Galvanized Sheet Metal – The Ultimate Guide

Galvanization is a popular technique for keeping metal from getting eroded. This sort of steel sheet has a layer of zinc on it. The zinc makes the steel last longer and keeps it safe from the elements. To prevent rust and broaden the existence of steel sheets, this strategy includes covering them with zinc. Depending on how the sheet metal is covered, the aroused surface may appear unique. It is an excellent option for use outdoors and in locations where rust can be a problem. The galvanized metal sheets needs to look perfect and capability outstandingly, with essentially no issues like spots, openings, breaks, thick covering, or scratches. They can be utilized in numerous projects. In order to ensure that your project meets the highest quality and performance standards, we will examine various kinds of galvanized sheet, their specifications, applications, and important factors to take into account when purchasing and utilizing this material in this guide.

Table of Contents

Toggle

Galvanized Metal Sheets – Definition

Galvanized sheet metal is steel that has been covered with zinc to make it more grounded and more impenetrable to rust. This suggests setting the steel in hot liquid zinc to make solid areas on its surface. This layer safeguards the steel from rust and damage, making it last longer. By keeping away from rust and disintegration, electrifying metal extends its future. Since the metal under is hurt in any case, the zinc layer guarantees the metal from being hurt. Sheets, wire, and shocks are a couple of the shapes that excited metal comes in. In this article, we’ll look at the uses and benefits of galvanized sheets.

