Metal Paint Spraying: What You Need to Know

Table of Contents

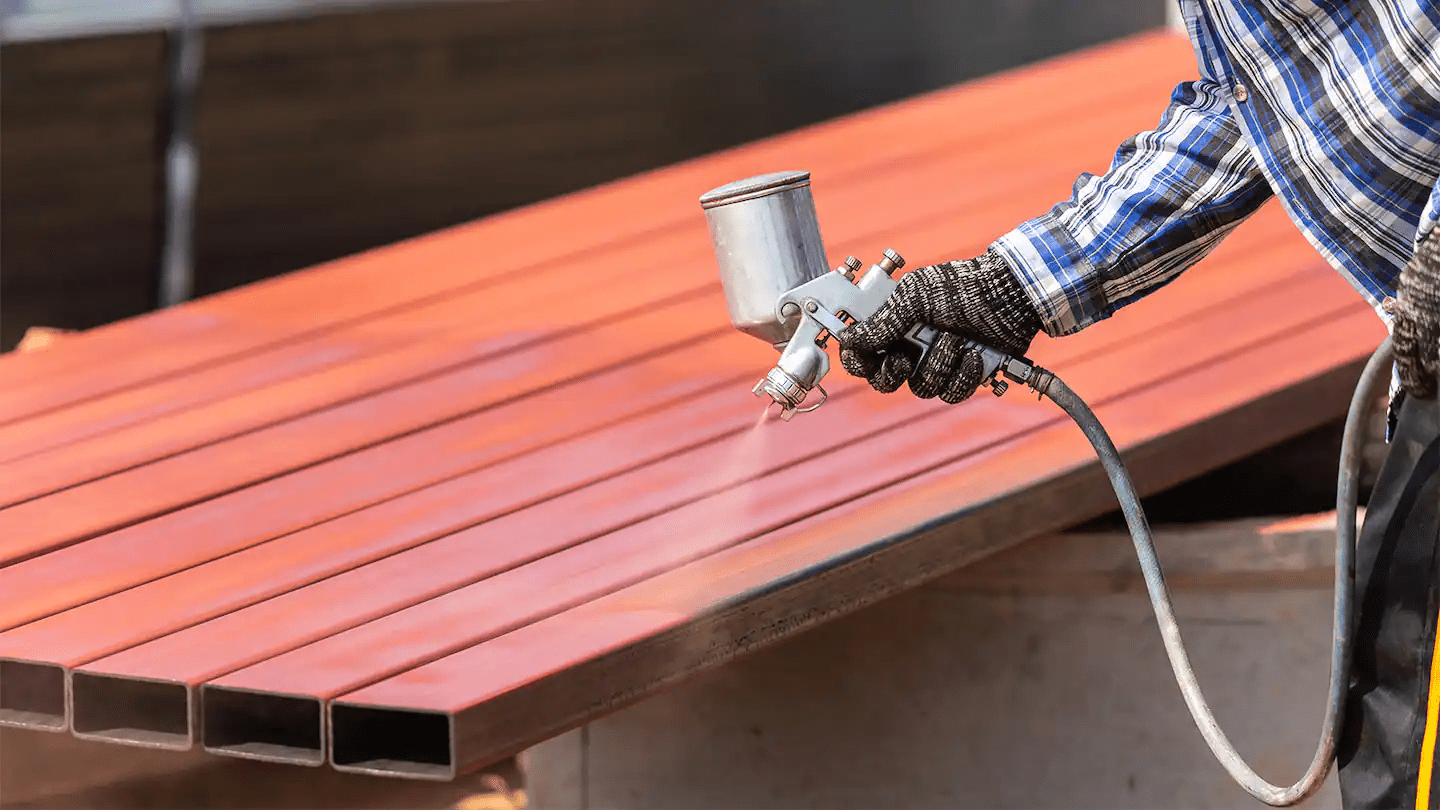

ToggleA defensive or embellishing coating of paint may be applied to metal surfaces using the adjustable technique of metal paint spraying to guarantee uniform coverage. It also offers adhesion by atomizing paint into small droplets and throwing them onto the metal surface.

It is perfect for several industries, including;

- construction,

- automotive,

- aerospace,

Because of its benefits, which include uniform finish, fast application, and durability, metal paint spraying delivers an economical and compelling alternative for surface preparation. It also has good corrosion resistance and aesthetic enhancement. To ensure both usefulness and aesthetic attraction, grasping the technique takes expertise and suitable tools.

