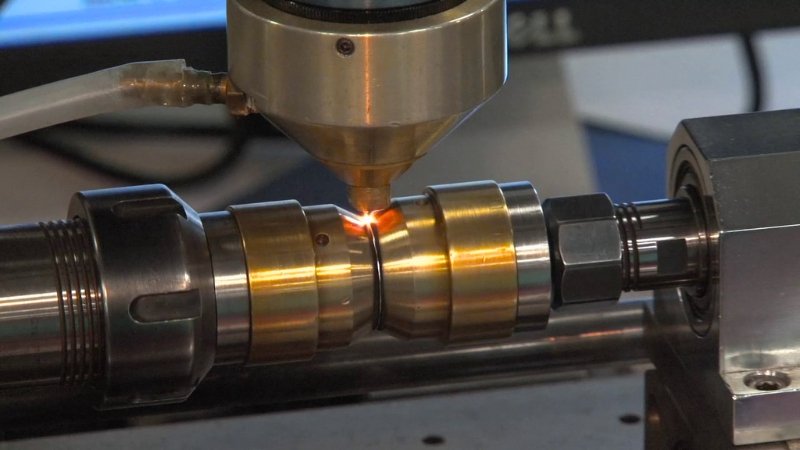

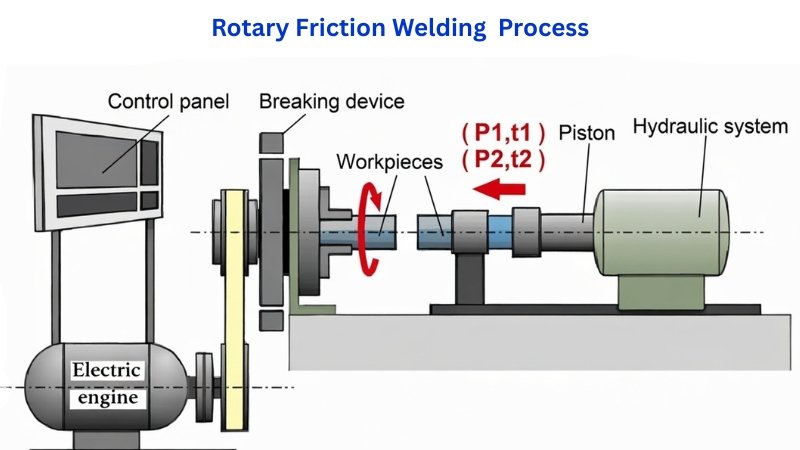

Rotary Friction Welding (RFW)

Rotary Friction Welding is a type of cylindrical welding that is performed by rotating one component against a stationary one under pressure. The interface is softened by heat to create solid-state, high-integrity, filler-free joints. RFW can be used with shafts, rods, fasteners, and aerospace or automotive parts that require precision and strength. It saves assembly time, removes the post-weld finish, and guarantees that it will perform reliably in extreme load, vibration, or temperature conditions.

Selecting the Best Aluminum Welding Method

- Cost Considerations

The choice of welding method begins with the consideration of the total cost effects. Total project costs are directly related to aluminum welding equipment, consumables and labor. It is important to think about whether initial investment or long-term operation cost is the most important to your application.

- Weld Performance Requirements

The desired application defines the desired weld performance. The most important factors to consider are strength, corrosion resistance, and fatigue life. The technique you select must be able to satisfy functional requirements, and structural integrity and reliability.

- Material Thickness and Geometry

The thickness of the material and the shape of the joint influence the appropriateness of the welding method. These sheets should be thin to reduce the amount of heat required to prevent burn-through or warping. A method that fits geometry and dimensions should be chosen to achieve optimal results.

- Production Speed and Repeatability

Large-scale projects require accelerated and regular welding processes. Robotic or automated MIG improves throughput. You need to decide which of speed or manual flexibility is more significant to your operation.

- Distortion Tolerance

Aluminum bends easily under heat. Low heat processes such as TIG reduce distortion in the course of welding activities. During the welding process you should plan to control dimensionality and part precision.

- Health and Safety Implications

The welding operations emit fumes, spatter and UV radiation. The exposure of workers is minimized by proper ventilation, protective equipment, and safety measures. When choosing a welding process to use by your team, you must place safety first.

- Supplier and Equipment Availability

Feasibility is influenced by availability of machines, consumables and skilled operators. Certain methods of welding cannot be done without specialized equipment or training. You ought to select a mechanism that is assisted by available resources in an effort to have a smooth production process.

Equipment Selection for Welding Aluminum

The choice of the appropriate aluminum welding equipment guarantees solid, clean, and flawless joints. Power sources used in welding can be either transformer-based or inverter-based with varying energy efficiency and arc stability, and AC waveform control gives accurate control of heat. In the case of MIG welding of aluminum, push-only systems, spool guns and push-pull systems are available, with different benefits and drawbacks based on the reach and feed consistency. TIG welding has AC capability, high frequency arc initiation, and control, providing you with a high degree of precision in thin or delicate aluminum work pieces.