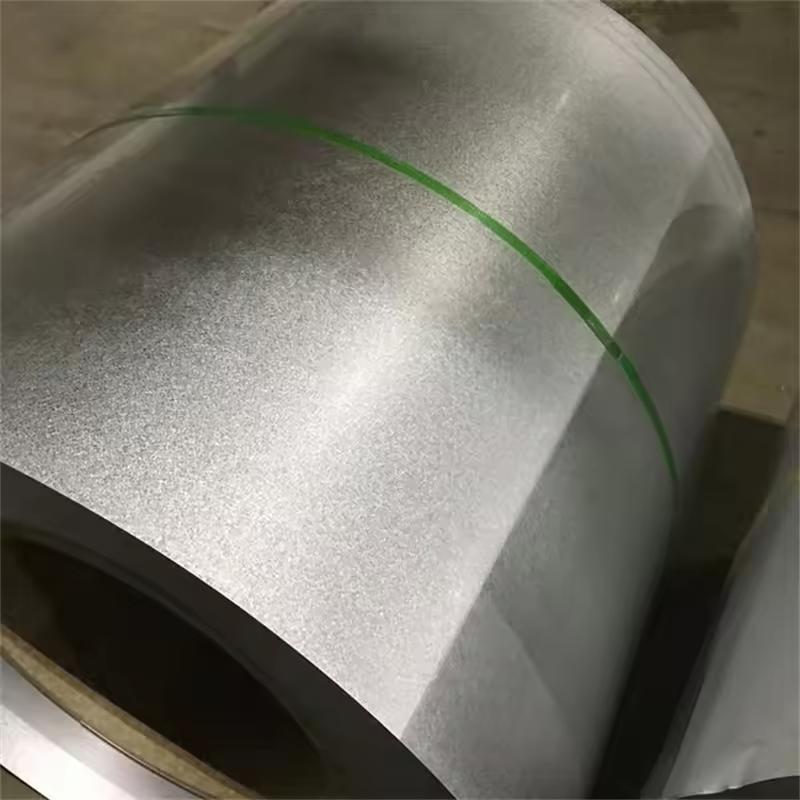

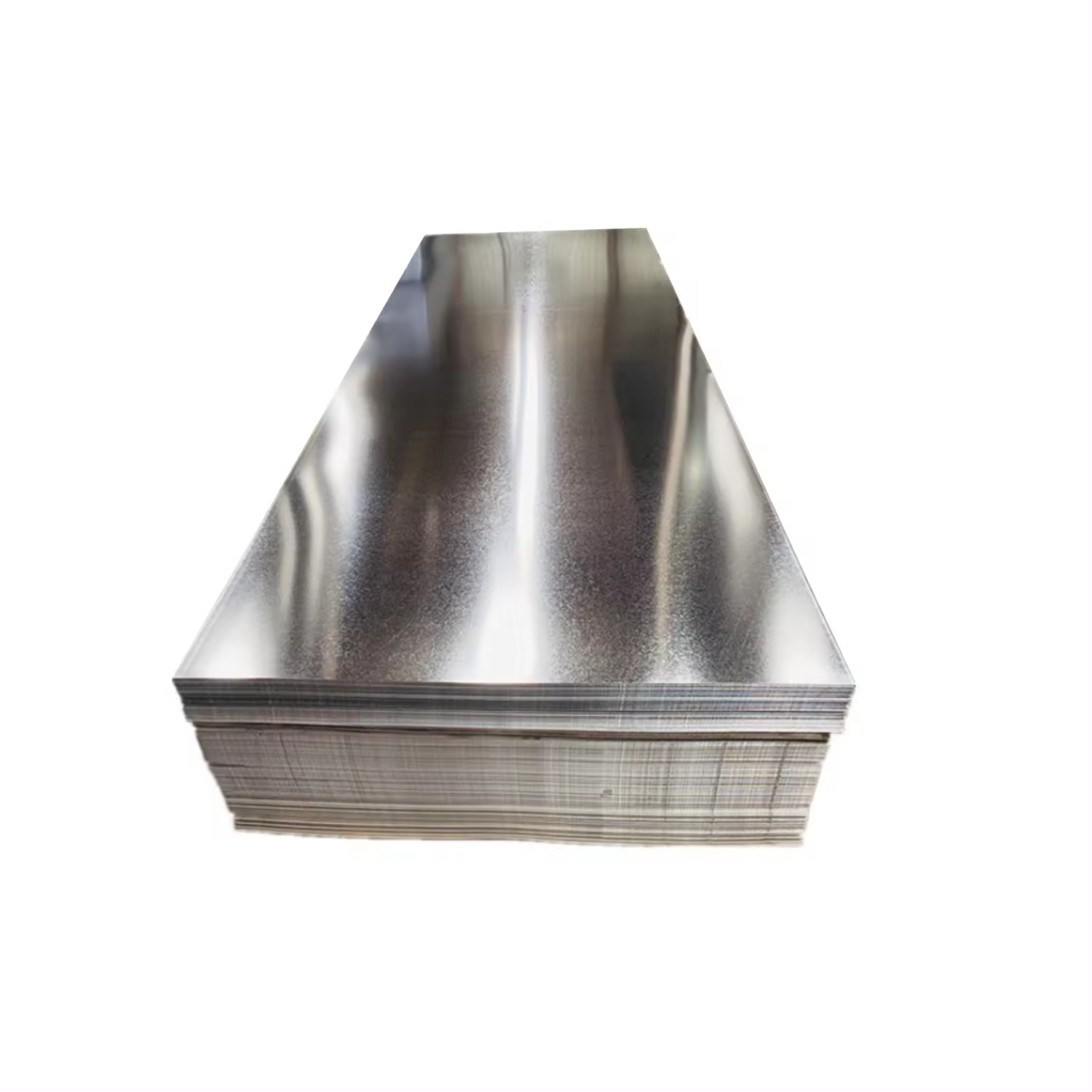

What Does Galvanized Steel SheetResemble?

Galvanized steel can appear dull, gray, or light gray. After being coated with galvanized, the surface of the metal displays a spangle pattern. Similar to marble countertops, the metal appears spotted as if different colors have been mixed together. You can see that this plan has both darker and lighter spots throughout. Steel that has not been treated typically has a uniform color and is smoother, but this can be very different.

Galvanized Sheet Metal – How to Use?