What is Metal Paint Spraying?

Applying paint on metal surfaces using a spray gun or aerosol canister is known as metal paint spraying and we use this method to make a smooth and uniform coating. An efficient and versatile method for applying decorative or protective coatings to metal surfaces is metal paint spraying. You may get professional-quality results on a variety of metal substrates by utilizing the right spray paint, using suitable surface preparation processes, and applying the paint according to the recommended ways. Metal paint spraying adds toughness, style, and resistance to corrosion to metal items and structures used in the construction, automotive, aerospace, and many other sectors.

The paint is atomized into small droplets and then moved onto the metal substrate. This technique produces good adherence to the metal surface and invariant coverage by promoting exact control over the application technique.

Types of Metal Paints:

Paints can be applied on metal surfaces in a variety of ways, such as:

- oil-based,

- acrylic,

- epoxy

- enamel paints

Depending on the requirements of the application, each form of paint has special qualities and benefits.

Epoxy paints

It has exceptional resistance against corrosion, whilst enamel paints have greater longevity and gloss retention. The main types of metal paints are:

Oil-based Paint:

Long-lasting, smoothes surface, and is impervious to corrosion and rust.

Water-based Paint:

Less durable than oil-based, but eco-friendly, quick to dry, and odourless.

Epoxy paint

It is frequently used in industrial settings because it is incredibly resilient and chemical-resistant.

Acrylic paint

This paint is weather and UV-resistant, quick to dry, and appropriate for outdoor usage.

Powder Coating:

This method produces a hard, long-lasting finish by applying a dry powder and heating it.

Enamel Paint:

Often used on appliances and automobiles, enamel paint produces a strong, glossy surface.

Rust Converter Paint:

Stops more corrosion by transforming rust into a stable substance. High concentrations of zinc dust in zinc-rich paint provide superior corrosion protection and are frequently used as primers.

Paint made of polyurethane: Offers a strong, glossy surface with superior resistance to chemicals, abrasion, and UV radiation.

Hammered Finish Paint:

Often used for ornamental purposes, this paint produces a rough, hammered impression that helps conceal surface defects.

Paint is designed to endure elevated temperatures without deteriorating; perfect for painting exhaust systems, engines, and grills.

Metallic paint:

Often used for ornamental and automotive applications, metallic paint contains metal flakes to produce an attractive, metallic appearance.

Gritty particles are added to anti-slip paint, which creates a rough surface that lessens slippage and is great for floors and pathways.

Primers:

Specialised base coatings that give additional corrosion resistance and improve topcoat adherence. Etching primers and rust-inhibitive primers are two examples.

Advantages 0f Metal Paint Spray Procedures;

Cost-Effective:

Spraying metal with paint is an affordable way to cover metal surfaces. Because of the process’s relative speed and effective paint application, labour expenses are decreased. Waste is also reduced, which results in additional cost savings.

Versatility:

From small delicate components to big industrial buildings, spray painting may be applied to a wide range of metal surfaces. Because of its adaptability, it may be used in a wide range of industries, including manufacturing, construction, aerospace, and automotive.

Improved Coverage:

Spray painting offers superior coverage, especially on intricate designs and challenging-to-reach regions. This guarantees that the coating covers the whole surface consistently, offering constant protection and look.

Enhanced Adhesion:

Newer metal spray paint formulas frequently have sophisticated ingredients that improve their adherence to metal surfaces. By doing this, a strong binding that is resistant to peeling and flaking is ensured.

Environmentally favourable Options:

Spray paints with lower volatile organic compound (VOC) emissions are available that are favourable to the environment. When used, these environmentally friendly solutions lessen their negative effects on the environment and enhance air quality.

Numerous Finishes:

Metal paint spraying methods enable a multitude of finishes, such as metallic, textured, satin, matte, and glossy finishes. With this variety of choices, customisation is possible to satisfy certain practical and aesthetic needs.

How Does Metal Paint Spraying Enhance Durability and Aesthetics?

Spraying metal with paint increases durability by forming a barrier that keeps the metal surface safe from abrasion, chemicals, and moisture. Complete covering is ensured by an even coat of paint, and this coat keeps rust and corrosion from developing.

Moreover, spray paint gives metal items and structures the capability to be customized and have a greater visual attraction by employing a variety of finishes and colors.