Shielding Gases for Welding of Aluminum

Shielding gases are important in the welding aluminium as they inhibit absorption of hydrogen which leads to porosity. They also stabilize the arc and regulate penetration and give strong and defect-free welds. There are a variety of choices that you can make depending on the application. 100% Argon provides great arc stability in most of the welding applications. Argon/Helium blends enhance the heat input and enhance weld penetration. 100% Helium is not commonly used in modern times, but may be useful in thicker materials. Quality and efficiency are enhanced by correct choice of gas.

Choosing the Right Filler Metal for Welding the Aluminum

The success of aluminum welding depends on the selection of the filler metal. Correct choice avoids cracking, facilitates good mechanical performance and corrosion resistance. The points you should take into consideration involve crack sensitivity, strength, ductility, color match, and compatibility with post-weld heat treatment. Your choice is also affected by service temperature and exposure to the environment. The choice of inappropriate filler may affect the structural integrity and durability. Knowing all the options will assist you in getting the best outcomes, minimize the number of reworks, and maintain the uniformity of the weldings. Common aluminum fillers used include the following that direct practice choice:

4043 aluminum filler – Excellent crack resistance, commonly used in automotive and general fabrication.

5356 aluminum filler – Higher strength, suitable for marine and structural applications.

4943 aluminum filler – Good corrosion resistance, ideal for heat-treated alloys and elevated temperatures.

Best Practices for Aluminium Welding

Cleaning and Surface Preparation

Begin with intense solvent cleaning to clean up grease, oils, and contaminants. Apply appropriate oxide removal methods to reveal clean surfaces of aluminum. To remove difficult oxides a stainless steel brush may be used to guarantee a better quality of aluminum welds.

Storage of Aluminum and Filler Metals

Eliminate moisture uptake by ensuring that the metals are dry. Apply vertical storage habits to reduce surface contact. The storage should be maintained at a constant temperature to prevent condensation and contamination.

Aluminum Welding Technique Recommendations

Stronger joints prefer stringer beads to weaving. Cleaner welds should be made with the push technique, and travel speed should be controlled to prevent burn-through or porosity.

Common Aluminium Welding Defects and Troubleshooting

- Lack of Fusion and Penetration

The absence of fusion may be due to the inadequacy of heat or the lack of good technique. Weakness of joints occurs due to low penetration. Adjust the speed of travel and the angle of the torch. Add amperage gradually and ensure that the electrodes are in the right place to allow complete fusion. - Burn-Through

Excessive heat may burn the thin aluminum sheets. Control heat flow by reducing current and velocity. Optimize the welding parameters and pre-fit joints, in such a way that they interconnect as snugly as possible to avoid accidental gaps. - Wire Feedability Issues

Bird nesting occurs when the drive rolls or liner snarl up with wire. Check liner cleanliness, straighten wire before feeding and set drive roll tension to smooth feed. Replaced liners or rolls when required. - Inconsistent Bead Profile

The presence of lumpy beads results in either bad workmanship or fluctuating parameters. Maintain the travel speed of the torch, on the right angle and at the same pace. Control wire feed and voltage to produce a smooth even weld bead. - Porosity

Gas entrapment or surface contamination results in porosity. Clean off base metal and provide adequate shielding gas coverage. Adjust flow rate to protect molten weld pool. - Distortion and Warpage

High heat in the input leads to deformation of parts. Less large passes, proper clamping, and planned series of welding. Alternate welds to minimize thermal stress and warpage.

Welding the Aluminum in Industrial Fabrication and Manufacturing

Aluminium welding in the industrial fabrication process is commonly associated with material thickness of thin sheets up to a few millimeters. Its application can be found in automotive frames, aerospace parts, marine structures and assemblies in construction where weight and strength are important. The productivity is directly influenced by process optimization, which ensures quicker cycle time and quality. The cost factors to consider are filler materials, aluminum welding equipment, and labor to ensure efficiency. A combination of the appropriate welding method and parameters enables you to optimize defect reduction, rework, and high-performance, durable joints in a variety of industrial applications.

Conclusion

Aluminum welding is one of the essential skills in contemporary fabrication, which provides lightweight, durable, and corrosion-free joints. The behavior of aluminum is unique, and its variations in alloys and temper influence, understanding these problems is essential to overcome the challenges such as porosity, distortion, and work hardening. The choice of welding process, filler metals, and shielding gases will guarantee you strong and high-quality welds. Optimization of the process, careful preparation of the surface, and the utilization of the equipment also increase the productivity and minimize defects. By learning how to weld aluminum and master these practices, you can get quality, efficient, and durable aluminum welds in any industrial use.