Galvanized heets are a reliable and long-lasting option for many projects because they do not easily rust. Nevertheless, you should sort out remarkable wariness and use specific methodologies while working with them to evade damage. Try the following when working with metal sheets:

Cutting Sheets

Wear security prepare like gloves and goggles while slicing galvanized sheets to get yourself from sharp edges. Sharp instruments are essential for making a clean cut. Gloomy edges can scratch the zinc coating, making it less likely for the metal to rust. Besides, evade making one long cut consistently since doing so could curve the metal.

Drilling Sheets

Use a metal-explicit enter bit while exhausting holes in metal sheets. This will result in precise and smooth gaps. Apply oil, WD-40, or a delicate press to the penetrate bit to extend its lifespan and prevent excessive warm buildup. To avoid taking in metal shavings, cautious attire is key.

Fastening Sheets

Galvanized sheets can be joined together with screws, nails, or jolts. For the explanation of expecting rust, select screws and shocks made of a similar metal. To keep away from the metal from bowing, it’s basic to exhaust holes some time as of late presenting the shocks and use a force to fix them agreeing to the maker’s illuminating. Finally, working with galvanized metal sheeting necessitates careful consideration and specific methods to ensure their proper installation and avoid potential hazards. If you use the right tools and follow these instructions, you can use galvanized metal sheets safely and effectively in your project.

Galvanized Sheeting – What Are the Different processes?

In especially unforgiving conditions, galvanized metal sheet might be a fundamental protect against disintegration. Steel can be strengthened and made more resistant to rust in different ways. Steel can be coated with zinc in a variety of ways, each of which has its own benefits and is suitable for different mechanical requirements. Here are the central procedures of galvanized steel:

Galvanized with a Hot-Plunge:

Hot-plunge galvanization is the place where you put steel to absorb zinc. This cycle makes serious solid areas for persevering through covering that guarding the steel from rust and harm. It’s ideal for including in outdoor adventures and outside. Channels, latches, and large basic shapes are just a few examples of the many items that this technique is frequently applied to.

The Process of Electrogalvanizing:

Electrogalvanizing, or electroplating, is when zinc is put on steel or iron to keep it away from rusting. Steel acts as a negative charge and zinc plates as a positive charge when power passes through a zinc-containing fluid. The power makes zinc particles move and stick to the steel, which makes a cautious layer. We can control how thick the zinc covering is using this method, which is great for things like precise instruments and vehicle parts that need to be completed smoothly.

Warm sprinkling:

Warm showering, moreover called metal or fire sprinkling, is when zinc is melted and showered onto a steel surface using a special gadget. This strategy uses force to change zinc into little particles and a short time later sprinkles it onto steel using vaporous pressure. When it stops chilling, this builds a defensive layer. It permits you to control how thick the covering unendingly is truly perfect for gigantic things or for fixing things that were by then blended. The steel is safeguarded from rust and natural mischief by this layer. It doesn’t need to chill off, so it will in general be used right away.

Sherardizing:

Sherardizing is the process of heating steel components to temperatures between 300 and 450 °C in a closed zinc-containing turning drum. It is named after its inventor, Sherard Cowper-Coles. On ferrous metals, it applies a zinc coating through thermal diffusion. In this cycle, the metal to be covered is set in a holder with zinc metal residue. In the presence of this dust, the workpiece experiences an increase in temperature of 400-450 °C. A zinc-iron alloy is created when the dust diffuses into the metal at a high temperature. Sherardizing is inclined toward for little parts and applications requiring tight layered protections. For little parts like the catch, this methodology is much of the time utilized to advance a uniform and controlled covering.

Tenacious Sheet Galvanizing:

This technique, which is essentially used for steel sheets, strips, or wires, incorporates running the steel through a persisting zinc shower. Constant sheet exciting gives steel that will be formed into things like central air courses, material, or divider sheets a sturdy covering. Because each galvanized method has its own applications, inclinations, and considerations, businesses can select the best type based on the practical requirements and typical conditions the steel will be exposed to.