Is spray painting metal Easy:

Yes, with the correct tools and methods, spray painting metal may be a very simple process. To attain professional results, nevertheless, numerous skills and practice are necessary.

Cleaning, sanding, and priming the surface properly is crucial for achieving a smooth finish and excellent adhesion. If you want to achieve consistent coverage and prevent drips or runs, it’s also essential to adjust the spray pattern and maintain the proper distance and angle when spraying.

Can We Spray Direct to Metal Paint?

Yes, paints designed specifically for direct-to-metal (DTM) surfaces may stick to metal without the need for priming. To offer superior adhesion and protection against rust and corrosion, these paints usually include corrosion inhibitors and other chemicals.

DTM paints are reasonable for both small- and large-scale metal painting jobs since they come in a variety of formulas, such as aerosol cans and spray guns. However, to guarantee the best adhesion and durability, good surface preparation is still necessary.

Metal surface Preparation for Paint Spraying:

On metal surfaces, paint coating adherence and persistence rely on proper surface preparation. There are usually many phases in this process:

Cleaning stage:

In this stage, we use an appropriate solvent or degreaser to remove any dirt, grease, oil, or other impurities from the metal surface. To encourage adhesion and avoid paint failure, this step is essential.

Sanding or Abrading stage:

To produce a profile that encourages mechanical adhesion, roughen the metal substrate’s surface with sandpaper, sanding discs, or abrasive pads. As a result, the paint sticks to the metal surface more successfully.

Priming Step

In addition to delivering a smooth foundation for the topcoat, the primer aids in sealing the metal surface.

Masking stage:

To protect sections like trim, handles, or sensitive components that shouldn’t be painted, use masking tape or masking film.

These procedures will help you guarantee that the metal surface is clean, appropriately primed, and ready for paint spraying, which will provide a finish that is strong and long-lasting.

What are the Different Methods used in Metal paint spraying:

Spraying metal paint can be done in several ways, such as:

Conventional Air Spray:

In this technique, paint particles are atomized and then blasted into the metal surface using compressed air. It works well with a variety of paint kinds and provides good control over the spray pattern.

Airless Spray:

Airless spray systems atomize paint without the need for compressed air by using high-pressure pumps. This technique can swiftly cover enormous surfaces and is appropriate for high-volume applications.

HVLP (High amount Low Pressure) Spray:

HVLP sprayers atomize paint by using a large amount of air at low pressure, which improves transfer efficiency and minimizes overspray. This is the best way to have a nice finish with the least amount of waste.

How do Techniques such as HVLP and Airless spray different in Application:

The main areas of difference between airless spray and HVLP procedures are in how they apply and atomize the material. HVLP sprayers are perfect for fine work and delivering a smooth finish with no overspray because they employ low pressure and a large air volume to create a soft, fine spray pattern.

Conversely, airless spray systems use high pressure to push paint through a tiny hole, producing a spray pattern like a fan. We use this approach in industrial environments.

What Safety Precautions Need to Be Taken During Metal Paint Spraying

If you are spraying metal you want to avoid endangering yourself or your loved ones.

Ventilation;

Work in a well-ventilated area or use exhaust fans to extract fumes and overspray from the work zone.

Respiratory Protection;

If you are using paint that will produce a lot of fumes, such as spray paint, wearing a respirator with cartridges will keep you from breathing in the paint fumes and airborne particles.

Protective Gear;

Wear gloves and goggles, and wear protective clothing to avoid skin contact with paint and solvents.

Fire Safety;

Be cautious around flames. Altogether avoid smoking in the spraying process because some paints are flammable.

Handling Hazardous Materials;

Adhere to safety precautions while storing, handling, and removing paints and other products

These safety precautions will help you prevent mishaps when you spray metal paint. Ensure a working environment.

Key Points to Consider for Metal Paint Spraying;

To ensure a top-notch finish and steer clear of issues during metal paint spraying keep these tips in mind;

- Proper Surface Preparation; A crucial step to ensure the paint adheres well without peeling off is cleaning, sanding and priming of the surface.

- Avoid Incorrect or Excessive Thinners; Using the type or amount of thinners can alter the paints consistency or flow leading to issues, like drips or an uneven coat.

- Mastering Spray Technique; Ensuring proper passes overlap maintaining the distance from the surface with the spray gun and consistent spraying speed can prevent problems such as overspray and uneven coverage.

Where is Metal Paint Spraying Commonly Utilized in Various Industries?