Method of Pre-Galvanizing

Pre-galvanization is an early direction of metal age. One more name for it is process galvanization. Utilized on metals, it won’t go through various cycles. This can be since working with galvanized metal sheet can hurt the protected layer, permitting the metal to handily rust even more. Steel plates and bars are reliably used to make pre-stimulated parts. This method helps mobilize things on a larger scale more quickly and successfully than traditional hot-dipping. After the metal is cleaned, it is covered by going it through hot zinc some time actually being immediately moved back up. Pre-exciting is most ordinarily utilized on materials that have proactively been cut into a specific shape.

Alloy and composite galvanized steel sheet

Zinc, other metals like aluminum, lead, and composite plating make up this sturdy metal plate. This steel plate has a strong coating that prevents rust. Galvanized steel plates with color, printed designs, and a PVC coating are just a few of the other options available. Hot-dip galvanized plate is still the type that is used the most frequently at the moment.

Galvanized Metal Sheeting Thickness Chart

To ensure satisfactory erosion protection and mechanical properties, the galvanized sheet coating thickness standard depicts specific requirements.

6mm Thickness

In the business, galvanized metal sheets with a thickness of 3 millimeters are normally utilized. This thickness is much of the time used for different things that ought to be significant solid areas for modestly impenetrable to rust. It keeps things away from rusting and being hurt by the environment, and it’s not unreasonably profound or expensive.

4mm Thickness

In the business, electrifies sheets with a thickness of 4 mm are normal. This thickness is more grounded and gets through longer than additional thin decisions. Extraordinary for things ought to be solid areas for genuinely outrageous, but simultaneously need security from rust.

Thickness: 5 – 6 mm

These strong 5mm thick sheets are much of the time used in things that ought to be really outrageous. This thickness makes things more grounded and prepared to hold profound things, so it’s truly perfect for enormous improvement adventures and significant machines. 2mm thickness For sheets with a workpiece thickness of less than 3 mm, the average coating thickness should be greater than 55 microns, and the neighborhood thickness should be greater than 45 microns. Parts that are bent or formed should be thicker than 65 microns, while parts that are welded should not be thicker than 55 microns. Parts that are welded should be at littlest 45 microns thick, and parts that are bowed or formed ought to be in excess of 50 microns thick.

Thickness of 1.5 mm

In addition, sheets with a workpiece thickness of less than 1.5 mm, where coating thickness control is difficult, must have a typical thickness greater than 35 microns and a adjacent thickness greater than 25 microns. Methods for estimating coating thickness, especially for hot-dip galvanized sheets, need to adhere to important benchmarks. In other approaches to treating erosion, these rules can be used as prerequisites for coating thickness.

22 GA. (.034″ thick) Galvanized Steel Sheet A653

The specified galvanized steel sheet has a thickness of about 0.034 inches and is 22 gauge. This gauge is frequently used in construction and industrial settings where moderate flexibility and strength are required. It is suitable for use both indoors and outdoors and has been coated with zinc to resist corrosion. For construction and fabrication projects that require corrosion resistance and long-lasting mechanical properties, the designation “A653” indicates compliance with ASTM standards.

24 GA. (.028″ thick) Galvanized Steel Sheet A653

The galvanized sheet has a check of 24 and is around 0.02 inches thick. Guttering, roofing, and interior panels are just a few examples of the thin and light things that this kind of measuring tool is commonly used for. It can be used inside or outside and is coated in zinc to prevent rust. The product’s name, “A653,” indicates that it complies with ASTM standards. This suggests that it is of the same high quality and that it can be used to build things that need to be resistant to rust and made of sturdy materials.

14 GA. (Having .079″ thickness) Galvanized Steel Sheet A653

This grade is frequently used in mechanical and development applications that require direct quality and adaptability. It is resistant to erosion and can be used outdoors and in marine environments. The assignment “A653” demonstrates compliance with ASTM standards for projects requiring erosion resistance and solid mechanical properties in manufacturing and development.

12 GA. (.108″ thick) Galvanized Steel Sheet A653

The desired galvanized metal sheet has a thickness of approximately 0.108 inches and is 12 gauge. This gauge is as frequently as conceivable used being developed and mechanical settings where a change of value and usefulness is major. It is suitable for marine and open-air applications because it is coated with zinc to resist erosion. For development and manufacturing projects requiring erosion resistance and solid mechanical properties, the assignment “A653” demonstrates compliance with ASTM standards.

11 GA. (.124″ thick) Galvanized Steel Sheet A653

The galvanized steel sheet that is required is 11 gauge, or approximately 0.124 inches thick. This gage is much of the time used in various turn of events and mechanical applications where a change of value and usefulness is required. Covered with zinc for disintegration obstruction, it is sensible for outdoors and marine circumstances. The assignment “A653” indicates compliance with ASTM standards, ensuring consistent quality for development and production projects requiring strong mechanical properties and erosion resistance.

8 GA. (.165″ thick) Galvanized Steel Sheet A653

The desired galvanized steel sheet is 8 gauge and approximately 0.165 inches thick. Because of its strength and quality, it is frequently used in mechanical and auxiliary applications. It is suitable for marine and open-air settings because it is coated with zinc to resist erosion. For development and manufacturing projects that require erosion resistance and strong mechanical properties, the assignment “A653” demonstrates compliance with ASTM standards.

7 GA. (.179″ thick) Galvanized Steel Sheet A653

The given galvanized steel sheet is 7 gauge and has a thickness of about 0.179 inches. It is commonly used in mechanical and everyday tasks that require quality and toughness. Covered with zinc for disintegration obstruction, it is perfect for outdoors and marine circumstances. The assignment “A653” demonstrates compliance with ASTM standards, ensuring consistent quality for manufacturing and development projects that require strong mechanical properties and resistance to erosion.

Metal Sheet Galvanized – Maintenance and Care

Galvanized metal sheets are strong and last a long time, but they need to be taken care of to keep working well. Keep these important things in mind: Your galvanized sheeting should be cleaned frequently.

- They can become damaged by dirt, leaves, and other things. This can be prevented by frequently washing your sheets with soap and water. Despite the fact that metal sheet galvanized are resistant to rust, they can still be scratched. If not addressed promptly, these marks may result in rust. When necessary, cover scratches with paint or sealant.

- Examine your galvanized sheets frequently for signs of damage, such as rust or dents, and address any issues as soon as possible. This may assist in preventing further, more extensive damage.

- Galvanized metal can deteriorate if it comes into contact with copper or lead, so you should stay away from them. Be careful not to place your sheets near anything that could harm them.

- Your galvanized sheet metal will endure longer and perform better in various applications assuming you keep them looking great.

Galvanized Sheet Metal – Considerations Before Using

There are a few important considerations to ensure before using galvanized sheets. Your project’s safety, strength, and efficiency could be affected by these factors. Keep these important things in mind:

- Limits on weight: Because galvanized sheets can be very heavy, it’s important to make sure the structures that hold them up can handle the weight.

- Compatibility: Copper and lead might react with galvanized metal sheets, which could cause them to rust.

- Safety precautions: When cutting or drilling galvanized sheets, microscopic zinc particles can enter the air and pose a threat. Masks and goggles are recommended for your safety and protection.

If you take these factors into consideration and deal with them appropriately, your project using galvanized sheets will produce better results and last longer.

Pros of Galvanized Steel Sheet

- Since it has an additional layer of zinc, galvanized steel is way better ready to oppose normal breaking down. It becomes stronger and more grounded as a result.

- Zinc goes probably as a guarded limit that protections steel from soddenness, oxygen, and other damaging parts, in this manner preventing rust.

- Galvanized metal sheet can last for in excess of 50 quite a while in normal circumstances and 20 quite a while in especially moist circumstances, giving it a more drawn out future.

- When coated with zinc, it does not rust and retains its protective coating.

- Fairly, you can see how sturdy the galvanized steel is by looking at it. Stretch tests can be done quickly and easily. They reveal the thickness of the zinc layer, indicating the steel’s security.

Cons of Galvanized Steels

Despite the way that steel has different inclinations, there are a couple of drawbacks to its use. As a result, galvanizing might not always be the best option for protecting steel.