Metal paint spraying finds application across industries for various purposes;

Automotive Sector; Spray painting metal components in vehicles, trucks and motorcycles helps prevent corrosion and enhances their appeal.

Aerospace Industry; Aircraft parts like fuselages, wings and engine components are coated with metal paint to combat corrosion and improve visibility.

Construction Field; Applying paint on metal structures such as buildings, bridges and pipelines serves as a measure against rust and weather induced damage.

Manufacturing Sector; Metal objects like equipment and appliances undergo paint coatings, for both appeal and durability enhancement.Ships, boats and marine equipment are often coated with paints to withstand the conditions of the sea and prevent corrosion.

Using metal paint spraying techniques can help businesses enhance the functionality, durability and visual appeal of their metal products. This not improves product quality. Also boosts customer satisfaction.

The application of metal paint spraying

The application of metal spray plays a role, in improving the quality and lifespan of products in different industries. Here are some key benefits;

- Corrosion Prevention;

Paint coatings act as a barrier shielding metal surfaces from moisture, chemicals and other external elements that could cause rust or corrosion.

- Enhanced Durability;

Utilizing high quality paint formulas and application methods can help metal surfaces withstand wear, abrasion and impacts over time ensuring lasting performance.

- Visual Enhancement;

Colors, finishes and textures achieved through metal paint spraying not enhance the look of products but also contribute to brand recognition and identity.

- Performance Improvement;

Specialized paint coatings with features, like heat resistance or anti graffiti properties can boost the functionality and efficiency of metal components.

By investing in metal paint spraying processes industries can elevate their product quality, durability and aesthetics significantly.

This results, in customer satisfaction and a stronger brand image as time goes on.

Instructions for Applying Metal Paint;

Below are the steps for applying paint to metal;

- Prepare the surface; Ensure to remove any existing paint, oil or dirt from the metal surface.

- Choose the paint; When selecting a paint specifically designed for metal surfaces consider factors like durability, color choices and finish.

- Set up your spray equipment; Make sure your aerosol can or spray gun is properly set up and clean. Adjust the spray pattern and air pressure if necessary.

- Apply the paint; Hold the spray gun or canister at an angle 6 to 8 inches from the metal surface. Use overlapping strokes for coverage.

- Allow time for drying; Follow the manufacturers instructions regarding drying time before applying coats or touching up areas with painted surfaces.

- Step; You may want to consider using an clear coat as an extra layer of protection.

Methods for Removing Spray Metal Paint from a Surface;

There exist techniques to eliminate spray paint, from metal surfaces;

- Start by using a paint remover as instructed by the manufacturer.

- Use a sanding block or rough sandpaper to remove spray paint from the metal surface. Begin with sandpaper, for a finish and gradually switch to finer grits.

- Heat the spray paint with a heat gun to soften it before scraping it off using a putty knife or scraper. Be mindful not to overheat the metal.

- Household solvents such as paint thinner, acetone and mineral spirits can dissolve spray paint effectively. Apply the solvent with a cloth. Gently rub the painted surface to loosen the paint.

- Power washers with pressure can be used to remove spray paint from metal surfaces. Ensure you do not apply pressure that may harm the metal.

Select the method that best suits your type of metal surface and personal preferences.

How much time is required for spray paint to dry on metal;

Various factors like the type of paint humidity levels and temperature can impact how quickly spray paint dries, on metal surfaces.

Here are some key factors to consider when determining how coats to use;

Factors Affecting the Number of Coats

- Type of Paint;

Primer; Generally one coat of primer is sufficient to create a base, for the topcoat. However in cases where the metal is heavily rusted or has a surface you may need two coats.

Topcoat; The number of layers required for the topcoat depends on the type of paint used. Some paints offer coverage. May require fewer coats.

- Paint Color;

Light Colors; Light shades such as white or pastels often require coats to achieve coverage.

Dark Colors; Darker colors typically provide coverage. May need fewer coats.

- Surface Condition;

Smooth Surfaces; prepared metal surfaces generally require coats compared to rough or textured surfaces.

Surface Condition; If you notice any rust or corrosion, on the surface it’s an idea to apply some coats to ensure coverage especially after applying primer.

Preferred Finish;

For a Shiny Look; Achieving a finish might require coats for a vibrant color.

For a Matte Appearance; Matte finishes usually need coats compared to ones.

Recommended Number of Coats

- Primer Application;

Applying One to Two Layers; While one coat of primer is often sufficient adding a second layer can improve coverage and adhesion on surfaces.