- Some pieces of steel are too big or too small to be submerged in hot zinc that has been dissolved to prevent rust.

- Besides, covering steel in alternate ways is fair too irksome for a couple of shapes. Galvanizing needs to be done with care.

- The zinc will not stick to the steel and the aroused steel won’t function admirably if it doesn’t have adequate chance to cool and set.

- When galvanizing, steel surfaces are more challenging to fix or modify diverged from untreated steel. Welding steel can convey perilous exhaust and may require additional protections or explicit equipment.

What Distinguishes Stainless Steel from Galvanized Steel?

Zinc is coated on galvanized and galvanized steel to prevent erosion, but their handling and forming properties are vastly different. Either hot-plunging or electrogalvanizing remove a glass-like zinc-iron layer that is shimmering and somewhat unforgiving from electrified steel. This covering is solid areas for especially great for applications expecting impenetrability to rust.

Galvanized steel depends upon the appeasing confirmation of zinc, which disintegrates remarkably to the chief steel. However, treated steel forms a dormant chromium oxide layer that provides unprecedented disintegration resistance—certainly in harsh conditions. The end result could be a matte wrap that provides excellent paint connection and additional protection against disintegration, making it suitable for use in vehicle and building applications where wrapping finishing is essential.

What Differ Galvanized Aluminum Sheet From Galvanized Steel ?

While galvanized metal sheet gives unavoidable quality and vigor, aluminum outperforms suppositions in applications requiring lightweight new development, similar to flight and vehicle associations, as well as in conditions where breaking down could be a fundamental concern, like marine and ocean side region. Moreover, aluminum’s better flexibility and conductivity cause it ideal for applications that to require electrical conductivity or complex shaping. Each surface has its focal centers, and the choice between jolts steel and aluminum depends upon explicit undertaking prerequisites, counting quality, weight, crumbling obstacle, and caused critical harm assessments. Since of the materials that are used to cover it, aluminized steel is less exorbitant.

Stainless Steel vs. Galvanized Steel

As we referenced, galvanized steel is unique in relation to treated steel and here is process. The way that hardened steel apparatuses and hardware are impervious to rust is one benefit. Despite the higher price, this steel is long-lasting and well worth the money. When left outside in rain, snow, or sleet, metals begin to rust and wear away. In view of the mix of metals it contains, tempered steel doesn’t rust. It has very little carbon and a lot of chromium and nickel, two metals that prevent rust from forming. When a number of things collide and touch the air, a film is made.

This film keeps the steel’s shine by preventing rust and minimizing material damage. Stainless steel is used in numerous industries due to its clean and smooth surface. Because it is easier to clean and looks better than aroused steel, hardened steel is used a lot in cooking and medicine. galvanized steel might strip and drop. Stainless steel has the potential to last for a very long time because of the distinctive combination of its components. However, it might rust if it comes into contact with salt. Over the long haul, metal that doesn’t rust stays smooth. Other metals, on the other hand, that rust eventually become brittle. Eventually, choosing hardened steel is an astounding long haul venture. When a piece of equipment is durable, it doesn’t need to be fixed or replaced frequently and lasts a long time.

Applications

Galvanized metal sheets are used in a variety of industries, including construction, automobiles, heating and cooling, agriculture, and others. Individuals and businesses alike make use of it.

Galvanized sheet metal is used to make car parts and body boards, which prevents rust and extends their lifespan. Because it does not effectively rust, galvanized sheet metal is an excellent choice for HVAC channels and hardware and is used in heating, ventilation, and air conditioning systems. Aroused sheet metal is used to major areas of strength for construct air structures like wall, limits, and wall.

Numerous businesses use galvanized sheet metal because of its toughness and resistance to erosion, making it suitable for both indoor and outdoor applications. It is frequently utilized in construction as a material, siding, and environment due to its resistance to natural elements. Stirred sheets are used by car manufacturers to make body sheets and other parts of the vehicle. By resisting rust and corrosion, stirred sheets help cars last longer. This texture is liked in agriculture for the development of grain storehouses and pony covers since it successfully forestalls rust in damp circumstances.

Likewise, stirred steel is utilized to make air conditioning ventilation work and electrical housings, giving fundamental insurance from clamminess and guaranteeing a long life expectancy. Its adaptability extends to the production of outdoor furniture and fencing, where its resistance to enduring is highly valued. Besides, the quality of fundamental portray goes with it a leaned toward choice for tasteful applications requiring a getting through wrap up.

Different Steels Comparisons Which Stands Up Better?

It is evident from examining their characteristics that these two kinds of steel are distinct. Even though they can serve different purposes, depending on the situation, one often takes precedence. For instance, chlorine water quickly degrades stainless steel, which outperforms expectations in saltwater conditions due to its resistance to erosion. Additionally, it is recommended to avoid coordinating contact between two tempered steel components when arranging with hardened steel to prevent them from squeezing or causing irritation. Then again, invigorated steel is incredibly energetic, but its utilization requires cautious thought.

Steel is normally stirred before welding since welding intensity can harm the defensive zinc covering at the weld focuses. To shield welded charges steel, a wary covering is focal post-welding. Due to its wide range of adaptability and resistance to disintegration, treated steel is crucial for specific applications such as the production of destroyer-specific transport. Additionally, submarines operating in marine environments require stainless steel. Notwithstanding, aroused steel is awesome and most practical choice for most of normal steel applications due to its solidarity, quality, and work and material investment funds.

Conclusion

Galvanized metal sheets are long-lasting and can be used in many different projects and industries. Automobiles, construction, fences, roofs, and galvanized sheeting all work well. Indeed, even in terrible climate, they are strong and can keep going quite a while. Furthermore, they forestall rust. Despite still being of high quality, galvanized metal sheeting are less expensive than stainless steel. Prior to using stirred metal sheets in your undertaking, taking into account their weight and similarity with different materials is fundamental. You need to take good care of metal sheet galvanized if you want them to last a long time. If things are cleaned on a regular basis and problems are fixed early, they can last longer and prevent damage. galvanized steel sheet can be repurposed into new products, despite the environmental impact of their production and disposal.

See for yourself how useful and strong galvanized sheets are by using them for your next project. If you have rusty steel sheet metal that needs to be fixed, we can help. We know how to fix anything, from aroused steel to any sort of metal. Before we start, we cautiously assess your excited steel. We’ll check for harm or rust. Once we know exactly how your metal is, we’ll come up with a custom fix. We utilize an interaction to reestablish the first appearance of your galvanized steel, so, reach out to us.

FAQs Section

What Kinds Of Metal Can Be Galvanized?

Galvanized is commonly made from press and zinc. Coatings made of zinc are typically associated with press and steel. Nonetheless, this treatment is also available for other metals. Zinc can be associated with a grouping of iron-containing metals, however it can’t be associated with sans iron metals.

A magnet can help you in concluding regardless of whether a metal is alluring. If it remains on a magnet, the metal it is made of has the ability to draw in magnets. The metal isn’t made of press if the magnet doesn’t stick.

What is the general price of galvanized sheet in Chinese market?

The Guangdong steel market offers galvanized metal sheets stock in a wide range of grades, finishes and origins. The sheets are priced by the ton and specify various thicknesses and widths, particularly in millimeters, with a “+C” for covered surfaces. The thickness of the options ranges from 0.4 mm to 2.5 mm, with additional customizations available upon request. One of the market’s most important offerings is galvanized sheets in a variety of patterns and colors, with a focus on zinc coatings ranging from 40 zinc to 275 zinc.