- Topcoat Application;

Using Two to Three Layers; Its recommended to apply two to three coats of topcoat on metal surfaces for durability and a polished appearance.

- Optional Clear Coat;

Applying One to Two Coats; If you desire protection and shine consider adding one or two coats of finish after the topcoat has dried.

Step-by-Step Application Process

- Apply primer evenly over the surface.

Preparation;

Cleaning the Surface; Remove any dirt, grease or rust using degreaser and sandpaper.

Scratch the metal surface is good for paint grip. Here are the instructions rewritten in a like manner;

Step 1;

Start by applying primer. Spray one to two layers of primer. Make sure each coat dries following the instructions.

Step 2;

Painting Process;

First Coat; Use movements to apply the spray paint ensuring each pass overlaps. Keep the spray can 10 to 12 inches, from the surface.

Second Coat; Apply this layer just like you did with the one. Check for coverage and consistency.

Additional Coats (if needed add coats to achieve your desired finish.

Step 3; Clear Coat Application (if required);

Apply a coat if needed for protection and a glossy finish once the topcoat is completely dry. Its recommended to apply one to two coats of coat.

Useful Tips;

Application Technique; To avoid drips and streaks apply coats than one thick coat.

Drying Time; Allow each layer to dry completely before applying another to prevent paint peeling or bubbles, from forming.

Adequate airflow is essential when spray painting to allow the paint to dry and reduce exposure, to fumes. Following these guidelines can help achieve a lasting finish on metal surfaces by applying layers.

What Spray Paint to use on Metal:

When selecting spray paint for metal it is important to choose a product specifically designed for metal substrates. Look for paints with adhesion, corrosion resistance and weather resistance labeled as ” surface spray paint” or “metal spray paint.” Consider factors like color options, finish (matte, satin or gloss) and suitability for the application.

While spray painting metal can be straightforward if done correctly it’s crucial to avoid mistakes like surface preparation and incorrect spraying techniques to achieve satisfactory results. Successful completion of tasks also relies on knowing how to remove spray paint from metal and understanding the curing time of the paint.

What is the Best Spray Paint for Metals:

The best choice of spray paint for metal surfaces will vary based on your requirements and preferences. Brands, like Rust Oleum, Krylon and Valspar are well known for their quality when it comes to painting metal surfaces.

When selecting paints, for your metal project look for options that provide adhesion, durability, coverage and resistance to fading and rust. Consider factors like color choices, finishes and how easy they are to apply when choosing the right spray paint.

Can you spray paint powder-coated metal

To achieve painting results on powder coated metal surfaces it’s important to prepare. Clean the surface thoroughly. Lightly sand it to ensure adhesion by removing any impurities or shiny coatings that could affect paint adherence. Opting for a high quality spray paint formulated for metal surfaces will ensure adherence and lasting outcomes.

What type of Spray Paint to use on Metal:

When deciding on spray paint for metal surfaces opt for products specifically tailored for use on metal. Look out for labels such, as “indoor/outdoor spray paint ” “surface spray paint,” or “metal spray paint” as they are formulated to provide finishes that adhere well to metal surfaces.

Consider factors, like the range of colors finishes (matte, satin, gloss) and how well they complement your project when choosing the spray paint type for your metal project.

How to seal spray paint on metal

To safeguard spray paint and preserve metal surfaces it is advisable to use a sealant. For results and durability opt for an acrylic. Enamel sealer specifically formulated for spray paint applications. Apply the sealer in layers following the manufacturers guidelines on drying times and reapplication as needed. Allow the sealer to completely dry before handling or exposing the painted surface to any stress or abrasion.

In summary;

Utilizing metal paint spraying offers advantages across industries. Achieving paint adhesion and durability on metal surfaces requires adhering to recommended surface preparation techniques such as cleaning, sanding and priming. Choosing the appropriate spray paint is essential, for achieving visually appealing finishes, whether it is specially designed for metal or suitable for various surfaces.

Whether you are painting home decor items, car parts or aerospace components the versatility and longevity of metal paint spraying significantly enhance the quality and lifespan of your product. Improving the resistance of spray paints to factors and extending their longevity can be accomplished by applying a sealer or clear coat.

Using metal paint spraying is a choice to improve the look feel and longevity of metal structures and items. That’s why both professionals and hobbyists, in industries opt for this technique.