The assessed 0.75*1219*C variety from Panhua somewhere in the range of 3990 and 4010. Costs for Shenlong stamped sheets assessed at 1.1*1219+C are checked at ¥4330 to ¥4360, reflecting a premium for higher zinc substance. Broadly, the plug shows a cost diminish of ¥50 for the thickest choices recorded, for instance, 1.8*1219*C with 275 zinc covering. What’s more, the stock comprises of cold-rolled foil (cold plates) with thicknesses going from 0.5 mm to 3.0 mm. These are redone to meet explicit client prerequisites, featuring the market’s flexibility to different mechanical necessities. The market’s hearty store network capacities in giving particular steel items are exemplified by this broad reach, which obliges different applications, including assembling and fabrication advancement.

Can galvanized steel be patched?

Bolts or a lock-seam are ideal for strengthening the connection and preventing it from breaking, whereas fasteners can be used to connect galvanized steel. As with any installation project, preparation and compliance with all security regulations are essential.

Is Galvanized Steel Unsafe?

Galvanized steel is thoroughly secure to use with sustenance in customary conditions. Acidic sustenances should not be taken care of in aroused steel holders since the destructive can hurt the covering and uncover the metal under.

Why Should Galvanized Steel Be Used?

We should use it because it is rust-resistance. When you apply zinc coating on it, then you are shielding you products from oxygen, moisture, and other harmful elements. This makes galvanized steel very strong and long-lasting, which is especially important in harsh environments like industrial settings or coastal areas where rusting is a big problem.

In addition, galvanized steel is simple to maintain and requires very little upkeep in comparison to untreated steel. Its capacity to oppose rust means it can keep going quite a while without separating, decreasing the requirement for successive fixes or substitutions.

Can We Weld galvanized steel?

Yes, we can weld it but you need to consider some considerations owing to zinc coating. When you want to weld galvanized steel, you need to know that when heating the sheet the zinc coating can produce harmful fumes which can be dangerous for your heath. Additionally, when we weld, the defensive zinc layer may be damaged at the weld site, resulting in the inevitable consumption of those areas.

Should you consider galvanized metal sheets?

Yes, it is worth because it doesn’t need to be fixed and can be used in many different fields. The zinc covering needn’t bother with to be continually checked or changed after the metal has been aroused interestingly. Likewise, a technique for insurance against rust endures quite a while. The finished product resists corrosion and lasts for a long time. It typically lasts for over 50 years in stable conditions.

What distinguish Zinc-Plated from Galvanized Steel?

Although both types of steel serve the products with basic aim to protect it from rust but the zinc coating thickness and how to process is quite different. In zinc-plated steel, manufacturers coated the object with a thin layer of zinc which they applied to the steel’s surface with electricity. This covering may provide some protection from rust, but it is not very thick and may peel off over time, particularly in harsh environments.

On the other hand, excited steel is made more grounded by submerging it in a shower of fluid zinc. This occurs when a stronger bond of a thicker layer of zinc to the steel strengthens its resistance to rust. Excited steel is in many cases involved external in things like rooftops, fences, and building parts where it’s significant for it to not rust for quite a while.

Can You Burn Galvanized Steel?

Zinc oxide vapor are delivered when galvanized steel is coated, which can be hurtful to your wellbeing. When heated to extremely high temperatures, galvanized steel’s zinc coating can release fumes of zinc oxide. Inhaling these fumes can cause coughing, stomach cramps, and breathing difficulties. The combustion of galvanized steel can put people’s health at risk by releasing harmful gases into the air. Thusly, being mindful while working with blended steel is fundamental. Use protective gear and a good airflow to keep the zinc coating from catching fire.

Is it possible to solder Galvanized Steel?

Yes, you can solder galvanized steel but it is challenging. Because of the chance of slowing down the holding system, the zinc covering can make it challenging to accomplish a durable and reliable weld joint. At the high temperatures required for soldering, the zinc coating may also vaporize, releasing harmful fumes.

If you want to do successful soldering then you need tp clear the surface from zinc coating. This ought to be possible through synthetic methods like corrosive pickling or mechanical strategies like crushing or sanding. The galvanized metal sheets can be patched utilizing standard fastening strategies and steel-explicit motions after the zinc covering has been eliminated.

Send Your Inquiry Today

+86-18969433502

sales@sheetmetalmasion.com